Phosphor in Glass based on High Refractive Index Glasses for LEDs

Vladimir Aseev, Anastasiya Bibik, Yuliya Tuzova, Elena Kolobkova, Ksenia Moskaleva and

Nikolay Nikonorov

Department of Optical Informatics Technologies and Materials, ITMO University, Birzhevaya Line, 199034,

Saint-Petersburg, Russian Federation

Keywords: Phosphor in Glass, High Refractive Index Glass, White LED, Phosphors, YAG:Ce.

Abstract: Composite “phosphor-in-glass” based on high refractive index lead-silicate glass and YAG:Ce and SiAlON

powder has been developed and synthesized. Glass composition optimization in the order to reduce

scattering at glass/phosphor interfaces has been performed. Samples of composite light-converting materials

for white LEDs were prepared by sintering glass powders and phosphor at 600 °С. Spectral, luminescent

and structural properties of the obtained composites have been investigated. White LEDs based on the

composite glass phosphor materials obtained have been tested. The color temperature of the probe LED was

found to be 4370 K with the luminous efficacy 58lm/W.

1 INTRODUCTION

White light-emitting diodes (LEDs) have attracted

considerable attentions now due to promising

features such as low energy consumption, long

lifetime, small size, fast switching, as mercury free

nonpolluting environment, so have a great

perspective for applications in display backlights,

transport and general lighting, advanced

communication technique, etc. (S. Ye, F. Xiao et al,

(2010), De Clercq et al. (2010)). There are two main

approaches for producing white light with LEDs. In

the first one, white light is generated by additively

mixing of multiple primary color LEDs with a high

luminous efficacy (LE) since there is no Stokes

losses. But the color rendering index (CRI) depends

on the number of selected primary color LEDs that

leads to increase their cost. In the second approach,

white light is generated by single or multiple

phosphors using down-conversion of blue light

pumped from InGaN chip into visible light. For

example, the single yellow Y

3

Al

5

O

12

:Ce phosphor

has already commercially used with blue-emitting

InGaN chip to fabrication low cost phosphor

converted white LEDs (pc-WLEDs). For fixing

powered phosphor on a chip usually use silicone

resins. But these materials are unstable to UV

exposure and temperatures above 150°C.

Degradation of resins result to dramatically

decreasing of WLED efficiency due to induced

absorption (N. Narendran,Y.Gu, J et al. (2004), M.-

H.Chang, et al (2012)).

Inorganic materials, like glasses and ceramics,

are more stable as polymer binders. For instance,

thin transparent ceramic plates based on

Y

3

Al

5

O

12

:Ce used as a phosphor for making WLED

(S. Nishiura, et al. (2011)). But sintering process is

difficult and therefore results in a high cost

ceramics.

2 EXPERIMENTAL

Lead-silicate glasses with different amount of lead

fluoride and aluminum fluoride have been

synthesized (40SiO

2

-20PbO-(40-x)PbF

2

-xAlF

3

, x =

25, 15, 10, 5, 0). Glass have been synthesized from

high purity materials – National Standart 13867-68.

All compounds have been weighted with a high

accuracy (±0.01 g). Glass synthesis has been

provided in electrical furnace with silit heaters at

900 °С for 30 min. Glass synthesis in opened

corundum crucible in air atmosphere provided high

glass quality (primarily, transparancy) and

corresponded to oxidative conditions. Obviously,

glass composition of synthesis has not been matched

with final glass composition because of high fluoride

losses in form of SiF

4

. Effect of fluorides on some

physical properties changing for lead-fluoride-

silicate glasses has been analyzed. Substitution of

248

Aseev, V., Bibik, A., Tuzova, Y., Kolobkova, E., Moskaleva, K. and Nikonorov, N.

Phosphor in Glass based on High Refractive Index Glasses for LEDs.

DOI: 10.5220/0005689502460250

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 248-252

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

lead oxide PbO with lead fluoride PbF

2

results in

increasing of total content of fluorides in glass. Just

after glass moulding, the glass has been quenched

just at 320 °С in muffle furnace.

Introduction of lead fluoride into glass reduces

the glass transition temperature, thereby reducing the

sintering temperature of the samples to prevent

thermal interaction between the components and

experimental phosphor-glass samples sintering,

because interaction between components can lead to

structural failure of the phosphor, whereby it may

lose luminescent properties, or they may be broken.

