InterCriteria Decision Making Approach for Iron Powder

Briquetting

Lyubka Doukovska

1

, Dimitar Karastoyanov

1

, Nikolay Stoymenov

1

and Ivan Kalaykov

2

1

Institute of Information and Communication Technologies, Bulgarian Academy of Sciences

Acad. G. Bonchev str., bl. 2, 1113 Sofia, Bulgaria

doukovska@iit.bas.bg, dkarast@iinf.bas.bg, nikistoimenow@gmail.com

2

Örebro University, School of Science and Technology

SE-701 82 Örebro, Sweden

ivan.kalaykov@oru.se

Keywords: InterCriteria decision making, Index matrix, Impact briquetting.

Abstract: In this paper, we present approach, called ‘InterCriteria Decision Making’ that utilizes the apparatus of

index matrices and intuitionistic fuzzy sets which from an existing multiobject multicriteria evaluation table

generates a new table that contains estimations of the pairwise relations among the set of evaluating criteria.

In the presented paper for the analysis purposes we have used experimental results of impact briquetting of

iron powder. In this study we illustrate the application of the one original methodology to the data achieved

for the following parameters - distance, speed and acceleration of the impacting bodies. The research and

the obtained results will show relations between the briquetting process parameters which will lead to

increase in its efficiency.

1 INTRODUCTION

Producing briquettes using metal chips and powder

is an actual scientific problem which is reflected in a

lot off publications. This technology recently is

being applied more widely as per (Penchev, 2014;

Radeva et al., 2014; Gustavson at al., 2014;

Doremus at al., 2010; Scoglund, 2001). The positive

results related to the density increasing with the

impact power increases are a reason for investigating

the effect using iron powder. In paper (Gustavson at

al., 2014) it is shown that when compacting iron

powder with impact speed 15 [m/s] a cylindrical

sample of size height Н = 20 [mm], diameter D = 25

[mm] and density ρ = 7.4 [gr/cm

3

] has been

produced. At the same time the monolith material

has a density ρ = 7.5 [gr/cm

3

]. This is mainly

influenced by the high impact energy determined by

the higher speed.

In this study we illustrate the application of the

one original methodology to the data achieved for

the following parameters - distance, speed and

acceleration of the impacting bodies. These are

analyzed by means of high speed camera and the

applicable software. The impact energy (Е

у

) and

power (F

у

) are calculated. To get more experimental

data an Xray tomograph Nikon XTH 225 Compact

Industrial CT Scanner has been used. They are part

of the equipment of the Smart Lab at IICT.

In process of the metal chips briquetting,

mechanical and hydraulic presses with nominal

force of several hundred to several thousand kN are

used. The goal is to obtain briquettes with good

density - the ratio H/D for different materials vary

within wide limits (H/D = 0.8 – 0.25), where H is

the height, and D is the diameter of the briquette.

The greater is the density of the briquettes, the

smaller are the losses in the transport and melting.

Basic data used to evaluate the effect of briquetting

operation is the specific density of the briquette (ρ,

[g/cm

3

]), and specific contact pressure for

briquetting (P, [MPa]).

In the presented paper we have analyzed

experimental results of iron powder briquetting. The

experiments are conducted using a complicated

(combined) impacting device, shown on Figure 1.

292

Doukovska L., Karastoyanov D., Stoymenov N. and Kalaykov I.

InterCriteria Decision Making Approach for Iron Powder Briquetting.

DOI: 10.5220/0005888402920296

In Proceedings of the Fifth International Symposium on Business Modeling and Software Design (BMSD 2015), pages 292-296

ISBN: 978-989-758-111-3

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Main element of this device is a cold rocket

engine 12, working on pressurized air with pressure

up to 33 [MPa]. The usage of such an engine allows

for a combined impact with power F

y

and additional

power R.

