Geographic Information Science and Technology as Key Approach to

unveil the Potential of Industry 4.0

How Location and Time Can Support Smart Manufacturing

Stefan Schabus

1

and Johannes Scholz

2

1

University of Salzburg, Salzburg, Austria

2

Graz University of Technology, Graz, Austria

Keywords: Geographic Information Science, Smart Manufacturing, Industry 4.0, Space and Time,

Abstract: Productivity of manufacturing processes in Europe is a key issue. Therefore, smart manufacturing and

Industry 4.0 are terms that subsume innovative ways to digitally support manufacturing. Due to the fact, that

geography is currently making the step from outdoor to indoor space, the approach presented here utilizes

Geographical Information Science applied to smart manufacturing. The objective of the paper is to model an

indoor space of a production environment and to apply Geographic Information Science methods. In detail,

movement data and quality measurements are visualized and analysed using spatial-temporal analysis

techniques to compare movement and transport behaviours. Artificial neural network algorithms can support

the structured analysis of (spatial) Big Data stored in manufacturing companies. In this article, the basis for

a) GIS-based visualization and b) data analysis with self-learning algorithms, are the location and time when

and where manufacturing processes happen. The results show that Geographic Information Science and

Technology can substantially contribute to smart manufacturing, based on two examples: data analysis with

Self Organizing Maps for human visual exploration of historically recorded data and an indoor navigation

ontology for the modelling of indoor production environments and autonomous routing of production assets.

1 INTRODUCTION

Geographic Information Science (GISc) is an

approach to describe, model, analyse and visualize

spatial phenomena as well as spatial processes

representing measurements. These representations

are used to identify the emphasis of spatial themes

and different entities including their relationships

between locations and features linked to locations

(Chrisman et al. 1989). In addition, Goodchild

(1991) sets the emphasis of a Geographic

Information System (GIS) to the handling and usage

of spatial data. Therefore, an understanding of

natural phenomena coupled with scientific methods

and knowledge is necessary in order to model spatial

real-world phenomena accordingly (Goodchild,

1991). Thus, a GIS is a framework to analyse spatial

information linked with attributes to generate new

results and insights out of spatial data.

Recently, higher efforts have been made in

outdoor geography than in indoor geography due to

the fact that already a high number of applications

and structured methods exists (Giudice et al. 2010;

Worboys, 2012). A comprehensive task is the

positioning both in indoor and outdoor environments

(Li et al., 2008). There are different challenges of

the positioning problem. Indoors, there are

limitations of the rooms’ size, the building and the

indoor environment in general. In contrary, outdoor

geography requires a regional or global coverage

(Mautz, 2008).

Indoor Geography related research is gaining

increasing interest.The variety of complex buildings

and the application specific development is

increasing the need for location based services

indoor (Goetz, 2012). In order to support complex

production processes Scholz and Schabus (2014)

developed an indoor navigation ontology that

describes the indoor production environment with all

relevant features including an autonomous

navigation for a production environment. According

to Janowicz (2008) and Gruber (1995), ontologies

are a specification of a conceptualization and are

able to model complex behavior as simplified

representations. Such spatially enhanced models

463

Schabus S. and Scholz J..

Geographic Information Science and Technology as Key Approach to unveil the Potential of Industry 4.0 - How Location and Time Can Support Smart

Manufacturing.

DOI: 10.5220/0005510804630470

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 463-470

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

include the ability to support the analysis of spatial

patterns. A movement behavior model has to be

developed accordingly which can be used to create

Self-Organizing Maps (SOM). SOMs are one type

of artificial neural network algorithm (Kohonen,

2013) to analyse attributive data over time.

For a manufacturing site, the productivity and

efficiency is a crucial issue. Therefore, smart

manufacturing is a new research field as it is

strategically important for the industrial sector as it

facilitates the competitiveness of a manufacturing

site (Davis et al. 2012). Additionally, companies are

collecting huge amounts of spatial-temporal data,

such as transport movement data, which could be the

basis for spatial-temporal data mining e.g. by

visualizing maps to enable intelligent pattern

recognition. This is useful as humans can identify

visual patterns easily (Compieta et al. 2007). Finally,

optimization of production processes depends on

allocation and sequencing of processes and assets.

This unveils the potential to increase the

productivity and efficiency going hand in hand with

cost-savings and increased performace, which could

be one interesting research field for indoor

geography and GIS (Nyström, 2006).

The scientific question in this paper can be

summarized as “Can GIS, applied in indoor space

and in indoor production line environments, help to

understand and optimize production processes”.

Thus, we focus on supporting Industry 4.0 with

spatial and spatial-temporal analysis to gain added

value out of big data using visual analytics.