In the synthesis of the starting glass, a smooth

variation in the refractive index has been produced

by the substitution of lead fluoride to aluminum

fluoride in a number of lead silicate glass matrix

(40SiO

2

-20PbO-(40-x)PbF

2

-xAlF

3

, x = 25, 15, 10, 5,

0). As mentioned, the character of the changes in

refractive index demonstrated in Fig. 1. associated

with a high specific refraction lead ions compared

with aluminum ions.

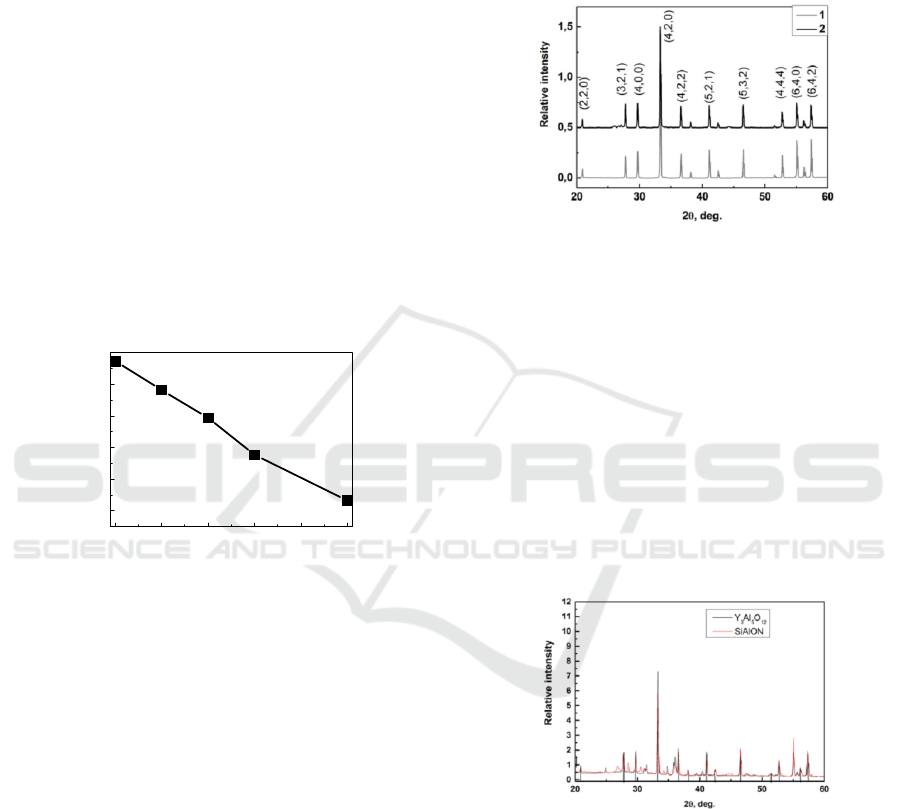

Figure 1: The dependence of the refractive index of the

glass on the aluminium concentration in the system

(40SiO

2

-20PbO- (40-x)PbF

2

-xAlF

3

), x = 25, 15, 10, 5, 0.

Fig.1 shows that increasing of the aluminium

fluoride results in increasing of the refractive index

from 1.82 to 2.08. By varying the ratio of aluminium

it’s possible to achieve full match of the refractive

indices of the crystalline phosphor YAG:Ce

3+

and

the glass matrix. In this case, a refractive index of

1.83 of glass, which coincides with the refractive

index of the YAG:Ce

3+

, is achieved when the

content of aluminium fluoride is about 5 mol. %.

One of the requirements for glass frit is the lack of

interaction with the crystalline phosphor powder of

YAG:Ce

3+

during sintering. This is due to the fact

that the broad band luminescence of cerium in the

yellow-green region of the transition member 5d -

4f, and its intensity depends strongly on the

surrounding structure. Cerium, which is in the

structure of garnet (Y

3

Al

5

O

12

) has one of the most

efficient luminescence bands and garnet structure

modification results in decreasing of the

luminescence intensity. The "phosphor in the glass"

sample has been investigated by X-ray analysis to

find out, has the interaction of the crystal structure

of garnet composite been broken not. For

comparison, the spectrum of the starting YAG:Ce

3+

powder is added (Fig. 2).

Figure 2: The powder XRD pattern of the crystal

Y

3

Al

5

O

12

:Ce (1) and composite "phosphor in glass" (2).

