varBPM

A Product Line for Creating Business Process Model Variants

Andreas Daniel Sinnhofer, Peter P

¨

uhringer and Christian Kreiner

Institute for Technical Informatics, Graz University of Technology, Austria

{a.sinnhofer, christian.kreiner}@tugraz.at, p.puehringer@inode.at

Keywords:

Software Product Lines, Feature Oriented Modelling, Business Processes, Tool Integration.

Abstract:

Business processes have proven to be essential for organisations to be highly flexible and competitive in

today’s market. To manage the life-cycle from modelling such business processes over the execution and

the maintenance, Business Process Management Tools are used in the industry. In many cases, different

business processes do only vary in few points. This leads to the situation that new business process variants are

formed through copy or clone of previous solutions leading to a high number of instantiated process templates.

However, this means that changes to a template affects many processes, where all of them need to be manually

updated, which can lead to a considerable amount of work and money for a bigger company. In this paper,

we will present a framework for the integration of business process modelling tools and software product line

engineering tools to provide a systematic way to reuse and trace process variations of whole process families.

1 INTRODUCTION

Business Process (BP) oriented organisations are

known to perform better regarding highly flexible de-

mands of the market and fast production cycles (Mc-

Cormack and Johnson (2000); Hammer and Champy

(1993); Valena et al. (2013); Willaert et al. (2007)).

These goals are achieved through the introduction of

a management process, where business processes are

modelled, analysed and optimised in iterative ways.

Nowadays, the business process management is also

coupled with a workflow management, providing the

ability to integrate the responsible participants into

the process and to monitor the correct execution of

the business process in each process step. To adminis-

ter the rising requirements, so called business process

management tools are used (BPM-Tools) which cover

process modelling, optimization and execution. In

combination with an Enterprise-Resource-Planning

(ERP) system, the data of the real process can be in-

tegrated into the management process.

In many cases, business processes do only vary in

some points, which leads to the situation, that new

process variants are created through a copy and clone

of old solutions (often called as templates). As a

result, such templates are instantiated in many vari-

ous processes which makes the propagation of pro-

cess improvements time and cost intensive for a big-

ger company. Also the consistency of the documenta-

tion of this huge number of process variants is a chal-

lenging task.

Software Product Line Engineering (SPLE) tech-

niques have been successfully applied for almost any

domain, providing a technique for the systematic

reuse of domain artefacts. Although the topic of prod-

uct line techniques in the domain of business process

modelling is not new (e.g. Gimenes et al. (2008);

Rosa et al. (2008); Fantinato et al. (2012); Derguech

(2010)) only little work is found for the issues related

to the correct configuration of whole process families

(e.g. Hallerbach et al. (2009a,b)), the integration into

existing toolchains and the reuse throughout various

production plants. Thus, our approach is focused on

developing a framework for the integration of a SPLE

Tool and a BPM Tool, to provide a generic way to

generate process variants of whole process families.

In particular, we use the SPLE Tool for a system-

atically reuse of expert knowledge in form of valid

process variations, designed in an appropriated BPM

Tool. The integrity of the process variations is secured

by the capabilities of the BPM Tool and a rich con-

straint checking in the SPLE Tool. Furthermore, our

proposed approach enables the abilities to automati-

cally trace all process variants for an automatic prop-

agation of changes and process improvements and

the systematic integration into the capabilities of the

BPM Tools such as documentation generation, work-

flow engines, process optimisation tools, etc.

184

Daniel Sinnhofer A., PÃijhringer P. and Kreiner C.

varBPM - A Product Line for Creating Business Process Model Variants.

DOI: 10.5220/0005886901840191

In Proceedings of the Fifth International Symposium on Business Modeling and Software Design (BMSD 2015), pages 184-191