The paper is organized as follows. Chapter 2

deals with indoor and outdoor geography and the

temporal dimension of the production processes.

Chapter 3 characterizes the variability of different

types of indoor spaces and the indoor space of a

production environment including it’s specific

pecularities. Chapter 4 highlights an approach to

visualize and analyze quality measurements and

transportation behavior followed by a conclusion

and a future research directions.

2 INDOOR GEOGRAPHY,

OUTDOOR GEOGRAPHY AND

THE TEMPORAL DIMENSION

Geographic Information Systems and Technology

are intensively used in outdoor contexts. Thus the

theory, methodologies and technologies are well

established (Giudice et al. 2010). In contrast, GIS for

the indoor context, which is subject of this paper, is

rather weakly developed (Worboys, 2012).

Nevertheless, the first papers on modeling indoor

space and indoor wayfinding were published by

Raubal and Worboys (1999) and Raubal (2001). The

latter uses an airport as indoor environment and

describes an agent-based indoor wayfinding

simulation. The term GIS, as used in this paper,

describes a computer system to analyze, store,

manipulate, analyze and visualize spatial data

accordingly (e.g. Longley et al., 2011). Hence, any

GIS – with appropriate data – is able to answer the

three basic questions:

- What happended?

- Where did a phenomenon happen?

- When did a phenomenon happen?

These questions are valid for any appliation area

indoor and outdoor. Also for mobile GIS

applications, like apps on a mobile device, a context

awareness, in terms of location and time, is

inevitable. In GISc, such context-aware services that

are consumed by mobile devices are called

Location-based Services (e.g. Küpper, 2005).

Classical spatial analysis algorithms are e.g.

summarized in De Smith et al. (2007). A

prerequisite for spatial analysis is an abstract

modeling of the universe of discourse. Therefore a

set of basic spatial primitives – point, line, polygon –

is utilized that helps to model and abstract reality

accordingly. Based on these spatial primitives, any

existing spatial relation of the objects can be

analyzed. The power of spatial analysis is based on

linkages and relationships of locations. Hence,

relative positions are more important than absolute

ones. Examples of topological relations are

adjacency, connectivity, and containment, while

non-topological relations are e.g. neighborhood or

distance.

In order to represent and model dynamic

situations in a GIS one needs to integrate the

temporal dimension. Hence, space has to be coupled

with time, with the basic assumption that one object

can only occupy a distinct part of space at a specific

point in time. To describe spatial and temporal

processes Hägerstrand (1970) developed an

approach named Time Geography. There

movements of objects are modeled as paths in a 3D-

cube with respect to space (i.e. latitude and

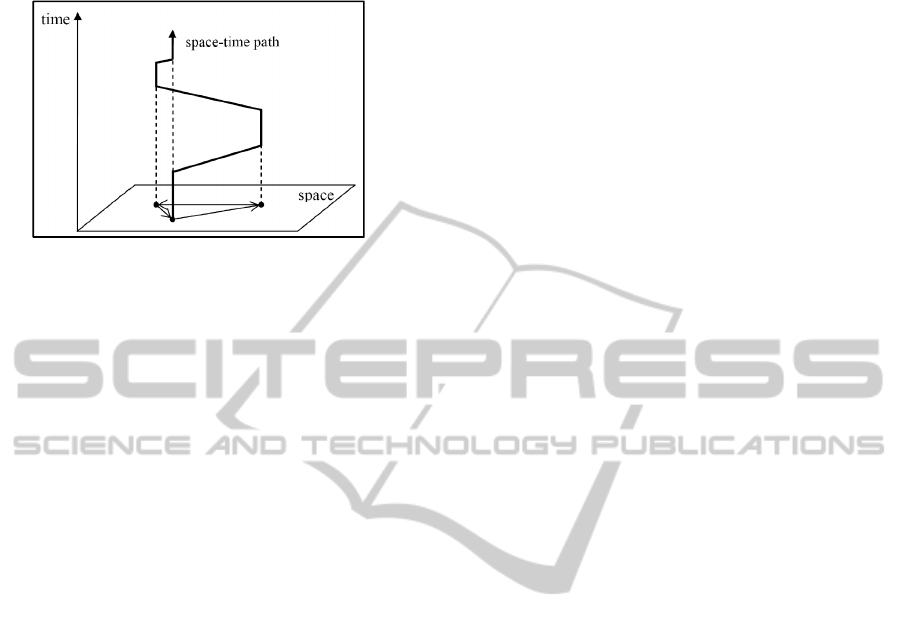

longitude) and time (see Figure 1). The

representation of space and time in a database is

basically done with two approaches: discrete vs.

continuous (Peuquet, 2001). The discrete approach

is comparable to a limited set of time slices with the

spatial entities as main elements. The continuous

approach favours a space and time representation,

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

464

where the spatial objects are denoted as attributes

attached in space-time.

