Evolving Close-to-Real Digital Microstructures in

Polycrystalline Materials

A Monte Carlo Simulation Approach

K. R. Phaneesh

1

, Anirudh Bhat

2

, G. Mukherjee

3

and K. T. Kashyap

4

1

Dept. of Mechanical Engineering, M. S. Ramaiah Institute of Technology, Bangalore, India

2

School of Aerospace Engineering, Georgia Institute of Technology, Atlanta 30332, U.S.A.

3

Consultant, Valley Stream Drive 513, Newark, 19702, Delaware, U.S.A.

4

Department of Mechanical Engineering, Atria Institute of Technology, Bangalore, India

Keywords: Monte Carlo Simulation, Metropolis Algorithm, Al-4% Cu, Annealing, Simulated Microstructure.

Abstract:

For more than three decades now simulation of recrystallization and grain growth phenomena in annealed

metals have been studied through a variety of computer modeling techniques including that of Monte Carlo

(MC) simulation. In this study, we have been able to show the efficiency of the MC technique by evolving

simulated microstructures comparable very closely to real microstructures. The real microstructures were

generated in about a 50% cold-worked alloy of Al-4% Cu (Duralumin) annealed to various degrees. The

digital microstructures were evolved through a 2D simulation of a square lattice using Potts model Monte

Carlo simulation technique based on the Metropolis algorithm. Through our work we have been able to

show the close similarity between microstructures of real metals and microstructures digitally evolved

through simulation, perhaps for the first time, thereby validating the MC technique as an efficient computer

simulation tool for grain growth studies.

1 INTRODUCTION

Annealing is an important heat treatment process

carried out widely in the industry during mechanical

and thermal processing of cold-worked

polycrystalline materials. During this process,

metals undergo three stages of microstructural and

behavioral transformation - recovery,

recrystallization and grain growth. While the first

two stages are driven by the energy stored in the

metals during cold working, grain growth is driven

primarily by the reduction of excess energy stored in

the grain boundaries (Humphreys and Hatherly,

2005). The final microstructure in a polycrystalline

material, i.e., the grain size & its distribution, grain

shape & its geometry, depends largely on the extent

of grain growth that has taken place which in turn is

influenced by time, temperature and the presence of

second phase particles.

The microstructures of polycrystalline materials

carry valuable information which helps predict their

mechanical behavior through study of their grain

shapes and sizes. The average grain size, especially,

has a profound effect on the strength of materials, as

given by the Hall-Petch equation. The average grain

size of polycrystals are known to vary according to

degree of growth driven by curvature on the one

hand, and on the other hand stunted by the presence

of second phase particles. The study of growth and

stagnation of grain size in polycrystals has been

widely aided by the simulation approach of

generating digital microstructures, which follow the

basic guide lines of formation of real

microstructures.

Microstructures of metals resulting from normal

grain growth is distinguished by two characteristics

– the first is the presence of microstructural

homogeneity, in the sense that the size of the largest

grain present in the ensemble is only 2.5 – 3 times

bigger than the average grain size of the

microstructure. The second characteristic is the time

invariance of the grain size distribution which

suggests self-similarity in grain shapes and sizes at

different stages of grain growth (Anderson et al.,

1984). Both these conditions of normal grain growth

found in real microstructures have been sufficiently

displayed in simulated microstructures by many

researchers through MC simulation studies

118

Phaneesh K., Bhat A., Mukherjee G. and Kashyap K..

Evolving Close-to-Real Digital Microstructures in Polycrystalline Materials - A Monte Carlo Simulation Approach.

DOI: 10.5220/0005531401180124

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 118-124

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

(Srolovitz et al., 1984; Saito, 1997; Wang et al.,

2009 and Phaneesh et al., 2013). These studies also

show the statistical similarity between

microstructures generated in real materials and

microstructures generated through MC simulation.

