Extracting Knowledge for Searching for and Identifying Hazards on

Construction Site

Ren-Jye Dzeng and Yi-Cho Fang

Department of Civil Engineering, National Chiao Tung University, 1001 Ta-Hsueh Road, Hsinchu, Taiwan

Keywords: Eye-tracking, Hazard Identification, Construction Safety, Knowledge Extraction.

Abstract: The construction industry accounts for a high number of accidents. Although identifying hazards before

construction starts or during construction is widely employed to prevent accidents, it typically fails because

of insufficient safety experience. The experience helps in training novice inspectors, although extracting and

describing tacit knowledge explicitly is difficult. This study created a 3-D virtual construction site, and

designed a hazard-identification experiment involving 14 hazards (e.g., falls, collapses, and electric shocks),

and an eye-tracker was used to compare the search patterns of the experienced and novice workers. The

results indicated that experience assisted the experienced workers in assessing hazards significantly faster

than the novice workers could; however, it did not improve the accuracy with which they identified hazards,

indicating that general work experience is not equivalent to safety-specific experience, and may not

necessarily improve workers’ accuracy in identifying hazards. Nevertheless, the experienced workers were

more confident in identifying hazards, they exhibited fewer fixations.

1 INTRODUCTION

The construction industry is one of the most

hazardous industries, and it accounts for an

extremely high number of accidents and fatalities.

Hazard identification is the most frequently

employed approach to preventing and reducing

accidents on construction sites. However, it is

difficult to extract hazard-identification knowledge

from experienced workers and describe explicitly in

text due to the dynamic work nature on job sites.

Understanding how experienced workers search for

and identify hazard may help formulating guidelines

and strategies that can be used in training materials

of related courses.

Some studies have successfully used eye-

tracking devices to evaluate the difference between

the approaches used by experienced and novice

drivers for identifying road hazards, and have shown

that visual strategies differ between these two groups.

Their valuable contributions have elucidated

approaches for comparing the inspection strategies

and search patterns employed by experienced and

novice workers in the construction industry. Thus,

this study attempts to use an eye-tracking device to

study differences between the experienced and

novice workers in identifying hazards in the

snapshots of virtual construction site that containing

hazards.

Hazard identification is important to construction

safety management. Nevertheless, Carter and Smith

(2006) reported that current hazard-identification

levels need considerable improvement. Furthermore,

the Ministry of Labour of Taiwan (MOL, 2013)

reported that the 33,332 construction site inspections

conducted in Taiwan have resulted in 2,412

suspensions, with 2,436 financial penalties valued at

US$3.73 million because of inappropriate or

insufficient safety management. However, the

corresponding fatalities in the construction industry

accounted for 45.8% (148 of 323) of all fatalities

among all industries in 2012. Poor safety awareness

among workers and managers is the primary reason

for the high incidence of accidents in the

construction industry (Cheng et al., 2010). Thus,

poor hazard-identification levels or insufficient

inspection quality is a crucial safety management

problem in the construction industry. Moreover,

providing effective hazard-identification training for

workers, managers, and inspectors is essential.

Hazard identification requires sufficient

knowledge and experience to identify potential

sources of physical, chemical, or physiological harm,

as well as for identifying situations related to labour,

367

Dzeng R. and Fang Y..

Extracting Knowledge for Searching for and Identifying Hazards on Construction Site.

DOI: 10.5220/0005522403670372

In Proceedings of the 10th International Conference on Software Engineering and Applications (ICSOFT-EA-2015), pages 367-372

ISBN: 978-989-758-114-4

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

equipment, material, and environmental factors that

could cause accidents, which may affect productivity

and profitability as well as injuries. It is also a

complex task that requires knowledge of both

regulations and experience because of the dynamic

nature of construction environments. Goh and Chua

(2009) indicated that safety experience may assist

workers in improving their safety performance and

preventing recurring mistakes, and those poor

hazard-identification processes are the result of a

lack of experience.

