Research of Security Analysis Technology based on Exploratory Well

Engineering of Oil Gas

Jianfang Jiang, Na ZHU, Jinzhou Yang, Jingyi Lian and Chaofei Wang

Research Institute of Enhanced Oil Recovery,China University of Petroleum (Beijing), Beijing, China

654145410@qq.com

Keywords: Security, Oil gas exploring, Evaluation.

Abstract: Aims at the security problems on well engineering of oil gas, this article will evaluate the security analysis

technology. At first, the writer describes the process of drilling engineering and evaluates the relative risk

factors at each phase. In the second place, we can find the security evaluation of this well engineering and

provides the system principle of security evaluation. At last, this article analyzes the level standard that

based on the analysis system model of drilling security. This paper supports positive function to the drilling

engineering workers and security evaluators.

1 INTRODUCTION

The present society is increasing the dependency

degree of oil and gas. Oil and gas has significant

connections with the national economy development

and living improvement. It is nothing to treat oil gas

as the “National lifeline”. Oil and gas Is the

important strategic resources of China. However, the

low prospecting degree and special condition of the

working environment causes the continuous accident

and seriously limited the oil gas development.

2 DRILLING ENGINEERING

Drilling is the system engineering with multiple

operations, occupation, continuous operation, and

the vertical crossing works. It has the characteristics

of high input, high risk and high technology

requirement. Security hazard happens everywhere

during the drilling process. The once accident might

cause maximum loss on engineering schedule and

funds, even the casualties.

2.1 Drilling Process

Drilling is the necessary part of oil gas exploitation.

Follow the drilling engineering we can sequence the

works: prespud operation, drilling engineering and

the completions engineer. Each phase needs to have

the specific works.

2.1.1 Prespud Preparation

Prespud preparation is the first process of the whole

engineering. Confirm the well position, and then we

can start the prespud preparation. It includes: well

position exploration and land expropriation, bridge

and road engineering, well site earthwork,

equipment removes and installation and so on.

2.1.2 Drilling Engineering

It divides into first drilling, second drilling and the

third drilling. During the drilling process, it needs a

drill stem-testing cooperation, electrical logging

cooperation, sidewall coring electrical logging of

finish drilling and drilling coring. Otherwise, drilling

engineering requires pipe service, drilling fluid

service, material supply service and drilling service

of exceptional well to protect engineering success.

2.1.3 Completions Engineer

Completions engineer needs to do running casing,

well cementation, and well cross in order to protect

oil gas exploitation.

2.2 Risk Evaluation of Drilling

Engineering

Drilling engineering is the complicate project. It

includes multiple uncertain factors. The relative

111

Yang J., Wang C., CHENG X., Lian J. and ZHU N.

Research of Security Analysis Technology based on Exploratory Well Engineering of Oil Gas.

DOI: 10.5220/0006020001110114

In Proceedings of the Information Science and Management Engineering III (ISME 2015), pages 111-114

ISBN: 978-989-758-163-2

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

111

enterprises, management departments need to

forecast the accident possibility, evaluate the risk

degree, find out the accident rules, reasons, and

adopt the remedial measure.

2.2.1 Dangerous Substance

Oil and gas are the flammable and combustible

materials. Gas has a higher specific gravity than air.

It can spread to lower places and burn once touched

the open fire. Otherwise, some crude oil has

sulfureted hydrogen, which has toxic. If you intake it

in short time, you will shed tears, photophobia,

cough, and confusion. The serious condition has

coma, edema, even death.

Otherwise, the raw material of drilling

engineering is the flammable and combustible

materials as well as mountain flour, grease and so

on. The drilling process will create effluent, dust,

and noise. We need to do the unity collection and

management by the professional workers.

2.2.2 Risk Factors of Drilling Engineering

Drilling engineering is full of risks. We need to

focus on the security questions. The drilling risks

have: object striker, high-altitude falling, fire, well

slough, thunder, and poisoning. The well

cementation risks have: electric shock, chemistry

corrosion, poisoning, casing failure, high pressure

damage, and tool damage.

2.2.3 Environmental Factors

Drilling engineering has various difficulties. We

need to consider the external environment factors

while avoid human error. For example:

meteorological condition, earthquake, and road

question.