But what has not been very well demonstrated is the

grain shapes in simulated microstructures imitating

the grains in the real microstructures. Through our

work, and perhaps for the time according to our

studies, we have been able to show a stark similarity

between certain grains of digital and the real

microstructures, and in the process, validate further

the relevance of MC simulation technique in grain

growth studies. What is exceptional here is the fact

that the digital microstructures that have been

selected for comparison have been drawn from

various combinations of parameters such as various

surface fractions of static second phase particles (f)

which inhibit grain growth, variation in matrix sizes

(N) which represent the sample material surfaces,

different Q states which represent grain orientations,

various simulation temperatures (kT) which act as

effects of higher temperatures during simulation,

various stages of grain growth as given by Monte

Carlo steps (MCS), and so on. Thus this is a

comprehensive comparison between digital

microstructures drawn from a large simulation

domain and some real microstructures generated

from a very commonly used non-ferrous alloy,

Duralumin.

2 THE MONTE-CARLO

METHOD OF SIMULATION

The Monte Carlo method is a probabilistic computer

simulation technique used to study grain growth and

related phenomena. While analytical models predict

ensemble characteristics of microstructural

evolution, computer simulations have helped to

generate snapshots of the evolving microstructure

with time. Using the computational version of

metallography, both local and ensemble properties

of the microstructure may be determined from these

snapshots. Among a few computer simulation

methodologies which have been evolved over the

years, the Monte Carlo method is one of the

prominent techniques employed to simulate

microstructural evolution in crystalline materials.

This method was developed by Ulam et al., (1947)

for basically studying the diffusion of neutrons in

fissionable materials. But adaptation of Monte Carlo

technique using Potts model for the simulation of

microstructure was first introduced by (Anderson et

al., 1984 and Srolovitz et al., 1984) for two-

dimensional grain growth and extended to three-

dimensional grain growth by Anderson et al.,

(1989).

The procedure for Monte Carlo Potts model

simulation of grain growth based on Metropolis

Algorithm is as follows:

1. Choose the lattice type i.e. square or triangular.

It is square in our case.

2. A square matrix of size ‘N’ is then generated,

which contains all its elements as random

numbers ranging from 1 to Q, where Q stands for

the number of grain orientations.

3. Among the N

2

elements present in the matrix, a

random site is chosen and is compared with all

its nearest neighboring elements, which is eight

in case of square lattice.

If i = element randomly picked, and j = any of the

eight neighboring elements that i is compared with,

then,

∂

ij

= 0 if i j

∂

ij

= 1 if i = j

where ∂

ij

= Kroneckar delta, a relative interaction

energy value between one element and any other

neighboring element. The Hamiltonian (E

1

) is then

calculated for the chosen element by the following

relation,

(E

1

) =

∑

si ∂sj 1

(1)

where J ( > 0) is an interfacial energy constant of the

system and n the total number of lattice sites in the

system.

4. The grain orientation corresponding to the

chosen element is changed into a new random

element in its place and the Hamiltonian (E

2

) is

calculated again for the new element using

equation (1), and then giving the energy change,

ΔE = E

2

- E

1

(2)

5. If ΔE ≤ = 0, the change is accepted else

if ΔE > 0, compute probability

p = exp (-ΔE/kT) (3)

where k = Boltzmann constant, and, T = temperature

If r < p where r is a random number generated and

uniformly distributed between 0 & 1, the change is

still accepted, else, rejected.

The entire steps from 3 to 5 form one iteration and

are repeated ‘N

2

’ times, which then constitute one

Monte Carlo Step (MCS), which is the measure of

time in simulation. Also, in the current paper,

EvolvingClose-to-RealDigitalMicrostructuresinPolycrystallineMaterials-AMonteCarloSimulationApproach

119

simulations have been carried out at both kT=0 and

at values 1>kT>0, under periodic boundary

conditions. It is to be noted here that the term kT in

simulation replaces both the Boltzmann constant and

the temperature as an assumed combined product.