ISBN: 978-989-758-111-3

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

A B C

B_1

B_2

B_3

B_4

Sub-Process B

Sub-Process B

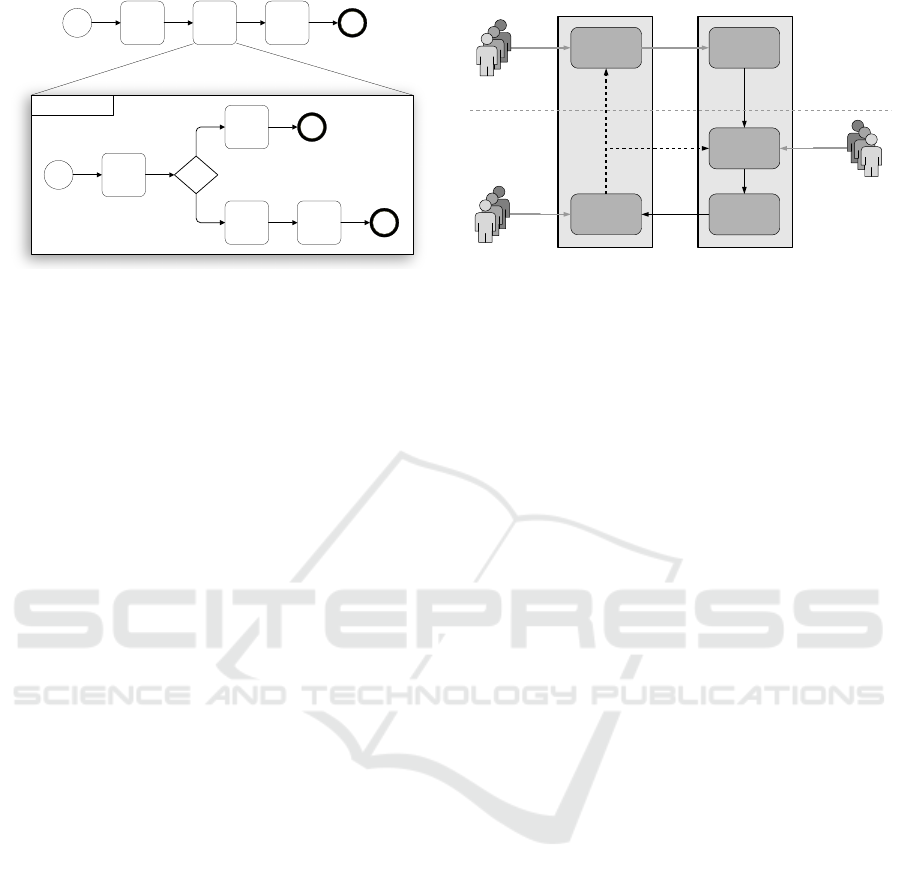

Figure 1: Principal structure of a business process accord-

ing to

¨

Osterle (1995) which is used for our approach. Start-

ing with an abstract description of the process, the tasks are

further described in sub-processes until a complete work

description is reached (microsopic level).

BPM Tool SPLE Tool

Business

Processes

Feature

Model

creates

modifies

derive

update

Feature

Selection

Transformation

Business

Process

Variant

derive

update

add

knowledge

add

input

influences

Process

Designer

Production

Experts

Production

Experts

Figure 2: Overall conceptual design. The upper side of the

Figure describes the domain engineering part and the lower

side of the Figure the application engineering part.

This work is structured in the following way: Sec-

tion 2 gives an overview over the concepts of tool in-

tegration and the design paradigm for business pro-

cesses which is needed for our framework. Section

3 presents the conceptual design of the framework

and states construction rules of the according feature

models and some design rules for the BPM Tool. In

section 4 we will introduce our case study regard-

ing some metrics and implementation details. Section

5 summarizes the related work and finally section 6

concludes this work and gives an overview of open

issues.

2 BACKGROUND

2.1 Tool Integration

According to the work of Karsai et al. (2005), two

possible patterns exists for tool integration. The first

approach is named ”Integration based on integrated

models” and is based on the idea of a common data

model which is shared between each participating

tool. This means that each tool needs two model

converters, one for the conversion of the native data

model into the common data model and one for the

opposite direction. The data is shared over a so called

integrated model server where each tool can publish

or consume data. For obvious reasons this approach

is meaningful applicable if each participating tool has

a similar data model. A drawback of this approach is

that it does not scale very good with the number of

connected tools.

The second pattern is named ”Integration based

on process flows” and is based on the idea of a point

to point message based communication. Each partic-

ipating tool registers itself at a backplane providing

information about what data is shared and what data

is intended to be consumed. As a result, this approach

scales better with the number of participants since po-

tentially fewer model transformations are needed at

which each model can be better optimized regarding

the communicating tools. This approach is used in

those situations, where the data is processed in a spe-

cific sequence.

For our framework both patterns would be possi-

ble. Due to the fact, that the number of participants is

small (in most circumstances there is only one SPLE

Tool and one BPM Tool) and since the representation

of business processes is very similar throughout vari-

ous tools, the first approach is more applicable.