Several studies have successfully employed eye-

tracking devices to evaluate the difference between

the visual search patterns that experienced and

novice drivers employ to identify road hazards

(Hosking et al., 2010). They showed that novice

drivers employ visual strategies that differ from

those used by experienced drivers (Falkmer and

Gregersen, 2005). Furthermore, under risky driving

conditions, the scanning behaviour of novice drivers

is narrower than that of experienced drivers;

moreover, novice drivers typically look directly

ahead, and they fail to perceive and assess hazard

information (Pradhan et al., 2005). Konstantopoulos

et al., (2010) reported that because experienced

drivers are more familiar with hazardous events than

novice drivers are, their fixations are shorter and

more frequent. The poor hazard-identification ability

or risk perception of novice drivers might explain

why novice drivers are involved in more accidents

(Ciceri and Ruscio, 2014).

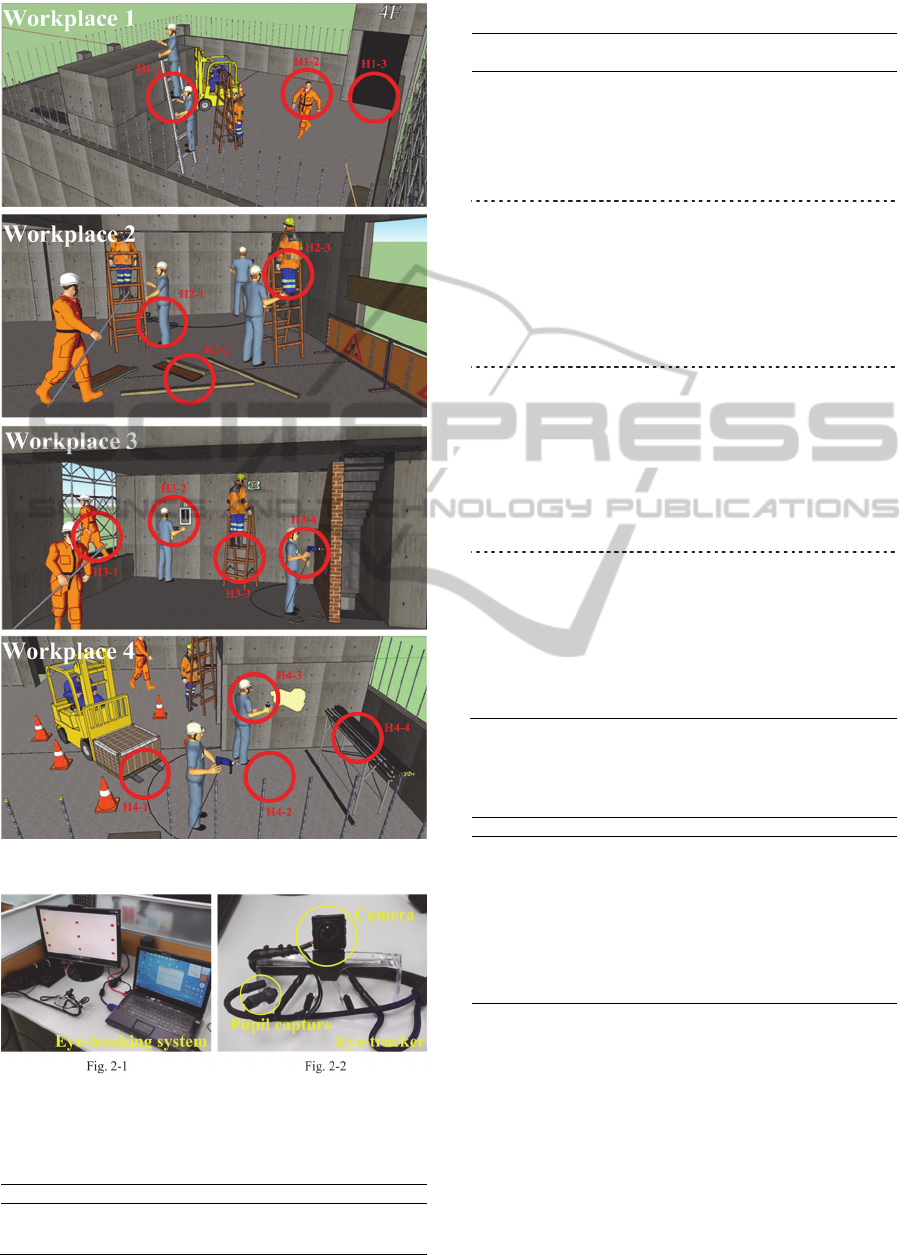

2 EXPERIMENT DESIGN

To extract the difference between the hazard-

identification ability of experienced workers and that

of novice workers, we prepared four snapshots from

the 3D virtual construction site model that was

developed specifically for this research. The virtual

model allows the experiment to accommodate a

variety of hazards that are infeasible to see on a

single construction site in real life as most

construction sites would already corrected hazards if

they allow us to conduct the experiment there. The

model contains various hazards that were identified

as the most frequently occured hazards in the

construction industry (MOL, 2014). The participants

were presented with the images sequentially, and

they were asked to identify potential hazards. The

identification accuracy and time were recorded for

further analysis. An eye-tracker was used to record

each participant’s fixation. Each participant was

interviewed following the experiment.

We collected cases of 350 construction industry

accidents in Taiwan from 2009 to 2011 (MOL,

2014). We limited our scope to building construction,

and identified 178 accidents fitting that category.

We selected 14 hazards of 6 accident types,

including falls, collapses, electric shocks, lacerations,

explosions, and unsafe actions.

We used Google SketchUp version 8 (Trimble

Navigation, Ltd) (Trimble Navigation, 2014) to

create a virtual three-story building construction site

featuring 8 workplaces that contain 21 hazards.

Among those hazards, snapshots of 14 hazards, as

shown in Fig. 1 (e.g., H1-1, H1-2, and H1-3 in

Workplace 1) located in four workplaces were taken

to be used as the test hazards in this experiment.

Table 1 details the hazards.

Twenty-five paid volunteers participated in the

