The Overview of Intelligent Cloth Inspection Machine

Zhang Chunfeng and Xue Tianyu

Information Engineering, Beijing Institute of Fashion Technology, Chaoyang District, Beijing, China

taihezcf@126.com, gxyxty@bift.edu.cn

Keywords: Intelligent, Inspection Machine, Overview.

Abstract: Now many textile companies to use more fabric defect detection testing methods of doing in front of the

player, and Inspection Machine operation is based on a series of operations of the analog signal, the traditional

Inspection Machine in the staff up to 200 defects found within one hour attention of staff to maintain up to

20-30 minutes, more than this time staff will produce fatigue, speed manual fabric inspection is only 5-20 m

/ min, more than this rate staff will appear leak test. This not only affects human health, but also reduces

productivity. This paper presents the concept of Intelligent Cloth Inspection Machine, and takes a brief

description, in order to have a new breakthrough in the study of late.

1 INTRODUCTION

Inspection Machine is a necessary equipment for

detecting a former garment industry production of

cotton, wool, linen, silk, chemical fiber and other

special large format, double-width and single fabric.

Process of Inspection Machine includes defect

detection, straight, playing volume series of

processes. It is mainly used to test the thick material,

heavy cloth, oxford cloth, comb weaving material,

fabric inspection, Chubb, the amount of code, rolling

and folding. Types of Inspection Machine include:

knitting Inspection Machine, weaving Inspection

Machine, no tension test volume, multifunction

Inspection Machine, needle shed dual Inspection

Machine, denim Inspection Machine, weaving comb

Inspection Machine (Chung-Feng Jeffrey Kuo,

2009).

Overseas Inspection Machine has been used as a

relatively mature textile equipment, while research in

all aspects of domestic Inspection Machine is not

mature, and cannot keep up the pace of development

of textile industry.

2 COMPARISON OF

TRADITIONAL AND

INTELLIGENT CLOTH

INSPECTION MACHINE

2.1 Method of Operation about

Inspection Machine

(I) The Traditional Cloth Inspection Machine

provides hardware environment, continuous

segments expand fabrics, and adequate light

source; by sight of the operator, we can

acknowledge cloth and color defects, and

Inspection Machine autocomplete remember long

and package finishing work (Chung-Feng Jeffrey

Kuo, 2008).

(II) Intelligent Cloth Inspection Machine with

intelligent defect detection device, image

acquisition and analysis system in real time,

images and detect defects circumstances collected

is transmitted to IPC, IPC analysis by the outcome

of the Inspection Machine sends commands to

control test boot volume machine, reverse, brake

and other operations.

2.2 The Basic Structure of Inspection

Machine

2.2.1 The Traditional Inspection Machine

The basic structure of a Traditional Cloth Inspection

427

Chunfeng Z. and Tianyu X.

The Overview of Intelligent Cloth Inspection Machine.

DOI: 10.5220/0006027804270430

In Proceedings of the Information Science and Management Engineering III (ISME 2015), pages 427-430

ISBN: 978-989-758-163-2

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

427

Machine includes:

