Optimizing Steel Melt Shop Operations using an Iterative

Hierarchical Decomposition based Discrete Event Simulation Model

Atanu Mukherjee and Arnab Adak

Dastur Business & Technology Consulting, A division of M. N. Dastur & Company (P) Ltd, Kolkata, India

Keywords: Steelmaking, Logistics, Bottleneck, Simulation, Modeling, Throughput, Utilization.

Abstract: Maximizing productivity in a steel melt shop requires appropriate equipment and facility design and the

synchronization of production across units like iron making, steel making, holding furnaces and casting of

the molten metal. This requires that blockages and bottlenecks in the production chain be identified and

overcome and the logistics in terms of equipment and facilities to move the materials appropriately

designed. Removal of blockages and bottlenecks requires a combination of process redesign and

investments in facilities and equipment in the production units supported by potential logistics redesign in

terms routing and scheduling of equipments like cranes, ladle cars hot metal ladles and steel ladles used in

the production shop . This approach addresses the system-wide bottleneck removal problem such that

congestions, interferences, delays, stoppages and idle times coupled with process and cycle time variations;

do not limit the end-to-end production. This paper presents how we improved the productivity in a melt-

shop by using an iterative hierarchical decomposition based modelling and simulation approach to help

identify the bottlenecks causing capacity loss, and experiment with options to redesign the system by

suggesting mechanisms for improvement and additional facilities and logistical resources. The

implementation of the system has resulted in a 28% increase in melt-shop throughput and increase and

significant increase in profitability by decreasing hot metal diversions to alternative casting facilities.

1 INTRODUCTION

Steel is produced from iron and ferrous ores and

scrap through two major processes – Iron-making

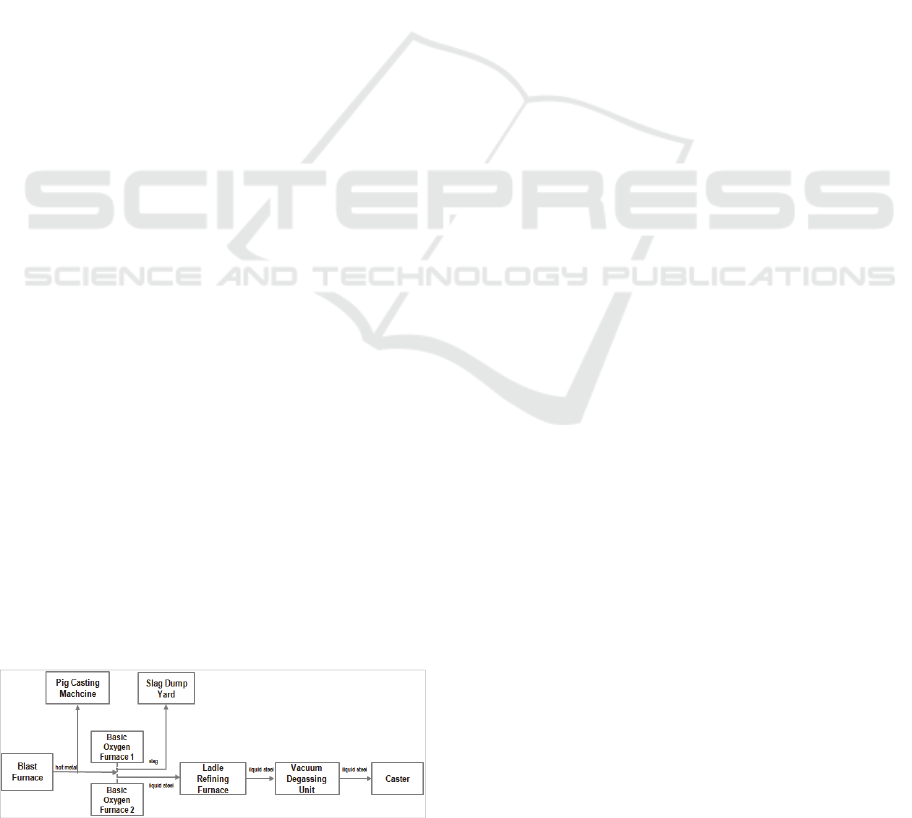

and Steelmaking. Figure 1 shows the overview of

the process of producing steel in an integrated steel

plant.

Figure 1: The steel production process overview.