The term kT generally takes a value between 0 and 1

and represents the thermal energy of simulation. It is

analogous to the thermal energy of experimental

systems but not directly related (Janssens et al.,

2007). Just as in the real world, when a phase

change is imminent when a metal is heated beyond a

critical temperature, there is a critical value for the

term KTs, beyond which the microstructure

evolution through simulation seizes and a disordered

state sets in.

3 EXPERIMENTAL HARDWARE

AND SOFTWARE

All the experiments were carried out on a specially

built system with 16 GB ram, INTEL CORE 15-

2500K-6M-3.3 GHZ Processor and a Asus P8H67-

MLE Motherboard B3 Model. The code was written

on a Java Core Eclipse platform and close attention

was paid to memory management since very large

arrays were run. The code invokes generation of

massive random numbers which was achieved

through the JAVA virtual machine (JVM).

Random number generation plays a crucial role

in the process of computer simulation of grain

growth. Since computers are basically calculating

machines, and use deterministic algorithms to

generate random numbers, they basically produce

pseudo random numbers, unless and until they are

accessing some external device such as a gamma ray

counter or a clock. The very foundation of Monte

Carlo method lies on generation of robust and long

range random numbers, especially since certain

simulation trials have to last millions of Monte

Carlo Steps, preferably without repeating the

sequence. The JAVA virtual machine (JVM) has a

reliable random number generator based on linear

congruential algorithm and can produce billions of

random numbers (2

48

, to be precise) on the trot,

before it repeats the sequence.

4 RESULTS AND DISCUSSIONS

In this work, Al-4% Cu samples, initially hot

extruded to about 50%, were annealed at a

recrystallization temperature of 480

0

C, and held for

various durations such as 1, 2, 3, 4 and 10 hours.

They were then polished with emery sheets (with

grit sizes 80 – 1200) and etched with Keller’s

reagent (2.5% HF, 1.5% HNO

3

, 1% HCl, rest

ethanol) for 10 seconds. They were then washed in

running water and dried with methanol and hair

dryer. The microstructures were observed under a

microscope and snapshots were taken, at

magnifications of 50x, 100x, 200x, etc. Al-4% Cu

was selected because upon annealing the alloy

precipitates fine second phase particles of CuAl

4

which pin grain boundaries and stagnate the average

grain size.

On the other hand, simulations were run on

various matrix sizes with different quantities of

second phase particles randomly interspersed to

represent polycrystalline materials. The matrices

were processed with millions of steps of the

Metropolis algorithm simulating grain growth which

takes place in metals during annealing. Simulated

grain structures were captured at different stages of

grain growth evolution of various matrix samples

and selected portions of these microstructures have

been used for pictorial comparisons with real

microstructures. Pictures from stagnation stage,

which refers to a stage where no more evolution is

possible due to grain growth inhibition by second

phase particles, have also been used in the

comparison.