2.2 Business Processes

A business process can be seen as a sequence of

tasks/sub-processes which needs to be executed in a

specific way to produce a specific output which is of

value to the costumer (Hammer and Champy (1993)).

According to

¨

Osterle (1995) the process design on the

macroscopic level (high degree of abstraction) is split

up into sub-processes until the microscopic level is

reached. This level is reached, when all tasks are de-

tailed enough, so that the process employees can use

it as work instructions.

In other words, a complete business process is

designed in layers, where the top layer is a highly

abstracted description of the overall process, while

the production steps are further refined on the lower

levels. As a result, the lowest level is highly de-

pendable on the concrete product and production en-

vironment, providing many details for the employ-

ees. In fact the top layers are – mostly – indepen-

varBPM: A Product Line for Creating Business Process Model Variants

185

dent from the concrete plant and the supply chain

and could be interchanged throughout the production

plants, whereas the lower levels (the refinements) of

the processes would need to be reconsidered. Figure

1 gives an overview of such a structure. Variability

of such a process structure can either be expressed

through a variable structure of a process/sub-process

(e.g. adding/removing nodes in a sequence) or by

replacing the process refinement with different pro-

cesses. The current version of our developed proto-

type focuses on the second method but the framework

is not limited to it.

2.3 Informal: Feature Model

A feature is defined by Kang et al. (1990) as a ”promi-

nent or distinctive user-visible aspect, quality, or

characteristic of a software system or system”. In

context of a Software Product Line, a feature model is

a model which defines all these features and explicitly

states their relationships, dependencies and additional

restrictions between each other. It enables the ability

to visually represent the variable parts of a system and

the options available for all products of a product line.

3 VARIABILITY FRAMEWORK

3.1 Conceptual Design

The overall conceptual design is based on a feature

oriented domain modelling approach and is displayed

in Figure 2. It is intended, that the domain experts

(process designer) design process templates in the ac-

cording BPM Tool, providing also all needed infor-

mation for e.g. a workflow engine. Based on these

templates and the abstract process model (the top

level description of the process) a feature model is

partially automatically created/updated with the guid-

ance of the domain experts. This is done by identifica-

tion of the variation points and the linkage of the ac-

cording variations on every process level. Each varia-

tion can contain additional variability by either defin-

ing new variation points where further refinement can

be linked to or by a variable process structure. Ad-

ditional constraints regarding the possible combina-

tion of features are intended to be modelled in the

SPLE Tool, but are not limited to it. In application

engineering the domain experts (not necessarily a pro-

cess designer, but someone who knows the current

needs of the production) adds his knowledge and se-

lects the needed features. The found description is

then automatically transformed in a real business pro-

cess which can be executed by the workers. During

Table 1: Needed process information within the SPLE Tool.

property

name

description

id A unique id to identify the pro-

cess/task

category id A unique id of the category of the

process

display

name

A human readable and understand-

able name of the process/task

children A list of ids which references the

processes/tasks of the process itself

(empty if the microscopic level is

reached)

additional

data

A list of additional data which is

needed for the concrete instantia-

tion of the process. E.g. data for

a workflow engine, the responsi-

ble workers, etc. This data can be

provided through the BPM Tool

(almost static) or can be design

variable in the SPLE Tool.

the process execution, loads of data is generated re-

garding the performance and efficiency of the process.

Thus, it is possible that some additional information

is added to the derived processes which leads to a

possible influence of the according business process

templates or a possible influence of the feature selec-

tion. This flowback mechanism is an important task

and needs to be considered for the maintenance and

the evolution throughout the lifecycle of a process.

For illustration a short example for the flowback

mechanism is given: Task B of the process displayed

in Figure 1 could be dependent on the logistic chain of

a supplier of a specific part or material. If during the

execution of the process the supplier is changed, it is

also likely that the overall control of the logistic chain

is changed due to the fact that the newly integrated

supplier can only deliver goods in a specific way. If

the process of the logistic chain was not already mod-

elled, then the process designer would need to create

a new process variant and would need to update the

existing feature models first. After this is done, our

proposed toolchain needs to update the feature selec-

tion of the respective process in the SPLE Tool. This

automatically updates the structure of the overall pro-

cess variant, leading to an almost on the fly update of

the complete process workflow especially when the

process variation was already modelled.