The first phase in steel production is iron-making

where oxygen and impurities are removed from iron

ore using other raw materials through a process in a

counter-current heat exchanger known as the blast

furnace. A Blast Furnace (BF) produces molten

iron/pig iron, termed as Hot-metal. In an iron-

making unit of a steel plant, the hot-metal from the

blast furnace is tapped in the cast house either in

open top ladles or in torpedo ladles. These ladles are

then moved to the Steel-making unit, also called

Steel Melting Shop (SMS) by locomotives to be fed

to the Basic Oxygen Furnace (BOF). The BOF

converts liquid iron from BF and scrap steel into

liquid steel which is then refined in ladles and finally

cast at the casters. In case the BOF is not ready to

accept hot metal due to production bottlenecks or

capacity mismatches it is sent to Pig Casting

Machine (PCM) to be cast into saleable iron ingots.

The goal of a steel plant is to synchronize

operations across the iron and steel making units

such that throughput is maximized. This translates

into specific unit optimization goals along with

synchronization and coordination requirements cross

the units. From a unit optimization perspective, it is

essential that the BOF does not have any wait time

other than the preparation time. This means that the

optimal number of ladles, the optimal number of

cranes and the optimal movement algorithm of

cranes needs to be determined such that the hot

111

Mukherjee A. and Adak A..

Optimizing Steel Melt Shop Operations using an Iterative Hierarchical Decomposition based Discrete Event Simulation Model.

DOI: 10.5220/0005524101110117

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 111-117

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

metal feed to the BOF is synchronous and without

wait. Also, timely arrival of hot metal from the iron-

making-unit needs to be ensured.

In the steel-melting-shop unit, the liquid steel

from the BOF is taken to the Caster where the liquid

steel is molded via secondary refining units

comprising of Ladle Refining Furnace (LRF) and/or

Vacuum Degassing (VD) units. The BOF should be

synchronized with the Casters such that the heat

sequences for different grades are maintained while

maximizing the utilization of the equipment to

ensure the highest throughput from hot-metal

charging to casting. It is always preferred to have

uninterrupted sequence during continuous casting to

achieve higher production and yield.

Our study was based on an integrated steel plant

having two BOFs, with one working and one

standby mode, one LRF, one Vacuum Degassing

unit and one three-strand Caster (operated with two

strands). The existing operations needed to be

studied and analyzed in detail and additional

facilities/ improvements in the system needed to be

proposed to utilize the Caster, LRF and BOF fully

and thereby increasing the overall throughput of the

system. It was also needed to suggest the number of

hot metal ladles and steel ladles in active circulation

required for the suggested production.

2 THE PROCESS AND

OPERATIONS

Hot metal in the Blast Furnace (BF) is cast as per BF

cast schedule into open top ladles placed in transfer

cars on railway tracks. The ladle transfer car is

carried to SMS or PIG Casting Machine (PCM) by

captive locomotive depending on the readiness of

the converter to accept the hot metal.

At SMS the full ladle is picked up from the

transfer car by an overhead crane and carried to the

sampling point. In case an empty ladle is ready for

return to BF, the full ladle is picked and kept on the

pit, the empty ladle placed on the transfer car and

then the full ladle is picked up again by the overhead

crane. Once the sampling is complete, the ladle is

carried to the BOF. In the mean time scrap is

charged to the BOF by scrap charging crane. On

completion, the hot metal is charged to the BOF and

blowing starts. Near the end of the blowing cycle,

temperature is measured and samples are taken for

analysis. After pouring of the hot metal to the BOF,

the ladle is carried to the pit by overhead crane for

sending back to the BF.

Steel ladle on steel transfer car gets under the

BOF vessel and steel is tapped into the ladle through

the tap hole. Once tapping is complete, slag pot car

gets under the BOF vessel and slag is poured into

the slag pot through the BOF vessel mouth.

After processing of 8 heats in the BOF,

maintenance operations, also known as dozing and

mouth jam cleaning are carried out. After 15 heats of

BOF operation the maintenance operation of tap

hole changing is performed. And after 75 heats,

other maintenance works on the vessel are carried

out. The numbers are varied depending on the status

and completion of the casting sequence.

After tapping of steel into the steel ladle, it is

transported to the ladle refining aisle by the ladle

transfer car, picked up by overhead crane and placed

on the LRF transfer car. The purging lines are fixed

and the transfer car goes into the LRF. The steel is

further refined in the LRF by adding alloying

materials to give it special properties as required.

