A Simulation-based Methodology to Test and Assess

Designs of Mechatronic Neural Interface Systems

Samuel Bustamante

1

, Juan C. Yepes

1,2

, Vera Z. P

´

erez

2

and Julio C. Correa

1

1

Grupo de Autom

´

atica y Dise

˜

no A+D, Facultad de Ingenier

´

ıa Mec

´

anica,

Universidad Pontificia Bolivariana, Cir. 1 #73-76, B22C, Medell

´

ın, Colombia

2

Grupo de Investigaciones en Bioingenier

´

ıa, Facultad de Ingenier

´

ıa El

´

ectrica y Electr

´

onica,

Universidad Pontificia Bolivariana, Cir. 1 #73-76, B22C, Medell

´

ın, Colombia

Keywords:

Methodology, Neural Interface Systems, Surface Electromyography, Upper Limb Prostheses, Rehabilitation,

Signal Processing, Myoelectric Control.

Abstract:

Neural interface systems (NISs) are widely used in rehabilitation and upper limb prosthetics. These systems

usually involve robots, such as robotic exoskeletons or electric arms, as terminal devices. We propose a

methodology to assess the feasibility of implementing these kind of neural interfaces by means of an online

kinematic simulation of the robot. It allows the researcher or developer to make tests and improve the design

of the mechatronic devices when they have not been built yet or are not available. Moreover, it may be used

in biofeedback applications for rehabilitation. The simulation makes use of the CAD model of the robot, its

Denavit–Hartenberg parameters, and biosignals recorded from a human being. The proposed methodology

was tested using surface electromyography signals acquired from the upper limb of a 25-year-old healthy

male. Both real-time and prerecorded signals were used. The robot simulated was the commercial robotic arm

KUKA KR6. The tests proved that the online simulation can be effectively implemented and controlled by

means of a biosignal.

1 INTRODUCTION

In 2011, the World Health Organization reported that

there were about one billion people worldwide with

some type of disability (World Health Organization,

2011). In the European Union, almost 45 million peo-

ple aged between 15 and 64 years reportedly had a

disability around that same year, which corresponds

to 14.1% of that age group (Eurostat, 2014). In the

United States of America, approximately 1.7 million

people had an amputation in 2008 (National Limb

Loss Center Information, 2008). Ziegler et al. esti-

mated that each year there are 185,000 new amputees

of an upper or lower limb. They also presented an esti-

mation of 3.6 million of people living with the loss of

a limb by the year 2050 (Ziegler-Graham et al., 2008).

Continuous search for engineering solutions with

the purpose of helping people experiencing physi-

cal disabilities or suffering deficit on the expression

of cognitive experiences, has led to the development

of artificial neural interfaces (Garc

´

ıa Quiroz et al.,

2007). Furthermore, the research to develop sys-

tems to help and assist restoration of sensory function,

communication and control to impaired humans has

brought new branches of experimental neuroscience

such as neural prostheses, neural interface systems

(NISs) and brain-machine interfaces (BMIs) (Hat-

sopoulos and Donoghue, 2009).

NISs are considered bidirectional transduction

systems that enable the direct contact between a de-

vice and a neurological structure. They are composed

of electrodes (or sensors), cables, data acquisition cir-

cuitry, and an effector system control unit (Garc

´

ıa

Quiroz et al., 2007). The main goal of NISs research

is to connect the nervous system to the outside world.

This connection can be achieved either by stimulat-

ing or by recording electric activity from neural tis-

sue to treat or to assist people with motor, sensory

or other neuronal function disabilities. The systems

that record electric activity from the neural tissues

are called output NISs, and are now migrating from

research proof of concepts and pilot human clinical

trials to useful devices (Hatsopoulos and Donoghue,

2009). Some of the most studied devices are neural

prostheses, exoskeletons and telemetry robots (Garc

´

ıa

Quiroz et al., 2007).

Robotic devices, therefore, can be used to improve

the quality of life of human beings. Some of these

78

Bustamante, S., Yepes, J., Pérez, V. and Correa, J.

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems.

DOI: 10.5220/0005698200780087

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 4: BIOSIGNALS, pages 78-87

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

robots can be considered robotic arms, and are similar

to serial manipulators. These devices consist of open-

loop kinematic chains, i.e., open-loop assemblies of

rigid bodies (links) connected by joints (Tsai, 1999).

