Internet of Smart Things

A Study on Embedding Agents and Information in a Device

Leo van Moergestel

1

, Melvin van den Berg

1

, Marco Knol

1

, Rick van der Paauw

1

, Kasper van Voorst

1

,

Erik Puik

1

, Dani

¨

el Telgen

1

and John-Jules Meyer

2

1

Institute of ICT, HU University of Applied Sciences, Utrecht, Netherlands

2

Information and Computing Sciences, Utrecht University, Utrecht, Netherlands

Keywords:

Agent-based IoT, Device Information, Life Cycle Dependent Information.

Abstract:

The term Internet of Things (IoT) is used for situations where one or more devices are connected to a network

or possibly the Internet. Most studies focus on the possibilities that arise when a device is capable to share its

data with other devices or humans. In this study, the focus is on the device itself and what kind of possibilities

an Internet connection gives to the device and its owner or user. Also the data the device needs to participate

in a smart way in the IoT are part of this study. Agent technology is the enabling technology for the ideas

introduced here. A proof of concept is given, where some concepts proposed in the paper are put into practice.

1 INTRODUCTION

Nowadays, many devices are connected to a network,

be it the Internet or another implementation of net-

work connectivity. The connectivity may be based on

wireless technology like Bluetooth or WiFi, but wired

solutions are also possible. The connectivity is used

by a device to share or exchange data with other de-

vices or humans. This so-called Internet of Things

(IoT) (Ashton, 2009) is considered to be the next step

in the direction of a world where everything is con-

nected. Most devices are offering data or accepting

data to operate in a certain environment. In this paper

the focus will be on using agent technology as a basis

for devices operating in the IoT.

The rest of this paper is organised as follows: Sec-

tion 2 is dedicated to IoT. Several classifications and

implementations are presented as well as the added

value that is offered by IoT. In Section 3, after a short

introduction of agent technology, the classes of IoT

devices where agent technology can be applied are

discussed. The reason why agent technology fits in

the IoT model is also explained in Section 3. The

roles of agents and the data a device needs to operate

in the IoT depending on the phase of the life cycle are

the subjects of Section 4. The use phase of the life cy-

cle of the product will be the phase that will have the

main focus, but the roles of the agents in other phases

are mentioned as well. In this section the technical

possibilities are also discussed.

The implementation is the subject of section 5.

Here the device to be produced is introduced and the

parts it consists of. This will lead to a device descrip-

tion format that is both computer- as well as human-

readable. This device description will be enhanced

by assembling instructions that will be the basis of

the information about the manufacturing. Next the

implementation of some ideas proposed in Section 4

will be explained. Section 6 discusses related work.

A conclusion and a bibliography will end the paper.

2 IoT

This section will discuss IoT. First, classifications of

IoT devices are presented followed by a short motiva-

tion what the merits are by connecting devices to the

Internet.

2.1 Classifications of IoT Devices

Three types of classification will be presented here:

1. classification based on administration;

2. classification based on connectivity;

3. classification based on the soft- and hardware ca-

pabilities of the device.

A possible way to classify IoT devices is looking at

their administration. By this is meant the way the de-

vices know each other and what they are expected to

102

Moergestel, L., Berg, M., Knol, M., Paauw, R., Voorst, K., Puik, E., Telgen, D. and Meyer, J-J.

Internet of Smart Things - A Study on Embedding Agents and Information in a Device.

DOI: 10.5220/0005659801020109

In Proceedings of the 8th International Conference on Agents and Artificial Intelligence (ICAART 2016) - Volume 1, pages 102-109

ISBN: 978-989-758-172-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

do in the IoT environment. Five different classes of

IoT systems are presented here.

1. Fully static systems. All the devices in the sys-

tem are pre-configured to communicate and inter-

act with each other. An example is an industrial

sensor network like WirelessHART (Song et al.,

2008).

2. Centrally administrated systems with a single ad-

ministration unit. In this case the devices are pre-

configured to interact with a central unit - This is

the registration step. Each device can query the

central unit to identify other devices that it needs

to interact with. Devices can communicate with

each other directly or they can communicate via

the central unit. An example of this class of IoT

devices are devices in smart homes with capabili-

ties for coordinating power usage, adapting to en-

vironmental conditions, ensuring security of the

home, etcetera.