Figure 1: Laboratory stend for a complicated impact

investigation:

1 – main plate weight of 220 [kg]; 2 – plastic element for

elastic impact investigation; 3 – plastic impact sensor; 4 –

inductive speed sensors; 5 – lower position inductive air

on/off sensor; 6 – falling part rails; 7 – trigger; 8 –

solenoid valve; 9 – air pressure controller; 10 – upper

position inductive air on/off sensor; 11, 15 – light sensor

and source for the falling part speed measurement; 12 –

cold rocket engine; 13 – falling part with weight of 6.17

[kg]; 14 – plate for sensors 4, 5, 11; 16 – control panel.

To conduct the iron powder briquetting

experiments we use the same stand and equipment

as we did for the iron chips. The size of the particles

of the iron powder we used (brand AS29-100) is

determined using Fritch Analysette 22 Nano Tec+.

After high speed filming of the impact the

material is processed using Vicasso 2009 product

and as a result we have diagrams of the distance,

speed and acceleration. Based on that we determine

the impact speed V

y

and acceleration A

y

. Then the

impact energy and power are being calculated using

this data.

2 INTERCRITERIA DECISION

MAKING APPROACH

The presented multicriteria decision making method

is based on two fundamental concepts: intuitionistic

fuzzy sets and index matrices. It is called

‘InterCriteria decision making’.

Intuitionistic fuzzy sets defined by Atanassov

(Atanassov, 1983; Atanassov, 1986; Atanassov,

1999; Atanassov, 2012) represent an extension of

the concept of fuzzy sets, as defined by Zadeh

(Zadeh, 1965), exhibiting function µ

A

(x) defining the

membership of an element x to the set A, evaluated

in the [0; 1] - interval. The difference between fuzzy

sets and intuitionistic fuzzy sets (IFSs) is in the

presence of a second function ν

A

(x) defining the non-

membership of the element x to the set A, where:

0 ≤ µ

A

(x) ≤ 1,

0 ≤ ν

A

(x) ≤ 1,

0 ≤ µ

A

(x) + ν

A

(x) ≤ 1.

The IFS itself is formally denoted by:

A = {〈x, µ

A

(x), ν

A

(x)〉 | x ∈ E}.

Comparison between elements of any two IFSs,

say A and B, involves pairwise comparisons between

their respective elements’ degrees of membership

and non-membership to both sets.

The second concept on which the proposed

method relies is the concept of index matrix, a mat-

rix which features two index sets. The theory behind

the index matrices is described in (Atanassov, 1991).

Here we will start with the index matrix M with

index sets with m rows {C

1

,…,C

m

} and n columns

{O

1

,…,O

n

}:

11 1 1 1

1

1

1

1

1, , , ,

,, ,,

,, ,,

,, ,,

,

kln

iikilin

jjkjljn

m mjmlmn

kln

CO CO CO CO

iCO CO CO CO

jCO CO CO CO

mCO CO CO CO

OOOO

M

Ca a a a

Ca a a a

Ca a a a

Ca a a a

=

KKK

KKK

MMOMOMOM

KKK

MMOMOMOM

KKK

MMOMOMOM

KKK

where for every p, q (1 ≤ p ≤ m, 1 ≤ q ≤ n), C

p

is a

criterion (in our case, one of the twelve pillars), O

q

in an evaluated object, a

C

p

O

q

is the evaluation of the

q-th object against the p-th criterion, and it is

defined as a real number or another object that is

comparable according to relation R with all the rest

elements of the index matrix M, so that for each i, j,

k it holds the relation R(a

C

k

O

i

, a

C

k

O

j

). The relation R

has dual relation , which is true in the cases when

relation R is false, and vice versa.

For the needs of our decision making method,

pairwise comparisons between every two different

R

InterCriteria Decision Making Approach for Iron Powder Briquetting

293

criteria are made along all evaluated objects. During

the comparison, it is maintained one counter of the

number of times when the relation R holds, and

another counter for the dual relation.

Let be the number of cases in which the rel-

ations R(a

C

k

O

i

, a

C

k

O

j

) and R(a

C

l

O

i

, a

C

l

O

j

) are simul-

taneously satisfied. Let also be the number of

cases in which the relations R(a

C

k

O

i

, a

C

k

O

j

) and its

dual (a

C

l

O

i

, a

C

l

O

j

) are simultaneously satisfied. As

the total number of pairwise comparisons between

the object is n(n – 1)/2, it is seen that there hold the

inequalities:

.