Once the LRF processing is complete, the ladle

transfer car brings out the ladle and the purging lines

are removed. The ladle is also moved to the VD unit

by overhead crane, and further treatment done.

The ladle is transported to the caster turret from

the LRF or VD by overhead cranes. The ladle sits in

a rotating turret at the casting machine. One ladle is

in the 'on-cast' position (feeding the casting

machine) while the other is made ready in the 'off-

cast' position, and is switched to the casting position

when the previous ladle is empty. Once casting of

one ladle is over, and the turret rotates, the empty

ladle is transported from the turret to the slag

dumping area and slag is dumped. After slag

dumping, the ladles are sent to the ladle preparation

area and placed back on the transfer car for the next

tapping from the BOF.

3 OVERALL THROUGHPUT

IMPROVEMENT

The process of steelmaking and casting, from BOF

to Caster, may be categorized into three distinct

stages, viz. primary steelmaking, secondary

steelmaking and casting. Primary steelmaking is

concerned with the production of liquid steel, which

is subsequently refined in terms of both its

composition and its cleanliness through a host of

secondary steelmaking processes. Molten steel with

desired composition, cleanliness and temperature is

finally transformed into solid products through

continuous casting. Figure 2 shows the categories of

the steelmaking process.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

112

Figure 2: The steelmaking process categories.

The overall throughput of the steel making process

depends on the functioning of each of these units at

efficiency levels which maximizes the total output.

The functioning of these units at their required

efficiency levels which maximizes output, depends

on:

Design or rated capacity of the unit

Operating efficiency

Overall shop logistics

The units can be operated at their design or rated

capacity by improving operating efficiency of unit or

shop logistics. Related work in the area of logistics

optimization (McGinty et al., 2008) and hidden

capacity discovery (Mukherjee et al., 2012) has been

carried out to address specific improvement goals

around this area. Our approach is an integrated

holistic approach to plant operations improvement

through simulation so as to include unit operations,

logistics, cycle times and their interactions.

4 APPROACH OF ITERATIVE

AND HIERARCHICAL

DECOMPOSITION

A large number of problems in production

operations can be initially analyzed using simple

relationships that do not require assumptions about

the distribution of service times and inter-arrival

times in a queuing network. Several such

relationships, called operational laws (Buzen, 1976)

(Jenning and Buzen, 1978) are useful in looking at

the starting point for the analysis. For example, the

melt-shop operations is a form of the queuing

network where the job flow balance is maintained

and obeys the forced flow law. Each unit operation

(BOF, LRF, Casting etc.) in such a system has a

service time and the unit utilizations are proportional

to their service times. The unit with the highest total

service time has the highest utilization and is called

the bottleneck unit. This unit is the key limiting

factor in achieving higher throughput to start with.

Identification of the bottleneck unit was the first step

in operations performance improvement of the

system. Using baseline simulation we can estimate

the highest service demand in the operation chain.

So the approach was to see the opportunity for cycle

time /service time reduction and hence capacity

improvement in the BOF, Caster, LRF or VD.

Once we could reduce the cycle time to the

minimum level possible at the bottleneck unit, we

again simulated the model and stack-ranked the

service times in the production chain and looked at

how the bottlenecks shift across the production

units. Frequently, the bottlenecks shift in the

production chain during iterations of improvement.

If there is an opportunity for improvement in the

other unit cycle times/service times as the

bottlenecks shift we continue iterating till there is no

further opportunities for practical cycle time

improvement across the production chain.

Once we exhausted the opportunities for cycle

time improvement we argued that given the

difference in variability in the service times in each

of the units and their distributions, there might be

further scope for improvement. This led us to

observe the behavior of capacity utilizations across

the downstream units which could potentially create

a bottleneck so as to give us further insights. We

hypothesized that if indeed the capacity utilizations

of some of the units changed and tended to move in

a way which would affect the performance of that

unit, there could be opportunity for further

improvement in system performance by adding

capacity. Addition of that unit capacity needs to be

guided by the economics and the cost benefit of such

an option. Typically as a thumb rule, buffering units

like the holding furnace (LRF) are good candidates

for capacity addition to improve performance. We

would similarly iterate and exhaust all capacity

addition options till there are no further

opportunities for overall improvement in the system.

This progressive hierarchical decomposition of

the chain and iterating based on the two heuristics

drives the simulation towards an optimal solution.