Figure 1: Time and Geography (Graphic from Yu (2006)).

Summarizing, GISc seems like a valuable approach

to model, analyze and visualize spatial-temporal

production relevant data. Especially, due to the

capability of any GIS, to analyze data in terms of

space and time, it can be helpful to gain new insights

in production relevant data.

3 CHARACTERIZATION OF

INDOOR SPACE

To characterize indoor space in general, certain

effort is needed to generate accurate and consistent

models. Due to the high complexity of indoor

structures and the context based linkage to the

buildings’ field of application the characterization is

not as straight forward as in outdoor geography

(Ascraft, 2008; Meijers et al. 2005). To address the

topic of indoor spaces and their characterization, the

variability of such indoor spaces is described in

section 3.1. In advance, section 3.2 outlines an

indoor production environment of a manufacturing

site, which results in an indoor navigation ontology

for production assets in section 3.3.

3.1 Variability of Indoor Spaces

There is a high variability of indoor spaces. In

addition to outdoor geography, indoor geography is

much more complex as it is context based (Ascraft,

2008; Meijers et al. 2005). An important topic for

the indoor geography is the positioning, as an exact

and accurate position is the basis for various

upcoming applications (Barnes et al., 2003).

According to Mautz (2008), the main difference

between outdoor and indoor is the different focus of

the positioning approach regionally or globally.

Therefore, indoor positioning solutions focus on

context-aware-services and on the location of e.g. a

person or production assets (Xiang et al., 2004; Al

Nuaimi and Kamel, 2011).

3.2 Indoor Space of a Production

Environment

The sophisticated arrangement of the indoor space

and the peculiarities of the production context

require high modelling effort. This section is based

on the work of Geng (2005), Osswald et al. (2013),

Scholz and Schabus (2014) and personal experience.

Pre-requisites of an indoor production

environment are, for example, the clean room

environment of a semiconductor fabrication, which

has to be built in a very compact way as the

construction is very cost-intensive and hard to

maintain (Schabus et al. 2014). However, the layout

of a production differs from classical production

halls using a conveyor belt metaphor as well as from

an ordinary indoor environment. According to

Schabus et al. (2014), buildings with a context of

e.g. residential use are mainly separated into rooms

and corridors which can be connected by doors. In

addition, a production environment differs through

distinguishable corridors with a substantial length

and different types of doors such as sliding doors or

doors going in one direction, in e.g. an air lock.

In general, the production of a microchip is a

complex sequence of equipment which is the context

of the indoor production environment of a

semiconductor fab. This sequence considers several

hundred different production steps which have to be

involved and are not aligned along a conveyor belt

to keep the flexibility. The flexibility is essential as

there is a high number of production assets present

at the same time which are also linked to different

sequences of production steps and a varying level of

completion. Hence, the overall processing time is

between several days up to a couple of weeks. To

imbue the flexibility, the equipment is also

distributed geographically throughout the production

hall and different equipment can carry out the same

production steps.