Summarizing this concept means that the SPLE

Tool is responsible for the following points: It needs

to assist the domain experts (process designer) during

Fifth International Symposium on Business Modeling and Software Design

186

settings root process variation point variation

addNode

deleteNode

1 1...*

1

0...*

1

0...1

1

0...1

1

0...*

0...*

1

1

0...*

1 1...*

1

1

0...*

0...*

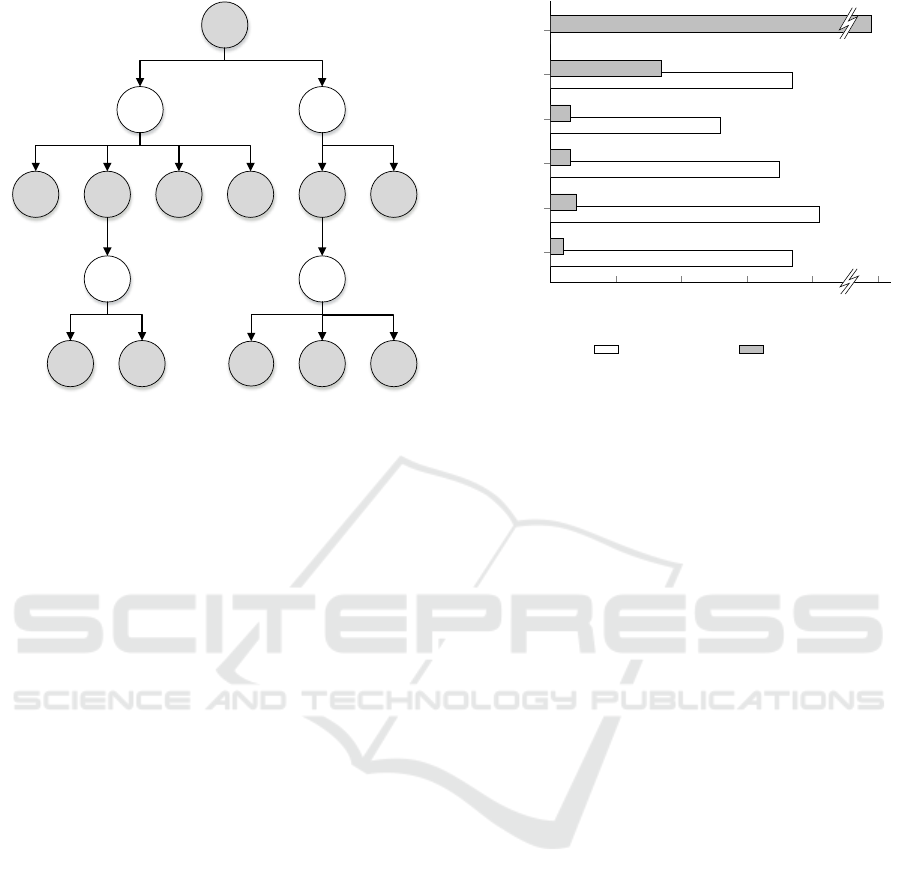

Figure 3: Feature model construction rules. The white parts

cover the variability on the process level itself and the dark

grey parts cover the variability between each layer of the

overall process structure.

the (partially) generation of the feature models and

during the selection and creation of the concrete prod-

uct variant. Furthermore, it has to keep track of all

generated process variants to automatically apply pro-

cess template improvements or changes to the overall

process structure and to flow back information added

during the execution in the BPM Tool. To do so, the

tool needs information about the properties of the pro-

cess displayed in Table 1. The BPM Tool is respon-

sible for the creation of semantically correct process

variants and to provide capabilities which are of value

for the developing company e.g. automatic documen-

tation generation, workflow engine, etc. For obvious

reasons, each Tool must have rich import/export capa-

bilities or the ability to integrate user defined plug-ins

to extend the functionality.

3.2 Type Model

To model the variability within the SPLE Tool in a

structured way, the feature model should support the

following type models:

• settings: Is a data model, containing information

for the tool adaptors to identify the right datasets

(e.g. identifier of the database of the BPM Tool

from which the process structure is imported; log-

in settings, etc.)

• root process: A process model of the top level

process and therefore an abstract description of

the overall process sequence. It consists of var-

ious nodes where some of them deal as variation

points.

• variation point: A node in a process where at

least one variation can be linked to.

• variation: A process model for a task or a sub-

process which can be linked to a number of vari-

ation points. If it is a process, it can also con-

tain variation points or a variable process structure

(addition/deletion of nodes).

• addNode: Adds a node (task or process model) at

a specific location of the process structure. This

added node can also be a variation point for fur-

ther refinements. The addition of the node can be

dependent on the feature selection.