Exoskeletons with three degrees of freedom are ex-

amples of these kind of robots.

The scope of this paper is to present a four-step

methodology that can be used to test a neural inter-

face system (NIS) in which the movement of robots

is controlled by means of a biosignal. The purpose is

to apply this technology in the future, specifically to

the design of robotic exoskeletons for rehabilitation

and robotic upper limb prostheses. The methodology

uses a kinematic simulation of a robot, which is use-

ful to test and discuss trajectories, movements, design

parameters, and any characteristic of the mechatronic

device the researcher may need to check without hav-

ing an actual robot available. For instance, it can be

used to support the design of a new robotic prosthe-

sis. As simulation is a part of the NIS itself, it may

be completely controlled by prerecorded or real-time

biosignals acquired from a human being.

The first step of the proposed methodology con-

sist of the development of a kinematic simulation of a

robot using its CAD model and Denavit–Hartenberg

(D-H) parameters. That kinematic simulation may

be implemented on any programming environment

that allows communication protocols, such as Octave,

Python or Matlab. Given that the access to these envi-

ronments is relatively easy inside the academic com-

munity, the simulation can be considered low-cost.

The simulated robot is expected to be a serial ma-

nipulator, otherwise the D-H nomenclature can not be

used and therefore the kinematic models used can not

be applied.

The second step consists of acquiring and process-

ing the biosignals of the neural interface being tested,

obtaining the inputs of the simulation. The third step

is to develop tests with prerecorded signals, which is

useful to debug and refine different parameters of the

models. By last, the fourth step is to establish real-

time communication between the simulation and the

acquired biosignal, making the neural interface work

with the simulation the same way it would with a built

and working robot.

To validate the methodology, the commercial se-

rial manipulator KUKA KR6, a robotic arm available

at our laboratories, was simulated and controlled by a

25-year-old healthy male through surface electromyo-

graphy (sEMG). Some devices like upper limb pros-

theses use sEMG signals as control commands, and

although these systems are simple they can be con-

sidered neural interfaces (Schultz and Kuiken, 2011).

The results of the tests with prerecorded signals and

in real-time determined that the online simulation can

be effectively implemented. Thus, it may be useful in

the fields of rehabilitation and upper limb prosthetics.

This paper is presented as follows. Section 2 ex-

plains the proposed methodology with a wide descrip-

tion of each step. Section 3 shows results of the appli-

cation of the methodology with the commercial robot

and sEMG signals, presenting a discussion in Sub-

section 3.5. Finally, section 4 presents the conclu-

sions regarding possible applications of the proposed

methodology.

2 PROPOSED METHODOLOGY

In this section, the four steps of the previously intro-

duced methodology to assess the feasibility of imple-

menting a neural interface are presented.

2.1 Simulation of the Kinematics of a

Robot

The purpose of this subsection is to give a brief guide

on how to build a simulation of a robot in a program-

ming environment. An example is given in Subsec-

tion 3.1.

As mentioned before, the simulation uses the

CAD model and the D-H parameters of a serial ma-

nipulator. The D-H parameters of a serial robot re-

fer to the notation introduced in 1955 by Jacques De-

navit and Richard Hartenberg to describe the geome-

try of a serial chain of links and joints (Corke, 2011).

Although a complete description of the D-H notation

will not be presented in this document, the reader can

refer to any robotics text for more information. A

simple and systematic methodology to assign the D-H

parameters is presented in (Corke, 2007), where more

information of the kinematic models described below

can be found. We also recommend the detailed de-

scription proposed in section 3.1 of (Crane and Duffy,

1998). The notation presented here is the same as in

that document: The parameters s

i

, θ

i

, a

i j

and α

i j

rep-

resent respectively the joint offset distances, the joint

angles, the link lengths, and the twist angles of the

robot.

The CAD model of the robot has to be obtained

in STL format. A STL file is a representation of a

solid object using small facets, similar to Finite Ele-

ment Analysis (FEA) meshes. Each triangular facet

is explicitly defined in the file by a normal vector and

its three vertices (Hon Wah, 1999). The user must ob-

tain an STL file for each mechanical link of the serial

manipulator. Files of additional details, such as mo-

tors or wires, can also be used. Considering that an

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems

79

STL file is essentially a text file, it can be easily im-

ported into the computer programming environment

used. There, the vertices can be extracted and plotted

using functions for filling polygons.