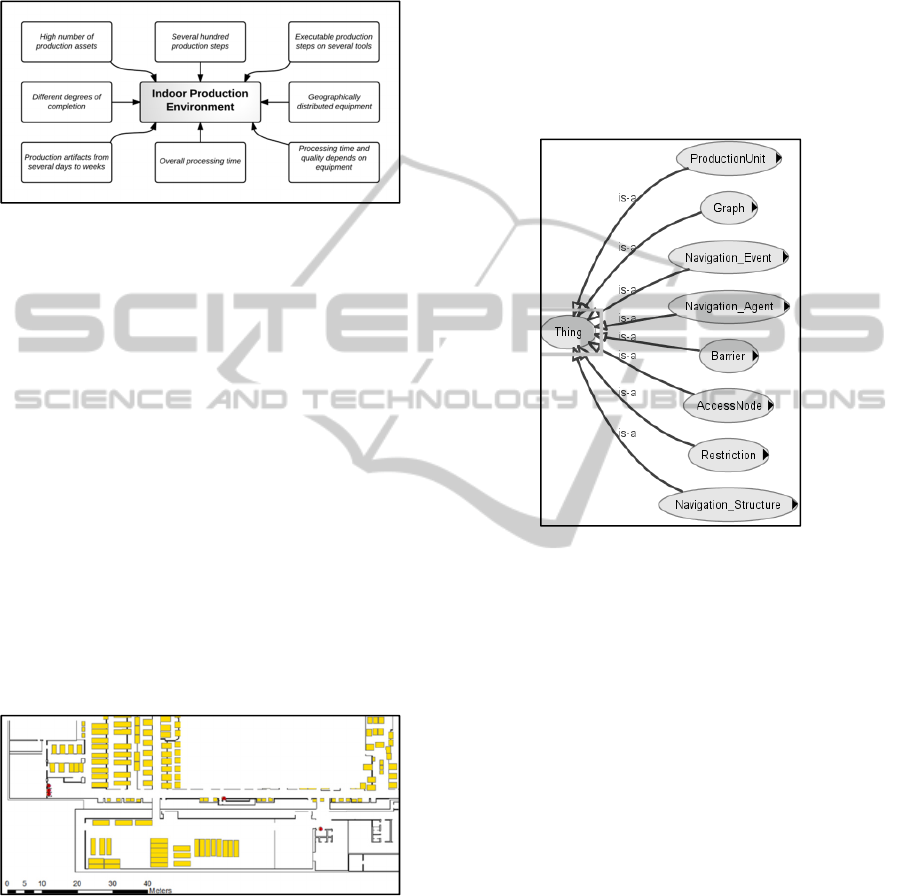

To summarize these peculiarities of an indoor

production environment, figure 2 highlights the eight

main factors - affordances and restrictions -

influencing the characterization of the indoor

production environment by considering the

production assets’ point of view. These context

based main factors are “a high number of production

assets”, “several hundred production steps”,

“executable production steps on several tools”,

“geographically distributed equipment”, “processing

GeographicInformationScienceandTechnologyasKeyApproachtounveilthePotentialofIndustry4.0-HowLocation

andTimeCanSupportSmartManufacturing

465

time and quality depends on equipment”, “overall

processing time”, “production artefacts from several

days to weeks” and “different degrees of

completion”.

Figure 2: Context-based factors for the indoor production

environment in the production assets’ point of view.

The indoor production environment of a

semiconductor manufacturing site is often separated

into corridors with a significant length which is

depicted in figure 3. Generally, production assets are

moving several kilometres within the production

environment. This highlights the potential for

decision support present within the indoor

geography, as managers would like to know where

and when issues arise concerning production

processes. Figure 3 highlights the equipment

visualized as standardized yellow rectangles and red

nodes for the accessing and transferring

within/between indoor spaces and outdoors.

To sum up, the indoor geography of a production

line environment is a complex environment, due to

the specific context of the production. The

characterization imbues many factors defining the

indoor production environment in detail.

Figure 3: Indoor geography of a production environment

using white spaces to hide the exact layout and

standardized polygons for visualization purposes.

3.3 Indoor Navigation Ontology for

Production Assets

Scholz and Schabus (2014) developed an indoor

navigation ontology for production assets in a

production environment. Their ontology supports an

autonomous navigation in the indoor environment

applied with an affordance-based approach.

The navigation ontology is based on eight main

entities visualized in figure 4. In general, figure 4

depicts an adapted version of the indoor navigation

ontology by Scholz and Schabus (2014). The

navigation elements are the moving production asset

as “NavigationAgent”; “NavigationEvent” as start,

end or any turn; “NavigationStructure” as generic

entities for the route calculation.

Figure 4: Modified and adapted main elements of the

navigation ontology by Scholz and Schabus (2014).

Further elements describing the indoor geography

are the “ProductionUnit” as facilities and processing

units; the “Graph” summing up edges and nodes; the

“Barriers” limiting the movement; “AccessNode”

establishing the accessibility or traversing between

spaces; the “Restriction” to specify affordances.

To sum up, Scholz and Schabus (2014)

developed an indoor navigation ontology describing

the indoor space and navigation elements. By

combining both parts, they successfully established

an autonomous indoor navigation approach for a

production line.

4 VISUALIZATION AND

ANALYSIS OF TRANSPORT

AND QUALITY

The visualization and analysis of transport and

quality data is the result of a new approach to unveil

the potential of smart manufacturing or Industry 4.0

using GISc and technologies. Therefore, geo-visual

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

466

analytics, map generation, spatial-temporal data

mining, trajectory pattern mining and artificial

neural network algorithms such as SOMs are used.

Geo-visual analytics and map generation

enhance the ability to generate and gain new

knowledge out of large datasets of spatial-temporal

data. Potential use cases of such visualizations can

be incorporated into the optimization of transport-

/movement behaviour or the analysis of quality hot

spots. Spatial-temporal data mining can be

implemented by SOMs as they are one type of

artificial neural network algorithm (Kohonen, 2013).