3. Centrally administered systems with multiple ad-

ministrative units where the administrative units

are centrally coordinated. These systems are typ-

ically widely distributed, hence several admin-

istrative units are used at different geographi-

cal locations. The devices are pre-configured to

locate/interact with nearby administrative units.

The administrative units keep track of all the de-

vices and ensure that each device is aware of the

other devices that it may need to interact with.

An example is an infrastructure system for auto-

mated guided vehicles (AGV) in a wide geograph-

ical area.

4. Centrally administered systems with multiple ad-

ministrative units where the administrative units

form a decentralized system. The administrative

units are mobile systems. These systems cooper-

ate with each other to identify and track all the de-

vices. The devices are made aware by the nearest

administrative unit of the other devices they may

need to interact with. Devices can communicate

with each other directly or they can communicate

via the administrative units. Devices themselves

are typically mobile units. An example for this

class of IoT are systems that keep track of chil-

dren and old people to ensure their safety.

5. Fully autonomous decentralized systems. In this

case each device is an independent unit that has

capabilities to identify other units and coordinate

with them. Devices communicate with each other

directly. Devices can be fixed or mobile units -

The autonomy is used to minimize the interaction

time while ensuring requisite coordination and co-

operation with other units. An example in this

case are avionic systems: each aircraft can au-

tonomously identify nearby aircrafts and coordi-

nate its motion in order to prevent accidents.

Another way to classify IoT devices is to look how

they are connected to the Internet, resulting in three

different classes.

1. A device can be part of a special network, wired

or wireless that is connected by a special net-

work device that will be the gateway to the In-

ternet. This situation occurs in the so-called sen-

sor networks, where simple devices use a dedi-

cated network technology to connect with each

other or the gateway. Examples of such networks

are WirelessHART (Song et al., 2008) and Zig-

Bee (Ian Akyildiz et al., 2002).

2. A device can have its own Internet address but is

only capable to reply to requests received from the

network to send data.

3. A device can have its own Internet address and be-

ing capable to communicate directly and actively

with other devices on the Internet.

The third classification that will presented here is

based on the computing capabilities of the device it-

self. Two classes are important for our discussion.

1. A device has only a single thread of execution to

make it work as an IoT device. Normally there

is not much storage capability in this type of de-

vice. An example is a sensor or actuator that is

connected to a network.

2. A device is capable to execute multiple threads,

resulting in a system that has more than one pro-

cess running. This type of device can even be ca-

pable to run an operating system and use some

local storage.

2.2 Benefits of IoT

By connecting devices to the Internet, the following

two possibilities arise:

1. Data collecting: data can be collected and anal-

ysed giving insight in all kind of situations where

the IoT devices are involved.

2. Control: because a device is connected, it can be

controlled. This results is three possibilities:

(a) Communication: this is an extension of data

collecting because the kind of data can be se-

lected.

(b) Interaction: remote control, updates and adjust-

ments are possible.

(c) Automation: a device can learn, but not in a

stand-alone situation, but in the situation where

Internet of Smart Things - A Study on Embedding Agents and Information in a Device

103

resources and other devices on the network can

support the learning system.

To see where agent technology fits in the aforemen-

tioned classifications we will give a short introduction

to agent technology and a definition of what an agent

is as used in this paper.

3 AGENT TECHNOLOGY

This section will start with a short introduction to

agents and the way they can be embedded in a device.

The section will continue with a motivation for using

agent technology. Finally, the types of IoT devices

as introduced in the classification, where the agent

model can be used are discussed.

3.1 Embedding Agents

An agent is an autonomous software system that is de-

signed to play its role and to achieve one or more of its

goals. Agents are autonomous entities that can be em-

bedded in a device under the condition that the device

itself contains a processor and memory to store the

agent code as well as to execute this code. In practice

this means that the device should be capable to run

a kind of operating system. Two important solutions

for embedding an agent in a device exist:

1. The agents can be a part of the device software

infrastructure. Without the agent the device can-

not operate properly. This situation applies when

the agent is developed in combination with the de-

vice software and the device infrastructure itself is

agent-based.

