Order-up-to Networked Policy for Periodic-Review Goods

Distribution Systems with Delay

Przemysław Ignaciuk

Institute of Information Technology, Lodz University of Technology, 215 Wólczańska St., 90-924, Łódź, Poland

Keywords: Inventory Control, Discrete-time Systems, Networked Control Systems, Time-delay Systems.

Abstract: In this paper, inventory control problem in goods distribution networks with non-negligible transshipment

delay is addressed. In contrast to the majority of earlier approaches, system modeling and policy design do

not assume simplified system structure, such as a serial, or a tree-like one. The network nodes, in addition to

satisfying market demand, answer internal requests with delay spanning multiple periods. The stock in the

network is refilled from uncapacited outside sources. A dynamic model of the considered class of goods

distribution systems is constructed and a new inventory policy is formulated. The proposed policy shares

similarity with the classical order-up-to one, yet provide improved performance owing to the networked

perspective assumed in the design process.

1 INTRODUCTION

The formal and computational difficulties have

directed the research effort in logistic system

optimization and control mainly to single stage

(Hoberg et al., 2007; Ignaciuk & Bartoszewicz,

2011), serial (Song, 2009, Movahed & Zhang,

2013), or tree-like configurations (Kim et al., 2005;

Ignaciuk, 2014). The new information and

communication technology advancements permit

now large-scale deployment of management

solutions in more complex – networked – settings.

However, as is the case of simplified structures

considered so far in the literature, the crucial aspect

behind the efficient operation and cost reduction in a

networked system is implementation of an

appropriate inventory control policy.

In this work, logistic networks with arbitrary,

mesh topology are considered in periodic-review

mode of operation. The stock replenishment orders

are realized with non-negligible lead-time delay that

may span multiple review periods. The external

demand is represented by uncertain, time-varying

functions, accepting any stochastic process typically

considered in inventory control problems. A

dynamic model of network node interactions is

constructed. Since the localized view of the goods

flow process reflected in the classical ordering

policies, e.g. order-up-to (OUT) one, may generate

significant cost increase in a real-world installation

(Cattani et al., 2011), an alternative – networked –

policy is proposed. The designed policy, while

sharing functional similarities with the classical one,

shows improved dynamical characteristics and

generates smaller costs.

2 PROBLEM SETTING

2.1 System Dynamics

The goods distribution system to be controlled

encompasses N nodes with the indices from the set

Ω

N

= {1, 2, ..., N}. The overall amount of goods in

the system is refilled from external sources. The set

of all node indices, including the controlled nodes

and external sources, Ω

M

= {1, 2, ..., M}, M ≥ N.

Let k = 0, 1, 2, ... be the independent variable

denoting subsequent review periods. The stock

balance equation at controlled node c, c ∈ Ω

N

:

goods delivered to node c

goods served by node

(1) () ()

() ()

MN

ccc

s

cc sc crr c

sr

c

xk xk dk

au k L au k T

∈Ω ∈Ω

+= −

+−−−

(1)

where:

x

c

(k) is the amount of goods (on-hand stock)

readily available at node c in period k;

498

Ignaciuk P..

Order-up-to Networked Policy for Periodic-Review Goods Distribution Systems with Delay.

DOI: 10.5220/0005561604980503

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 498-503

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

u

c

(k) is the amount of goods requested by node

c in period k to replenish its stock;

a

sc

is the part of the overall order u

c

(k) to be

acquired from node s ∈ Ω

M

by node c;

L

sc

= T

s

+ T

sc

is the lead-time delay in providing

the goods from node s to node c, L

sc

∈ {2, 3,

..., L}, L denotes the maximum lead-time

delay in goods transfer between any two

neighboring nodes;

T

s

is the order processing time at node s,

including all the activities related to preparing

the order for the requesting node, T

s

∈ {1, 2,

..., L – 1},

T

sc

is the time of transporting the goods from

node s to node c, T

sc

∈ {1, 2, ..., L – 1},

The (external) demand is modeled as an

uncertain, bounded function of time

0 ≤ d

c

(k) ≤

max

c

d

, where

max

c

d

≥ 0 denotes the upper

estimate of

d

c

(k). No assumption is taken regarding

the nature of stochastic process describing the

evolution of

d

c

.