We think that this method can be applied to large

scale manufacturing scenarios with many units and

can be a useful method for analyzing and potentially

optimizing large scale systems through simulation.

5 BASELINE SIMULATION

MODELING AND ANALYSIS

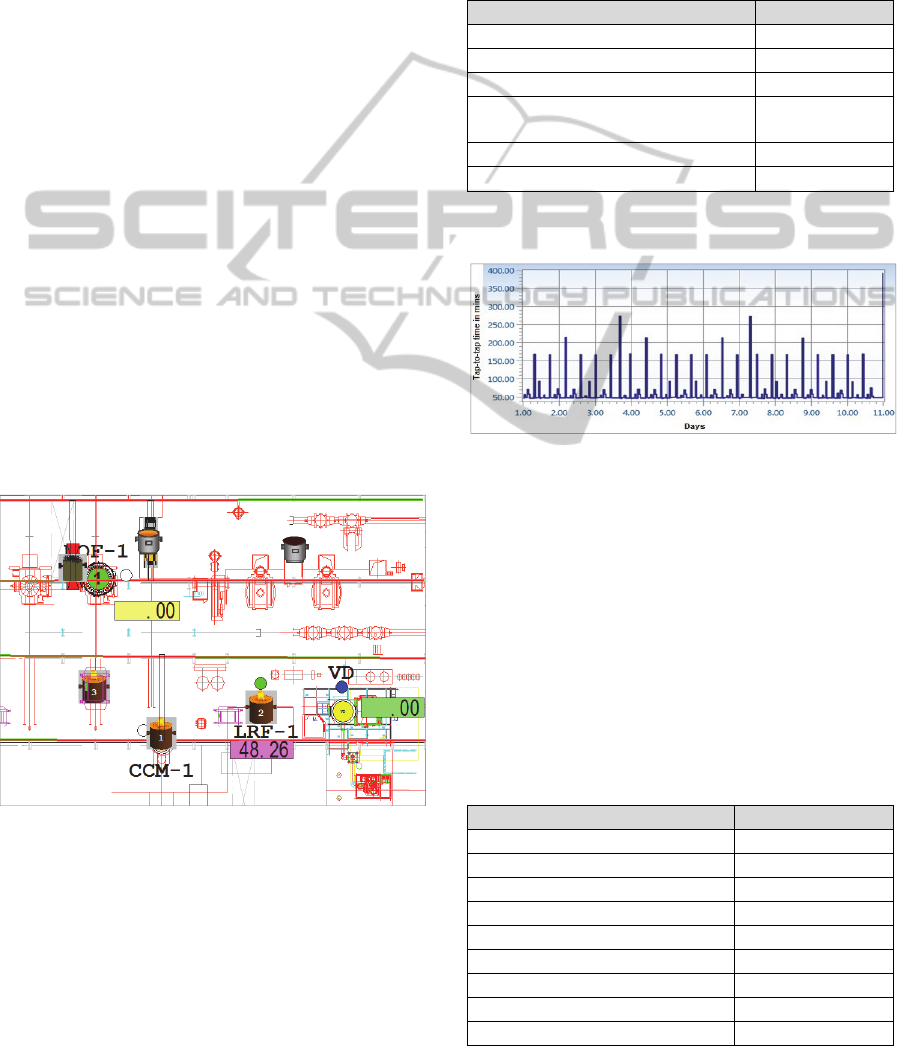

A baseline simulation model was built using the

Promodel software to simulate the operations of

SMS with the existing service times of the units. The

service time for each unit operation (also referred as

cycle time) included processing time, downtimes

due to maintenance, preparation times and transfer

BOF LRF + VD Caster

P

rimary steelmaking Secondary steelmaking Casting

OptimizingSteelMeltShopOperationsusinganIterativeHierarchicalDecompositionbasedDiscreteEventSimulation

Model

113

times. Logistics movements including rail

movement of the transfer cars and the crane

movements was modeled in the software using its

feature of network path and entity driven simulation.

