Assistive Robot for Standing with Physical Activity Estimation

based on Muscle Arrangements of Human Legs

Daisuke Chugo

1

, Takahiro Yamada

1

, Satoshi Muramatsu

2

, Sho Yokota

3

and Hiroshi Hashimoto

4

1

School of Science and Technology, Kwansei Gakuin University, Sanda, Hyogo, Japan

2

School of Information Science and Technology, Tokai University, Hiratsuka, Kanagawa, Japan

3

Department of Mechanical Engineering, Toyo University, Kawagoe, Saitama, Japan

4

Advanced Institute of Industrial Technology, Shinagawa, Tokyo, Japan

Keywords: Standing Assistance, Musculoskeletal Model, Joint Traction, Physical Activity Estimation.

Abstract: A physical activity estimation scheme is proposed for patients who use a robot for standing assistance. In

general, conventional assistive robots do not require patients to use their own physical strength to stand,

which leads to decreased strength of the elderly. Therefore, an assistive robot that maximally uses a

patient’s remaining physical strength is desired. The assistive robots can achieve this objective by

estimating the physical activity of the patient when they stand. The activity estimation proposed here is

primarily based on a human musculoskeletal model of a lower limb, which exhibits a biarticular muscle

function. The patient generates a natural standing motion using the biarticular muscle function, and the

proposed model enables the assistive robot to estimate the patient’s physical activity, without using

biosensors, such as electromyographs, which are normally stuck on patients. The proposed estimation is

implemented with a prototype assistive robot that assists elderly patients to use their remaining physical

strength based on the estimated results, thus testing the effectiveness of the proposed method.

1 INTRODUCTION

The act of standing may be the most serious and

important activity in the daily life of an elderly

person lacking physical strength (Alexander et al.,

1999; Hughes et al., 1996). However, assisting

elderly patients to stand is a heavy task for

caregivers and this can be the primary source of the

lumbago that many experience (Cabinet Office,

Government of Japan, 2011). Therefore, creating a

care service robot capable of assisting the elderly

when they stand is important, and thus many such

assistive devices have been developed and presented

in previous works (Nagai et al., 2003; Funakubo et

al., 2001).

In Japan, elderly people requiring assistance in

daily life are classified into five different care levels

(Cabinet Office, Government of Japan, 2011), where

requiring care level 1 is a minor and requiring care

level 5 is a serious condition. Generally, the elderly

whose care level is 1 or 2 have difficulty in standing

on their own but are able to perform normal daily

life activities if standing assistance is provided.

However, in many cases, standing assistance devices

provide all the power necessary for the patient to

stand and do not use the patient’s remaining physical

strength. Thus, the patient’s physical strength

decreases (Hirvensalo et al., 2000). In fact, between

2002 and 2003, more than 10% of care level 1

patients were subsequently assigned to higher care

levels in next year (Cabinet Office, Government of

Japan, 2011). Thus, to improve the quality of life of

elderly patients with low care levels, assistive robots

should use the patient’s remaining physical strength.

However, no studies have been conducted toward

this end.

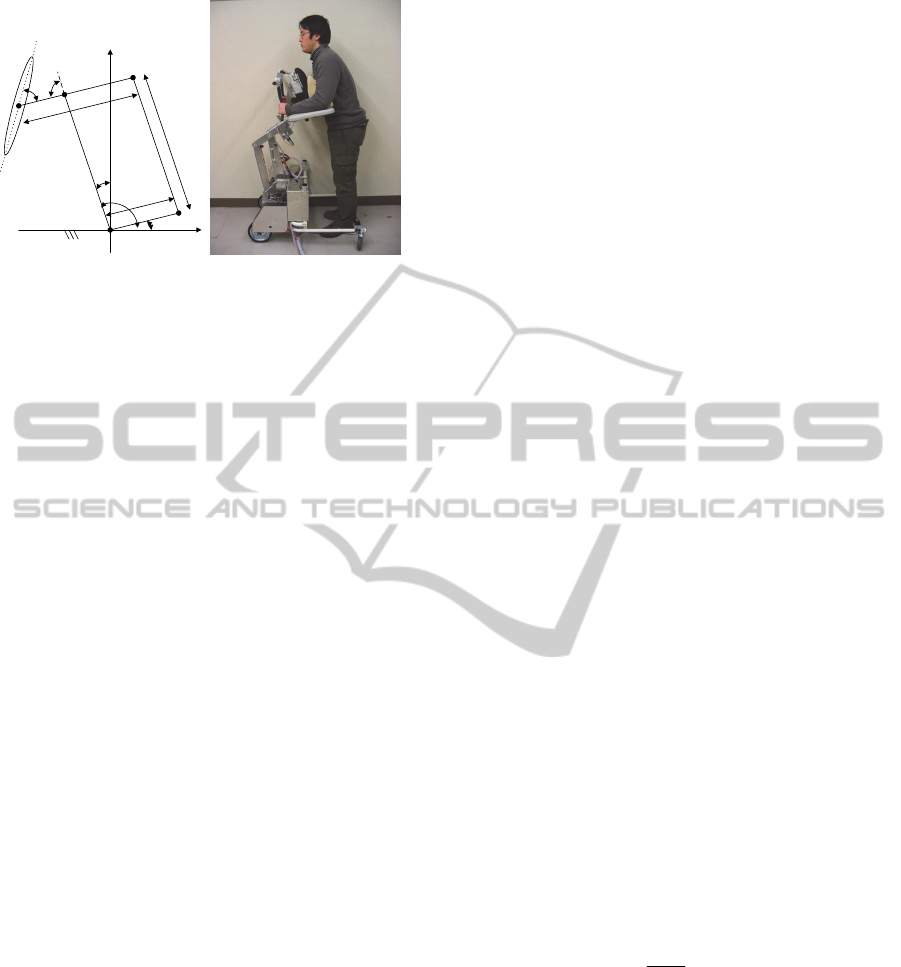

Therefore, we have developed a novel assistive

robot designed to aid patients in using their own

physical strength to stand (Chugo et al., 2012). The

robot is based on a walker (a popular assistance

device for aged people in normal daily life) and uses

a support pad, which is actuated by manipulators

with three degrees of freedom (Fig.1), to assist

patients in standing.

To maximally utilize the remaining physical

strength of a patient while providing standing

assistance, the robot is required to accurately

estimate the physical activity of the patient because

the robot is required to coordinate its assistive force

35

Chugo D., Yamada T., Muramatsu S., Yokota S. and Hashimoto H..

Assistive Robot for Standing with Physical Activity Estimation based on Muscle Arrangements of Human Legs.