Without loss of generality the network is

assumed connected (there is no isolated node) and

full order partitioning takes place, i.e.

1.

M

sc

c

s

a

∈Ω

=

∀

(2)

When treated as a graph, although arbitrary flow

orientation is permitted, the network is also assumed

directed, i.e. if a

sc

≠ 0, then a

cs

= 0 for c, s ∈ Ω

N

.

Moreover, for any c ∈ Ω

N

, a

cc

= 0, so that no

controlled node is a source of goods for itself.

According to (1), the goods to other nodes within

the controlled network are sent with at least one

period delay that covers the time to prepare all the

necessary documentation and shipment. Meanwhile,

the demand is served immediately in period k, which

implies that answering the external requests

(demand) takes precedence over the internal goods

traffic. Each node may serve the requests coming

from other nodes inside the managed network as

well as answer the external demand, which closely

reflects the actual real-life settings (Cattani et al.,

2011).

2.2 Classical Out Policy

In order to replenish the stock depleted according to

market demand (and internal requests) at a network

node, the OUT policy may be applied. When

demand forecasting is not used, the OUT policy

calculates the order quantities according to (Silver et

al, 1998):

1

() () (),

Msc

k

out

ccc scc

sjkL

uk x xk au j

−

∈Ω = −

=− −

(3)

where the sum represents the work-in-progress (the

order placed but not yet realized as a result of delay).

In the serial and tree-like topologies, it can be

shown that with sufficiently large

out

c

x

, for k > 0, the

orders generated by the OUT policy according to (3)

satisfy (Ignaciuk & Bartoszewicz, 2012)

() ( 1),

cc

uk dk=− (4)

i.e. the ordering signal issued in a current period

matches the demand from the previous one. In

consequence, the bullwhip effect is prevented.

Unfortunately, in the case of networked system with

full (mesh) connectivity this favorable property does

not hold. In order to mitigate the negative influence

of demand variability on the costs in the network,

one may apply alternative (local) strategies with

smoothing properties, e.g. (Ignaciuk, 2012), or, as is

proposed in this work, construct a new policy taking

into account the network dynamics.

3 NETWORKED MODEL

In order to formulate a networked inventory policy,

it is convenient to describe model (1) in an

appropriately chosen state space. The following

state-space representation is proposed:

1

(1) () ( )(),

L

j

j

kk kjk

=

+= + − −

xxBud

(5)

where:

x(t) = [x

1

(t) ... x

N

(t)]

T

is the vector of on-hand

stock levels inside the controlled network;

u(t) = [u

1

(t) ... u

N

(t)]

T

is the vector of stock

replenishment signals;

d(t) = [d

1

(t) ... d

N

(t)]

T

is the vector of demands

imposed at the controlled nodes with

d

max

= [

max

1

d

...

max

N

d

]

T

grouping the

information about the demand upper bounds;

matrices

1

1

1

112 13 1

:

21 2 23 2

:

31 32 3

:

1,

123

:

i

i

i

in

in

iL j

in

iL j

j

i

iL j

nn

nn n in

iL j

ab b b

bab b

bb a

b

bb b a

=

=

=

−

=

=

B

(6)

Order-up-toNetworkedPolicyforPeriodic-ReviewGoodsDistributionSystemswithDelay

499

for j = 1, ..., L hold the information about the node

interconnections; the elements on the main diagonal

reflect the goods acquisition with lead time j

(incoming shipments), whereas the off-diagonal

ones

, if ,

0, otherwise,

iw i

iw

aTj

b

−=

=

(7)

with w ∈ Ω

N

, correspond to the goods provision with

processing time j (the outgoing shipments inside the

network).

For further derivations, it is also convenient to

define

1

.

L

j

j =

=

BB

(8)

It follows from (2) that

B = I + E, where I denotes

an N × N identity matrix and

E is a hollow matrix

with entries a

ij

∈ [–1, 0] column-wise summing at

most to –1, is invertible.

4 NETWORKED OUT POLICY

4.1 Proposed Inventory Policy

Let x

d

= [

1

out

x

...

out

N

x

]

T

denote the vector of target

inventory levels. The proposed policy for the

considered goods distribution system establishes the

orders using the equation

1

1

() [ () ( )].