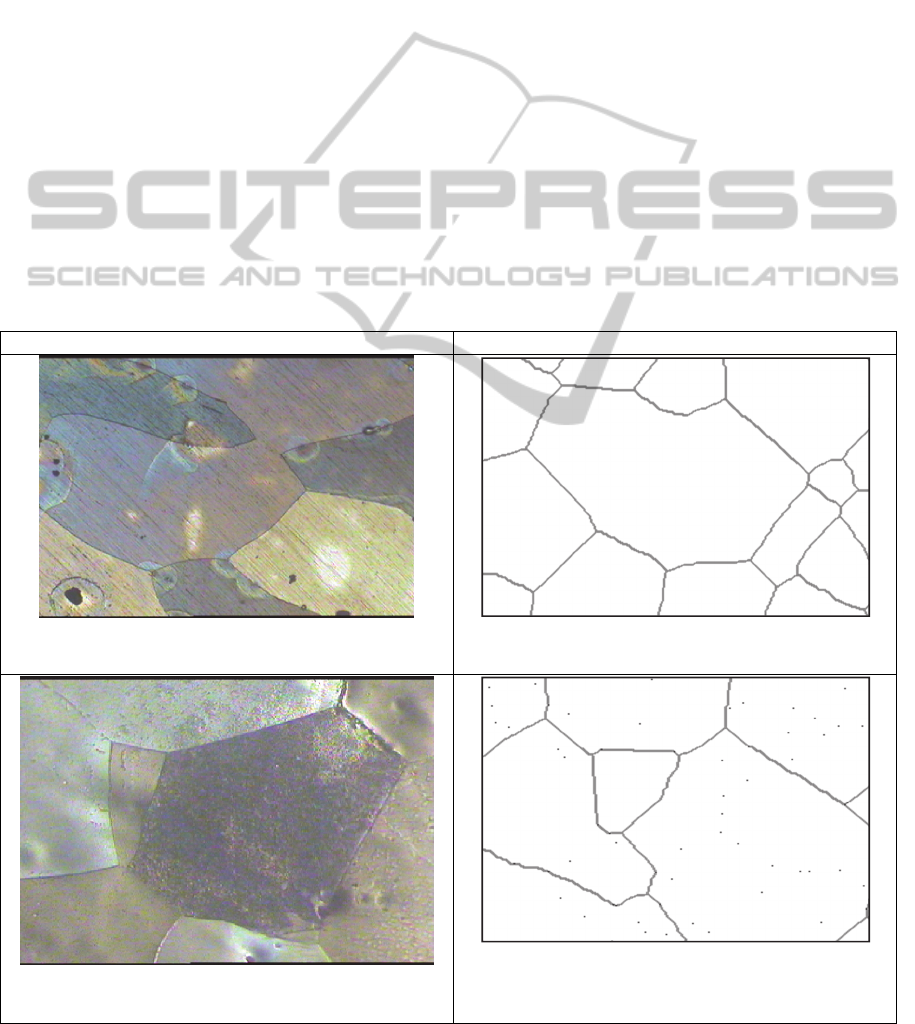

Table 1 shows pictorial comparisons between

various real microstructures on the left hand side,

and, the simulated microstructures on the right hand

side. The first set of pictures shown in Figure 1(a)

and 1(b) allows for a comparison between an Al-

4%Cu alloy annealed at 480

0

C for one hour, and

photographed at 100x magnification, with a portion

of the simulated microstructure evolved with a

square matrix of size (N) 1000 x 1000, a Q-state

value of 16, with zero percent of second phase

particles representing a pure metal and finally a

certain stage in grain growth as represented by the

number of Monte Carlo steps of 50,000.

Figures 2(a) and 2(b) show the comparison

between the same alloy annealed for two hours with

a digital microstructure having parameters N=1000,

Q=64, f=0.001, kT=0.5 and MCS=1,394,926 (at

stagnation). The selected crystal surface is based on

1000 x 1000 matrix with an assumed 64 (Q) grain

orientations. A value of f=0.001 means that a

surface fraction representing 0.1% of the surface of

the microstructure is occupied by second phase

particles each having a size of one unit being

randomly distributed throughout the matrix. These

static particles are shown as tiny dark spots in the

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

120

digital photos. Such second phase particles are also

present in the real microstructure of the Al-4% Cu

alloy but cannot be seen under normal metallurgical

microscope and at lower magnifications. These

second phase particles pin the grain boundaries and

stagnate them from growing any further. This is

observed both in reality as well as in Monte Carlo

simulation making it another valid reason for

adopting this technique. Figure 2(b) here represents

the stagnated stage of grain growth in simulated

environment. A value of kT=0.5 means that a higher

temperature effect (but which cannot be equated to

an exact real temperature) is introduced into grain

growth under simulation. It is very well known that

grains grow faster at higher temperatures and higher

values of kT show the same effect as well. Finally

grain growth has been stagnated due to inhibition of

grain boundaries by second phase particles at more

than a million steps of the algorithm, which is

equivalent to passage of time in simulation.

It should be, however, noted here that there are

no conclusions made to equate the simulation

samples to the real alloy samples but an effort is

made towards realistic representation of actual

microstructures through computer simulation. At

current levels of research, simulated microstructures

just represent generic metals and not particular

alloys. But future research may well be represent

real alloys through their simulated counterparts. This

opens the door for understanding grain structures of

real metals and their grain growth better.