DOI: 10.5220/0005527400350043

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 35-43

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Actuator 2

Actuator 1

o

p

Actuator 3

x

y

α

β

L

1

L

2

L

3

L

i

n

k

1

L

i

n

k

2

θ

1

θ

2

θ

3

(a) Flame kinematic model. (b) Overview of our robot.

Figure 1: Our developed robot for standing assistance.

accordingly. However, generally, such estimations

without biosensors, as electromyographs (EMG), are

difficult; further, physical activity estimation with

biosensors, which are required to be stuck on the

patient, is impractical because assistance robots

should be low cost and easy to use.

Previous works have proposed physical activity

estimation using human models comprising linkages

and joints without such biosensors (Nuzik et al.,

1986; Hatsukari et al., 2009). These schemes

evaluate the patient’s physical activity using joint

traction, which is calculated using the kinematical

model as an index. However, many muscles generate

human body movements, and traction, which

muscles can generate maximally, changes according

to the relative positions of bones and muscles.

Therefore, maximum joint traction is not constant

but it changes according to the patient’s posture.

During a standing motion, the patient’s posture

changes considerably, which should be taken into

consideration when evaluating a patient’s physical

activity.

Therefore, in this paper, we propose a real-time

physical activity estimation for patients using a

standing assistance robot without additional

biosensors. The paper is organized as follows: in

Section 2, we propose an estimation scheme of a

patient’s activity according to their posture during

the standing motion using a human musculoskeletal

model of a lower limb, which expresses a biarticular

muscle function; in Section 3, we demonstrate an

assistance control scheme on our robot, which uses a

patient’s strength based on estimated results; in

Section 4, we provide experimental results obtained

using our prototype; and Section 5 concludes this

paper.

2 PHYSICAL ACTIVITY

ESTIMATION

2.1 Overview of Proposed Estimation

Scheme

In the linkage model of a human (Nuzik et al., 1986;

Hatsukari et al., 2009), a joint traction is used as an

index of a patient’s load. However, a joint traction

does not consider the posture of the patient, and in

some cases, this index and the experience of nursing

specialists are different, especially when the patient

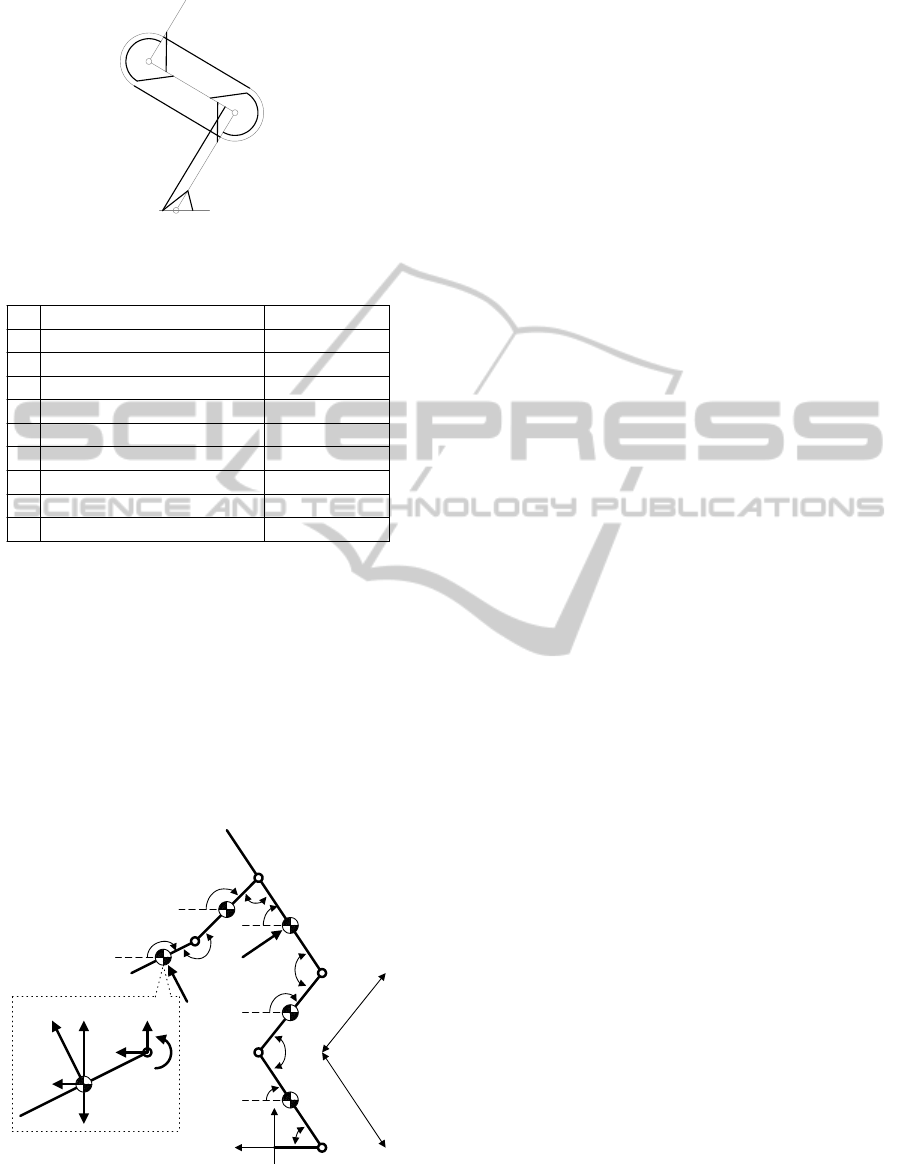

is in a half-sitting posture. When the patient stands,

the muscles shown in Fig. 2 generate the lifting

motion (Nishida et al., 2011). Many muscles (shown

in Table 1) are used to accomplish the standing

movement, and the traction, which muscles can

generate maximally, changes according to the

relative position between frames and muscles.

Thus, we propose a novel physical activity

estimation scheme that takes all this into

consideration. In this paper, we focus on the traction

of the knee and waist joints, which are the main

forces propelling the patients to stand. Our proposed

algorithm is as follows:

First, we derive the required traction (knee joint

req

k

and waist joint

req

k

) to accomplish a standing

motion with our assistive robot.

Second, we derive the maximum traction (knee

joint

max

k

and waist joint

max

k

) the muscles can

generate for the posture at this time.

Comparing the two derived tractions, we

evaluate the physical activity of patient

i

,

which demonstrates how much the patient uses

their own physical strength as compared with

their maximum power (1). i is the identification

character. (For example, in the case of the knee

joint, i is k.)

max

i

req

i

i

(1)

2.2 Derivation the Required Traction

To estimate the applied load to each joint, we

approximate human motion based on the movement

of the linkage model on a two-dimensional (2D)

plane (Nuzik et al., 1986). Using this model, we can

derive the traction of each joint and estimate the

patient’s load.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

36

hip

knee

ankle

1

2

3

4

5

6

7

8

9

Figure 2: Muscle arrangements in the human leg.