LL

j

iji

kkki

−

==

=−− −

d

uBxx Bu

(9)

4.2 Policy Properties

Assuming zero initial input, i.e. u(k) = 0 for k < 0,

from (5), the stock level in arbitrary period k > 0 can

be expressed as

11

10 0

11

10 0

() (0) ( ) ()

(0) ( ) ( ).

Lk k

i

ij j

Lki k

i

ij j

kjij

jj

−−

== =

−− −

== =

=+ −−

=+ −

xx Bu d

xBud

(10)

At the initial time,

u(0) = B

–1

[x

d

– x(0)].

Afterwards, for any k > 0, the ordering signal

satisfies the condition specified in the following

theorem.

Theorem 1. For k > 0, the stock replenishment

signal established according to (9) for system (5)

satisfies

u(k) = B

–1

d(k – 1). (11)

Proof. First note that (9) can be equivalently

written as

1

1

1

() [ () ()].

Lk

i

ijki

kk j

−

−

==−

=−−

d

uBxx Bu

(12)

Substituting (10) into (12), yields

11

1

10 0

() [ (0) () ()],

Lk k

i

ij j

kjj

−−

−

== =

=−− +

d

uBxx Bu d

(13)

and using (8),

11

1

00

() [ (0) () ()].

kk

jj

kjj

−−

−

==

=−− +

d

uBxxBu d

(14)

Then, applying (14),

u(k + 1) can be expressed as

1

00

11

1

00

1

111

(1) [ (0) () ()]

[(0) () ()]

[() ()]

() () () (),

kk

jj

kk

jj

kjj

jj

kk

kkkk

−

==

−−

−

==

−

−−−

+= − − +

=−− +

−−

=− + =

d

d

uBxxBud

Bx x B u d

BBu d

uBBuBd Bd

(15)

which ends the proof.

Let

1

() () ( ),

LL

j

iji

kk ki

==

=+ −

zx Bu

z ∈ ℝ

N

, (16)

which represents a network analogue of inventory

position (sum of on-hand stock and open orders).

Proposition 2. The dynamics of

z(t) can be

described by

(1) () ()().kkkk+= + −zzBud (17)

Proof. Taking into account the zero initial input,

directly from the definition of

z one obtains

z(0) = x(0). In turn, applying (5) to (17), yields

1

1

(1) (1) (1 )

(0) 0 (0) (0)

(0) (0) (0),

LL

j

iji

L

j

j

i

==

=

=+ −

=+−+

=+ −

zx Bu

xdBu

zBud

(18)

thus showing that (17) is satisfied in period k = 0.

Then, using (5), for arbitrary k > 0 the following

relation can be established

1

1

(1) (1) (1)

() ( ) () ()

() () (),

LL

j

iji

LL

j

iji

kk ki

kkikk

kkk

==

==

+= ++ +−

=+ −+ −

=+ −

zx Bu

xBuBud

zBud

(19)

which ends the proof.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

500

Theorem 3. System (5) under the control of

policy (9) is bounded-input-bounded-output stable.

Proof. Since finite

u and x yield finite z, and d

influences (5) and (17) in the same way, the stability

assessment of both systems subject to policy (9) is

equivalent. Substituting

u(k) = B

–1

d(k – 1) into (17)

yields

(1) ()(1)(),kkkk+= + −−zzdd (20)

which implies that

z(t) (and thus x(t)) is bounded for

any bounded demand. This conclusion ends the

proof.

4.3 Selection of Target Stock Level

A successful control policy in modern supply

networks is expected to achieve a high service level.

In this work, the service level is quantified by the

demand fill rate, i.e. the part of imposed demand

realized from readily available resources at the

nodes. The fill rate is influenced by the choice of

target stock level. Owing to the overall complexity

of the networked system interconnections, the

optimal target stock

x

d

needs to be determined

through numerical computations for given network

parameters – demands imposed at the nodes and

inter-node lead time. Below, an intuitive procedure

to calculate

x

d

for minimizing backlog and thus

obtaining high fill rate is shown. The procedure

assumes only the knowledge about the demand

upper estimate

d

max

(not its statistical parameters).