• deleteNode: Deletes a node (task or process

model) at a specific location of the process struc-

ture. The deletion of the node can be dependent

on the feature selection and hence it is also possi-

ble to link further refinements to this node.

The construction rules for this type model can be

seen in Figure 3. The settings node is only instantiated

once in such a model. The root process is somehow

very similar to a variation, but with the difference that

it must contain variation points (to prohibit a ”Blob”

anti pattern [Brown et al. (1998)]).

3.3 Design Rules for Business Processes

Aforementioned, the processes should be designed

as stated by

¨

Osterle (1995). Secondly we have no-

ticed, that almost every bigger BPM Tool supports

the assignment of specific group identifiers to groups

of processes, providing a more structural design of

the processes. Thereby it is possible to automatically

map specific groups of processes to a specific varia-

tion point. This leads to the situation that new varia-

tions can be automatically detected and can be advo-

cated for an integration into existing feature models.

Furthermore, the structuring in groups of processes

enables the ability to introduce a constraint check so

that variation points are limited to specific groups of

processes. This increases the assurance in the creation

of semantically valid processes.

4 INDUSTRIAL CASE STUDY:

VARBPM

In this section an overview over our industrial case

study is given, which describes the domain of our in-

dustry partner and the developed toolchain.

4.1 Industrial Project Partner

Our project partner Magna Cosma

1

is an interna-

tional company in the metal stamping and assembly

industry – specialised on class-A car body panels and

closure parts (e.g. doors) – with several plants all

over the globe. The implemented business processes

1

http://www.magna.com/de/kompetenzen/karosserie-

fahrwerksysteme

varBPM: A Product Line for Creating Business Process Model Variants

187

are mostly controlled by an SAP infrastructure and

are designed with the BPM-Tool Aeneis

2

. Although

some plants are specialised on the same production

parts, almost every plant develops and maintains their

own business processes, which makes it difficult to

compare processes, mark bottlenecks, optimise the

processes and publish the changes to other plants.

4.2 Tool Integration

As mentioned before, the tool integration of the SPLE

Tool (pure::variants

3

) and the BPM Tool (Aeneis) is

based on the Pattern ”Integration based on Integrated

Models”. The integrated data model contains the rel-

evant data enumerated in Table 1 where all fields are

of type String respectively an array of Strings for the

children and data field. This means that the native

data model of the SPLE Tool is the integrated data

model and hence only the BPM tool adaptors need

to implement a data conversion. To support an up-

date mechanism without sending the complete pro-

cess, each published dataset can be assigned to a spe-

cific type indicating what should happen with this

dataset. Possible types are:

• New: Indicating that this dataset was not pub-

lished before and hence it should be integrated di-

rectly just as is.

• Update: Contains the id of the according dataset

and the data which shall be updated. Non speci-

fied attributes are not affected.

• Remove: Contains the id of the according dataset

which should be deleted out of the system. Linked

variations of such a process are not affected.

The developed tool adapters are also applicable to

get notified when data is added/updated so that such

changes are processed almost immediately. If this

mechanism is not supported by the participating tool

connector, an operator needs to trigger this update

mechanism manually. In the current development, the

SPLE Tool needs to check manually for updated data

since this task is intended to be supported by an do-

main expert, whereas the BPM Tool uses the benefits

of the immediate notification system. The communi-

cation of the tools is done by an XML based file ex-

change and due to some consistency issues the com-

munication is only possible if both tools are running.

I.e. deriving process variants is only possible if the

BPM Tool is running too.

2

http://www.intellior.ag

3

http://www.pure-systems.com

4.3 pure::variants

pure::variants is a feature oriented domain modelling

tool and is based on Eclipse. As such, it can easily be

extended based on java plug-in development. During

the implementation of this project, five different plug-

ins where developed:

• An import plug-in, which is capable of importing

the process structure - including the definition of

variation points and the according variations - and

converting it into a feature model compliant to the

construction rules displayed in Figure 3 without

the white parts.

• An extension to the internal model compare en-

gine so that different versions of created feature

models can be compared with each other.

• An update mechanism to automatically search

for deleted / added variations or updated process

structures, providing graphical assistance for the

domain expert.

• An extension to the internal model transformation

engine so that the feature selection is automati-

cally converted into a business process in the com-

mon data model; This process is then delivered to

the attached BPM Tools, so that a native version of

the process can be created/updated and executed.