The approach followed in the model building

was LEAP (Locations, Entities, Arrival, and

Processing). The first task in building the model was

to identify the locations which included source

locations, destination locations and intermediate

locations where the entities will arrive at and exit

from during the movement in the system. It was also

necessary to identify the entities which will originate

at the BF and BOF and exit from Caster; and the

entities like hot metal ladles and steel ladles which

will keep on moving in the system to facilitate

movement of other entities. Also, resources like

transfer cars, cranes, locomotives were created

which will move the entities from one location to the

other. Once the entities were identified and created,

the arrival of the entities had to be modeled as per

the arrival schedule. That included hot metal at BF;

Scrap at scrap yard for charging to BOF; and Steel

and Slag at the BOF for tapping. The next task was

to create the appropriate network path for transfer

car movements and crane movements. The final step

was to create the processing logics for the entities at

a particular location and thereafter creating the

routing logics for moving to the next location using

the required resources. Figure 3 shows a screenshot

of the simulation model.

Figure 3: The model screenshot.

To model the behaviour of various operation

parameters, one year operation data was collected

for the BOF, LRF, VD and Caster and were fitted

into various distributions and best fit distribution

was selected with the help of goodness of fit tests.

The model was run with the existing operation

parameters taking into consideration the stochastic

behaviour of the parameters involved in various

processes like blowing time at the BOF, tapping

time, LRF process time, VD treatment time, crane

availability etc. The transient response of the model

stabilized after 30 days of simulation time. The

results yielded are as shown in the Table 1.

Table 1: Results of simulation runs for 10 days with

existing parameters after attaining stabilization.

Results

Total heats 217

Average BOF tap-to-tap time 65 mins

LRF utilization 79.83 %

Caster utilization (using 2

strands)

52.60 %

VD utilization 47.60 %

Caster heat sequence Maintained

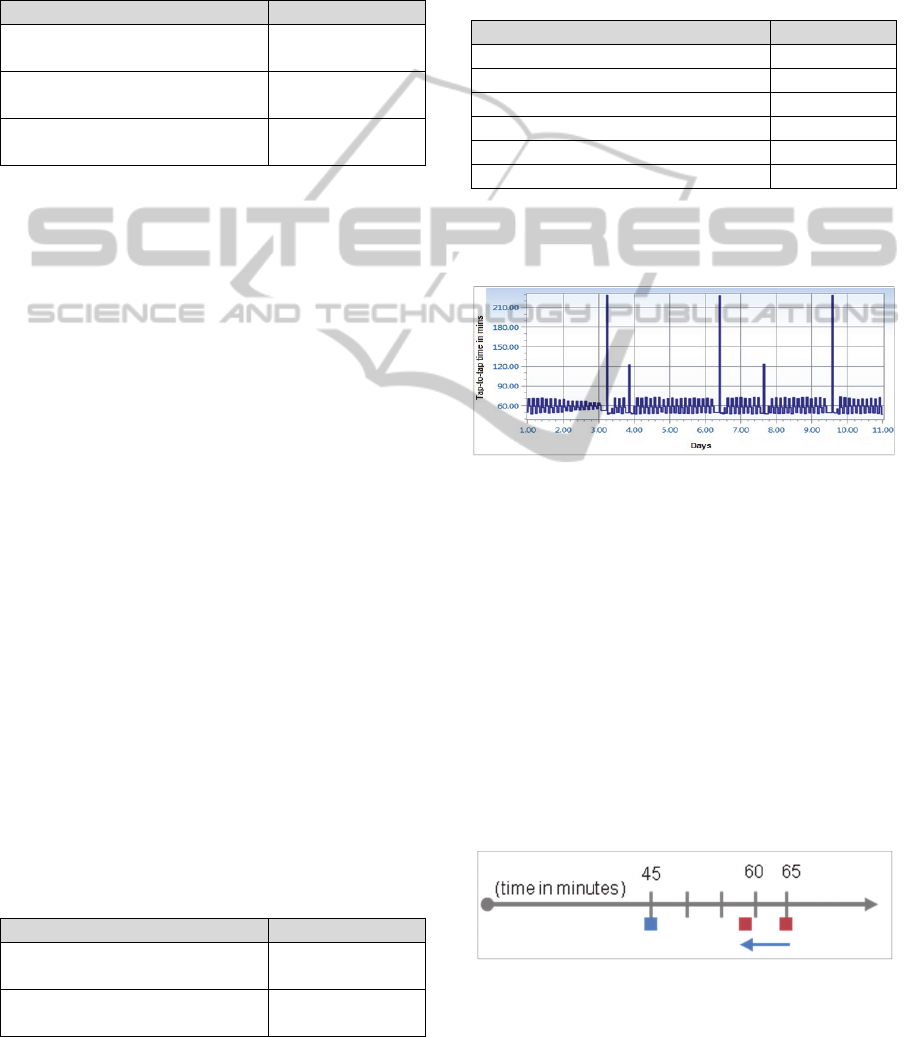

Also the behavior of the BOF tap-to-tap time turned

out to be as shown in Figure 4.