It follows from Theorem 1 that steady-state

replenishment signal

u

ss

in response to steady-state

demand

d

ss

satisfies

1

.

−

=

ss ss

uBd

(21)

Then, using (9) and (21), the steady-state stock level

is determined as

1

1

1

1

1

.

Lk

i

ijki

L

i

i

L

i

i

i

i

−

==−

=

−

=

=− −

=− −

=− −

ss d ss ss

dssss

dssss

xx BuBu

xBuBu

xBBdd

(22)

In the worst case,

d

ss

= d

max

. Thus, setting

1

1

()

L

i

i

i

−

=

>+

dmax

xBBId

(23)

will result in reduced backlog.

On the other hand, in the absence of external

demand x

ss

= x

d

. It follows from the numerical

analysis presented in the next section that the

proposed policy provides oscillation and overshoot

free stock level evolution. Therefore, setting the

warehouse capacity at the network nodes equal to x

d

gives enough space to store the goods locally. The

stock level x(k) ≤ x

d

and costly emergency storage

outside the controlled network is not required.

5 SIMULATION EXAMPLE

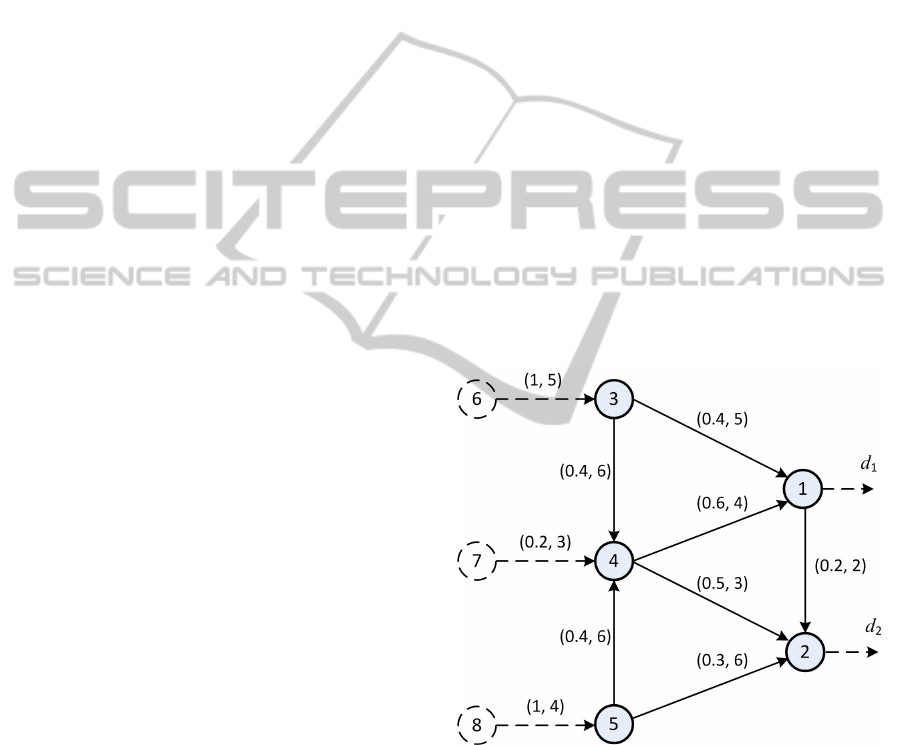

Let us consider the goods distribution network

illustrated in Fig. 1. Nodes 1–5 are managed by a

single organization – they constitute the controlled

elements – while nodes 6–8 are the exogenous

sources used to replenish the stock inside the

network. Nodes 1 and 2 constitute the contact points

with the external market, responding to demands d

1

and d

2

. Nodes 3 and 5 serve as intermediate

suppliers and node 4 represents a distribution centre.

The arrows in the graph indicate the flow of goods.

With each connection there is associated a pair of

values (a

ij

, L

ij

): a

ij

denotes the fraction of stock

replenishment signal issued by node j for node i and

L

ij

is the delay in procuring orders from node i to j.

The processing time at each node equals one period.

Figure 1: Goods distribution system.