• Additions to the internal model check engine

to model and create only valid processes (e.g.

checks related to the feature selection, the consis-

tency of the feature model, etc.).

To keep track of all generated business process

variants, a list including all ids of the processes is

stored and maintained in a file located in the same

directory as the variant description model (feature se-

lection), but hidden from the user perspective. This

list is automatically updated when a process variant is

deleted in the BPM Tool or created with the SPLE

Tool. pure::variants also provides a framework for

the comparison of different models, which enables the

ability to compare different process variants in an ef-

ficient way.

4.4 Studied Use Cases and Results

In the list below, use cases can be found which we

investigated during the development of our approach

regarding the performance of our toolchain (time sav-

ing). The according results are displayed in Figure

5, where the white bars are related to the manual

case and the grey bars to our approach. Although the

varBPM approach automatically integrated each de-

rived process into the capabilities of the BPM Tool

Fifth International Symposium on Business Modeling and Software Design

188

Root

VP 1 VP 2

Var

01

Var

02

Var

03

Var

04

Var

05

Var

06

VP 3 VP 4

Var

07

Var

08

Var

09

Var

10

Var

11

Figure 4: The variability structure of the process for the

evaluation examples.

(documentation generation, workflow engine), the

manual approach only reflects the time used for the

creation of the bare process structure. The used pro-

cess structure is part of a bigger process used for an

on-demand manufacturing of spare parts for different

car manufacturer.

Use case 1: For this use case, the time was mea-

sured that a domain expert needs to create a new

process variant manually or using an existing feature

model. The process setup consisted of four variation

points (two top-level variation points and two varia-

tion points on lower levels) where a total number of

twenty-seven different process variants were possible

(for illustration, the variability structure can be seen

in Figure 4). The number of other processes in the

database of the BPM tool was considered to be low

(20 other processes). The experiment was repeated

with different experts and different process setups (the

overall variability structure was kept the same but the

process structures changed). The results of this use

case are divided with the number of variation points

to get a rough estimate for the time saving per varia-

tion point.

Use case 2: This use case is an addition to the

first one, with the difference of a high number of other

processes in the database (200 processes).

Use case 3: Is related to the topic of maintenance.

In this scenario a process template was changed and

all process variants should be updated. The domain

expert was told that there is a number of six variants

he needs to update providing only the name and the

id of the changed process template. The size of the

database was limited to 50 processes. The change to

0 10 20 30 40 260

Use case 1

Use case 2

Use case 3

Use case 4

Use case 5

Use case 6

Time in seconds

Manual Manipulation

Using varBPM

Figure 5: The results of the evaluation use cases. The grey

parts are the time spent using the varBPM approach and the

white parts states the time taken if a manual manipulation is

used.

the template was a deletion/addition of a node. The

results displayed in Figure 5 are normed to the update

of one process.

Use case 4: This use case is an addition to the

previous case, but with the difference that the domain

expert was now told how the process variants where

called (assuming that the domain expert was responsi-

ble for the creation of the process variants and exactly

knows the variants).

Use case 5: In this situation, a new process varia-

tion was created by a process designer and the domain

expert should now derive a new product variant out of

it (in fact, a new variation for the Variation Point ”VP

3” was developed). It is assumed that the processes

are designed according to our proposed design rules.

The number of other processes in the database was

considered as low (20 processes). This use case also

gives a good estimate on how much overhead is pro-

duced, to update an existing feature model.

Use case 6: In this case, a new feature model was

developed according to the variability structure dis-

played in Figure 4 to generate a metric on how much

overhead is produces for the initial creation of the fea-

ture model. To get a rough estimate on the overhead

per variation point, this number is divided by four.

The results of ”Use case 2” were surprising, since

our developed approach performs worse in relation

to the previous scenario. The reason for this is that

the project now consists of ten times more processes,

leading to a more time demanding search for the right

processes. For humans, it was still quite easy to find

the right processes since they were organised in a

clear ”human understandable” manner. As a result the

varBPM: A Product Line for Creating Business Process Model Variants

189

increasing number of processes do not have a high in-

fluence to a manual manipulation if the processes are

structured in a clear and meaningful way. Otherwise

the time would increase more significantly.