SOMs visualize data and set up the basis for visual

data mining. Kohonen (1998) implies that SOMs are

usable to solve complex tasks like process analysis,

perception of machines and control communications.

Additionally, Skupin (2010) describes the TRI-space

approach linking the geographic space, temporal

space and the attributive space.

The topics in this section address an approach for

the visualization in section 4.1 followed by an

example how the transport-/movement behaviour

could be visualized in section 4.2. Additionally,

section 4.3 adds the analysis part of the transport-

/movement behaviour and quality measurements.

4.1 Approach to Unveil the Potential of

Visualization and Analysis

A general approach for smart manufacturing under

consideration of GIS starts with the modelling and

analysis of the base data. Therefore, use cases

consider questions about what is temporal or spatial

information. Temporal information involves e.g. the

duration of something or the timestamp of an event

occurrence. Spatial information considers questions

such as where was something; what is the shortest

path. Defined use cases together with the indoor

ontology lead to a spatial-temporal data model,

which can serve as general “data warehouse” within

a company. The additional spatial component of the

database enables further queries.

Figure 5 illustrates possible existing systems

within a company. It is briefly depicted how a funnel

aggregates the data warehouse combining distributed

databases, AutoCAD data used for planning

purposes and a static viewer of the manufacturing

site. This leads to an aggregation and finally to a

company-wide GIS. This shows that necessary data

sources are available, but have to be integrated and

harmonized to unveil their full potential. Thus, a

GIS based on one general data warehouse has the

potential to unveil the potential of Industry 4.0.

Figure 5: Aggregation of possible existing systems to set

up a system building the basis for a GIS.

4.2 Visualization of Transport

Behaviour

The visualization of the movement-/transport

behaviour is the first step towards the optimization

potential within the transport of production assets.

Basically, the transport is visualized as the

movement itself is recorded and stored as historic

information within a data warehouse described in

section 4.1. Based on recorded timestamps of the

movement and the linking to a specific production

asset an approximation of the movement or transport

is recovered.

To establish the visualization of movements

through a production line, a network structure is

necessary. In order to represent possible walking

ways or transport corridors within a network

accurately, a graph based network is developed.

Such a graph based network exists of edges and

nodes combining equipment in the production line

and facilities which have to be included in a routing

approach – which are defined in the indoor

navigation ontology. Furthermore, the indoor

navigation ontology includes access points to the

indoor space and junctions to enter corridors and

enhance the network with the ability to include

turns. This network is created using a semi-

automatic approach and is the key to the

visualization of transport and the movement.

By considering a graph based network

representing transport ways or walking ways within

a production line, the movement behaviour can be

mapped on the network and visualized. Via a routing

algorithm, for example Dijkstra, it is possible to

create different paths. One path can represent the

real path of the movement based on historically

recorded data, by combining the visited equipment

in a temporal order and tracked positions in between.

Another path, for e.g. the same production asset, can

represent the shortest path that combines the visited

equipment of in a temporal order. Finally, two

possible paths for each production asset can be

GeographicInformationScienceandTechnologyasKeyApproachtounveilthePotentialofIndustry4.0-HowLocation

andTimeCanSupportSmartManufacturing

467

compared with respect to length or areas traversed.

This gives insight in the detailed movement

behaviour and about deviations between the shortest

or optimal path and the path used in reality. The

calculation of real paths based on historical data and

optimal paths can also be implemented in a data

warehouse which is described section 4.1. Therefore,

a spatial database management system, such as

Postgres, has to be extended by a spatial cartridge,

e.g. PostGIS, and a routing extension, e.g.

pgRouting.

In order to monitor the transport behaviour based

on extracted trajectories, it is also possible to sum up

how often edges are traversed by a specific

production asset. This highlights the edges mostly

used and thus could be possible bottle necks or areas

with special transport necessities.