The plot of all the facets shows a 3D representa-

tion of the serial manipulator as if it was inside a CAD

environment. Moreover, movement can be given to

the model: all the vertices of each part of the robot

constitute a cloud of points, susceptible to a homoge-

neous spatial transformation, such as a rotation or a

translation. Each transformation consist of a 4x4 ma-

trix that maps a homogeneous position vector from

one coordinate system into another (Tsai, 1999). As-

suming that the robot will move through multi-point

trajectories, transformation matrices for the cloud of

points of each part of the robot must be defined for

each individual step of the trajectory. The user will

obtain new clouds of points that, when plotted using

the same functions as before, will show the robot in

new positions. If multiple plots are made, the move-

ment of the robot will be shown in different frames

through time, as in an animation. Hence, with the use

of these mathematical tools the kinematics of the 3D

model of an entire robot can be simulated.

Recall that, in order to apply the procedure de-

scribed above, the position of each point of each piece

of the robot has to be measured in reference to its lo-

cal origin. However, when the STL file of the robot

is imported and plotted, the device appears in the po-

sition it was assembled in the CAD software, and all

of its points are measured with reference to the ab-

solute origin in the base of the robot instead of their

respective local frame. For that reason, a previous

step in the process is to apply the inverse kinematic

analysis, which is the process of finding the joint an-

gles that satisfy a given position and orientation of

the end-effector (Fu et al., 1987), along with inverse

transform matrices to restore each of the pieces of the

robot to its local origin. The inverse kinematics of

a serial manipulator are not straightforward, and the

mathematics vary with each device in particular.

Up to this point, it can be generated a 3D sim-

ulation of the actual movement of the robot moving

smoothly through the demanded positions and fol-

lowing specific trajectories demanded by the user. It

is important during the simulation process to test the

kinematics of the robot: The user can define a trajec-

tory of their interest and perform a simulation. This

desired trajectory can be either of the joints of the

robot (direct analysis) or of its end-effector (inverse

analysis).

The last task of this step in the methodology is the

creation of a simplified model of the robot. It simu-

lates with straight lines the moving parts of the robot,

i.e., the mechanical links. The cloud of points of each

part, hence, only has two points, representing the start

and the end of the part. Both the direct and the in-

verse kinematic analysis previously discussed can be

applied to the simplified models as well. This is im-

portant due to the fact that the simulation of the CAD

model may include many details, and the computa-

tional resources required to run it in real-time appli-

cations are very high. Thus, the simplified model can

facilitate the analysis of the performance of the sys-

tem. However, if the user has a very high computa-

tional resource it is still possible to use the complete

CAD model in real-time applications. In that way the

interaction with the system will be very realistic. If in-

stead the user has a conventional office computer, we

strongly recommend the use of the simplified model.

In this way, the methodology can be used by any re-

searcher almost independently of the computational

resources available.

It is important to note that a kinematic simulation

of a serial manipulator in a programming environment

using its CAD model was first presented in (Correa

et al., 2010).

2.2 Signal Acquisition, Processing and

Control Algorithms

Biosignals obtained from tests such as electroen-

cephalogram (EEG), electrocardiogram (ECG), elec-

trooculogram (EOG) or electromyogram (EMG) can

be monitored and measured from human bodies.

In order to integrate the kinematic models and the

biosignals into a NISs, a signal acquisition device, a

signal processing algorithm and a control algorithm

must be used.

The idea of the signal acquisition device is to ac-

quire the biosignals for the NIS. For the purpose of

the present methodology, this device must be able to

record signals in a database and to allow their process-

ing in real-time inside the programming environment

being used.

The sensors or electrodes should be connected to

the device and located either on a healthy person or on

a patient. This process must be developed according

to the parameters given by international standards and

recommendations for acquiring each specific signal.

The tasks of this steps are the following: First, the

user must record in a database all the signals needed

to test the NIS. This could be done either in the soft-

ware provided by the manufacturer of the acquisition

device or in a custom made developed software.