Figure 4: BOF tap-to-tap time with the existing

maintenance downtimes.

6 THE BOF PROCESSING AND

UTILIZATION ANALYSIS

The BOF converter unit being the generation point

in the steelmaking process, it was envisaged that

improving the cycle time by reducing downtimes at

the BOF will increase its throughput and hence the

overall throughput. Table 2 shows the various basic

activities involved in the BOF operations.

Table 2: Basic time components in BOF process.

Activities Time in minutes

Scrap charging 1 to 2

Hot metal pouring 4

Blowing 16 to 18

Deslagging 2 to 3

Temperature & Analysis 5

Tapping 4 to 6

Slagging off 2

Slag coating 5

Total 45 (max)

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

114

In addition to the above, currently there also

exists recurring events of dozing, mouth jam

cleaning, tap hole changing and other maintenance

operations as shown in Table 3 which contributes to

the BOF tap-to-tap time thereby reducing the BOF

throughput.

Table 3: Current BOF maintenance downtimes.

Event Time in minutes

Mouth jam cleaning and

dozing after every 8 heats

90

Tap hole changing after 15

heats

45

Other maintenance after 75

heats

180

With these BOF processing times the overall

steelmaking process behavior needed to be studied

and analyzed. Simulation has been used for studying

and analyzing systems operations previously and the

methodology applied has been ‘highly efficient’

when applied in complex logistic systems.

Considering the complexity of operations, criticality

of sequencing activities and the interdependencies of

the logistics parameters, it was decided to develop a

discrete event simulation model of the system and

evaluate the improvement options.

7 IMPROVEMENT STRATEGY

AT THE BOF

The baseline simulation results showed that the

number of heats from the BOF is constrained by the

higher tap-to-tap time caused by recurring

maintenance delays. It was evident that if these

delays can be reduced, the number of heats from the

BOF can be increased. Based on the technology

available it was envisaged that these delays could be

reduced using tap hole sleeves in the BOF vessel

which will allow a minimum corrosion and erosion

during the operation of the BOF and improving

operating efficiency. With the above measures the

maintenance downtimes was envisaged to be

brought down as shown in Table 4.

Table 4: Proposed BOF maintenance downtimes.

Event Time in minutes

Mouth jam cleaning and

dozing after every 15 heats

90

Tap hole cleaning and other

maintenance after 75 heats

180

However the envisaged maintenance downtimes

would affect the entire sequencing of activities from

the BOF to the Caster and needed to be evaluated

and validated using the model built. The model was

run again with the changed maintenance delays and

results were obtained as shown in Table 5.

Table 5: Results of simulation runs of 10 days with

proposed parameters after attaining stabilization.

Results

Total heats 237

Average tap-to-tap time 59 mins

LRF utilization 92.27 %

Caster utilization (using 2 strands) 60.29 %

VD utilization 54.88 %

Caster heat sequence Maintained

The behavior of the BOF tap-to-tap time with

proposed maintenance operations was found to be as

shown in Figure 5.

Figure 5: Tap-to-tap time with proposed operations.

It is clear that with the frequency of downtimes

reduced in the proposed mode of operation, the

surges in the tap-to-tap time are lesser resulting in a

lower average tap-to-tap time and hence higher

number of heats would be possible from the BOF.