The XRD-curve shows that the peak position

coincides in any matrix that indicates the presence of

the same crystal phase Y

3

Al

5

O

12

. The difference in

the intensity of the peaks indicates a different

volume of the crystalline phase in the samples.

To show that the crystal structure of the garnet

has not broken, when added red phosphor powder

based on the oxynitride into the "phosphor in glass"

sample – the sample was investigated by X-ray

analysis. Figure 3 shows the X-ray diffraction for the

"phosphor in glass" with SiAlON and heat-treated

sample of the same composition.

Figure 3: The powder XRD pattern of the pure crystal

Y

3

Al

5

O

12

:Ce powder (black) and composite "phosphor in

glass" with SiAlON (red).

XRD-curve shows that the peak position

coincides in any matrix that indicates the presence of

the same crystal phase of Y

3

Al

5

O

12

. Adding in the

SiAlON composition does not affect on the structure

of the Y

3

Al

5

O

12

under heat treatment.

0 5 10 15 20 25

1,80

1,85

1,90

1,95

2,00

2,05

Refractive index

Concentration of AlF

3

, mol.%

Phosphor in Glass based on High Refractive Index Glasses for LEDs

249

3 RESULT AND DISCUSSION

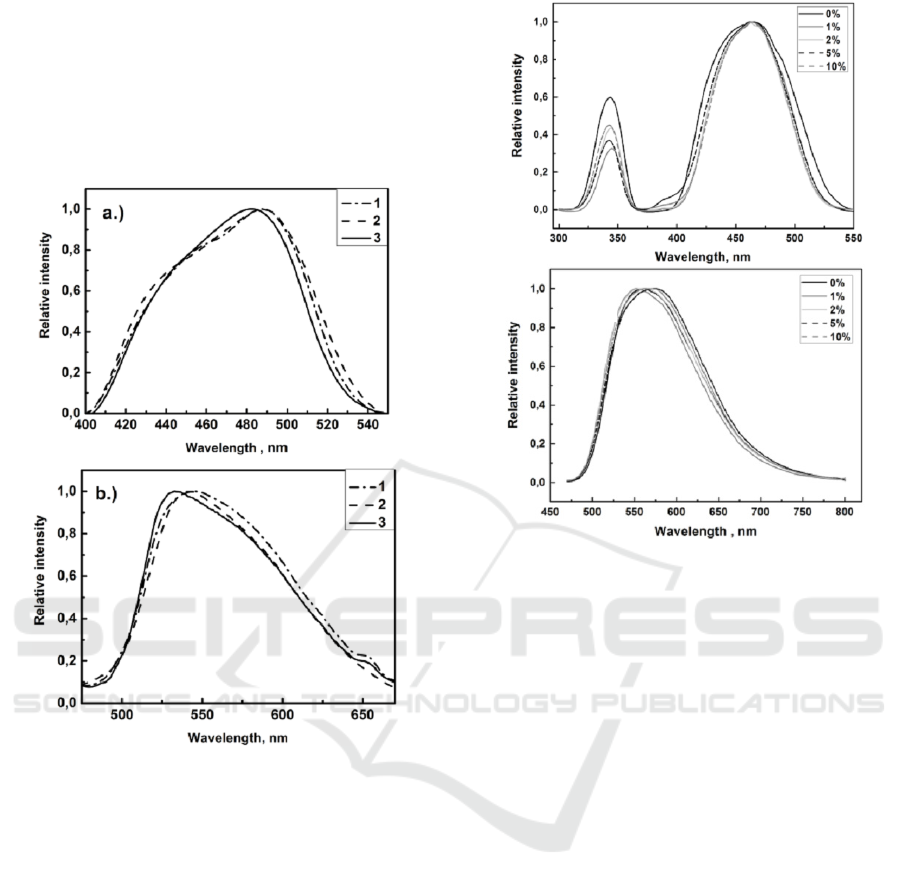

Let us compare the excitation spectra (Fig. 4a) and

luminescence spectra (Fig. 4b) of origin crystal

powder of YAG: Ce

3+

with the spectra of YAG: Ce

3+

in different matrices: commercial silicone and

developed PiG.

Figure 4: The excitation spectrum (a) and luminescence

spectrum (b) of origin powder of YAG: Ce

3+

(1), the

composite "phosphor in glass" (2) "phosphor in the

polymer" (3).