For every k, l, such that 1 ≤ k ≤ l ≤ m, and for

n ≥ 2 two numbers are defined:

.

The pair constructed from these two numbers

plays the role of the intuitionistic fuzzy evaluation of

the relations that can be established between any two

criteria C

k

and C

l

. In this way the index matrix M

that relates evaluated objects with evaluating criteria

can be transformed to another index matrix M* that

gives the relations among the criteria:

The final step of the algorithm is to determine

the degrees of correlation between the criteria,

depending on the user’s choice of µ and ν. We call

these correlations between the criteria: ‘positive

consonance’, ‘negative consonance’ or ‘dissonance’.

Let α, β ∈[0; 1] be given, so that α + β ≤ 1. We

call that criteria C

k

and C

l

are in:

• (α, β) - positive consonance, if µ

C

k

,C

l

> α

and ν

C

k

,C

l

< β

;

• (α, β) - negative consonance, if µ

C

k

,C

l

< β

and ν

C

k

,C

l

> α

;

• (α, β) - dissonance, otherwise.

Obviously, the larger α and/or the smaller β, the

less number of criteria may be simultaneously

connected with the relation of (α, β) - positive con-

sonance. For practical purposes, it carries the most

information when either the positive or the negative

consonance is as large as possible, while the cases of

dissonance are less informative and can be skipped.

3 EXPERIMENTAL RESULTS

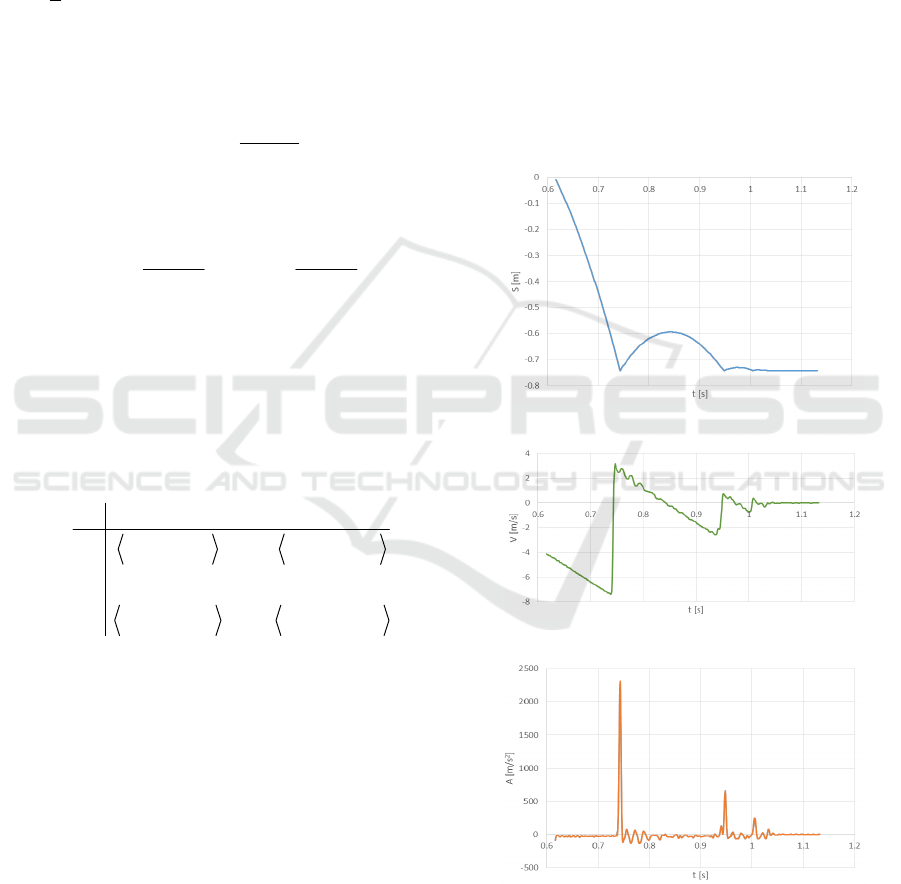

In the presented paper for the analysis purposes we

have used experimental results of impact briquetting

of iron powder. Figure 2 shows the distance, speed

and acceleration diagrams when briquetting iron

powder.

a)

b)

c)

Figure 2: Distance (a), speed (b) and acceleration (c)

diagrams when briquetting iron powder.