2. The agent can be a software system that oper-

ates separately from the device infrastructure it-

self. In this situation, the device will operate prop-

erly without the agent. An advantage is that the

agent can be added at any time and the agent can

even run in cyberspace. In the latter case a con-

nectivity with the device is compulsory.

3.2 Why Agent Technology?

The main reason for using agent technology is the

fact that an agent can operate without human inter-

vention. It is autonomous in a sense. Intelligence can

be a property of an agent as well as mobility. A mo-

bile agent can move from one workspace to another

opening the possibility to embed it in a product when

the product is made, let the agent move to cyberspace

when needed and let the agent go to another device.

Agents can communicate, thus exchange information

So if a mobile agent is not possible in certain situ-

ations, a newly created agent can take over valuable

information from another agent.

3.3 IoT Device Types

As stated already, the device should have the capa-

bilities to run the agent. This means that it must be

capable to run multiple threads or even better pro-

cesses. The device should be connected directly to the

Internet, because when the device is hidden behind a

gateway, as in the situation of some implementations

of sensor networks, standard software techniques can-

not be used to communicate with the agent embedded

in the device. It depends on the situation if the de-

vice operates actively or just waits for requests. In

regard to the administration, agents can be used in all

five types mentioned. However, in practice fully static

systems (the first type in the list) require human inter-

vention in configuring. This approach conflicts with

the idea that the system should work and configure

itself autonomously.

4 AGENT ROLES IN IoT

In this section the focus will be on generic roles that

an agent can play in a device. The roles depend on the

phase in the life cycle of a product. First these phases

will be introduced including the possible roles for a

product agent. Next, for every role in every phase,

the data or knowledge of the device is summarized.

A more thorough discussion of agents roles in the life

cycle of a product can be found in (Moergestel et al.,

2010).

4.1 Phases in the Life Cycle of a Product

A device starts its life during manufacturing. Mo-

ergestel et al. (Moergestel et al., 2011) describes a

production system where a product starts its life as a

software agent that is responsible for the manufactur-

ing of a single possibly unique product. This so-called

product agent contains the blueprint of the product to

be manufactured and is the basis for the concept of the

IoT in other phases of the life cycle of the product it is

embedded in. In Figure 1 the life cycle of an arbitrary

product is shown. After the design, the product is pro-

duced in the manufacturing phase. After manufactur-

ing, the product is distributed. Next comes a very im-

portant phase, being the use of the product and finally

the phase where the product should be recycled. In all

of these phases, the product agent can play a role that

will be globally described in the next subsections. For

ICAART 2016 - 8th International Conference on Agents and Artificial Intelligence

104

every phase and associated role, an overview of infor-

mation acquired or used is given. A more extended

discussion can be found in (Moergestel et al., 2014).

We remark that in the literature the term product life

Design Manufacturing Distribution Use Recycling

Figure 1: Life cycle of a product.

cycle (PLC) is commonly used to denote a concept

that is different from what we call the life cycle of a

product. The product life cycle can be defined as the

process wherein a product is introduced to a market,

grows in popularity, and is then removed as demand

drops gradually to zero (Lilien et al., 2003).

4.1.1 Design and Manufacturing

A trend in modern manufacturing is that the de-

sign of a product will be greatly influenced by the

individual end-user requirements. Nowadays cost-

effective small scale manufacturing will become more

and more important. This trend is enabled by Inter-

net technology and new developments in manufactur-

ing like 3D printing opening possibilities to adapt a

manufacturing system to individual end user require-

ments. In (Moergestel et al., 2015) an implementation

of manufacturing as a service (MaaS) is described. In

this MaaS system the product agent is created. Im-

portant is the fact that the product agent is responsi-

ble for the manufacturing of the product as well as

for collecting relevant production information of this

product. This concept is the basis for the roles of the

product agent in later phases of the life cycle. The

product agent carries the product design as well as

the production data and can be viewed as the software

entity that represents the product in cyberspace. The

information available should open the possibility for

a the device to clone itself.