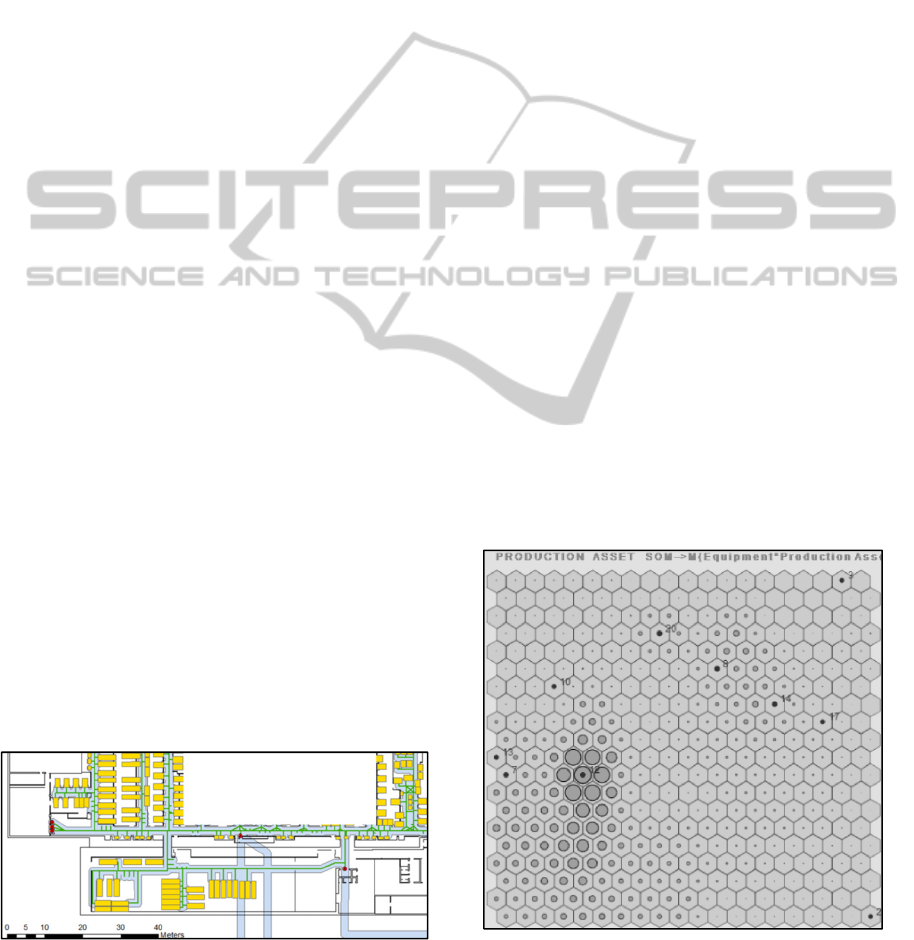

Figure 6 highlights such a visualization using a

graph based network. The graph based network is

visualized using a green colour and connecting the

equipment, facilities and specific nodes enabling the

accessibility to the indoor space in red. A buffer is

created around the network to represent the walking

ways in a more appropriate way and also to compare

the network more easily with real corridors in the

production environment. To connect different

production halls, virtual connections are established

which are marked as blue buffers without a green

network line. Based on this network, extracted tracks

of production assets can be projected and compared.

White spaces are used intentionally to hide detailed

arrangements of equipment.

To sum up, the visualization of the transport or

movement behaviour is based on a graph-based

network which has to be implemented in a semi-

automatic workflow. The network represents

possible walking ways within the indoor production

environment. Paths can be extracted from the

historically recorded data and mapped onto the

network to enable comparisons of paths or the

visualization of bottle necks or critical areas

showing potential to be improved.

Figure 6: Example showing the graph-based network

through the production line environment and possible

walking ways as corridors.

4.3 Analysis of Transport Behaviour

and Quality Measures

The analysis of spatial-temporal patterns of

production assets is important, as especially for

semiconductor production processes quality is a key

to success. The ability to analyse the transport

behaviour and quality implies a conceptualization of

the movement and transport. Based on a

conceptualization it is possible to use SOMs for an

automatic data analysis (Kohonen, 2013). To model

the movement of a production asset, it can be

modelled as a sequence of equipment that shall be or

has been visited by a production asset. These

sequences of equipment can be used to compare

similarities of different sequences and to analyse

how different equipment are present in a sequence.

A similar approach was implemented by Schabus et

al. (2014) highlighting equipment which is used in

similar groups of production assets. Figure 7

highlights a SOM showing the frequency of visited

equipment. This analysis method enables the user to

monitor if production assets have a different quality

according to the likelihood of used equipment.

Figure 7 highlights one randomly selected

component plane of a SOM showing the frequency

of used equipment. By projecting production assets

onto such a component plane, it can be seen if it is

likely if a production asset will be processed by an

equipment. The size of circles within the component

plane represents the likelihood of occurrence, the

bigger the more likely is the processing at this

specific equipment.

Figure 7: SOM showing a component plane of equipment

highlighting the likelihood, if a production asset will be

processed or not.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

468

In addition to the likelihood of used equipment,

another example uses SOMs to analyse quality

measures of production assets based on an extracted

sequence of equipment until a quality measure is

triggered. This means, that each used equipment of a

production asset is extracted until a quality

measurement is triggered according to a certain pre-

defined threshold. Conceptually, a triggering event

separates the overall sequence of used equipment

into sub-sequences, which will be used to compare

the likelihood of an equipment resulting in a quality

measure. Therefore, the SOM looks similar than in

figure 7 with other component planes and quality

measures are projected onto the SOM.