,kl

S

μ

,kl

S

ν

R

,,

(1)

0

2

kl kl

nn

SS

μν

−

≤+≤

,,

,,

2, 2

(1) (1)

kl kl

kl kl

CC CC

SS

nn nn

μν

μν

==

−−

11 11 1 1

11

1

1,C,C ,C,C

,C ,C ,C ,C

*

.

,,

,,

mm

mm mmmm

m

CC C C

mCC C C

CC

M

C

C

μν μ ν

μν μ ν

=

K

K

MMOM

K

Fifth International Symposium on Business Modeling and Software Design

294

Figure 2 shows also that the acceleration and

hence the force when briquetting iron powder is

38.4% higher compared to the corresponding values

when briquetting iron chips.

Our experiments show that in order to improve

the capabilities of this deformation process,

additional investigations are required. We also prove

that to have a better density in detail’s walls, where

we have big tension powers, a lubricant has to be

added.

The analysis shows that for specific energy

Е

c

=488 [J/cm

3

] and impact speed V

y

=7.37 [m/s] a

cylindrical compacted iron powder sample has been

produced, having density of ρ=6.7582 [gr/cm

3

].

These impact process parameters can be assumed the

best ones achieved for rocket engine thrust of R=226

[kN].

Based on the experimental research the values of

eleven parameters of the iron powder briquetting

process have been obtained:

1 - V

y

– Impact speed, [m/s];

2 - A

у

– Impact acceleration, [m/s

2

];

3 - H

Δ

– Trimming height, [mm];

4 - Н

– Briquette height, [cm];

5 - D

– Briquette diameter, [cm];

6 - V – Briquette volume, [cm

3

];

7 - G

– Briquette weight, [gr];

8 - ρ – Briquette density, [gr/cm

3

];

9 - E

у

– Impact energy, [J];

10 - E

c

– Impact specific energy, [J/cm

3

];

11 - F

y

– Power of impact, [N].

Table 1: Membership pairs of the intuitionistic fuzzy InterCriteria correlations for the iron powder briquette.

μ

1 2 3 4 5 6 7 8 9 10 11

1

1.000 0.528 0.389 0.417 0.333 0.417 0.611 0.611 1.000 0.611 0.528

2 0.528 1.000 0.694 0.167 0.250 0.167 0.306 0.639 0.528 0.861 1.000

3 0.389 0.694 1.000 0.361 0.278 0.361 0.167 0.333 0.389 0.611 0.694

4 0.417 0.167 0.361 1.000 0.722 1.000 0.694 0.306 0.417 0.028 0.167

5 0.333 0.250 0.278 0.722 1.000 0.722 0.722 0.500 0.333 0.278 0.250

6 0.417 0.167 0.361 1.000 0.722 1.000 0.694 0.306 0.417 0.028 0.167

7 0.611 0.306 0.167 0.694 0.722 0.694 1.000 0.611 0.611 0.333 0.306

8 0.611 0.639 0.333 0.306 0.500 0.306 0.611 1.000 0.611 0.722 0.639

9 1.000 0.528 0.389 0.417 0.333 0.417 0.611 0.611 1.000 0.611 0.528

10 0.611 0.861 0.611 0.028 0.278 0.028 0.333 0.722 0.611 1.000 0.861

11 0.528 1.000 0.694 0.167 0.250 0.167 0.306 0.639 0.528 0.861 1.000

These have been analysed applying InterCriteria

decision making approach. The results are presented

in Тable 1.

The results show a strong relation between the

parameter pairs: 1 (‘Impact speed‘) – 9 (‘Impact

energy‘); 2 (‘Impact acceleration‘) – 11 (‘Power of

impact‘); 4 (‘Briquette height‘) – 6 (‘Briquette

volume‘); 2 (‘Impact acceleration‘) – 10 (‘Impact

specific energy‘); 10 (‘Impact specific energy‘) – 11

(‘Power of impact‘); 5 (‘Briquette diameter‘) – 6

(‘Briquette volume‘); 5 (‘Briquette diameter‘) – 7

(‘Briquette weight‘).