Table 1: Human leg muscles.

20.0

23.0

8.7

60.2

248.1

43.5

247.6

99.1

19.7

Physical Areas [cm

2

]

Gluteus masimum (GMAX)9

Iliopsoas (IL)8

Biceps femoris and short head (BFSH)7

Semimenbranosus (SM)6

Vastus lateralis (VAS)5

Rectus femoris (RF)4

Soleus (SOL)3

Gastrocnemius (GAS)2

Tibialis anterior (TA)1

Muscle actuatorNo

20.0

23.0

8.7

60.2

248.1

43.5

247.6

99.1

19.7

Physical Areas [cm

2

]

Gluteus masimum (GMAX)9

Iliopsoas (IL)8

Biceps femoris and short head (BFSH)7

Semimenbranosus (SM)6

Vastus lateralis (VAS)5

Rectus femoris (RF)4

Soleus (SOL)3

Gastrocnemius (GAS)2

Tibialis anterior (TA)1

Muscle actuatorNo

The assistance system is designed in such a way

that patients lean on the pad and grasp the armrest

while standing with our assistance (we will explain

our prototype more closely in the next section),

which means that our system uses the pad to apply

force to the patient’s chest and the armrest to apply

force to their forearm. These forces move vertically

(at the pad) and horizontally (at the armrest).

Considering these conditions, we propose a linkage

model that approximates the human body with our

assistance device (see Fig. 3).

0

x

y

(x

1

,y

1

)

(x

2

,y

2

)

(x

3

,y

3

)

(x

4

,y

4

)

(x

5

,y

5

)

f

armrest

f

pad

(x

e

,y

e

)

(x

s

,y

s

)

(x

w

,y

w

)

(x

k

,y

k

)

(x

a

,y

a

)

req

a

req

k

req

w

req

s

req

e

5

4

3

2

1

Link1

Link2

Link3

Link4

Link5

Link6

req

e

Link1

f

armrest

f

yarmrest

f

xarmrest

f

xe

f

ye

m

1

g

l

4

l

5

Figure 3: Linkage model of a human.

This model consists of six linkages. The armrest

applies the assistance force (

armrest

f

) to the center

position of Link 1 and the support pad applies the

force (

pad

f

) to the center position of Link 3.

i

m

is

mass of the link (

6,,1

i

) and

i

I

is the moment

of inertia.

ii

yx ,

is the position of the center of

gravity on each link, and

ii

yx ,

(i = a, k, w, s, and

e) is the position of each joint. We assume that each

linkage is in pillar form with its mass distributed

uniformly.

Using the balance of applied force and its

moment, we can derive the required traction of each

joint as (7) and (8). Our robot measures the user’s

posture using the kinematical information provided

by the assistance manipulator and a laser range

finder, which is equipped as shown in Fig. 1(b),

without additional biosensors that would have to be

stuck onto the patient. Using these equations, we can

calculate the required traction for each joint (

req

k

,

req

k

). For further information, please refer to our

previous paper (Chugo et al., 2012).

req

swsws

wsws

ww

ypadwxpadw

yarmresttsxarmrestts

req

w

Igyxxxyym

gyxxxyym

gyxxxyym

fxxfyy

fxxfyy

33111

222

33333

33

(2)

req

wwkwk

wkwk

wkwk

kk

ypadyarmrestkw

xpadxarmrestkw

req

k

Igyxxxyym

gyxxxyym

gyxxxyym

gyxxxyym

ffxx

ffyy

44111

222

333

44444

(3)

Here, we use body parameters chosen from a

standard body of data of Japanese adult males

(Okada et al., 1996); see Table 2. To derive the

required body parameters for calculating the

moment force, we measure the length of each body

segment and the mass of the entire body of each

individual patient.

2.3 Deriving the Maximum Traction

In the field of biomedicine, a human

musculoskeletal model that considers the role of

both an antagonistic muscle and a biarticular muscle

has been proposed (see Fig. 4) (Oshima et al., 1999).

This model shows that the antagonistic muscle and

the biarticular muscle interact to generate human

body movement.

AssistiveRobotforStandingwithPhysicalActivityEstimationbasedonMuscleArrangementsofHumanLegs

37

Table 2: Human body parameters.

No Name M [%] C.G [%] K [%] Length [m] *

1 Forearm 3.2 41.5 27.9 0.35

2 Humerus 5.4 52.9 26.2 0.39

3 Trunk 57 49.3 34.6 0.48

4 Femur 22 47.5 27.8 0.61

5 Leg 10.2 40.6 27.4 0.56

6 Foot 2.2 59.5 20.4 0.26

M The mass ratio of the body segment to the mass of the body.

C.G. The ratio of segmental length, which shows the location of

the center of gravity on the longitudinal axis.

K The ratio of the gyration radius of the body segment to the

length of its segment.

We know from previous research (Oshima et al.,

1999) that when the maximum force each muscle

can realize at the ankle joint is

1me

F

,

2me

F

,

3me

F

,

1mf

F

,

2mf

F

, and

3mf

F

, the output distribution of the force at

the ankle joint is expressed kinematically as a

hexagon (see Fig. 5).

The directions of

1me

F

and

1mf

F

are parallel to the

leg, the directions of

2me

F

and

2mf

F

are parallel to

the straight line that connects the waist and ankle

joints, and the directions of

3me

F

and

3mf

F

are

perpendicular to the leg. Furthermore, Oshima et

al.’s previous research demonstrates that there is a

relationship between the force output vector and the

activation level

i

of the muscle working in the

force output direction. This relationship is shown in

Fig. 4, and our system can estimate the activation

level of each muscle using the output force at the

ankle joint. For example, when the output force is

example

F

as in Fig. 4, the direction of the force

vector is between e and f.

Therefore, the activation levels of each muscle

are

%100

31

ee

,

%0

31

ff

, and

%50

22

fe

, as shown in Fig. 4.

Using this model, we propose a physical activity

estimation scheme of a patient according to their

posture. First, our system calculates the required

traction of the waist joint

req

w

and of the knee joint

req

k

using (2) and (3), respectively. From the

kinematical relationship shown in Fig. 4, the force

output vector

yx

ff ,

at the ankle joint is derived:

5544 5 54 4

55 5 5

sin sin cos cos

sin cos

req

w

req

k

x

y

f

ll l l

f

ll

(4)

defabcd

0

100

0

100

0

100

f1 e1

f2 e2

f3 e3

Muscle Activation level [%]

F

example

e

1

e

2

f

1

f

2

e

3

f

3

a

b

c

d

e

f

F

me2

F

mf1

F

me3

F

me1

F

mf2

F

mf3

F

example

waist

joint

knee

joint

ankle

joint

r

r

Figure 4: Musculoskeletal model considering the role of

the antagonistic and biarticular muscles.