experiment. Ten participants were experienced

construction workers with an average of 5 years

working experience and 6 hours formal safety

training, which is required annually by the

regulation, and 15 were graduate students studying

construction engineering and management at

National Chiao-Tung University, Taiwan, who had

no work experience and safety training in

construction. The construction workers represented

experienced workers, whereas the graduate students

represented novice workers. All participants had

normal or corrected-to-normal vision, and passed an

eye-tracking calibration test.

A 19-inch liquid-crystal display (LCD) monitor

with a resolution of 1280 × 1024 pixels was

connected to a laptop to display the images. We

recorded eye movement by using the EyeFrame

SceneCamera System model of the ViewPoint

EyeTracker, manufactured by Arrington Research,

Inc. (Arrington Research, 2014) (Figs. 2-1 and 2-2)

at a sampling rate of 30/60 Hz, spatial resolution of

0.15 degrees of the visual arc, and accuracy between

0.25 and 1.00 degrees of the visual arc.

The experiment facilitator assisted each

participant in fitting and calibrating the eye-tracker.

Subsequently, the participant started the experiment

by inspecting the snapshots and using a mouse to

identify potential hazards sequentially from

Workplaces 1 to 4 without time limitations, and

without knowing the total number of target hazards.

A successful identification was recorded only when

a participant clicked on a hazard and correctly

explained the reason for the spot to be a hazard. The

participants’ head and eye movement were

unrestricted during the experiment. An interview

followed the experiment to clarify how the

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

368

participants searched for and identified potential

hazards.

We calculated the identification accuracy, miss

rate, and identification time to evaluate the

participants’ hazard-identification ability. We also

developed a computer program to analyze the search

pattern based on the participants’ fixation, to

identify the difference between the hazard-

identification ability of experienced and novice

workers. The program was written in Visual Basic

for Applications and run on Microsoft Excel. In this

study, fixations with durations longer than 500 ms

were retained as attention points.

3 RESULTS

Table 2 shows the identification accuracy, miss rate,

and identification time of the experienced and

novice workers for the four workplaces. Table 3

shows the independent t-test results for comparing

the ability of the experienced and novice workers in

identifying hazards. Regarding the identification

accuracy or miss rate, the experienced workers

outperformed the novice workers on average (i.e.,

86.71% versus 80.39% or 30.00% versus 49.17%).