The initial condition x(0) = [80 80 60 60 60]

T

units and the target stock level, selected according to

(23) with d

max

estimate [20 20 0 0 0]

T

units as

x

d

= [125 100 80 110 50]

T

units. It is also assumed

that there is no goods in transit before the control

process commences, i.e. u(k) = 0 for k < 0.

The performance of proposed networked policy

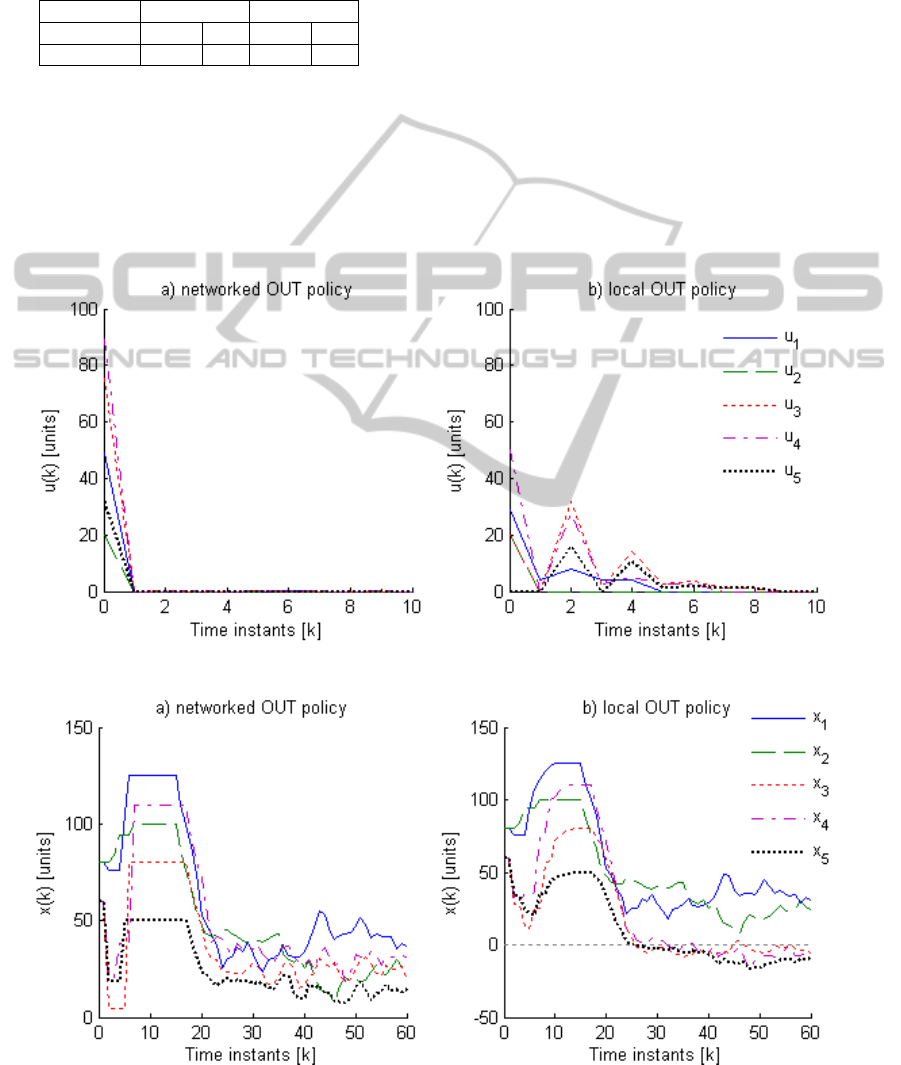

(9) is compared with benchmark local policy (3).

The test proceeds in two phases: for k < 15 – the

Order-up-toNetworkedPolicyforPeriodic-ReviewGoodsDistributionSystemswithDelay

501

goods accumulation phase (from x(0) to x

d

) in the

absence of demand; for k ≥ 15 – reaction to the

highly variable, uncertain demand following the

Poisson process with mean equal to 15 units.

Table 1: Bullwhip indicator.