4.1.2 Distribution

In (Burmeister et al., 1997) a logistic application

based on a multiagent system is described. Agent-

based logistic applications have transport from source

to destination as the main goal. However, other

important data can be information about product

handling and external conditions, like temperature,

shocks etcetera. These data can be measured by cheap

possibly wireless sensors and collected by the product

agent in its role of guidance agent during the transport

or after arrival at the destination. The handling and

external conditions during transport can be important

for the other coming cycles in the life phase, because

they influence product quality thus having impact on

maintenance and repair. The information available

gives an overview in time of the physical and condi-

tional data. The main problem related to this phase is

powering the device during transport. That is the rea-

son that in most cases it is better to collect the trans-

port information at arrival, when de device is powered

on. Low power battery-operated sensors already exist

that can collect and store information during trans-

port. These devices will collect the needed informa-

tion and can be read by the product agent when it pow-

ered on.

4.1.3 Use

In the use phase, the product agent can perform ac-

tions that will help and support the end-user by keep-

ing valuable information at hand, offering a user man-

ual or preventing or minimizing the effects of mis-

use. By giving feedback about the usage and prob-

lems that occur during usage it can also help the man-

ufacturer to improve its products. Finally in the re-

cycling phase, the information collected during usage

can be very helpful.

In the next paragraphs several topics of usage of

the product agent are discussed.

Collecting Information. A product agent will col-

lect information about the use of the product as well

as the use of the subparts of the product. Testing the

health of the product and its subsystems or subparts

can also be done by the agent. These actions should

be transparent for the end-user. To perform these ac-

tions, the product agent should be connected to sen-

sors and software subsystems in the product.

Advising and Control. The information collected

by the product agent gives a clue about the product

use and the use of the subsystems. An agent can sug-

gest maintenance or replacement of parts. The agent

can advice a user about the usage of a product, this

can be done directly but also automatically without

direct user intervention. An example of the latter is:

If a product needs resources like electric power, an

agent can suggest a product to wait for operation un-

til the cost of electric power is low i.e. during the

night. It depends of course on the type of device if

this should be implemented.

Maintenance and Repair. An agent can identify a

broken or malfunctioning part or subsystem. This

could be achieved by continuous monitoring, mon-

itoring at certain intervals or a power-on self test

(POST). Condition monitoring is the process of con-

trolling the functioning of parts of a device or of the

Internet of Smart Things - A Study on Embedding Agents and Information in a Device

105

device itself. It is an important possibility to pre-

vent malfunctioning. Three types of information play

an important role: the manufacturing information,

the transport information and the usage information.

This is exactly the information that is collected by the

product agent. Repairing a product is easier if infor-

mation about its construction is available. Issues dur-

ing transport have an influence on the quality as well

as the way a product has been used.

Other Possibilities. Some possibilities that could

be achieved by using a product agent are:

• Transparency of the status of a product after main-

tenance by a third party. The agent can report to

the end-user what happened during repair so there

is a possibility to check claimed repairs. Of course

the agent should be isolated from the system dur-

ing repair to prevent tampering with it.

• Recovery and tracing in case of theft or loss

are also possible by using the embedded product

agent technique.

• Advising the end-user who wants to replace a cer-

tain device by a new one. The product agent can

give advice about the properties the replacing de-

vice should have, based on what the product agent

has learned during the use phase.

4.1.4 Recycling

In Moergestel et al. (Moergestel et al., 2014) the role

of the product agent in the reuse of subsystems and

components is mentioned as well as in locating ex-

pensive or rare material.

Another advantage of having a product agent at

hand in case of recycling is the fact that the prod-

uct agent has the information how a product is con-

structed. This is helpful when a product must be taken

apart. For certain steps a kind of undo-steps should be

carried out to dismantle a product. These undo-steps,

if they exist, can be incorporated at the moment the

product is assembled.

4.2 Embedded Knowledge for Different

Phases

The whole design including the user preferences that

are taken into account form the basis of the knowl-

edge or information of the product agent. The prod-

uct agent will use this knowledge to guide the prod-

uct to be made during manufacturing. This concept is

treated in (Moergestel et al., 2010). The design will

lead to sequences of production steps. In the man-

ufacturing phase itself other knowledge is added to

the knowledge base, especially the information about

how the manufacturing has been carried out for all the

production steps and what parameters where used. In

the distribution phase, all kind of conditions met dur-

ing transport can be collected. The transport route

itself could also be of interest and can be enabled by

the use of a global position system (GPS). This might

be helpful to trace a device to its end-user. However,

as mentioned before the device should be capable to

operate during transport. In the use phase, user pref-

erences during use and usage of subparts are interest-

ing data to be collected. In the recycling phase, data

about the whole manufacturing process is available.