However, the difference was statistically

nonsignificant. Regardless, the experienced workers

required significantly less time compared with the

novice workers in identifying hazards (t = −4.16, p <

0.001).

The following lists our findings pertaining

identification accuracy, miss rate, and identification

time.

The experienced workers did not perform

significantly better than the novice workers did,

indicating that years of construction experience

did not necessarily assist the experienced

workers in identifying hazards.

General work experience is not equivalent to

safety-specific experience, and may not

necessarily improve workers’ accuracy in

identifying hazards.

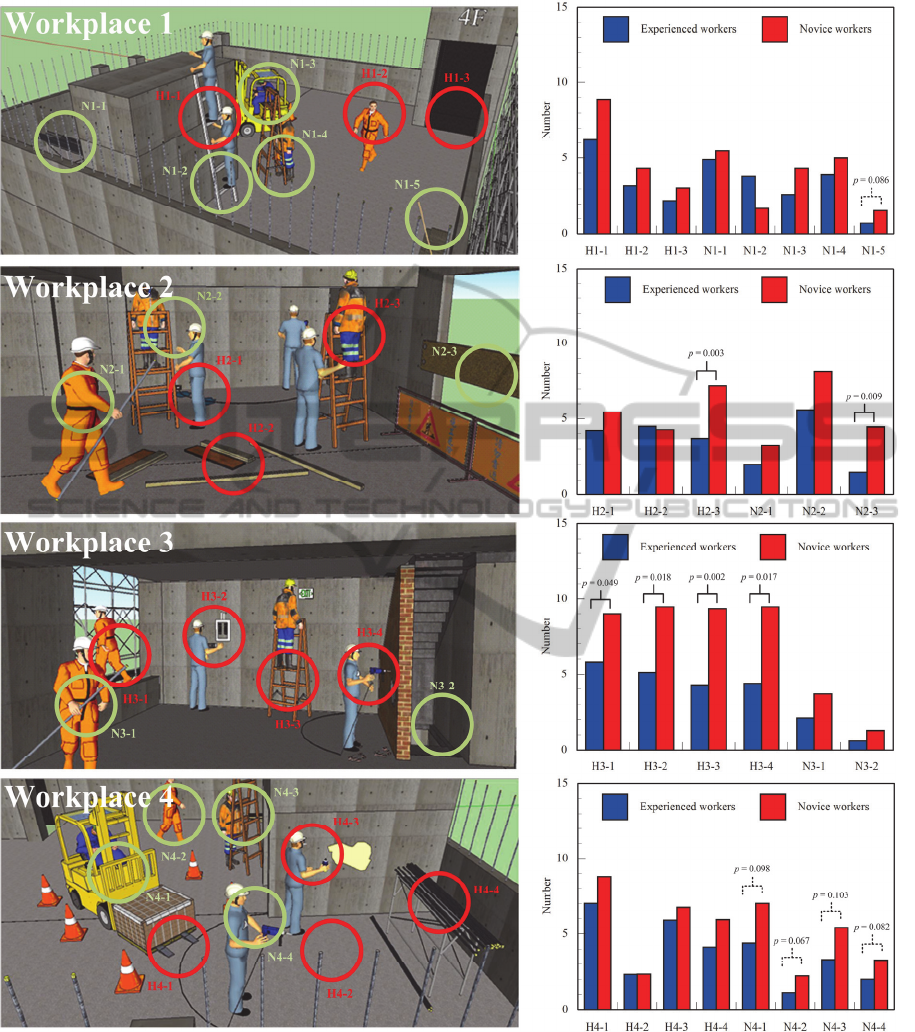

Figure 3 shows the fixation frequency for all

attention points inspected by the participants, where

H and N represent hazards and non-hazards,

respectively. The mean fixation frequency among

the novice workers fixations was more than that of

the experienced workers for most attention points,

except for N1-2 and H2-2 in Workplaces 1 and 2,

respectively. Regarding Workplace 3, the mean

fixation frequencies among the novice workers on

H3-1, H3-2, H3-3, and H3-4 were significantly more

than those of the experienced workers (p = 0.002–

0.049). Regarding Workplace 4, the difference

between the fixation frequency of the experienced

and novice workers was marginally non-significant

for N4-1, N4-2, N4-3, and N4-4 (p = 0.067–0.103).