Part of these relations is due to the specific

physical properties of the briquettes, which confirms

the reliability of the proposed InterCriteria decision

making approach. The benefit here is that this allows

for finding strong dependencies as well as such

where the relations are not so visible.

The graphical interpretation results with the

intuitionistic fuzzy pairs of InterCriteria

consonances is shown on Figure 3.

Figure 3: Geometrical visualisation of the InterCriteria

correlations for the case of iron powder briquette onto

the intuitionistic fuzzy interpretational triangle.

InterCriteria Decision Making Approach for Iron Powder Briquetting

295

4 CONCLUSION

The research conducted shows that when producing

rectangular form briquettes presence of air is

observed in the final product. This is due to not

absolutely complete filling of the peripheral part of

the briquette. As a result the briquettes are of low

density and decreased quality. To increase the

product quality it is proposed elements with smaller

size to be used. A possible solution is using iron

powder.

The present paper proves the application of this

original InterCriteria decision making approach,

which eases the analysis if the relations between the

criteria, giving better production quality.

ACKNOWLEDGEMENTS

The research work reported in the paper is partly

supported by the project AComIn “Advanced

Computing for Innovation”, Grant №316087, funded

by the FP7 Capacity Programme (Research Potential

of Convergence Regions) and partly supported under

the Project № DFNI-I-02-5/2014.

REFERENCES

Atanassov K. (1983). Intuitionistic fuzzy sets, VII ITKR's

Session, Sofia, June 1983 (in Bulgarian).

Atanassov K. (1986). Intuitionistic fuzzy sets. Fuzzy Sets

and Systems. vol. 20, № 1, pp. 87–96.

Atanassov K. (1991). Generalized Nets. World Scientific,

Singapore.

Atanassov K. (1999). Intuitionistic Fuzzy Sets: Theory

and Applications. Physica Verlag, Heidelberg.

Atanassov K. (2012). On Intuitionistic Fuzzy Sets Theory.

Springer, Berlin.

Atanassov K., D. Mavrov, V. Atanassova (2013). Inter-

Criteria decision making. A new approach for multi-

criteria decision making, based on index matrices and

intuitionistic fuzzy sets. Proc. of the 12

th

International

Workshop on Intuitionistic Fuzzy Sets and General-

ized Nets, Warsaw, Poland.

Zadeh L. A. (1965). Fuzzy Sets. Information and Control

vol. 8, pp. 333-353.

Penchev T., D. Karastoyanov (2014). Experimental Study

of Upsetting and Die Forging with Controlled Impact,

International Conference on Manufacturing Science

and Engineering (ICMSE 2014), 17-18 April 2014,

Lisbon, Portugal, published in: International Science

Index vol. 8, № 4, Part IV, e-ISSN 1307-6892, pp 529-

533.

Radeva T., I. Yatchev, D. Karastoyanov, N. Stoimenov, S.

Gyoshev (2014). Coupled Electromagnetic and

Thermal Field Modeling of a Laboratory Busbar

System, International Conference on Electrical

Engineering and Technology, ICEET 2014, 8-9

September 2014, Geneva, Switzerland, published in:

International Science Index vol. 8, № 9, Part I, e-ISSN

1307-6892, pp. 172-176.

Gustavson G. at al. (2014). Experimental studies and

modelling of high – velocity loaded iron-powder

compacts, Powder Technology, vol. 268, pp. 293-305.

Doremus P. at al. (2010). High-velocity and conventional

compaction of metallic powders: comparison of

process parameters and green compact properties,

Proc. of the ImechE, 224 E, pp. 117-185.

Scoglund P. (2001). High density PM parts by high-

velocity compaction, Powder Metallurgy, vol. 44, pp.

199-202.

http://www.iict.bas.bg/acomin/

Fifth International Symposium on Business Modeling and Software Design

296