Policy

Network Local

Node 1 2 1 2

BI 0.974 1 1.024 1

The graphs depicted in Figs. 2 and 3 indicate that

both policies make the stock level converge to the

target value and, afterwards, follow the trend set by

mean demand. Local OUT policy (graph b) requires

larger safety stock to prevent backlog (occurring for

negative stock level) which translates to higher

holding costs with respect to the networked policy

(graph a). The local OUT policy also generates a

larger ripple in response to highly variable demand.

According to the bullwhip indicator (BI) data –

order-to-demand variance ratio (Chen et al., 2000) –

grouped in Table 1, the networked policy

successfully counteracts demand variations from

affecting the ordering signal.

6 CONCLUSIONS

The paper presents a new inventory control policy

for networked goods distribution systems. The

policy ensures stable system performance in the

presence of arbitrary delay in goods provision. The

proposed policy outperforms the classical OUT one

by avoiding oscillations and backlog, thus showing

the benefits of adopting networked perspective in

Figure 2: Control input: a) networked policy, b) local policy.

Figure 3: Stock level at the nodes: a) networked policy, b) local policy.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

502

The paper presents a new inventory control policy

for networked goods distribution systems. The

policy ensures stable system performance in the

presence of arbitrary delay in goods provision. The

proposed policy outperforms the classical OUT one

by avoiding oscillations and backlog, thus showing

the benefits of adopting networked perspective in

control scheme design. However, the internal traffic

may still lead to the bullwhip effect. If order

smoothening is of priority, one should seek

alternative networked strategies. Also new, more

realistic measures of the bullwhip effect in the

networked environment should be developed.

ACKNOWLEDGEMENTS

This work has been performed in the framework of

project no. 0156/IP2/2015/73, 2015–2017, under

“Iuventus Plus” program of the Polish Ministry of

Science and Higher Education. The author holds the

Ministry Scholarship for Outstanding Young

Researchers.

REFERENCES

Cattani, K.D., Jacobs, F.R., Schoenfelder, J. 2011.

Common inventory modeling assumptions that fall

short: Arborescent networks, Poisson demand, and

single-echelon approximations. Journal of Operations

Management 29(5): 488-499.

Chen, C., Drezner, Z., Ryan, J.K., Simchi-Levi, D. 2000.

Quantifying the bullwhip effect in a simple supply

chain: the impact of forecasting, lead times, and

information. Management Science 46(3): 436–443.

Hoberg, K., Bradley, J.R., Thonemann, U.W. 2007.

Analyzing the effect of the inventory policy on order

and inventory variability with linear control theory.

European Journal of Operational Research 176(3):

1620-1642.

Ignaciuk, P. 2012. Dead-time compensation in continuous-

review perishable inventory systems with multiple

supply alternatives. Journal of Process Control 22(5):

915-924.

Ignaciuk, P. 2014. Nonlinear inventory control with

discrete sliding modes in systems with uncertain

delay. IEEE Transactions on Industrial Informatics

10(1): 559-568.

Ignaciuk, P., Bartoszewicz, A. 2011. Dead-beat and

reaching-law-based sliding-mode control of perishable

inventory systems. Bulletin of the Polish Academy of

Sciences: Technical Sciences 59(1): 39-49.

Ignaciuk, P. & Bartoszewicz, A. 2012. Sliding mode dead-

beat control of perishable inventory systems with

multiple suppliers. IEEE Transactions on Automation

Science and Engineering 9(12): 418-423.

Kim, C.O., Jun, J., Baek, J.K., Smith, R.L., Kim, Y.D.

2005. Adaptive inventory control models for supply

chain management. International Journal of Advanced

Manufacturing Technology 26(9-10): 1184-1192.

Movahed, K.K., Zhang, Z.-H. 2013. Robust design of

(s, S) inventory policy parameters in supply chains

with demand and lead time uncertainties. International

Journal of Systems Science, in press.

Silver, E.A., Pyke, D.F. & Peterson, R. 1998. Inventory

Management and Production Planning and

Scheduling. Hoboken: John Wiley & Sons, Inc.

Song, D.-P. 2009. Optimal integrated ordering and

production policy in a supply chain with stochastic

lead-time, processing-time, and demand. IEEE

Transactions on Automatic Control 54(9): 2027-2041.

Order-up-toNetworkedPolicyforPeriodic-ReviewGoodsDistributionSystemswithDelay

503