Subsequently, the biosignals must be imported in

the computational programming environment being

used. Then, they should be processed, using one or

BIOSIGNALS 2016 - 9th International Conference on Bio-inspired Systems and Signal Processing

80

more signal processing algorithms reported in the lit-

erature to develop feature extraction or classification

(Merletti and Parker, 2004), such as filters, amplifiers,

envelope detectors (Lenzi et al., 2012), peak detec-

tors, artificial neural networks (Wojtczak et al., 2009),

wavelets (Lucas et al., 2008), Hilbert Huang trans-

form (Revilla et al., 2013) Kalman Filters (Delis et al.,

2006; Kyrylova et al., 2014), and others. These signal

processing algorithms should be selected in order to

fulfill the requirements of the NISs to be tested, either

to enhance the signal, detect the intended movement

of human joints, detect human gestures, and so on.

Finally, in order to control the movement of the

joints or the end-effector of the kinematic model,

a control algorithm must be developed in the pro-

gramming environment used. It could be a classic

or modern algorithm; some examples of them are

PID controllers (Pan et al., 2015), Neuro-Fuzzy Con-

trol (Kiguchi et al., 2004), Computed Torque Control

(Lasso et al., 2010), among others. The processed

biosignals must be integrated with the control algo-

rithm in order to move the kinematic model as desired

in the real NIS.

2.3 Tests with Prerecorded Signals

A test with prerecorded biosignals is very useful be-

fore proceeding with actual real-time signals, because

it allows the user to check if different elements of the

NIS are working properly.

These tests are also useful to check trajectories

and discuss design parameters of the moving robot.

It is suggested to record several trials with different

characteristics, simulating diverse real-life scenarios.

If the simulation shows a good behavior, the real-time

montage can be implemented. That is stage 4.

2.4 Tests with Real-time Signals

In this step, the signals must be acquired in real-time

using the biosignal acquisition device. This device

must transmit continuously each sample to the pro-

gramming environment. The transmission of the data

can be either wired or wireless, but the latency of the

transmission must be lower than the sample time and

the signal processing time, so that it does not affect

the algorithms and the whole NIS. Control systems

should not create delays perceivable by the user dur-

ing the operation. There are also reports of real-time

constrains on myoelectric control systems when hav-

ing smooth and continuous controls (Asghari Oskoei

and Hu, 2007).

Each sample must be processed in real-time with

a signal processing algorithm similar to the algorithm

evaluated before in the non-real-time tests. The out-

put of the real-time signal processing algorithm, must

interact with the control algorithm to compute the

movement of the robot.

As explained in Subsection 2.1, to maintain the

proposed methodology low-cost, it is recommended

to develop this step with the simplified model of the

robot rather than with the 3D model of the entire

robot, due to the high computational resources needed

with the complete model. In these tests, many vari-

ables of the NIS can be analyzed such as the working

range, specified movements, delays, and so on. If the

simulation of the robot behaves in the way the user

pretends, the NIS can be developed to further stages.

3 EXPERIMENTS AND RESULTS

In this section, we present the experiments performed

to test the methodology, and the results obtained.

The methodology proposed in Section 2 was ap-

plied to a prosthetic-like neural interface consisting

of the control of a KUKA KR6 robot by means of the

sEMG signals of a 25-year-old healthy male. The rea-

son we chose this particular robot is because an actual

prototype is available at our laboratories, and the fol-

lowing step of the global project after the testing stage

is to implement the NIS so that myoelectric control of

the real robot can be achieved.