The information about the condition of parts or com-

ponents is also known. This will help to identify parts

that might be available for further use. In this case,

the device should be operating. If that is not possi-

ble, the component where the agent is stored should

be reachable so the information is available. Making

backups in cyberspace during the use phase can be a

solution for situations where the embedded agent is

completely lost.

5 IMPLEMENTATION

To illustrate the concepts mentioned in the previous

sections a device has been chosen that is capable to

play Internet audio streams. For the end-user it will

look like a radio device also know as an Internet radio.

The goal of the work presented here is to embed a

product agent together with the knowledge collected

during manufacturing. The product agent will play

its role in the use phase. It will collect information,

advise the user and display information that can be

helpful in case of repair or maintenance.

5.1 The Internet Radio

The Internet radio adheres to the requirements given

in section 3. It is connected to the Internet, it has com-

puting power available for extra processes and it con-

sists of different components that can be monitored

during use phase, making it a good test case to imple-

ment ideas mentioned in Section 4. The end-user can

also give his or her preferences in the design phase. In

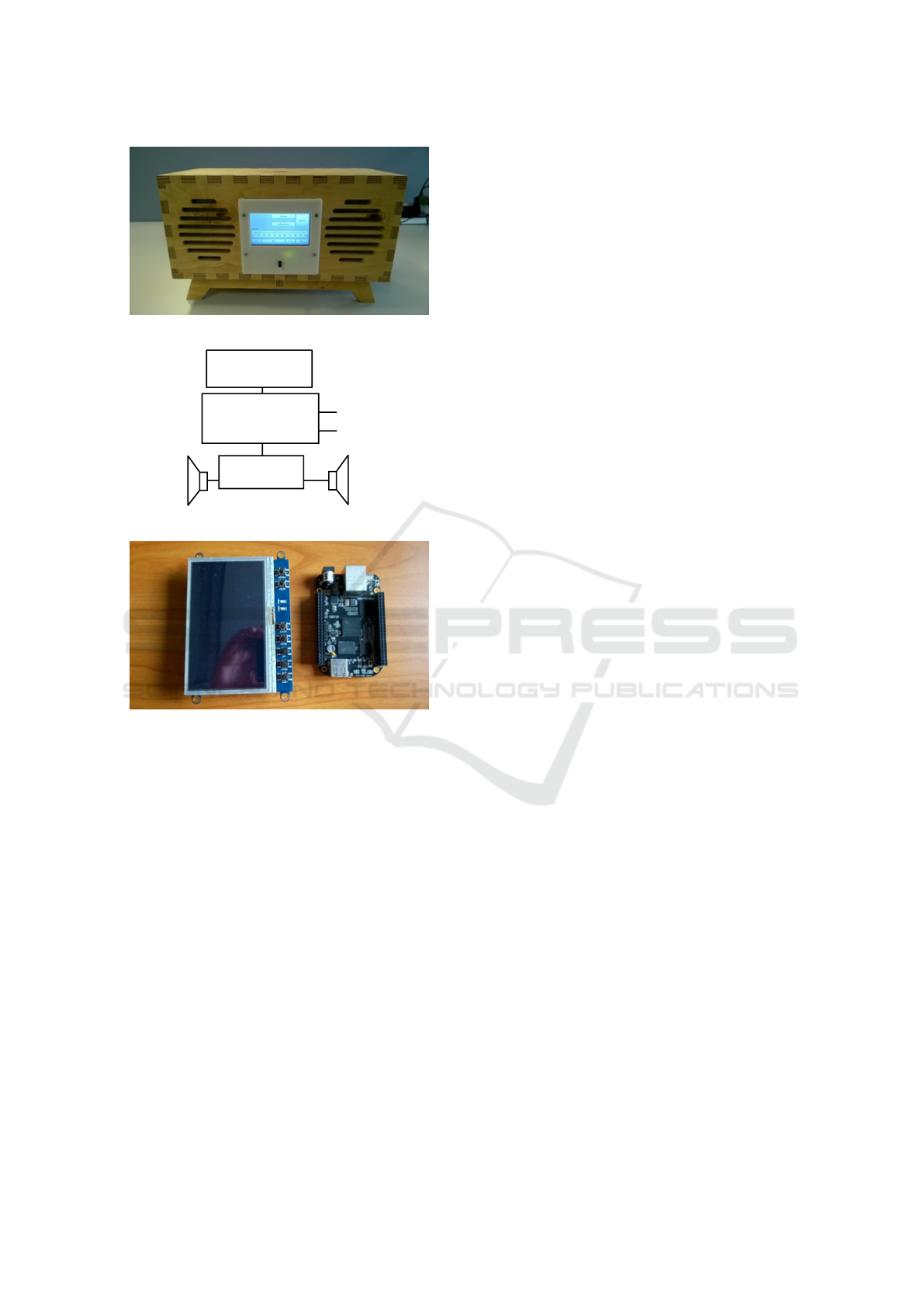

Figure 2, the prototype of the Internet radio is shown.

A block schematic is given in Figure 3. The device

consists of a BeagleBone computerboard, a display,

an audio subsystem connected to an USB-port, speak-

ers and a casing. The main electronic parts are shown

in Figure 4.

ICAART 2016 - 8th International Conference on Agents and Artificial Intelligence

106

Figure 2: Radio.

Main board

(Beaglebone)

USB-Sound

System

power

Internet

Touch-Screen

Figure 3: Radio.

Figure 4: Main electronic parts of the radio.

5.2 XML Description

All information is stored in XML-format. The main

reason for using XML is that it is a widely accepted

open standard. A lot of libraries for many program-

ming environments exist. An alternative could have

been JSON. Some examples of information storage

will be presented in this section. In the design phase a

top-down composition of the radio is given. The radio

consists of six panels (front, back, top, bottom, left

and right) with zero or more attachments. The end-