To get a rough estimate of the break-even point,

the following equation is used:

p ≈

Overall Overhead

Average time saving

=

259

4 · 29

≈ 2.2 (1)

The overall overhead is the time spent to create

the feature model (”Use case 6”) and the average time

saving is calculated using the average time saving

per variation point multiplied by the number of varia-

tion points. Interestingly, when software product line

techniques are applied to pure software systems, the

break-even point is also located at around three sys-

tems (according to Pohl et al. (2005)).

4.5 Restrictions

Depending on the API of the used BPM Tool, your

approach can be limited in terms of the available fea-

tures. This means that if the BPM Tool only provides

access to the basic process structure, our framework

is limited to the creation of derived processes with-

out the ability to automatically integrate the models

into the capabilities of the BPM Tool (e.g. workflow

engine).

5 RELATED WORK

As stated in the survey of Fantinato et al. (2012), ma-

jor challenges in the field of business process variabil-

ity modelling are related to the reaction time of pro-

cess changes and of the creation and selection of the

right business process variants, which are also main

topics in our approach.

Derguech (2010) presents a framework for the

systematic reuse of process models. In contrast to

our approach, it captures the variability of the pro-

cess model at the business goal level and describes

how to integrate new goals/sub-goals into the existing

data structure. The variability of the process is not

addressed in his work.

Gimenes et al. (2008) presents a feature based

approach to support e-contract negotiation based on

web-services (WS). A meta-model for WS-contract

representation is given and a way is shown how to in-

tegrate the variability of these contracts into the busi-

ness processes to enable a process automation. It does

not address the variability of the process itself but en-

ables the ability to reuse business processes for differ-

ent e-contract negotiations.

While our approach reduces the overall process

complexity by splitting up the process into layers with

increasing details, the PROVOP project (Hallerbach

et al. (2009a,b) and Reichert et al. (2014)) focuses

on the concept, that variants are derived from a basic

process definition through well-defined change oper-

ations (ranging from the deletion, addition, moving

of model elements or the adaptation of an element at-

tribute). In fact, the basic process expresses all possi-

ble variants at once, leading to a big process model.

The work of Gottschalk et al. (2007) presents an

approach for the automated configuration of workflow

models within a workflow modelling language. The

term workflow model is used for the specification of

a business process which enables the execution of it

in an enterprise and workflow management system.

The approach focuses on the activation or deactiva-

tion of actions and thus is comparable to the PROVOP

project for the workflow model domain.

Rosa et al. (2008) extends the configurable pro-

cess modelling notation developed from Gottschalk

et al. (2007) with notions of roles and objects provid-

ing a way to address not only the variability of the

control-flow of a workflow model but also of the re-

lated resources and responsibilities.

The work of Leitner and Kreiner (2010) addresses

the process variability through a bottom up approach

by examining the possible configurations through the

scan of the according ERP System (SAP). In contrast

to this approach, we focus on an top down method to

abstract the complexity of the underlying ERP Sys-

tem.

The Common Variability Language (CVL Haugen

et al. (2013)) is a language for specifying and resolv-

ing variability independent from the domain of the ap-

plication. It facilitates the specification and resolution

of variability over any instance of any language de-

fined using a MOF-based meta-model. A CVL based

variability modelling and a BPM model with an ap-

propriate model transformation could lead to similar

results as presented in our work.

6 CONCLUSION AND OUTLOOK

The reuse of business process models is an important

step for an industrial company to survive in a com-

petitive market. With our work we have proposed a

way to combine the benefits of software product line

engineering techniques with the capabilities of a busi-

ness process modelling tool to provide a framework

for the systematic reuse of business processes. With

the proposed design rules, our approach results in an

automatic detection and propagation of new and/or

Fifth International Symposium on Business Modeling and Software Design

190

changed business process variations. On the other

hand it leads to an automatic integration of new as-

sembled process variants into the BPM capabilities

such as an automatic integration into a workflow en-

gine, integration of responsibilities and resources, etc.

Our developed framework covers the variability of

the process in two different ways: Through the link-

age of different process variations to variation points

and through a variable process structure (deletion / ad-

dition of nodes) in each layer. Due to the fact that

our developed framework is in an early stage of us-

age, further research efforts would address the col-

lection and evaluation of data regarding the evolution

and maintenance of the process models. In this con-

text, an integration of Six Sigma

4

into our framework

is aimed to provide a complete framework from mod-

elling and improving process models. Additionally

the customization of the ERP system of the underly-

ing system (in this case SAP) is an interesting topic,

providing a complete framework for the topics of pro-

cess modelling, execution and maintenance including

the planing of the resources of the concrete produc-

tion facility.