Fig. 4 shows that the shape of the spectrums is

almost constant from the buffer composition of the

binder material. These results also indicate that

significant interaction between glass and crystalline

phases does not occur during all period of sintering.

The spectral-luminescent analysis of sintered

samples "phosphor in glass" with two phosphors in

its composition was held.

Figure 5 shows the results of spectrum’s

measurements of composites with varying contents

of phosphors. The curves of luminescence and

excitation for samples with two phosphors in their

composition represent the cumulative spectrums of

radiation from two phosphors, which are yellow and

red.

Figure 5: The excitation spectrum (a) and luminescence

spectrum (b) of "phosphor in glass" with the different

content of SiAlON 10%, 5%, 2%, 1% and 0%.

According to figure 5, it is clear that the shape of

spectrums does not practically change in dependence

on the composition of buffer binder material. This

fact proves that significant interaction between glass

and crystalline phases does not occur during

sintering. In addition, figure 5 shows the possibility

of modifying the spectral composition of radiation,

by changing the ratio in YAG:Ce /SiAlON - glass

composites. By picking up the required ratio, it is

possible to get different values of color temperatures

and color rendering indexes of white light, that

corresponding to high-quality requirements. To find

out how the radiation intensity of the LED is altering

in dependence on different excitation wavelengths,

the dependence of values of quantum yields on

excitation wavelength for samples “phosphor in

silicone” and “phosphor in glass” were measured.

The resulting dependencies are presented in figure 6.

That graph is illustrated that the variety of quantum

yield’s positions in the measured range of

wavelengths, which include wavelengths from 440

to 470 nm for samples based on silicone and glass

are the same and amounts to 1.5%.

a.)

b.)

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

250

Figure 6: The comparison between the dependencies

quantum yields from the excitation wavelengths for

samples "phosphor in silicone" (1) and "phosphor in the

glass" (2).

The value of the quantum yields varies

accordingly in the range of 97.3 - 98.9% for the

silicon sample, and 90.7 - 92.2% for the sample of

the phosphor in the glass. The difference in the

magnitude of values may be associated with defects

of production technology. The resulting composite

contains inclusions that make additional acquisitions

that may reduce the value of quantum yield.