Second, our system derives the distribution of the

output force at the ankle joint from the patient's

posture. Then, our system adapts the force output

vector

yx

ff ,

derived from (4) to the hexagon from

Fig. 4, which expresses the distribution of the output

force, and derives the muscle activation level

i

at

this time.

We know from previous research (Spector et al.,

1980) that the maximum force

max

i

F

that the muscle

can generate is

ii

AF

max

(5)

where

i

A

is the cross-sectional area of each muscle

and

is a maximum force that the muscle per unit

area can generate. In this study, we set

2

50 cmN

(Oshima et al., 1999) and use the

values shown in Table 1 for a cross-sectional area of

each muscle (Okada et al., 1996). i is an

identification number of the muscle.

When the muscle activation level is

i

, the

maximum traction output of the waist joint

max

w

and

the knee joint

max

k

that the muscle can generate with

the posture at this time is derived as

rFF

rFF

ffee

ffeew

max

33

max

33

max

11

max

11

max

(6)

rFF

rFF

ffee

ffeek

max

33

max

33

max

22

max

22

max

(7)

where r is a moment arm of each joint (Hoy et al.,

1990).

max

w

and

max

k

change according to the relative

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

38

position between muscles and frames, which means

that it reflects the posture of the patient.

Using (2), (3), (6) and (7), we can derive the

physical activity of the patient

i

as (1). If the

physical activity (1) is a large value compared with

the maximum activity that the muscles can generate,

then we can evaluate the load is heavy. Usually, the

patient does not use their maximum power, and in

this study, we set the threshold showing the

capability of the patient as

%40

max

, which is

based on the opinions of nursing specialists (Oshima

et al., 1999).

3 ASSISTANCE CONTROL

3.1 System Overview

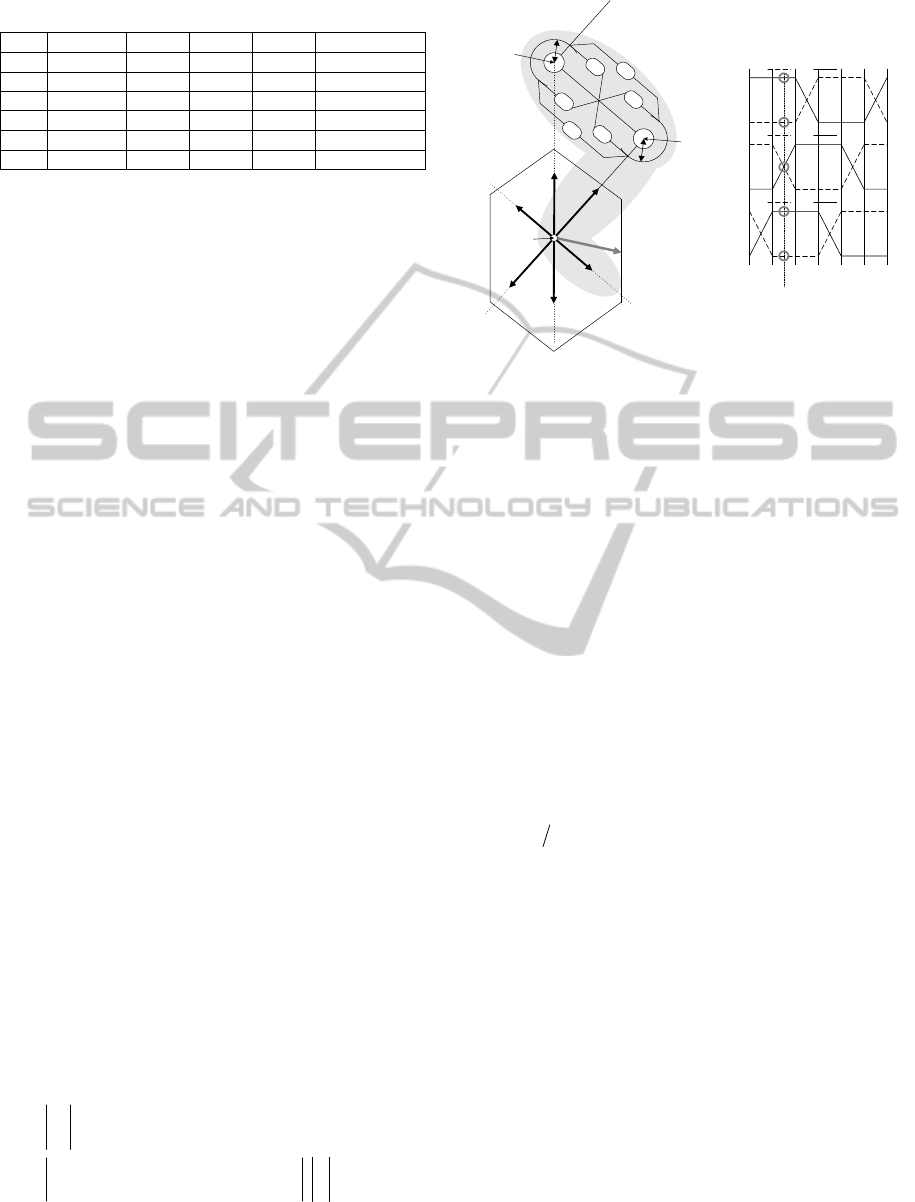

Fig. 5(a) shows our proposed assistance robot. The

system consists of a support pad with three DOF and

the walker. The support pad is activated by our new

assistance manipulator, which has four parallel

linkages (Chugo et al., 2012). The patient leans on

the support pad and grasps the armrest while

standing with assistance (see Fig. 1(b)). In general,

fear of falling forward during the standing motion

reduces elderly patients’ standing ability (Maki et

al., 1991). With the proposed scheme, patients can

easily maintain their posture during the standing

motion without the fear of falling forward.

Fig. 5(b) shows the prototype of the proposed

robot. The prototype is able to lift patients up to 180-

cm tall and weighing up to 150 kg. Furthermore,

because of its actuated wheels, the prototype can

assist patients walk. To measure a patient’s posture,

the prototype has a force sensor and a laser range

finder in its body (see Fig. 5(b)).

Our physical activity estimation scheme, which

is proposed in the previous section, requires real-

time data regarding its assistance force and the

patient’s posture. To measure its assistance force,

our support pad has two force sensors on its body

that measure

pad

F

and

armrest

F

(see Fig. 5(b)). To

measure the patient’s posture, we use a laser range

finder; thus, calibration or special markers are not

required to be stuck on the patient.