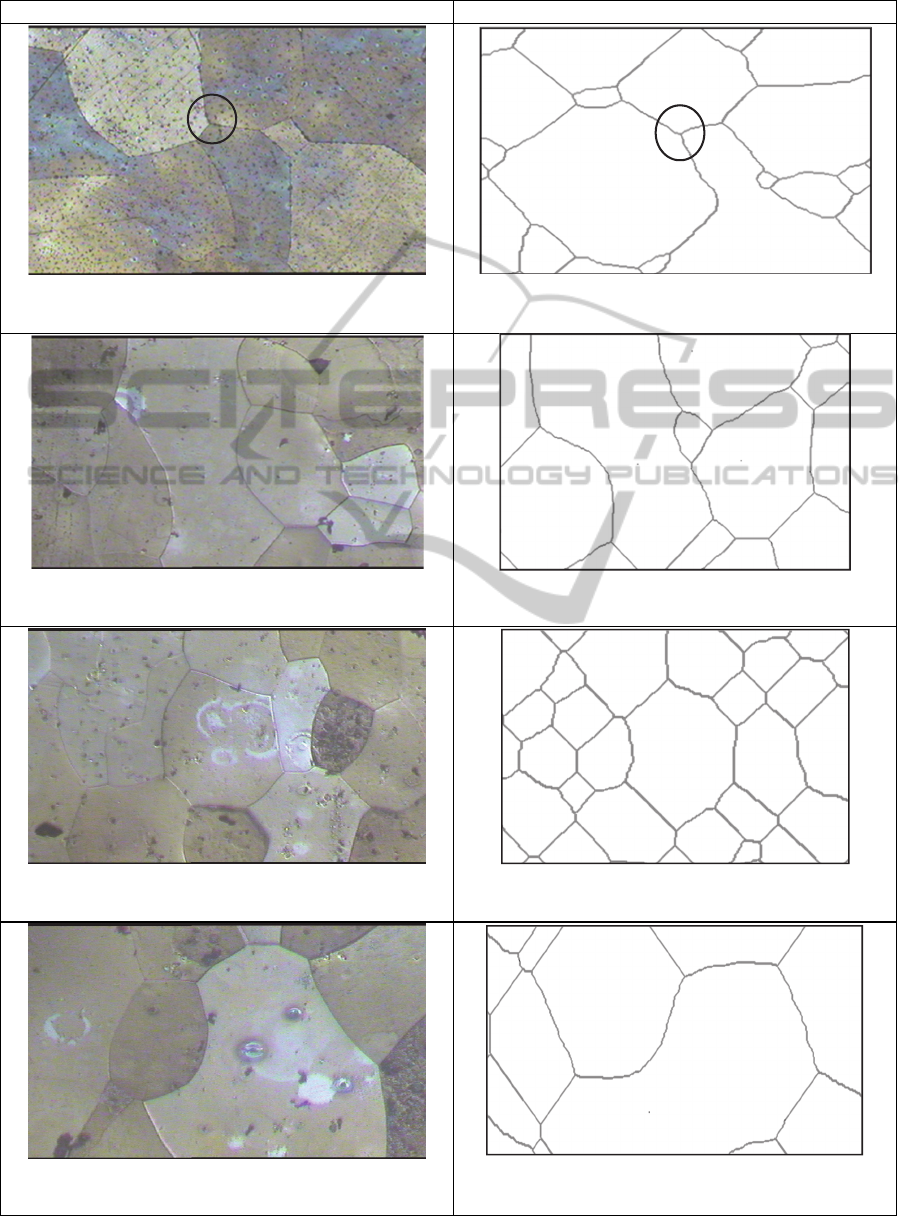

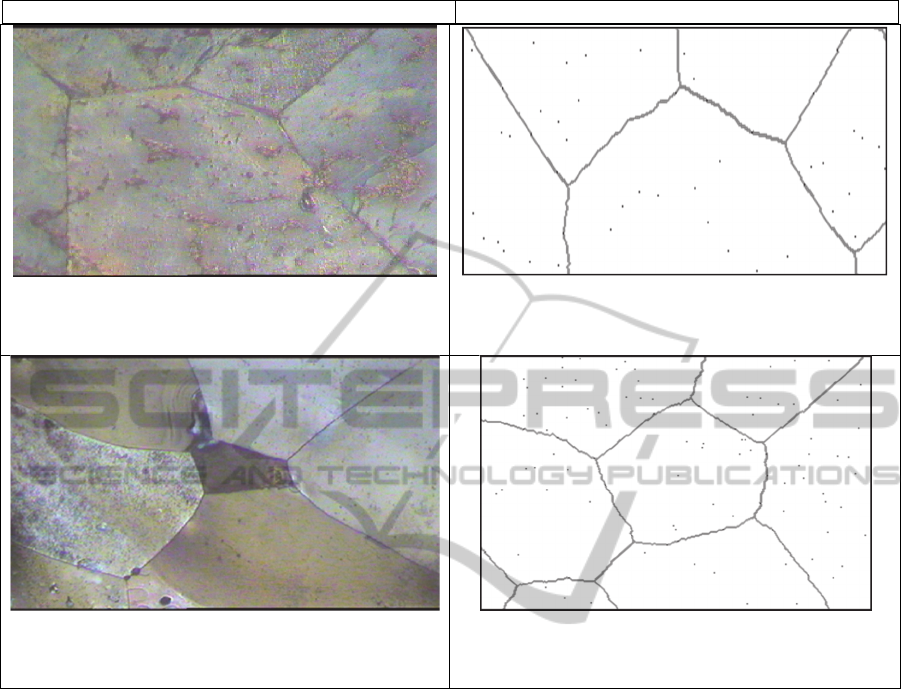

All the rest of the photos from Figure 3 to Figure

8 show comparison between real and simulated

grain regimes under different parameters but show

excellent shape similarities between certain grains

on either side. Figures 3(a) and 3(b) show a

comparison between two vertices on either side by

encircling them. According to theory (Smith, 1952)

three grains meeting at a vertex should be at an

angle of 120

0

to each other for a stable grain

structure. This could very well be seen in the

vertices encircled and also in all real and simulated

microstructures further validating the technique.

Table 1: Comparison between Real and simulated microstructures.

Real microstructures from annealed Al-4% Cu alloy Simulated microstructures

Figure 1(a): Annealed at 480

0

C for 1hr, at 100x.

Figure 1(b): N=1000, Q=16, f=0, MCS=50000.

Figure 2(a): Annealed at 480

0

C for 2hr, at 100x.

Figure 2(b): N=1000, Q=64, f=0.001, MCS=1394926 (at

stagnation).

EvolvingClose-to-RealDigitalMicrostructuresinPolycrystallineMaterials-AMonteCarloSimulationApproach

121

Table 1: Comparison between Real and simulated microstructures. (cont.)

Real microstructures from annealed Al-4% Cu alloy Simulated microstructures

Figure 3(a): Annealed at 480

0

C for 3hr, at 100x.

Figure 3(b): N=1000, Q=32, f=0, MCS=50000.

Figure 4(a): Annealed at 480

0

C for 3hr, at 100x.

Figure 4(b): N=1000, Q=32, f=0, MCS=50000.

Figure 5(a): Annealed at 480

0

C for 3hr, at 100x.

Figure 5(b): N=1000, Q=32, f=0, MCS=50000.

Figure 6(a): Annealed at 480

0

C for 3hr, at 200x.

Figure 6(b): N=1000, Q=64, f=0.001, MCS=60000.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

122

Table 1: Comparison between Real and simulated microstructures. (cont.)

Real microstructures from annealed Al-4% Cu alloy Simulated microstructures

Figure 7(a): Annealed at 480

0

C for 4hr, at 200x.