user can select a shape, resulting in these six panels.

This results in a toplevel XML-file where the radio is

defined to consist of a these six panels in combination

with actions describing how to assemble the radio us-

ing these panels.

<Radio>

<Source>

six panels

</Source>

<Actions>

assembly instructions

</Actions>

</Radio>

Details of the panels themselves should be added.

A small abbreviated part of the XML-file describing

the front panel of the radio looks like:

<Front>

<Source>

<Panel>

info about panel

</Panel>

<Attachments>

<Speakers>

info about position and type

</Speakers>

<Display>

info about display position

</Display>

</Attachments>

</Source>

<Actions>

info about construction

</Actions>

</Front>

The panel info part contains the file used by the

water jet cutter device that was used to construct the

panel and also the material used. An instruction video

or instruction list can be part of the information in the

Actions-section. The components that are attached

to the panel are also included in the Attachments-

section. Again a video instruction or instruction list

in the Actions-section can help to construct the com-

plete part.

What is now available in this file is information

about the parts, the way they are made, the way they

should be combined, in fact the production steps. Af-

ter the manufacturing phase an extended XML-file is

created containing information when it was actually

constructed including the production feedback. The

manufacturing phase consists of a sequence of pro-

duction steps. Every step is carried out by produc-

tion equipment or by human workers. The results of

the steps are collected by the product agent in the ex-

tended XML-file. In the last step the product agent

will be embedded in the product together with all the

information collected so far. At this stage is is also

possible to add information about reversing the pro-

duction steps if possible at all. This information can

be helpful to disassemble the device at the end of its

life cycle or for repair or maintenance.

There are two types of user-specified properties

that will be added to the knowledge base of the prod-

uct agent being the XML-file. The properties that the

Internet of Smart Things - A Study on Embedding Agents and Information in a Device

107

user selected when the design of the radio was made

and the properties the user specifies during its use.