3.2 Standing Motion as Recommended

by Nursing Specialists

Previous studies have proposed many types of

assisted standing. Based on her experience as a

nursing specialist, Kamiya proposed using the

Actuator1

Actuator2

Actuator3

Support Pad

(3DOF)

Actuator1 and 2

Actuator3

Motor Position

Fpad

Farmrest

Actuator1

Actuator2

Actuator3

Support Pad

(3DOF)

Actuator1 and 2

Actuator3

Motor Position

Fpad

Farmrest

Fpad

Sensing

area of

LRF

Force Sensor

LRF

Fpad

Sensing

area of

LRF

Force Sensor

LRF

(a) The robot’s actuators. (b) The robot’s sensors.

Figure 5: Prototype of the assistive robot.

patient’s maximum strength to stand, as shown in

Fig. 6. For effective standing assistance, we use a

control reference as shown in Fig. 7 (Kamiya, 2005).

Fig. 7(a) shows the support pad’s position tracks,

and Fig. 7(b) shows its angle tracks. The movement

pattern in Fig. 7(b) refers to a ratio of the standing

motion as determined by (8).

s

t

is the time required

to complete the standing operation, and

t

is the

present time.

s

t

t

s

ˆ

(8)

20

50

80

110

140

170

200

0 25 50 75 100

Movement Pattern (%)

Angle (deg

)

Trunk

Knee

Ankle

(a) Standing motion. (b) Angular value of each joint.

Figure 6: Standing motion recommended by nursing

specialists.

0.7

0.9

1.1

1.3

1.5

-0.2 -0.1 0 0.1

X-axis Position

(

m

)

Y-axis Position (m

)

50

60

70

80

90

0 20 40 60 80 100

Movement Pattern (%)

Angle (deg

)

(a) Position of P

pp

yx ,

(b) Inclination

p

Figure 7: Derived control references. The coordination is

defined in Fig. 1(a).

3.3 Assistance Control Scheme based

on the Physical Activity

For using the remaining physical strength of a

patient, our assistance system uses new control that

Ankle

Knee

Trunk

AssistiveRobotforStandingwithPhysicalActivityEstimationbasedonMuscleArrangementsofHumanLegs

39

combines damping control and position control

(Chugo et al., 2007). Damping control is suitable for

controlling objects with contact. From (2) and (3),

the assistance force

ypadyarmresty

ffF

in the lifting

direction will reduce the required traction of each

joint (

req

w

and

req

k

) because coefficients of

y

F

,

ws

xx

and

3

xx

w

in (2) and

kw

xx

in (3)

will be negative in usual standing posture.

Therefore, we can expect that the damping control

which increases

y

F

will reduce the required load of

a patient during standing motion.

In our proposed control algorithm, if the physical

activity of the patient is heavy, our system uses the

damping control for reducing the patient’s load. On

the other hand, if the activity of the patient is light,

our system uses the position control, which does not

assist the force, for using the remaining physical

strength of the patient. In our previous works, our

system uses a joint traction as an index of the

patient’s load for this algorithm (Chugo et al., 2012).

In this paper, we extended our assistance algorithm

using a proposed index of the patient’s physical

activity defined in (1).

3.3.1 Deriving the Reference

Before using the robot for assistance, we measure

the height and mass of each patient individually. The

length of each body segment is derived based on

Table 2 and used by the reference generator as it

derives the velocity control reference of each

actuator (No. 1, 2, and 3) (9) from the motion

reference (shown in Fig. 6) using the following

equation:

T

ref

i

ref

i

ref

i

ref

i

vsvv 1,,

ˆ

,,0 v

(9)

where

ref

i

v

is the velocity control reference

3,2,1i

, which is a function of the movement

pattern

s

ˆ

defined in (8). For more details regarding

the calculation process, please refer to our previous

work (Chugo et al., 2012).

3.3.2 Control Algorithm

Our system estimates the physical activity of the

patient using the proposed scheme (1) while

assisting patients as they stand. Based on this

estimation, the system selects a suitable control

scheme for damping and position controls. For this

to happen, the output of each actuator is derived

from

ref

iiyy

ref

ii

xxKFFBvv

0

(10)

where

ypadyarmresty

ffF

is the applied force to the

vertical direction on the support pad and armrest.

ref

i

x

is the angular position reference derived from

(9), and

i

x

is the actual angular position.

i

v

is the

updated reference that our system inputs to the

motor controller during the assisted standing motion.

0y

F

is the coefficient and force that the patient

applies to the support pad while he or she stands.

Using (10), our system can switch between the

position control mode and the damping control

mode.

3.3.3 Controller’s Parameter Coordination

B and K are constants that coordinate the ratio

between the damping and position controls. Our

system applies damping control when the maximum

estimated load of each joint

i

, which is defined in

(1), exceeds the threshold

%40

max

. i is the

identification character. (For example, for the knee

joint, i is k.) For applying damping control, the

coefficient B, which validates damping control, is

derived from

max

maxmax

0

i

ii

ifB

ifbB

(11)

Using this parameter coordination, our system

assists the patient with increased force when the

patient’s load is heavy. On the other hand, position

control is always useful because it helps the patient

maintain stable posture during the standing motion.

Thus, we set coefficient K, which validates position

control, as constant. In this study, the values b and K

are derived experimentally.

4 EXPERIMENTS

4.1 Experimental Setup

To verify the effectiveness of our proposed scheme,

eight subjects test the prototype robot, which is

implemented on the basis of the proposed estimation

scheme. Two subjects (Subjects A and B) are young

students and four subjects (Subjects C–F) are 54–72

years old with care levels of 1 or 2. Two subjects

(Subjects G and H) are hemiplegics aged 32 and 64

years. The young subjects (Subjects A and B) wear

special clothing designed to limit their motion in

order to simulate an elderly person’s limited

mobility (Takeda et al., 2001).

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

40

Unless otherwise noted, each subject tests the

following three cases five times. In Case 1, the robot

assists with the standing motion using only the

position control mode. Only subjects A and B test

this case because the robot does not assist with force

and the subject is required to stand using only their

own physical strength. In Case 2, the robot assists

the subject with the force control mode when the

subject’s physical activity exceeds their capability

threshold. In this case, the robot uses our proposed

load estimation scheme, and we set the threshold of

the subject’s capability as

%40

max

based on the

opinion of nursing specialists (Oshima et al., 1999).

In Case 3, the robot assists the subject with the force

control mode as necessary, similar to Case 2. The

difference between Cases 2 and 3 is that in Case 3,

the robot estimates the physical activity of the

subject using joint traction, as in our previous work

(Chugo et al., 2012). In this case, we set the

threshold of the subject’s capability as

kgNm

prev

5.0

max

based on previous research

(Omori et al., 2001).

In all cases, we use the standing motion

recommended by nursing specialists (Kamiya, 2005)

as specified in Section 3.2.