To compare the SOMs, they are integrated in an

interactive website to explore a TRI-space approach

based on spatial-temporal information of a

production line environment. An example is created

to compare SOMs with other spaces like time and

location. The example implementation results in an

interactive website showing two different types of

SOMs, the location based on a map of the equipment

and a time-slider to add the third component. The

example shows that by changing the time on the

time-slider, quality issues are projected onto the

SOMs highlighting similarities with respect to the

high dimensional attributive space and the triggering

equipment is highlighted in the physical space.

Summing up, the analysis of the transport

behaviour and quality measurements can be made

possible by implementing a neural network

algorithm such as SOM. Furthermore, the

visualization itself bears high potential by

comparing different possible tracks a production

asset has taken or which way would be more

optimal. Spatial-temporal data mining is

implemented to analyse a high dimensional

attributive space which is adjusted due to a

conceptualization of relevant data. Thus, the

exploration and combination is possible by

considering a TRI-space based approach.

5 DISCUSSION AND

CONCLUSION

This research paper elaborates on a GIS based

approach to unveil the potential of smart

manufacturing and Industry 4.0. The emerging

interest in indoor geography, leads to an

interdisciplinary approach coupling GISc, indoor

geography, and smart production or industry 4.0.

To highlight how GIS can support smart

manufacturing, the approach in this paper describes

the integration of existing systems present at

companies and how the combination of different

data may help to gather new insights. A graph-based

network is created that opens up the opportunity to

map the movement of production assets by

extracting the trajectories out of historical data. The

visualization and analysis is done by comparing

different paths such as an optimal path between used

equipment or the tracked path of the production

asset. Hence, the tracks can be mapped on the

network. The spatial-temporal analysis part of the

paper focuses on SOMs. SOMs have the capability

of analysing a high-dimensional attributive space of

big data leading to new knowledge when a visual

exploration is done as follow-up process. This

indicates, that it is possible to gain new knowledge

out of existing data based on the utilization of GISc

and existing data sources.

Future research directions include a variety of

self-learning algorithms to gain new knowledge out

of big data. Furthermore, the general application

field of an indoor production environment bears

huge potential concerning indoor navigation tasks.

Furthermore, the real-time production relevant data

of SCADA systems could be integrated in a

Geographical Information System, which leads to

new decision support possibilities (Back et al.,

2014). Additionally, the paper contributes to indoor

geography such as spatial-temporal analysis of

movements, which helps to develop the simulation

of movement behaviour further.

ACKNOWLEDGEMENTS

The work has been performed in the project EPPL,

co-funded by grants from Austria, Germany, The

Netherlands, Italy, France, Portugal- ENIAC

member States and the ENIAC Joint Undertaking.

REFERENCES

Al Nuaimi, K. and Kamel, H. (2011), A survey of indoor

positioning systems and algorithms, in ‘Innovations in

Information Technology (IIT), 2011 International

Conference on’, IEEE, pp. 185-190.

Ascraft. H., 2008. Building information modeling: A

framework for collaboration. Construction Lawyer,

28(3):1-14, 2008.

Barnes, J., Rizos, C., Wang, J., Small, D., Voigt, G. and

Gambale, N. (2003), ‘High precision indoor and

GeographicInformationScienceandTechnologyasKeyApproachtounveilthePotentialofIndustry4.0-HowLocation

andTimeCanSupportSmartManufacturing

469

outdoor positioning using locatanet’, Journal of

Global Positioning System 2(2), 73-82.

Chrisman, N. R., Cowen, D. J., Fisher, P. F., Goodchild,

M. F., & Mark, D. M. 1989. Geographic information

systems. Geography in America, 353-375.

Compieta, P., Di Martino, S., Bertolotto, M., Ferrucci, F.

and Kechadi, T. 2007, ‘Exploratory spatio-temporal

data mining and visualization’, Journal of Visual

Languages & Computing 18(3), 255-279.

Davis, J., Edgar, T., Porter, J., Bernaden, J., & Sarli, M.

2012. Smart manufacturing, manufacturing

intelligence and demand-dynamic performance.

Computers & Chemical Engineering, 47, 145-156.

De Smith, M. J., Goodchild, M. F., & Longley, P., 2007.

Geospatial analysis: a comprehensive guide to

principles, techniques and software tools. Troubador

Publishing Ltd.

Geng H, (eds), 2005, Semiconductor manufacturing

handbook. McGraw-Hill.