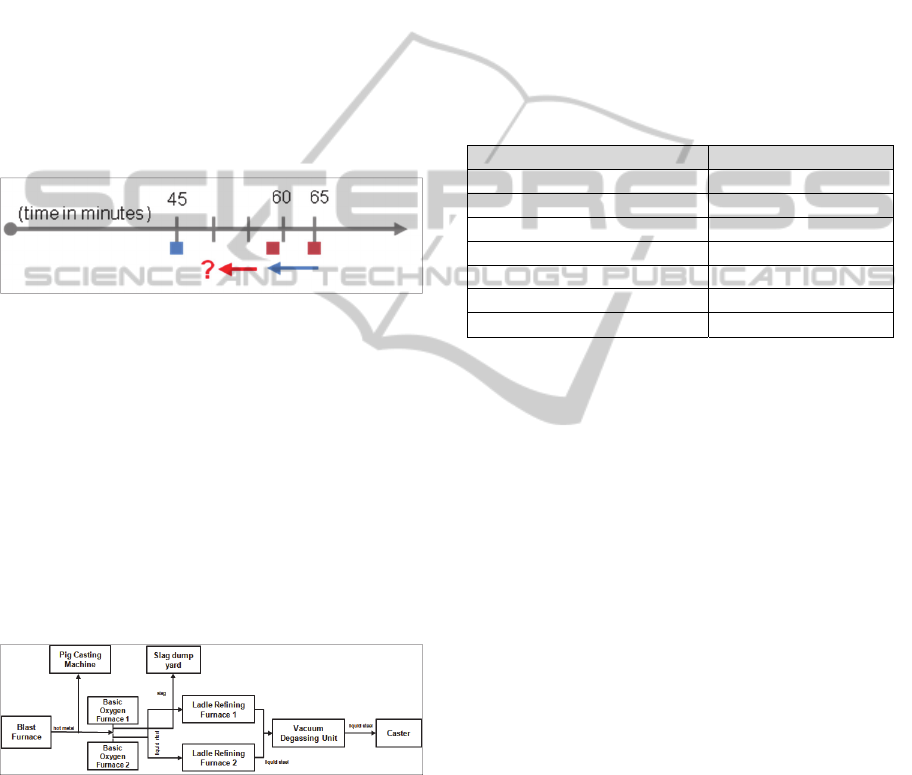

According to the results, the average BOF tap-to-tap

time could be reduced from 65 mins to 59 mins as

shown in Figure 6, considering the reduced

downtimes at the BOF and the constraints in the

upstream and downstream facilities, with 45 mins of

minimum tap-to-tap time required in the BOF,

thereby increasing the overall throughput of the

system. Individually, the BOF had the potential to

reduce its tap-to-tap time further.

Figure 6: Reduced BOF tap-to-tap time.

However the additional component in the tap-to-tap

time over and above the basic BOF processing time

OptimizingSteelMeltShopOperationsusinganIterativeHierarchicalDecompositionbasedDiscreteEventSimulation

Model

115

is not only due to BOF maintenance downtimes, but

also is probably due to contributions from

downstream blockages like the LRF. The utilization

of the LRF being on the higher side points to a

probable blockage in the LRF (as per the result). So

if the downstream blockages can be removed it was

envisaged that the average BOF tap-to-tap time can

be further reduced to increase the throughput while

maintaining the synchronization between the BOF

and the caster.

Our next goal was to find out as to how much of

further reduction in tap-to-tap time is possible by

removing the downstream bottlenecks. So the next

step was to find a strategy to remove the

downstream blockage through additional buffering

thereby reducing the converter tap-to-tap time and

improving the overall throughput.

Figure 7: Further reducing the BOF tap-to-tap time.

It was further reasoned, that with higher LRF

utilization it would not be feasible to accommodate

more heats from the BOF and transport to the caster

at a higher rate. Hence the bottleneck was in all

likelihood the existing capacity of the LRF. It was

suggested that an additional LRF could be a

probable solution to make use of the additional BOF

capacity as well as the additional caster capacity

with three strands in operation. The modified

operations of the iron making and steel making unit

of the plant can be outlined by the schematic as

shown in Figure 8:

Figure 8: The steelmaking process with additional LRF.

8 SIMULATING WITH

ADDITIONAL LRF CAPACITY

Engineering of the additional LRF led to modified

layout with provision of transfer cars and crane

accessibility to the additional LRF. The sequencing

of heats with the additional LRF and operations

using three strands of the caster needed to be

validated to ensure proper synchronization of the

BOF with the Caster such that the heat sequences for

different grades are maintained while maximizing

the utilization of the Casters. It was also required to

find the maximum possible heats keeping in mind

when a heat sequence has started in a Caster, it

should complete the cast sequence without

interruption due to the unavailability of heat.

The model was run with the additional LRF and

appropriate sequencing of heats at the LRFs. The

results found were as shown in Table 6.

Table 6: Results of simulation run with additional LRF for

10 days after attaining stabilization.