4.2 Experimental Results

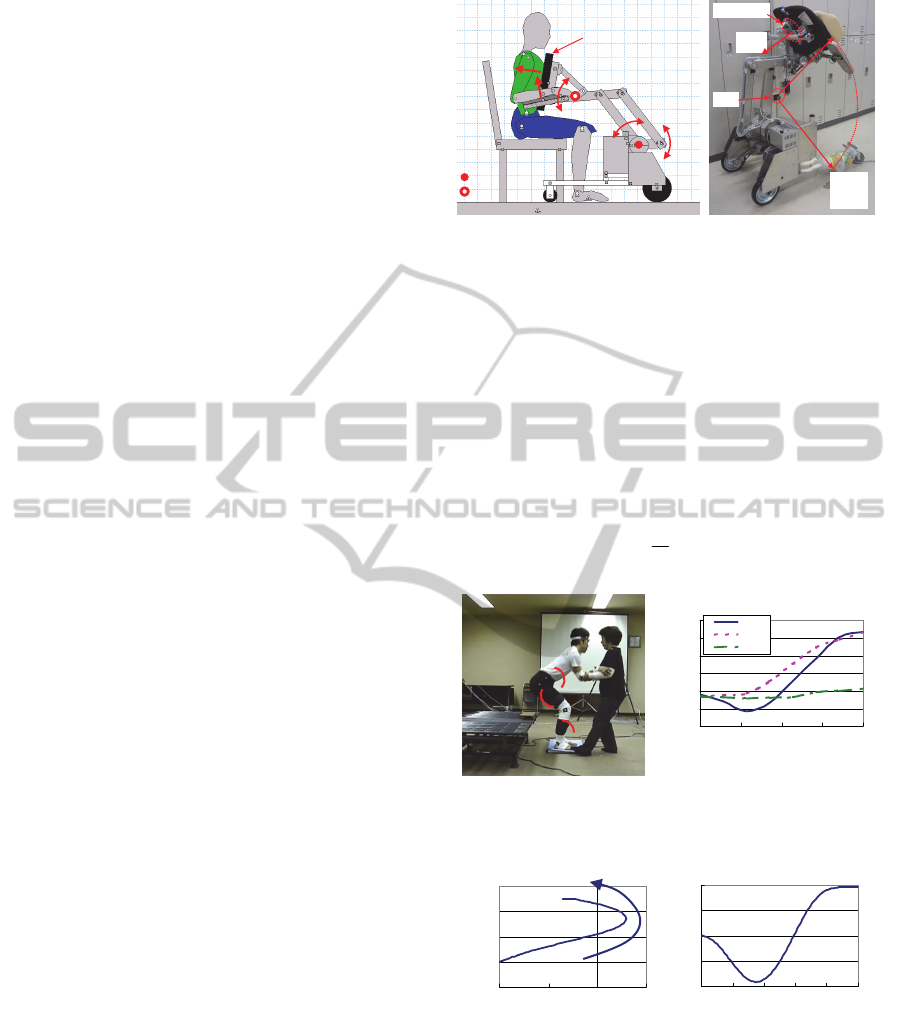

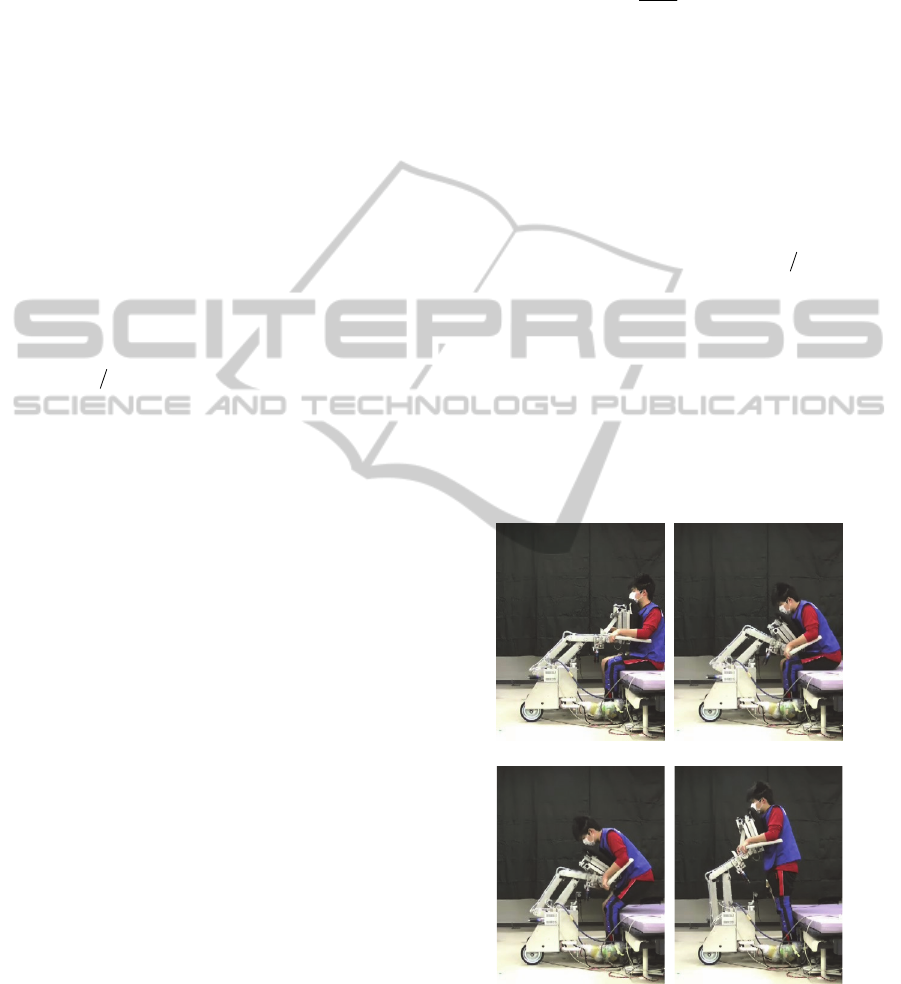

The subject stands up as shown in Fig. 8. Fig. 9

shows the required traction

req

i

, the maximum

traction

max

i

(defined in (2), (3), (6), and (7)), and

the estimated physical activity of the subject

i

(defined in (1)) for each joint. As Fig. 8 shows, there

are different tendencies between

max

i

and

i

. The

estimated load

i

increases—especially at 40–75%

movement in a knee joint, around which time the

subject lifts their upper body and their load tends to

be heavy. This result is similar to the experiences of

nursing specialists (Nuzik et al., 1986).