The following lists our findings pertaining

fixation frequency.

The novice workers were less confident than

their experienced counterparts when determining

whether an attention point was a hazard, whereas

the experienced workers typically decided sooner,

as indicated by the shorter identification times.

The fixation frequency of the novice workers

was significantly more than that of the

experienced workers only for non-hazards

because of the complexity involved in

Workplace 4, where non-hazards might have

distracted both novice and experienced workers.

The attention points involving ladders typically

received a high number of fixations, and thus for

which the participants required more time to

decide whether they were hazards, and they can

thus be considered key points in hazard-

identification training courses.

Two exceptions to the aforementioned finding are

observable in N1-2 of Workplace 1 (i.e.,

unconnected rebar) and H2-2 in Workplace 2 (i.e.,

obstacles impeding access), where the mean number

of the novice workers’ fixations was less than that of

the experienced workers. An explanation is that the

experienced workers did not perceive the rebar

because injuries related to this hazard are

comparatively minor; for example, lacerations only

accounted for 15% (90 of 599) and 0.8% (1 of 115)

of serious injuries and fatalities in Taiwan,

respectively (MOL, 2013). By contrast, obstacles

impeding access are so obvious that even the novice

workers were aware of the hazard.

In addition to the identification time, fixation

frequency was an indicator of the difficulty

perceived by the participants. Except for Workplace

3, the attention points with the highest number of

fixations (H1-1 in Workplace 1, N2-2 in Workplace

2, and H4-1 in Workplace 4) were identical for both

the experienced and novice workers. Based on Fig. 3,

the attention points involving ladders typically

received a high number of fixations. The hazards

receiving comparatively more fixations indicate

hazards for which the participants required more

time to decide whether they were hazards, and they

can thus be considered key points in hazard-

identification training courses.

ExtractingKnowledgeforSearchingforandIdentifyingHazardsonConstructionSite

369

Figure 1: Workplace scenarios.

Figure 2: Eye-tracking system.

Table 2: Identification accuracy, miss rate, and time of the

experienced workers and novice workers.

Group Accuracy (%) Miss rate (%) Time (sec)

Experienced 86.71 30.00 40.19

Novice 80.39 39.17 74.91

Table 1: Hazard description.

Hazard

Accident

type

Description

Workplace 1

H1-1 Falls

Two workers ascended the same

ladder simultaneously.

H1-2

Unsafe

actions

The worker did not wear a helmet.

H1-3 Falls

The opening should have a

guardrail.

Workplace 2

H2-1

Electric

shocks

When using electronic equipment,

the wire should be elevated in wet

environment.

H2-2 Collapses

The work area should be

unimpeded and clear of obstacles.

H2-3 Falls

The worker should not use the

ladder within 2m to the hazard that

requires a guardrail.

Workplace 3

H3-1 Falls

The opening between structure and

scaffold should have a guardrail.

H3-2

Electric

shocks

The worker did not wear insulating

gloves during live-line operation.

H3-3 Falls

The ladder should be open

completely to have fixed support.

H3-4 Collapses

The demolition of the brick wall

did not follow a strict top- down

sequence.

Workplace 4

H4-1 Collapses

The wire overlapped with the

moving path of the forklift.

H4-2

Laceration

s

Each rebar should be capped.

H4-3 Explosions

Smoking is prohibited during paint-

spraying or welding.

H4-4 Collapses

Rebar should be tied and placed in

secured fashion.

Table 3: Independent t-test comparison of identification

accuracy, miss rate, and time for identifying hazards

between the experienced workers and novice workers.

Source N Mean SD t p

Accuracy (%)

Experienced 10 86.71 11.31

1.19 0.247

Novice 15 80.39 14.03

Miss rate (%)

Experienced 10 30.00 11.46

-1.70 0.102

Novice 15 39.17 14.18

Time (sec)

Experienced 10 40.19 9.85

-4.16 0.000

Novice 15 74.91 24.96

4 CONCLUSIONS

The experimental results indicated that the

experienced workers exhibited similar identification

accuracies and miss rates compared with the novice

workers, and their experience assisted them only

based on the speed at which they identified hazards.