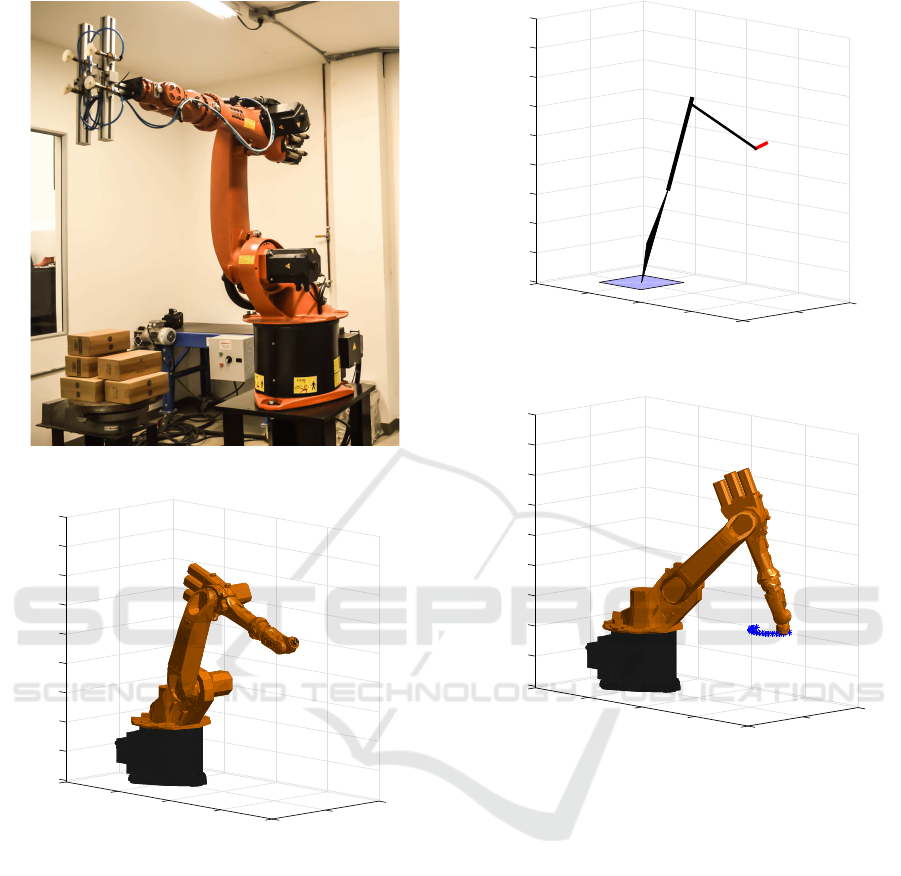

An image of a commercial robotic arm KUKA

KR6 is shown in Figure 1. This robot has six de-

grees of freedom and a spherical workspace, and its

D-H parameters are cited in Table 1. Since all of the

joints of the KUKA KR6 are revolute joints, the time-

dependent variable θ

i

, in degrees, is the variable that

represents the input of the actuators of the robot.

Table 1: Denavit–Hartenberg parameters of the KUKA

KR6 robot, obtained from (Yepes et al., 2013).

Frame α

i j

(°) a

i j

(mm) s

i

(mm)

1 180 0 -675

2 90 260 0

3 0 680 0

4 -90 35 -670

5 90 0 0

6 -90 0 -115

3.1 Simulation of the Kinematics of the

KUKA KR6

The CAD model of the robot was obtained and suc-

cessfully imported in a computer programming envi-

ronment trough the procedure described in Subsection

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems

81

Figure 1: Commercial robotic arm KUKA KR6.

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

1000

1200

1400

1600

1800

0

200

400

600

800

-500

Z (mm)

Figure 2: 3D simulation of the KUKA KR6.

2.1. The 3D model obtained is shown in Figure 2. The

quality of the shape and the details can be set when

the STL file is exported in a CAD environment such

as Solid Edge or Solid Works. Depending on the com-

putational power available, less details mean a faster

simulation.

A simplified model of the robot was created as

well, in order to optimize real-time tests. This model

is shown in Figure 3. Excepting the base of the robot,

each link consists only of two points. The plot, in-

side the programming environment used, facilitated

the creation of straight lines between the points. The

red line is the end-effector. Recall that the robot is in

the same spatial position in Figures 2 and 3.

A kinematic test was performed in order to debug

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

200

400

600

800

1600

1400

1200

1000

1800

0

-500

Z (mm)

Figure 3: Simplified simulation of the KUKA KR6.

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

0

200

400

600

800

1000

1200

1400

1600

1800

-500

Z (mm)

Figure 4: Circular path executed by the simulated robot.

and validate the kinematic models. The task was to

make the end-effector of the simulated robot to follow

smoothly a circular trajectory. As showed in Figure 4,

the simulation performed the task correctly. The com-

putational model of the robot was hence validated.

3.2 Biosignal Acquisition, Processing

and Control Algorithms

EMG has been widely used in physical rehabilitation

systems and in upper limb prosthetics. There are two

methods to obtain EMG signals: surface electromyo-

graphy (sEMG) and intramuscular electromyography

(iEMG). In the first, electrodes are respectively at-

tached to the user skin, and in the latter they are in-

serted through the skin (Mon and Al-Jumaily, 2013).

sEMG signals have been effectively used in pros-

theses control systems (Merletti and Parker, 2004).

Therefore, sEMG signals were used to test the pro-

BIOSIGNALS 2016 - 9th International Conference on Bio-inspired Systems and Signal Processing

82

posed methodology.