Furthermore, Fig. 10 shows the EMG data of a

vastus lateralis (VAS) muscle that is normalized by

maximum voluntary contraction. This data reflects

the activity of the knee joint. The activity of the

VAS muscle in Fig. 10(a) has the same tendency as

our proposed load estimation index. In Fig. 10(b),

the estimated load exceeds the threshold

(

%40

max

), and our robot assists with force for

the standing motion. Therefore, the load of the

subject decreases during the knees’ 40–75%

movement. These results show that our proposed

load estimation scheme is effective.

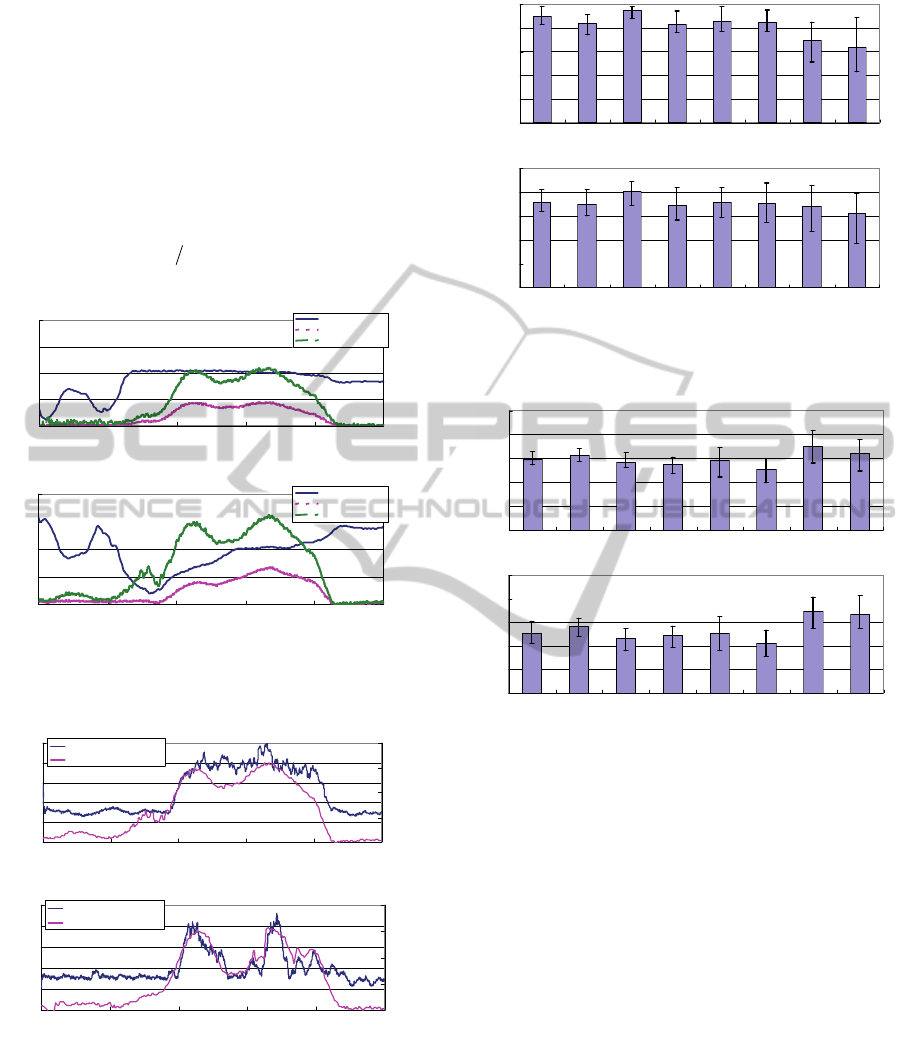

Fig. 11 shows the ratio

which shows the correct

answer rate of the estimated physical activity from

(12).

s

match

t

t

(12)

where

s

t

is the time required to complete the

standing operation and

match

t

is the time when the

estimated physical activity exceeds the threshold

%40

max

and the measured muscle activity

exceeds 40%, too.

In Case 2 (Fig. 11(a)), our system uses the

proposed activity ratio

%40

max

as an index of

high physical activity; in Case 3 (Fig. 11(b)), our

system uses joint traction

kgNm

prev

5.0

max

as the

index. These results show that our proposed physical

activity estimation scheme (Case 2) is more accurate

than the previous index, which uses joint traction

(Case 3). Two subjects (Subjects G and H) are

hemiplegics and the estimation results for both cases

are inaccurate because their standing motions were

different from the motion recommended by nursing

specialists (Kamiya, 2005); therefore, different

muscles may be used when they stand up. Future

work will discuss the muscle model for hemiplegics.

(a) 0[%] (b) 30[%]

(c) 60[%] (d) 100[%]

Figure 8: Standing motion with our assistance robot (Case

1, Subject A).

Using the estimated physical activity of the

subject, our robot assists with force control only

when necessary. As a result, Fig. 12 shows the

AssistiveRobotforStandingwithPhysicalActivityEstimationbasedonMuscleArrangementsofHumanLegs

41

maximum traction output

req

knee

(peak load) which the

subject is required to output for standing completely

and Fig. 13 shows the required output power for one

standing motion of a knee joint. From Fig. 12(a) and

(b), we see that the workload in Case 2 is larger than

that in Case 3, which means that the subject uses

more physical strength with our proposed load

estimation (Case 2). On the other hand, from Fig.

13(a) and (b), we see that the peak load is almost the

same and does not exceed the capability of the

subject,

kgNm

prev

5.0

max

, which means that our

robot assists with enough force when necessary.

0

0.5

1

1.5

2

0 20406080100

Movement Pattern (%)

Traction (Nm/kg)

0

20

40

60

80

Activity Ratio (%)

Maximum Traction

Required Traction

Physical Activity

(a) A waist joint

0

0.5

1

1.5

2

0 20 40 60 80 100

Movement Pattern (%)

Traction (Nm/kg)

0

20

40

60

80

Activity Ratio (%)

Maximum Traction

Required Traction

Physical Activity

(b) A knee joint

Figure 9: A required traction, a maximum traction, and the

estimated physical activity. (Case 1, Subject A).

0

20

40

60

80

100

0 20406080100

Movement Pattern [%]

EMG Ratio [%]

0

20

40

60

80

Activity Ratio [%

]

EMG-MVC

Estimated Physical Activity

(a) Case1 (Without a force assistance)

0

20

40

60

80

100

0 20406080100

Movement Pattern [%]

EMG Ratio [%]

0

20

40

60

80

Activity Ratio [%

]

EMG- MVC

Estimated Physical Activity

(b) Case2 (With a force assistance)

Figure 10: The estimated physical activity and the

measured muscle activity during a standing motion.

(Subject A).

These results show that our proposed load

estimation allows the robot to assist with standing in

such a way that the subject’s remaining physical

strength is used as much as possible.