1) Fabric back solution, shuffling and re-winding

device

2) The inspection cloth station, a light source

3) Mnemonic devices

4) Fabric finishing equipment

5) Start, reverse and brake units

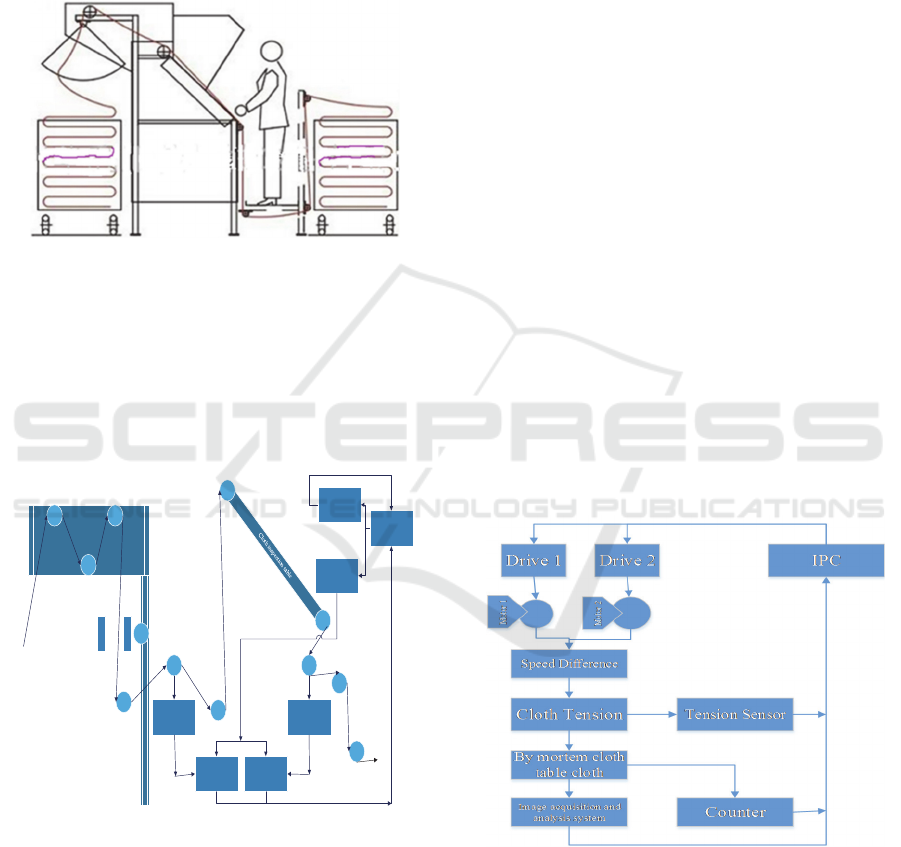

Figure 1: The Traditional Inspection Machine.

2.2.2 The Intelligent Inspection Machine

Intelligent Cloth Inspection Machine includes post-

mortem cloth station, master-slave motor, inverter,

IPC, image acquisition and analysis system, tension

sensor, record length and so on (K. L. Mak, P. Peng,

2008).

Figure 2: The structure.

2.3 The Advantages of the Intelligent

Inspection Machine

The Traditional Cloth Inspection Machine offers

hardware environment of cloth inspection,

continuous segments expand fabrics, and adequate

light source; by sight of the operator, we can

acknowledge cloth and color defects, the Traditional

Cloth Inspection Machine autocompletes remember

long and package finishing work (Radovan

Stojanovic, 2001). The Intelligent Cloth Inspection

Machine with the image acquisition and analysis

system in the cloth inspection process is completed

by the embedded real-time system control image

acquisition and complete defecting detection, and

then to collect the images and defect detection

situation through Ethernet port to the industrial

machine, thereby industrial machine interface

displays real-time images captured and defect

detection of cases, additionally there will be operation

buttons for Inspection Machine, such as start, reverse,

brake. Whereby the cloth inspection speed, quality,

efficiency is greatly improved.

3 THE PRELIMINARY DESIGN

OF INTELLIGENT CLOTH

INSPECTION MACHINE

Fabric imported by the main motor drive mechanism

through cloth inspection table, and then by the motor

pulled into the take-up roll. Cloth inspection table

offers image acquisition and analysis system for real-

time image capture on canvas and defect detection via

Ethernet port transfers the result to the IPC, the Live

View image on the cloth IPC, and test roll machine

control.

Figure 3: The preliminary design.

I. Textile, printing and dyeing step is to test the

volume of the original fabric (newly produced, the

more disorderly loose cloth), after inspection /

repair after error, roll into a roll, and then go to the

next step. Throughout the process, more difficult

to solve the problem is the tension in the cloth roll

cloth process, since the cloth tension directly

Reducer

DriveDrive

Reducer

IPC

Suction

side

Into the

fabric

Image acquisitio n

and analysis

system

Tension

Sensor

Coiling

ISME 2015 - Information Science and Management Engineering III

428

ISME 2015 - International Conference on Information System and Management Engineering

428

affects the quality of cloth and remember long

problem (Hyung Taek Choi, Sung Hoon Jeong,

2001). The Intelligent Cloth Inspection Machine

through real-time communication between the

drive and the IPC, as well as coordination tension

sensor in a timely manner to control the motor

speed, so that the tension of the cloth process

requirements:

II. Fabric with a certain laxity by cloth inspection

table;

III. It sometimes requires motor reversal, in order to

find the defect quickly, then it should still

maintain fabric original relaxed state;

IV. It finds defects or faults when fast braking.

(2) Traditional Cloth Inspection Machines are both

fabric comptroller function, but mostly Inspection

Machine uses a drive unit, the fabric pulled

directly from the drive roller inspection table cloth

through, so easy to cause the fabric stretched so

that the comptroller is not accurate, to thin ,

especially elastic fabric. In demanding situations,

the use of loose type transmission, enabling the

fabric to maintain a certain slack in cloth

inspection process to ensure that the Comptroller,

accurate defect detection to meet the

requirements:

① accurate record length

② normal fabric, latitude and longitude lines without

distortion.