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

370

Figure 3: Fixation frequency for attention points of the experienced workers and novice workers.

The experienced workers spent significantly less

time than the novice workers did in identifying

hazards (p < 0.001).

The search pattern analysis results showed that

the novice workers were less confident in

determining whether an attention point was a hazard,

and they exhibited more fixations on almost every

attention point compared with the experienced

workers. By contrast, the experienced workers

typically made faster decisions, thereby resulting in

shorter identification times.

Based on the findings, general work experience

is not equivalent to safety-specific experience, and

may not necessarily improve workers’ accuracy in

ExtractingKnowledgeforSearchingforandIdentifyingHazardsonConstructionSite

371

identifying hazards. The experienced and novice

workers exhibited similar hazard-identification

abilities and search patterns, apart from the

identification time and numbers of fixations,

potentially because hazard identification requires

both sufficient knowledge and experience. However,

site supervisors and managers were not necessarily

experienced in directly conducting safety inspection

or safety training; though they had considerably

more on-site work experience, this additional

experience or self-confidence only accelerated their

inspection processes; their identification ability was

comparable to that of the novice workers.

The search pattern analysis results could provide

valuable information for safety trainers and

educators. Both the experienced and novice workers

exhibited a high number of fixations on attention

points involving ladders, implying that they require

more time to determine whether these situations are

hazards.

ACKNOWLEDGEMENTS

The authors would like to first thank Wei-Ting Chi,

a Master’s student at National Chiao-Tung

University, for his effort in collecting and processing

the experimental data. The authors would also like to

thank the Ministry of Science and Technology of

Taiwan for finically supporting this research under

Contract No. 102-2627-E-009-002 and No. 102-

2221-E-009-066-MY2.

REFERENCES

Arrington Research, 2014. Scene Camera Eye Tracking.

http://www.arringtonresearch.com/

Carter, G., Smith, S. D., 2006. Safety hazard identification

on construction projects. Journal of Construction

Engineering and Management 132, 197-205.

Cheng, C.-W., Lin, C.-C., Leu, S.-S., 2010. Use of

association rules to explore cause–effect relationships

in occupational accidents in the Taiwan construction

industry. Safety Science 48, 436-444.

Ciceri, M. R., Ruscio, D., 2014. Does driving experience

in video games count? Hazard anticipation and visual

exploration of male gamers as function of driving

experience. Transportation research part F: traffic

psychology and behaviour 22, 76-85.

Falkmer, T., Gregersen, N. P., 2005. A comparison of eye

movement behavior of inexperienced and experienced

drivers in real traffic environments. Optometry &

Vision Science 82, 732-739.

Goh, Y., Chua, D., 2009. Case-based reasoning approach

to construction safety hazard identification: adaptation

and utilization. Journal of Construction Engineering

and Management 136, 170-178.

Hosking, S. G., Liu, C. C., Bayly, M., 2010. The visual

search patterns and hazard responses of experienced

and inexperienced motorcycle riders. Accident

Analysis & Prevention 42, 196-202.

Konstantopoulos, P., Chapman, P., Crundall, D., 2010.

Driver's visual attention as a function of driving

experience and visibility. Using a driving simulator to

explore drivers’ eye movements in day, night and rain

driving. Accident Analysis & Prevention 42, 827-834.

Minstry of Labor (MOL), 2013. The annual report of labor

inspection. http://www.mol.gov.tw/cht/index.php?

code=list&ids=458.

Minstry of Labor (MOL), 2014. The annual report of

construction industry accidents.http://

www.mol.gov.tw/cht/index.php?code=list&flag=detail

&ids=450&article_id=3173.

Pradhan, A. K., Hammel, K. R., DeRamus, R., Pollatsek,

A., Noyce, D. A., Fisher, D. L., 2005. Using eye

movements to evaluate effects of driver age on risk

perception in a driving simulator. The Journal of the

Human Factors and Ergonomics Society 47, 840-852.

Trimble Navigation, 2014. SketchUp. http://

www.sketchup.com/

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

372