Figure 7(b): N=1000, Q=64, f=0.001, kT=0.4,

MCS=1589026(stagnation).

Figure 8(a): Annealed at 480

0

C for 10hr, at 50x.

Figure 8(b): N=1000, Q=64, f=0.001, kT=0.4,

MCS=1589026(stagnation).

5 CONCLUSIONS

This work has been able to show close similarity

between microstructures generated after annealing a

prominent non-ferrous alloy and the simulated

microstructures evolved by the Monte Carlo

simulation technique. The striking closeness

especially between certain set of grains between real

and simulated microstructures enhances the validity

of the MC technique to investigate grain growth and

its inhibition in polycrystalline materials. The 120

0

angle vertices found in stable grain structures in real

metals can also be seen prominently in digital

structures. But it should be iterated here that the

comparison only allows for the topological and grain

shape similarities between the two sets of

micrographs and no other comparisons are made

with respect to their evolution vis-a-vis time and

temperature. It is an ongoing work to relate real and

simulated microstructures on all parameters so that

MC simulation can be applied to particular alloys as

against generic as is being done now.

ACKNOWLEDGEMENTS

Acknowledgements are due to - Visvesvaraya

Technological University, Karnataka, India, which

funded this project (No. VTU/Aca/2009-10/A-

9/11417); Dr. S. Y. Kulkarni, Principal, Dr. Ramesh

Rao, Prof. & Head, Dept of Mechanical

Engineering, M. S. Ramaiah Institute of

Technology, Dr. R. Chandrashekar (rtd.), MSRIT,

Bangalore; Dr. K. N. B. Murthy, Principal, Dr. C. S.

Ramesh, P E S Institute of Technology, Bangalore.

REFERENCES

Anderson, M. P., Srolovitz, D. J., Grest, G. S. & Sahni, P.

EvolvingClose-to-RealDigitalMicrostructuresinPolycrystallineMaterials-AMonteCarloSimulationApproach

123

S. (1984) Computer simulation of grain growth - I.

Kinetics, Acta Metallurgica. 32. p.783-792.

Burke, J. E. & Turnbull, D. (1952) Recrystallization and

grain growth, Progress in Metal Physics. 3. p.220-292.

Hillert, M. (1965) On the theory of normal and abnormal

grain growth, Acta Metallurgica. 13 (3). p. 227-238.

Humphreys, F. J. & Hatherly, M. (2005) Recrystallization

and Related Annealing Phenomena. 2

nd

Ed. Elsevier,

Pergamon: U. K.

Janssens, K. G. F., Raabe, D., Kozeschnik, E.,

Miodownik, M. A. and Nestler, B. (2007)

Computational Materials Engineering - An

introduction to Microstructure Evolution. 1

st

Ed.

Elsevier.

Phaneesh, K. R., Bhat, A., Mukherjee, G. and Kashyap, K.

T. (2013) Bulletin of Material Science. 36 (4). p. 709 –

713.

Ryum, N. and Hunderi, O. (1989) On the analytic

description of normal grain growth, Acta Metallurgica.

37. p. 1375-1379.

Saito, Y. (1997) The Monte Carlo simulation of

microstructural evolution in metals, Material Science

& Engineering. A223. p. 114–124.

Smith, C. S. (1952) Grain shapes and other metallurgical

applications in topology, in: Metal Interfaces, ASM,

Cleveland, p. 65-108.

Srolovitz, D. J., Anderson, M. P., Sahni P. S and Grest, G.

S. (1984) Computer simulation of grain-growth: II.

Grain size distribution, topology, and local dynamics,

Acta Metallurgica. 32. p. 793-802.

Ulam, S., Richtmyer, R. D. and Von Neumann, J. (1947)

Statistical methods in neutron diffusion, Los Alamos

Scientific Laboratory Report. LAMS. p. 551.

Wang, H., Liu, G. and Qin, X. (2009) Grain size

distribution and topology in 3D simulation with large-

scale Monte Carlo method, International Journal of

Minerals, Metallurgy and Materials. 1. p. 37.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

124