0

20

40

60

80

100

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Estimation Ratio [%

]

(a) Case2 (with proposed estimation)

0

20

40

60

80

100

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Estimation Ratio [%

]

(b) Case 3 (with previous scheme)

Figure 11: Ratio of the estimated physical activity and the

measured muscle activity.

0

10

20

30

40

50

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Workload [Ws]

(a) Case2 (with proposed estimation)

0

10

20

30

40

50

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Workload [Ws]

(b) Case 3 (with previous scheme)

Figure 12: Workload of the knee joint.

5 CONCLUSIONS

This paper proposes both a physical activity

estimation scheme that considers muscle

arrangements and a novel assistance system that uses

those estimated results to take advantage of the

patient’s remaining physical strength in such a way

that the patient’s muscular strength will not decline

over time. By using our proposed scheme, our

system can reduce a patient’s load when the

patient’s posture is such that it is difficult to use any

of the patient’s own physical strength.

In our system, the subject is required to set

parameters, such as a cross-sectional area of each

muscle. Previous researchers have proposed a

derivation method of these values using easy

gymnastics (Oshima et al., 1999). We plan to

develop an automatic individual parameter

derivation scheme in future work.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

42

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Peakload [Nm/kg

]

(a) Case2 (with proposed estimation)

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Subject A Subject B Subject C Subject D Subject E Subject F Subject G Subject H

Peakload [Nm/kg

]

(b) Case 3 (with previous scheme)

Figure 13: Peakload of the knee joint.

ACKNOWLEDGEMENTS

This research is supported in part by Grant-in-Aid

for Scientific Research C (25350693) from Japan

Society for the Promotion of Science (JSPS).

REFERENCES

N. B. Alexander, A. B. Schultz and D. N. Warwick, 1991.

Rising From a Chair: Effects of Age and Functional Ability

on Performance Biomechanics.

In J. of Geometry:

MEDICAL SCIENCES, Vol.46, No.3, M91-98.

M. A. Hughes, M. L. Schenkman, 1996. Chair rise

strategy in the functionally impaired elderly. In J. of

Rehabilitation Research and Development, Vol.33,

No.4, pp.409-412.

Cabinet Office, Government of Japan, 2011. KOUREISHA

HAKUSHO (The whitepaper on the aged society),

ISBN: 4904681010, pp.25, (in Japanese).

K. Nagai, I. Nakanishi and H. Hanabusa, 2003. Assistance

of self-transfer of patients using a power-assisting

device. In Proc. of the IEEE Int. Conf. on Robotics

and Automation, pp.4008-4015.

A. Funakubo, H. Tanishiro and Y. Fukui, 2001. Power

Assist System for Transfer Aid. In J. of the Society of

Instrument and Control Engineers, Vol.40, No.5,

pp.391-395.

M. Hirvensalo, T. Rantanen and E. Heikkinen, 2000.

Mobility difficulties and physical activity as predictors

of morality and loss of independence in the

community-living older population. In J. of the

American Geriatric Society, Vol.48, pp.493-498.

D. Chugo, Y. Morita, Y. Sakaida, S. Yokota, H.

Kobayashi, H. Hashimoto and K. Takase, 2012.

Standing Assistance Control using a Physical Strength

of a Patient with Load Estimation. In Proc. of 21st

IEEE Int. Symp. on Robot and Human Interactive

Communication, pp.234-239.

S. Nuzik, R. Lamb, A. Vansant and S. Hirt, 1986. Sit-to-

Stand Movement Pattern, A kinematic Study. In

Physical Therapy, Vol.66, No.11, pp.1708-1713.

T. Hatsukari, S. Kuroko, N. Miyake, R. Kawazoe, J.

Higuchi, Y. Hirata and K. Kosuge, 2009. Self-help

Standing-up Method Based on Quasi-static Motion. In

Proc. of the IEEE Int. Conf. on Robotics and

Biomimetics, pp.342-347.

I. Nishida, M. Maeda, T. Kawano and K, Shirase, 2011.

Estimation Method of Muscle Forces of Lower Limb

Considering the Role of Antagonistic Muscles and

Biarticular Muscles –Estimation of Muscle Forces of

Lower Limb during Vertical Jumping–. In J. of Japan

Ergonomics Society, Vol.47, No.6, pp.244-251.

H. Okada, M. Ae, N. Fujii and Y. Morioka, 1996. Body

Segment Inertia Properties of Japanese Elderly. In

Biomechanisms, No.13, pp.125-139.

T. Oshima, T. Fujikawa and M. Kumamoto, 1999.

Functional Evaluation of Effective Muscle Strength

Based on a Muscle Coordinate System Consisted of

Bi-articular and Mono-articular Muscles –Contractile

Forces and Output Forces of Human Limbs–. In J. of

Precision Engineering, Vol.65, No.12, pp.1772-1777.

S. A. Spector, P. F. Gardiner, R. F. Zernicke, R. R. Roy

and V. R. Edgerton, 1980. Muscle architecture and

force-velocity characteristics of cat soleus and medial

gastrocnemius: implications for neural control. In J. of

Neuro-physiol, Vol.44, pp.951-960.

M. G. Hoy, F. E. Zajac, M. E. Gordon, 1990. A

Musculoskeletal Model of the Human Lower

Extremity: The Effect of Muscle, Tendon, and

Moment Arm on the Moment-Angle Relationship of

Musculotendon Actuators at the Hip, Knee, and Ankle.

In J. of Biomechanics, Vol.23, No.2, pp.157-169.

E. Maki, P. J. Holliday and A. K. Topper, 1991. Fear of

falling and postural performance in the elderly. In J. of

Gerontology, Vol.46, No.4, pp. 123-131.

K. Kamiya, 2005. Development and evaluation of life

support technology in nursing. In Proc. of 7th RACE

Symp., Research into Intelligent Artifacts for the

Generalization of Engineering, pp.116-121.

D. Chugo, W. Matsuoka, J. Songmin and K. Takase, 2007.

Rehabilitation Walker with Standing-Assistance

Device. In J. of Robotics and Mechatoronics, Vol.19,

No.6, pp. 604-611.

K. Takeda, Y. Kanemitsu and Y. Futoyu, 2001.

Understanding the Problem of the Elderly through a

Simulation Experience – Difference in the Effect

between Before and After Clinical Practice –. In

Kawasaki Medical Welfare J. Vol.11, No.1, pp.64-73.

K. Omori, Y. Yamazaki, H. Yokoyama, U. Aoki, M.

Kasahara, K. Hiraki, 2001. The relationship between

strength in the lower extremity and the ability to stand

up from a chair in elderly inpatients. In Sogo

Rehabilitation. Vol.30, No.2, pp.167-171.

AssistiveRobotforStandingwithPhysicalActivityEstimationbasedonMuscleArrangementsofHumanLegs

43