Traditional machines for the introduction of a single

motor drag tension transmission; in order to achieve

no tension control, transmission control scheme was

redesigned by controlling the main drag of the motor

speed difference from the two to achieve a loose style

fabric inspection.

(3) Defects of Traditional Cloth Inspection Machine

are often found by a manual operation, fewer

defects detected, slow-mortem cloth, and fabric

inspection work will cause fatigue over a certain

time, then these factors can cause the error

detection, the problem of the leakage test. The

image acquisition and analysis system of

Intelligent Cloth Inspection Machine in the cloth

inspection process is completed by the embedded

real-time system control image acquisition and

complete defect detection, and then to collect the

images and defect detection situation through

Ethernet port to the industrial machine, industrial

machine interface displays real-time images

captured and defecting detection of cases, there

will be operation buttons for Inspection Machine,

such as start, reverse, brake. Whereby the cloth

inspection speed, quality, efficiency is greatly

improved.

4 CONCLUSIONS

With China's accession to WTO, relationships of the

domestic textile manufacturers and international

famous brand clothing sales business have become

more closely, while fabric quality problems and

disputes are more and more accurate and reliable

testing methods and equipment of fabric close related

to the fate of the textile industry and the

competitiveness of the international market.

Requiring the use of Intelligent Cloth Inspection

Machine, on the one hand to improve the defect

detection rate, accuracy, on the other hand to improve

labor productivity, reduce the number of

employment; to adapt to WTO competition on the

textile, printing and dyeing industries.

Intelligent Cloth Inspection Machine, it can

replace the manual, automatic fabric inspection and

grading, cut open, to defect to play tag. Intelligent

Cloth Inspection Machine is controlled by the IPC,

relied on image acquisition and analysis system fabric

inspection, the general fabric inspection speeds of up

to 120 m / min, defects were found in the screen that

can display and reporting, speed is quick and

Intelligent Cloth Inspection Machine can adapt to the

high frequency of defects or new defect infrequent.

Application of Intelligent Cloth Inspection Machine

can classify the fabric, and achieve the subject fabric

defect statistics, storage capabilities. Intelligent Cloth

Inspection Machine to automate testing the fabric of

the road, I believe that I will be for some time through

continued research efforts, intelligent inspection

technology will walk into the textile fabric

enterprises, an important part of automated form.

ACKNOWLEDGEMENTS

This research was financially supported by Beijing

Institute of Fashion Technology 2014 university

innovation team project: Integration of

electromechanical equipment test volume based on

computer vision; Item Number: 2014A-27

REFERENCES

Chung-Feng Jeffrey Kuo, 2009. Intelligence control of on-

The Overview of Intelligent Cloth Inspection Machine

429

The Overview of Intelligent Cloth Inspection Machine

429

line dynamic gray cloth inspecting machine system

module design I. Tension controller design, Fibers and

Polymers. 3th edition.

Chung-Feng Jeffrey Kuo, 2008. Intelligence control of on-

line dynamic gray cloth inspecting machine system

module design II. Defects inspecting module design,

Fibers and Polymers, 6th edition.

K. L. Mak, P. Peng, 2008. An automated inspection system

for textile fabrics based on Gabor filters. Robotics and

Computer-Integrated Manufacturing.

Radovan Stojanovic, 2001. Real-Time Vision-Based

System for Textile Fabric Inspection. Real-Time

Imaging.

Hyung Taek Choi, Sung Hoon Jeong, 2001. Detecting

Fabric Defects with Computer Vision and Fuzzy Rule

Generation Part 1l: Defect Identification by a Fuzzy

Expert System. Textile Research Journal.

Ajay Kumar, 2003. Neural network based detection of local

textile defects. Pattern Recognition.

ISME 2015 - Information Science and Management Engineering III

430

ISME 2015 - International Conference on Information System and Management Engineering

430