Giudice, N. A., Walton, L. A., Worboys, M. 2010, The

informatics of indoor and outdoor space: A research

agenda. In Proceedings of the 2nd ACM SIGSPATIAL

International Workshop on Indoor Spatial Awareness,

ACM, pages 47–53.

Goetz, M., 2012, Using Crowdsourced Indoor Geodata for

the Creation of a Three-Dimensional Indoor Routing

Web Application. Future Internet 4(2): 575-591.

Goodchild, M. F. 1991. Geographic information

systems. Journal of Retailing,67(1), 3-15.

Gruber. T. R., 1995, Toward Principles for the design of

ontologies used for knowledge sharing? International

journal of human-computer studies, 43(5):907-928.

Hägerstrand, T., 1970. What about people in regional

science?. Papers of the Regional Science Association

24 (1): 6–21.

Janowicz, K., 2008. Observation driven geo-ontology

engineering. Transactions in GIS, 16(3):351-374,

Kohonen, T. (1998), ‘The self-organizing map’,

Neurocomputing 21(1), 1-6.

Kohonen T, 2013, Essentials of the self-organizing map.

Neural Networks, 37:52-65.

Küpper, A., 2005. Location-based services: fundamentals

and operation. John Wiley & Sons.

Back, S., Kranzer, S., Heistracher, T. and

Lampoltshammer, T., 2014, Bridging SCADA

Systems and GI Systems. In: 2014 IEEE World Forum

on Internet of Things (WF-IoT) (WF-IoT 2014),

Seoul, Korea, pp. 41-44.

Li, B., Quader, I. J. and Dempster, A. G. 2008, ‘On

outdoor positioning with wi-fi’, Journal of Global

Positioning Systems 7(1), 18-26.

Longley, P. A., Goodchild, M. F., Maguire, D. J., and

Rhind, D. W., 2011. Geographic Information Systems

and Science. England: John Wiley & Sons, Ltd.

Mautz, R. 2008, Combination of indoor and outdoor

positioning, in ‘1st International Conference on

Machine Control & Guidance’.

Meijers, M., Zlatanova, S., and Pfeifer N., 2005, 3D

geoinformation indoors: structuring for evacuation.

In

Proceedings of Next generation 3D city models,

pages: 21-22.

Nyström, R. H., Harjunkoski, I. and Kroll, A. (2006),

‘Production optimization for continuously operated

processes with optimal operation and scheduling of

multiple units’, Computers & chemical engineering

30(3), 392-406.

Osswald S, Weiss A and Tscheligi M, 2013, Designing

wearable devices for the factory: Rapid contextual

experience prototyping. In: International Conference

on Collaboration Technologies and Systems (CTS)

2013, IEEE, 517-521.

Peuquet, D. J., 2001. Making space for time: Issues in

space-time data representation. GeoInformatica, 5(1),

11-32.

Raubal, M., and Worboys, M.: A formal model of the

process of wayfinding in built environments. In:

Spatial information theory. Cognitive and

Computational Foundations of Geographic

Information Science, Lecture Notes in Computer

Science 1661 (1999) 381-399.

Raubal, M.: Ontology and epistemology for agent-based

wayfinding simulation. International Journal of

Geographical Information Science 15(7) (2001) 653-

665.

Schabus, S., Scholz, J., and Skupin, A., 2014, Spatial-

temporal Patterns of Production Assets in an Indoor

Production Environment. In Proceedings of Workshop

"Analysis of Movement Data'14" Workshop at

GIScience 2014, Poster Presentation, Vienna, Austria.

Web: http://blogs.utexas.edu/amd2014/

Scholz, J. and Schabus, S., 2014, An indoor navigation

ontology for production assets in a production

environment, in ‘Proceedings of GIScience 2014,

Vienna, Austria - Lecture Notes in Computer Science,

Springer’.

Skupin, A. (2010), Tri-space: Conceptualization,

transformation, visualization, in ‘Sixth International

Conference on Geographic Information Science’, pp.

14-17.

Worboys, M. 2012, Modelling Indoor Space. In:

Proceedings of the 3

rd

ACM SIGSPATIAL

International Workshop on Indoor Spatial Awareness,

ACM, pages 1 – 6.

Xiang, Z., Song, S., Chen, J., Wang, H., Huang, J. and

Gao, X. (2004), ‘A wireless lan-based indoor

positioning technology’, IBM Journal of Research and

Development 48(5.6), 617-626.

Yu, H., 2006. Spatio-temporal GIS Design for Exploring

Interactions of Human Activities. Cartography and

Geographic Information Science, 33(1), 3-19.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

470