ACKNOWLEDGEMENT

We want to gratefully thank Magna Cosma for spon-

soring this project, Danilo Beuche from pure::systems

and Intellior AG for their support.

REFERENCES

Brown, W. J., Malveau, R. C., McCormick, H. W. S., and

Mowbray, T. J. (1998). AntiPatterns: Refactoring

Software, Architectures, and Projects in Crisis: Refac-

toring Software, Architecture and Projects in Crisis.

John Wiley & Sons.

Derguech, W. (2010). Towards a Framework for Business

Process Models Reuse. In The CAiSE Doctoral Con-

sortium.

Fantinato, M., Toledo, M. B. F. d., Thom, L. H., Gimenes, I.

M. d. S., Rocha, R. d. S., and Garcia, D. Z. G. (2012).

A survey on reuse in the business process management

domain. International Journal of Business Process In-

tegration and Management.

Gimenes, I., Fantinato, M., and Toledo, M. (2008). A Prod-

uct Line for Business Process Management. Software

Product Line Conference, International, pages 265–

274.

4

Six Sigma is a set of techniques and tools for a system-

atic management of process improvements based on quality

management methods, including some statistical methods.

Gottschalk, F., van der Aalst, W. M. P., Jansen-Vullers,

M. H., and Rosa, M. L. (2007). Configurable Work-

flow Models. International Journal of Cooperative

Information Systems.

Hallerbach, A., Bauer, T., and Reichert, M. (2009a). Guar-

anteeing Soundness of Configurable Process Variants

in Provop. In Commerce and Enterprise Computing,

2009. CEC ’09. IEEE Conference on, pages 98–105.

IEEE.

Hallerbach, A., Bauer, T., and Reichert, M. (2009b). Issues

in modeling process variants with Provop. In Ardagna,

D., Mecella, M., and Yang, J., editors, Business Pro-

cess Management Workshops, volume 17 of Lecture

Notes in Business Information Processing, pages 56–

67. Springer Berlin Heidelberg.

Hammer, M. and Champy, J. (1993). Reengineering the

Corporation - A Manifesto For Business Revolution.

Harper Business.

Haugen, O., Wasowski, A., and Czarnecki, K. (2013). Cvl:

Common variability language. In Proceedings of the

17th International Software Product Line Conference,

SPLC ’13.

Kang, K., Cohen, S., Hess, J., Novak, W., and Peterson,

A. (1990). Feature-oriented domain analysis (foda)

feasibility study.

Karsai, G., Lang, A., and Neema, S. (2005). Design pat-

terns for open tool integration. Software & Systems

Modeling, pages 157–170.

Leitner, A. and Kreiner, C. (2010). Managing erp configura-

tion variants: An experience report. In Proceedings of

the 2010 Workshop on Knowledge-Oriented Product

Line Engineering, KOPLE ’10, pages 2:1–2:6.

McCormack, K. P. and Johnson, W. C. (2000). Business

Process Orientation: Gaining the E-Business Com-

petitive Advantage. Saint Lucie Press.

¨

Osterle, H. (1995). Business Engineering - Prozess- und

Systementwicklung. Springer-Verlag.

Pohl, K., B

¨

ockle, G., and Linden, F. J. v. d. (2005). Soft-

ware Product Line Engineering: Foundations, Princi-

ples and Techniques. Springer.

Reichert, M., Hallerbach, A., and Bauer, T. (2014). Lifecy-

cle Support for Business Process Variants. In Jan vom

Brocke and Michael Rosemann, editor, Handbook on

Business Process Management 1. Springer.

Rosa, M. L., Dumas, M., ter Hofstede, A. H. M., Mendling,

J., and Gottschalk, F. (2008). Beyond control-flow:

Extending business process configuration to roles and

objects. In Li, Q., Spaccapietra, S., and Yu, E., editors,

27th International Conference on Conceptual Mod-

eling (ER 2008), pages 199–215, Barcelona, Spain.

Springer.

Valena, G., Alves, C., Alves, V., and Niu, N. (2013). A

Systematic Mapping Study on Business Process Vari-

ability. International Journal of Computer Science &

Information Technology (IJCSIT).

Willaert, P., Van Den Bergh, J., Willems, J., and De-

schoolmeester, D. (2007). The Process-Oriented Or-

ganisation: A Holistic View - Developing a Frame-

work for Business Process Orientation Maturity.

Springer.

varBPM: A Product Line for Creating Business Process Model Variants

191