The first type of properties are mostly fixed if it con-

cerns hardware properties, while the second type may

change during use. The shape and colour of the case is

fixed, but settings and preferences controlled by soft-

ware can change. An example of the user preferences

made during design that might alter during usage, is

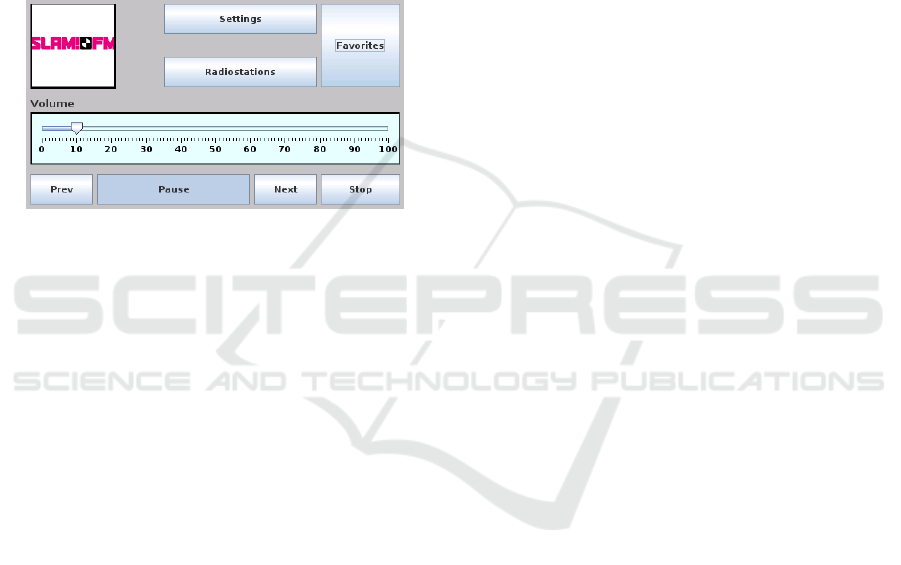

the layout of the control display. In Figure 5 an exam-

ple is given how the display arrangement can be made

by the end-user using a web-interface and generating

an XML-layout file to be used by the GUI software.

This information is also included in the XML-file.

Figure 5: Display and touchscreen.

5.3 Embedding the Product Agent

In the prototype an existing agent platform has been

used. The platform Jade (Bordini et al., 2005) was

chosen for the following reasons:

• Jade is Java-based. Java is a versatile, widely sup-

ported and powerful programming language;

• Because Jade is Java-based it also has a low learn-

ing curve for Java programmers;

• Jade offers possibilities for agents to negotiate. If

we need extra capabilities, the Jade platform can

easily be upgraded to an environment that is es-

pecially designed for BDI agents like 2APL (Das-

tani, 2008) or Jadex (Bordini et al., 2006). Both

2APL as well as Jadex are based on Jade but have

a more steep learning curve for Java developers;

• The Jade runtime environment implements

message-based communication between agents

running on different platforms connected by a

network.

• In Jade, agents can migrate, terminate or new

agents can appear. This feature is important for

the implementation described here.

When information is embedded, the question

arises how much detail should the information give.

In the example of the radio, the electronic heart of the

system is a BeagleBone single board computer. This

computer will be considered as a building block with-

out details about its components like chips, capacitors

and other electronic parts. This could be included in

a separate product agent belonging to the board itself.

If such an agent exists a method of contacting it is the

only thing needed. If there is no such agent available,

the information should be accessible by using Inter-

net technologies in another way. This method can be

used for mass-produced components and prevents the

situation where all this information is replicated.

So far, the radio contains the design and manu-

facturing information as well as the information col-

lected during usage. The list of preferences is ad-

justed to the usage of the device by the end-user. The

information is available to the Internet and can be in-

spected using a web-interface.

6 RELATED WORK

This work started by investigating new manufac-

turing methods as described in (Moergestel et al.,

2011). The agent-based manufacturing opened the

method to preserve the manufacturing information per

product. Agent-based manufacturing has been de-

scribed and developed by Bussmann. In the work

of Bussmann a work-piece agent resembles the prod-

uct agent proposed in our paper. An important dif-

ference is that the work-piece agent ceases to ex-

ist when the product has been made. Among other

work that focusses on agent-based manufacturing, the

work of Paolucci should be mentioned here (Paolucci

and Sacile, 2005), because this work gives a good

overview of the possibilities that arise by using agent

technology. The possibilities of using the agents

in the whole life cycle of the product are described

in (Moergestel et al., 2010). In (Moergestel et al.,

2013) a system is presented that embeds a product

agent in an already complete product that supports re-

pair and reuse of material.

An example of energy saving using multiagent

technology is described by Ruta e.a. (Ruta et al.,

2012). This work has the focus on domotics and

agents play a role in negotiating to lower the energy

usage in a domotic environment. In this case the

agents are not part of the devices themselves as de-

scribed in our paper, but they represent energy con-

suming devices.