3 RISK EVALUATION OF OIL

GAS EXPLORATION

3.1 Risk Evaluation Content.

3.1.1 Drilling Design Evaluation.

Drilling

design

includes

geology,

engineering

and

construction. Geology design needs to collect

pressure factors, oil gas location, and geological

factor. Drilling engineering design includes

standard, regulation, well structure, feasibility and

the rationality analysis of well cementation and well

completion. Drilling construction needs to follow the

design of geology and engineering to analyze the

construction rationality and the risk of uncertainty

factors.

3.1.2 Construction Environment Assessment

We need to inspect the geology, weather, and

hydrology. Moreover, evaluate the effect proportion

and the maximum protection of people and property

security when facing the emergency.

3.1.3 Construction Site

From the site test, we can evaluate the security

degree of people and equipment, and then formulate

rules and safety regulations to protect the correct

operation. During the construction process, we can

abstract the relative parameters, obtain the materials,

evaluate the practical condition and avoid the risk.

3.1.4 Emergency Capacity Evaluation

We can reference the engineering experiences and

evaluate the site investigation in order to design the

emergency plan and train the workers.

3.2 Risk Evaluation Principles of

Drilling Engineering

3.2.1 Systematicness

The whole security system includes people,

equipment, and environment. The relative functions

build the whole system with the inseparable details.

3.2.2 Pertinence Principle

Drilling engineering is complicated. We need to

evaluate the engineering based on the practical

condition in order to depend on the experiences and

principles. Different engineering has the various

security indexes. The details are different with

similar keys.

3.2.3 Simple Scientificity

Risk evaluation supports service to the engineers.

The evaluation index should be simple and clear that

can reflect the detailed engineering condition.

3.2.4 Stabilization Comparability

Drilling process steps should be quantized. We can

adjust the operation error.

ISME 2015 - Information Science and Management Engineering III

112

ISME 2015 - International Conference on Information System and Management Engineering

112

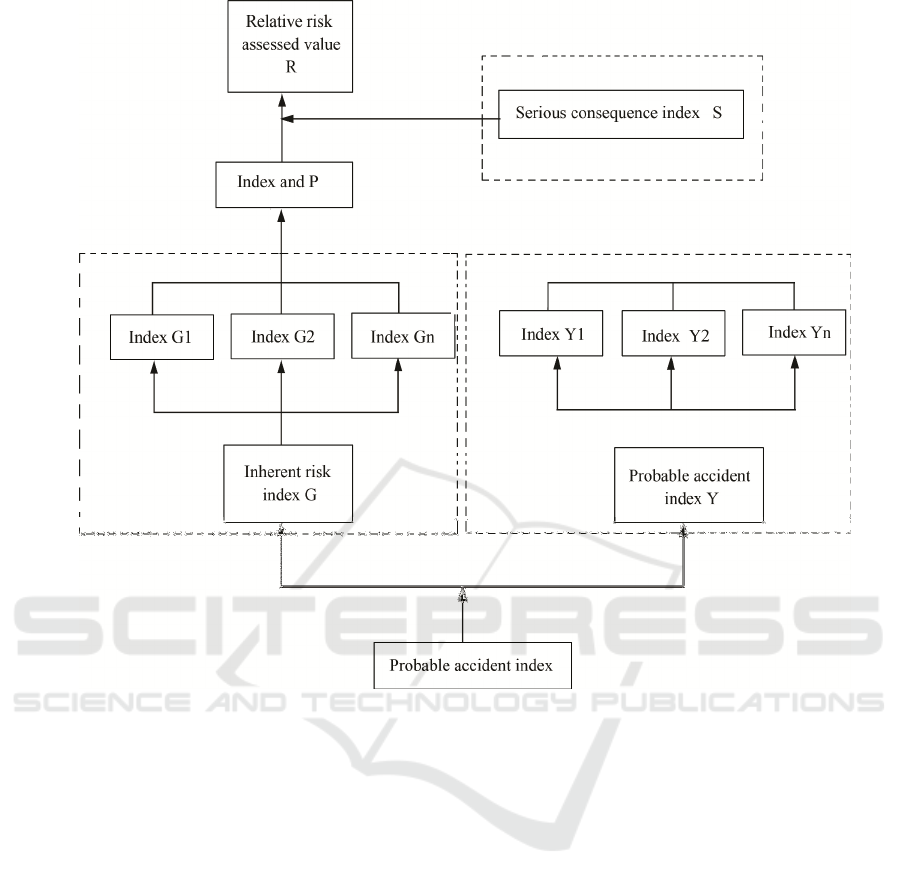

Figure 1: Model of security evaluation system.