The sensors, sensor placement and signal process-

ing methods to acquire and record sEMG signals were

based on some of the recommendations of the SE-

NIAM project (The Seniam Project, ). According to

ISEK Standards for Reporting EMG Data (Merletti,

1999) the characteristics of the procedure are shown:

The raw signal was detected using three pairs of

10-mm commercial, disposable and adhesive gel sur-

face electrodes placed in different parts of the forearm

of a healthy 25-year-old subject, along with a refer-

ence electrode located at the elbow. The electrodes

had a disc shape, an area of 3.48 sq cm, and were

made in silver-chloride. They were placed with a

inter-electrode distance of approximately 2 cm (center

point to center point) at the following muscles in order

to detect flexion and pronation (Florimond, 2010):

• Biceps brachii, detecting activation when the el-

bow joint was flexed.

• Brachioradialis, detecting activation when the

wrist pronation occured.

• Flexor carpi radialis, detecting activation when

the wrist joint was flexed.

The electrodes were placed in parallel to the mus-

cle fiber direction using the dominant middle portion

of the muscle belly for best selectivity and avoiding

the region of motor points. The signal was acquired

using an 8 channel low-cost sEMG signal acquisition

device designed and developed in our research labs.

The device has a differential configuration, an input

impedance of 10 kΩ, a signal-to-noise ratio (SNR)

of 112 dB and it was configured with a gain of 12.

The biosignal was sampled at 1 kHz. The low-cost

sEMG signal acquisition device transmitted the signal

through a serial port to a PC, and the programming en-

vironment used, recorded or captured in real-time all

three differential channels. The signals were obtained

one at the time, and they were normalized to the range

of (-1, 1).

Subsequently, the signal was rectified with Root

Mean Square (RMS) and it was converted into an am-

plitude envelope as presented in the literature (Mon

and Al-Jumaily, 2013). The RMS was calculated one

value at the time using the equation

RMS

emg

(n) =

s

1

n

∗

n

∑

s=1

sEMG(s)

2

, (1)

where sEMG(s) represents the amplitude estimation

(Ruiz et al., 2009) of the signal in the sth sample and

n is the total number of samples in a window from

the vector of the signal. The window used was 0.01

seconds, meaning each window had 10 samples. The

signal was not filtered again in the computational soft-

ware, but the RMS curve was normalized in the range

of (0, 1) so it could be useful in the procedure de-

scribed below.

The Normalized RMS curve of the sEMG was the

input of the kinematic analysis, in order to move the

model of the robot when the subject intended to move

his arm. From this resulting signal, labeled as input,

it was calculated the value of the position of the ma-

nipulator’s joints by means of a linear transformation.

In order to achieve this, each of the muscles, and cor-

respondent movements, were related to three joints of

the kinematic model of the KUKA KR6 serial manip-

ulator.

In order to test the proposed methodology, a sim-

plified EMG-based assistive control algorithm was

implemented. The mathematical relation was defined

so that the robot would move whenever the muscle

was activated, and in a proportional way to the ampli-

tude of the sEMG signal. If the muscle was not acti-

vated, the robot would not move from its home posi-

tion. When there was a muscle activation, the model

would change its position in a proportional way. This

movement was done inside the robot position limits,

meaning (0) the home position and (1) a custom po-

sition close to the maximum angle of the joint with a

comfortable safety distance.

The direct kinematic analysis was then effectuated

and the movement of the robot was displayed in the

screen using the D-H parameters. It was established

that joints 1, 2 and 6 were going to be immobile in

the home position of the robot (0

◦

, −90

◦

and 0

◦

re-

spectively). This indicates that the kinematic model

of the robot was used with only three joints, meaning

a 3 degrees of freedom (3-DOF) manipulator.

For the elbow flexion, the normalized RMS of the

biceps brachii signal, labeled as input3, was associ-

ated to the joint three of the kinematic model. The

maximum and minimum angles for this joint were set

to 220

◦

and 180

◦

respectively, and the angle of the

the joint three

θ

3

= 220 − 40 × input3 (2)

was computed from the input signal. For the wrist

flexion, the normalized RMS of the flexor carpi radi-

alis signals, input5, the maximum angles were set to

0

◦

and −45

◦

, and the angle of the the joint five

θ

5

= −45 × input5 (3)

was computed from the input signal. By last, for the

wrist pronation, the normalized RMS of the brachio-

radialis signals, input4, the maximum angles were set

to 0

◦

and 90

◦

, and the angle of the the joint four

θ

4

= 90 × input4 (4)

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems

83

was computed from the input signal. This means that,

if the amplitude envelope of each input was small or

null (0), each joint of the kinematic model was close

to the home position, and if the amplitude envelope of

each input was big or maximum (1), each joint of the

kinematic model was close the maximum angle. As

the tests were performed with only one signal and its

corresponding joint at the time, the other two joints

were set at an arbitrary position.