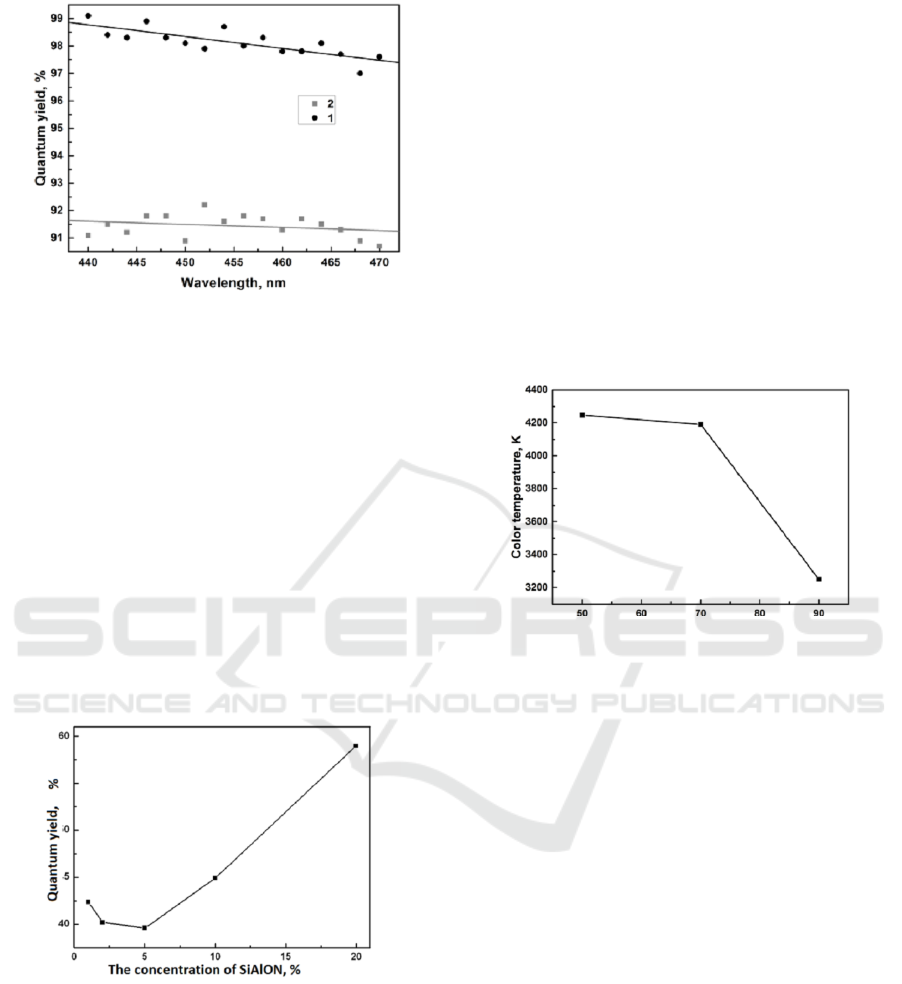

To see possible values of quantum yield for

composites with red phosphor in their composition,

the dependence of quantum yield of the radiation

from the composition of samples was measured. The

results of measurement are presented in figure 7.

Figure 7: The dependence of the values of quantum yield

from composition of samples "phosphor in glass" with

different content of the SiAlON phosphor.

The highest value of quantum yield (59%) refers

to the synthesizing sample with the content of

SiAlON 20%. The standard silicone composite used

in the manufacture of white LEDs has a higher value

of quantum yield - about 96%. Such a reduction in

the quantum yield’s value associated with the

molecular interaction between the components of

glass charge and phosphor’s powder, because the

brightness and the chromaticity does not change

significantly in the process of temperature impact

due to thermal stability of their crystal structure.

That happens through the some components of

charge during sintering destroy the structure of

oxynitride and forms compounds, which strongly

absorbs excitation radiation. The light sources used

for household lighting should have a warm white

light, characterized by a color temperature in the

range of 3500 K and 6,000 K. For radiation, given

by the model of white LED, which includes samples

of "phosphor in glass", the color temperatures

(calculated by the program using the obtained

spectrums) were measured. The results of the

calculations are presented in figure 8.

Figure 8: The dependence of color temperature from the

phosphor’s concentration.

According to the research results, presented in

figure 8 it is clear that the type of dependence of

color temperatures from the phosphor concentration

in mixture is of exponential nature. Next, the

effectiveness of the obtained layout of the led with

the ratio of the phosphor powder to glass 70:30 was

measured. The resulting layout of the led emits

radiation of white light with a color temperature of

4200 K. Luminous efficacy of radiation amounted to

58 lumens/watt. Values for traditional LEDs with

silicone are about 85 Lm/W at a comparable color

temperature. Also, simultaneously with the

calculation of the color temperatures the color

rendering indexes of phosphors emission were

calculated. For samples consisting of one type of the

phosphor the values lie in the range of 62 – 65 %.

For samples with two phosphors index value

increases in comparison with previous sample and

lies in the range of 75-78 %. This confirms that the

addition of the red phosphor in the composition

allows improving the color characteristics.

Concentration of the YAG powder in sample, %

Phosphor in Glass based on High Refractive Index Glasses for LEDs

251

4 CONCLUSIONS

The spectral and luminescent properties of PiG

(phosphor-in-glass) samples have been investigated

to define the relationships between light conversion

efficiency, composition and structures. Optical

properties of the phosphor have been investigated. It

was shown that the optical properties of WLED

based of such material can be easily adjusted by

changing thickness of phosphor, ratio of glass to

phosphor.

ACKNOWLEDGEMENTS

This work was financially supported by Russian

Scientific Foundation (Agreement # 14-23-00136).

REFERENCES

N. Narendran,Y.Gu, J.P. Freyssinier, H.Yu, and L.Deng,

2004. J. Cryst. Growth 268, 449.

M.-H.Chang, D. Das, P.V.Varde, and M.Pecht, 2012.

Mircoelectron. Reliab. 52, 762.

S. Nishiura, S. Tanabe, K. Fujioka, and Y. Fujimoto, 2011.

Opt. Mater. 33(5), 688–691.

S. Ye, F. Xiao et al, 2010. Materials Science and

Engineering, R71, 1–34.

De Clercq, John, et al, 2010. US patent application

20100001648.

Park, Joo-Seok, et al., 2010 US patent application

20100163896.

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

252