3.2.5 Indexity

Use detailed value to analyze the security degree

will raise the staff attention from each number

changing and reflect the safety condition.

3.3 Index Evaluation System

The evaluation system combines with index system,

scoring system, risk ranking standard and specialists.

The security risks of different phases of the index

system. The advantage of perceptual intuition

requires more consideration. Scoring system

provides reasonable values to each index. The

advantage of its abundant information content has

the disadvantage of stronger subjectivity. Risk level

depends on the risk standard and the probable hazard

rating. The specialists include relative technician and

the experts from other fields to help the data

analysis.

4 ESTABLISHMENT OF

SECURITY EVALUATION

SYSTEM

4.1 Model of Security Evaluation

System

The model of the security evaluation system

combines with inherent risk index, serious

consequence index and probable accident index.

Figure 1 is the basic model.

(1) Inherent risk index: all the drilling

engineering has this unmodifiable risk. For example:

the environment and geology of this engineering

(2) Probable accident index: drilling engineering

is complicated. The accident did not happen

individually. It might be caused by one small

accident, then give rise to the serious accident. We

can use the formula (1) to describe the accident

ponderance.

Research of Security Analysis Technology based on Exploratory Well Engineering of Oil Gas

113

Research of Security Analysis Technology based on Exploratory Well Engineering of Oil Gas

113

R P*S (G+Y)*S (1)

R is the relative risk assessed value, P is the sum

of the inherent risk index (G) and the Probable

accident index (Y), and S means the serious

consequence index.

(3) Probable accident index: during the

engineering operation, the probable accident is

changeable that we can avoid the accidents through

regulation and security operation.

4.2 Risk Ranking Standard

Based on the practical condition and evaluation

system of the drilling engineering, this article

divides the risk into four levels through the security

question research of the oil gas drilling engineering.

The details are in table 1.

Table 1: Risk ranking standard.

Level Value-at-risk Description

1 Less than 100 Los risk

2 100--200 Medium risk

3 200--350 Superior risk

4 350--500 High risk

5 More than 500 Extreme risk

5 CONCLUSION

This article starts the research based on the security

analysis of oil gas drilling. The oil gas exploiting has

the direct bearing on the national economy and the

people’s livelihood. At the same, the exploratory

well engineering of oil gas is complicated with high

risk. It will cause as minor cost as the waste of

funds, equipment and time. Moreover, it might to

cause the casualty, which requires relative people

pay high attention to it. For the length limitation, this

article did not support the related index of security

evaluation system. Hope the interested readers will

perfect this article based on the local requirement.

REFERENCES

Sun Lianjie, Discussion of security analysis and security

assessment routine,Journal of Safety Science and

Technology,19(1),24-26, 1999

Han Da. Present situation and countermeasure of Hazard

identification and risk assessment in enterprise ,Safety,

Health & Environment, the 3rd volume(7),pp.22-24,

2003

Gong Botao. Application of fuzzy mathematics theory

during the safety evaluation [J] . Electric Safety

Technology,2(4),pp.10-12,2000

Chen Yuangao. Causes and countermeasures of oil drilling

accidents, Safety, Health & Environment,(3),pp.14-

18,1994

Huang Renshan. Example analysis and drilling security

countermeasure of the drilling engineering accident,

Petroleum Drilling Techniques,26(4),pp.54-57,1998

Dai Yongshou. A total drilling monitoring system for oil

and gas production well, Acta Petrolei Sinica,

24(5),pp.99-103,2003

ISME 2015 - Information Science and Management Engineering III

114

ISME 2015 - International Conference on Information System and Management Engineering

114