7 CONCLUSION

This paper described the possibilities of Internet-

connected devices, when agent technology is added

ICAART 2016 - 8th International Conference on Agents and Artificial Intelligence

108

to make the device a powerful and also versatile com-

ponent in the IoT. Embedding and collecting infor-

mation enables possibilities that will benefit the end-

user as well as the manufacturer and the environment.

It makes the task of data mining more reachable be-

cause the agent can select interesting data and it helps

to improve products. Storing data can be done in

cyberspace as well as in the device itself depending

on the circumstances like internal storage capabilities

and continuous network connection. In the prototype

presented in this paper only a few possibilities are

implemented. In future research, other possibilities

mentioned in this paper should be implemented.

REFERENCES

Ashton, K. (2009). That ’the internet of things’ thing. RFID

Journal, (22 july).

Bordini, N., Dastani, M., Dix, J., and Seghrouchni, A. E. F.

(2005). Multi-Agent Programming. Springer.

Bordini, R., Braubach, L., Dastani, M., Seghrouchni, A.,

and Gomez-Sanz, J. (2006). A survey of programming

languages and platforms for multi-agent systems. The

Free Library.

Burmeister, B., Haddadi, A., and Matylis, G. (1997). Appli-

cation of multi-agent systems in traffic and transporta-

tion. IEEE Proceedings on Software Engineering 144

(1), pages 51-60.

Dastani, M. (2008). 2apl: a practical agent programming

language. Autonomous Agents and Multi-Agent Sys-

tems, 16(3):214–248.

Ian Akyildiz, I., Su, W., Sankarasubramanian, Y., and

Cayirci, E. (2002). A survey on sensor network. IEEE

Communications Magazines, August.

Lilien, G., Kotler, P., and Sridhar Moorthy, K. (2003). Mar-

keting models. Prentice-Hall of India.

Moergestel, L. v., Meyer, J. J. C., Puik, E., and Telgen, D.

(2010). The role of agents in the lifecycle of a product.

CMD 2010 proceedings, pages 28–32.

Moergestel, L. v., Meyer, J. J. C., Puik, E., and Telgen,

D. (2011). Decentralized autonomous-agent-based

infrastructure for agile multiparallel manufacturing.

ISADS 2011 proceedings, pages 281–288.

Moergestel, L. v., Meyer, J. J. C., Puik, E., and Telgen,

D. (2013). Embedded autonomous agents in products

supporting repair and recycling. Proceedings of the

International Symposium on Autonomous Distributed

Systems (ISADS 2013) Mexico City, pages 67–74.

Moergestel, L. v., Meyer, J. J. C., Puik, E., and Telgen, D.

(2015). Implementing manufacturing as a service: A

pull-driven agent-based manufacturing grid. Proceed-

ings of the International Conference on ICT in Edu-

cation, Research and Industrial Applications (ICTERI

2015) Lviv Ukraine, pages 172–187.

Moergestel, L. v., Puik, E., Telgen, D., Folmer, H., Grn-

bauer, M., Proost, R., Veringa, H., and Meyer, J. J. C.

(2014). Enhancing Products by Embedding Agents:

Adding an Agent to a Robot for Monitoring, Mainte-

nance and Disaster Prevention, volume 449 of Com-

munications in Computer and Information Science.

Springer Berlin Heidelberg.

Paolucci, M. and Sacile, R. (2005). Agent-based manufac-

turing and control systems : new agile manufacturing

solutions for achieving peak performance. CRC Press,

Boca Raton, Fla.

Ruta, M., Scioscia, F., Loseto, G., and Di Sciascio, E.

(2012). An agent framework for knowledge-based

homes. Third International Workshop on Agent Tech-

nologies for Energy Systems (ATES 2012). A work-

shop of the Eleventh International Conference on

Autonomous Agents an Multiagent Systems (AAMAS

2012).

Song, J., Song, H., Mok, A., and Chen, D. (2008). Wire-

lesshart: Applying wireless technology in real-time

industrial process control. Symposium on Real-Time

and Embedded Technology and Applications, pages

377–386.

Internet of Smart Things - A Study on Embedding Agents and Information in a Device

109