Proposed Operation

Total heats 278

Average tap-to-tap time 51 mins

LRF-1 utilization 45.86 %

LRF-2 utilization 45.78 %

Caster utilization 71.60 %

VD utilization 64.63 %

Caster heat sequence Maintained

The simulation results showed that with additional

LRF and the envisaged BOF maintenance

downtimes, the average BOF tap-to-tap time could

be brought down to 51 minutes and the caster could

be operated with three strands; as a result the

number of heats will increase substantially. The

simulation results also suggested that there needs to

be 4 hot metal ladles in active circulation and 4 steel

ladles in active circulation to support the logistics

and achieve the desired production.

9 COST BENEFIT ANALYSIS

A cost-benefit analysis was performed to analyze the

return on investment. Improving the overall

throughput increased the production of saleable steel

in terms of billets which otherwise was being

diverted to the pig casting machine for casting iron

ingots. The price of billets is generally higher than

price of iron ingots on a per ton basis. The marginal

cost of producing steel through caster or the pig

casting machine is minimal and is assumed to be

zero. The marginal cost of processing of steel in the

LRF was non-trivial. Additional operational costs

for BOF tap-hole sleeves were also non-trivial. It

was assumed that all the billets or pig cast ingots

that were produced were sold in the market at

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

116

average market prices. Investments in additional

buffer and processing capacity were in the form of a

35 ton LRF.

Table 7 shows the CAPEX, OPEX, revenue and

payback period based on the proposed modifications

in terms of capacity expansion and operating

practices.

Table 7: Cost benefit analysis.

Unit Costs & Operational Parameters

Tap hole sleeves 200 mm, 10

sleeve pack

$3000

Sleeve change interval 75 heats

Electrode consumption in

LRF

12 gm/KWH

Electricity consumption in

LRF

0.5 KwH/Degree

Celcius/ton

Average heating in LRF 5 Degree Celcius

Cost of Electricity 10 C/ KWH

Investments

1X35 Ton LRF 8 MM$

Product Price

Average Billet Price $480 /ton

Average Pig Iron Price $ 400/ton

Marginal Revenue R 5.3 MM$/year

Marginal Cost C (Sleeve

Cost + Electrode

Consumption + Power

Consumption)

~$400,000

Additional profit , P 4.9 MM$

Payback Period for

Investment

1 Year and 7

Months

10 CONCLUSIONS

The paper presents an approach for increasing the

overall throughput of a steel melt shop in an

integrated steel plant constrained by unit operations’

service times and capacity of facilities with the help

of simulation. Global optimization of the

steelmaking process has many interdependent

variables which are also probabilistic in nature

making the analysis intractable through traditional

analytical methods. Discrete event simulation with a

hierarchical iterative approach allowed us to

progressively analyze and re-design cycle time,

logistics and capacity improvement across the

operating units in the steel melt shop for better

throughput. The result showed that only reducing

downtimes at the BOF was not effective in

increasing the shop production and an additional

LRF was also necessary to obtain the benefits. The

recommendations resulted in effective utilization of

all the units so that the overall throughput was

maximized. Based on our recommendations the

number of heats processed increased from an

average of 21 per day to an average of 27 per day

resulting in an increase of 28%. The increased

overall steel production and reduced converter wait

times decreased the diversion of hot metal to the pig

casting machine improving the profitability of the

melt shop. The proposed system design and

recommendations is currently being implemented.

REFERENCES

McGinty, J. T., Young, J. D., Greene, C. E, Kendrick,

V.C., 2008. Use of Dynamic Computer Simulation for

Optimal Melt shop Logistics. In Iron & Steel

Technology.

Mukherjee, A., Adak, A., Raj, P., Kirtania, S., 2012.

Enhancing a System’s Performance by Utilizing its

Hidden Capacity using Discrete Event Simulation: A

Case Study of a Steel Melt Shop. In International

Simulation Conference of India. IIT Bombay, India.

Buzen, J. P., 1976. Fundamental operational laws of

computer system performance. In Acta Informatica.

Jenning, P., Buzen, J., 1978. The Operational Analysis of

Queuing Network Models. In Journal of ACM

Computing Surveys.

Harrell, C., Ghosh, B. K., Bowden, R. O., 2012.

Simulation Using Promodel, McGraw-Hill. USA, 3

rd

edition.

OptimizingSteelMeltShopOperationsusinganIterativeHierarchicalDecompositionbasedDiscreteEventSimulation

Model

117