3.3 Testing using Pre-recorded Signals

sEMG signals were recorded from the subject during

three trials of 20 seconds using the procedures pre-

sented in section 3.2. On each trial the subject was

told to perform movements in order to detect activa-

tion of each of the three muscles described. On the

first trial, he was told to flex his elbow two times. On

the second trial, he was told to pronate his wrist four

times. And on the third trial, he was told to flex his

wrist three times. Muscle activation was measurable

when these movements happened.

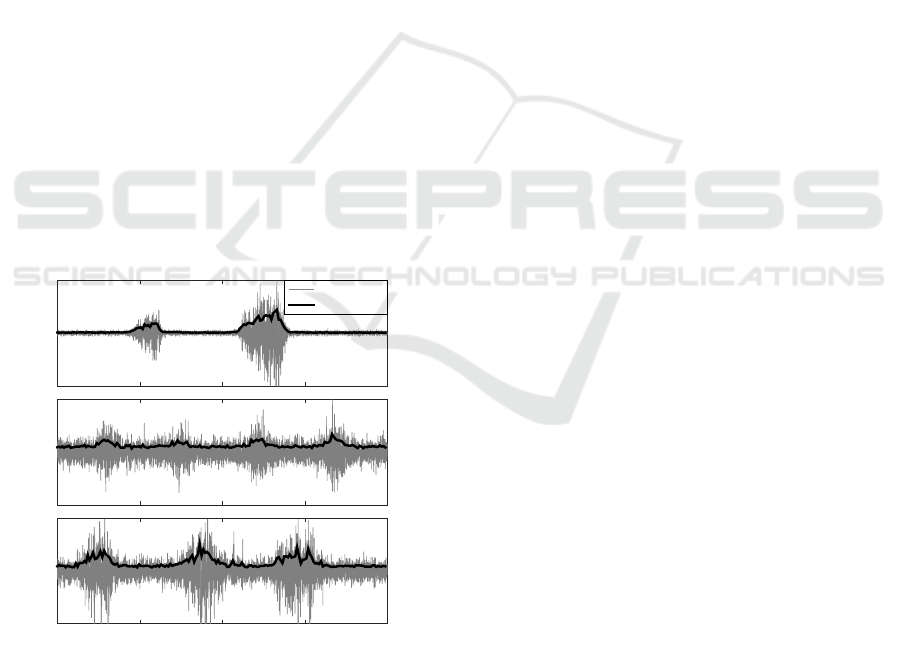

The sEMG signals obtained from each muscle and

their RMS values are shown in Figure 5. It is impor-

tant to remark that the results in this Figure are shown

before the RMS value was normalized and introduced

in the kinematic model. In this figure, the activation

and deactivation of the biceps brachii are represented

by five letters.

-1

0

1

Biceps brachii

sEMG signal

RMS value

Normalized Voltage

-1

0

1

Brachioradialis

Time (s)

0 5 10 15 20

-1

0

1

Flexor carpi radialis

a

b

c

d

e

Figure 5: Biosignals recorded with the low-cost sEMG ac-

quisition device.

The output of the NISs is presented in Figure

6. It shows different positions of the robot dur-

ing the simulation of the NISs with the data pre-

viously recorded from the activation of the biceps

brachii. This signal was selected due to the fact

that presents the greater contrast between muscular

activation-deactivation. Also, it has different levels of

contractions producing different levels of signal am-

plitude, and for that reason is more didactic and visu-

ally representative in the simulation.

Each frame of the Figure 6 corresponds to a po-

sition in time. The first frame (a) corresponds to the

start of the trial, the second frame (b) to the first acti-

vation, which was really weak as can be seen in Fig-

ure 5 section (b), the third frame (c) corresponds to

the time between activations, the fourth frame (d) to

the second (and strongest) activation as can be seen in

Figure 5 section (d) and the fifth frame (e) to the time

after the activation. As these results were satisfactory,

the real-time tests were implemented.

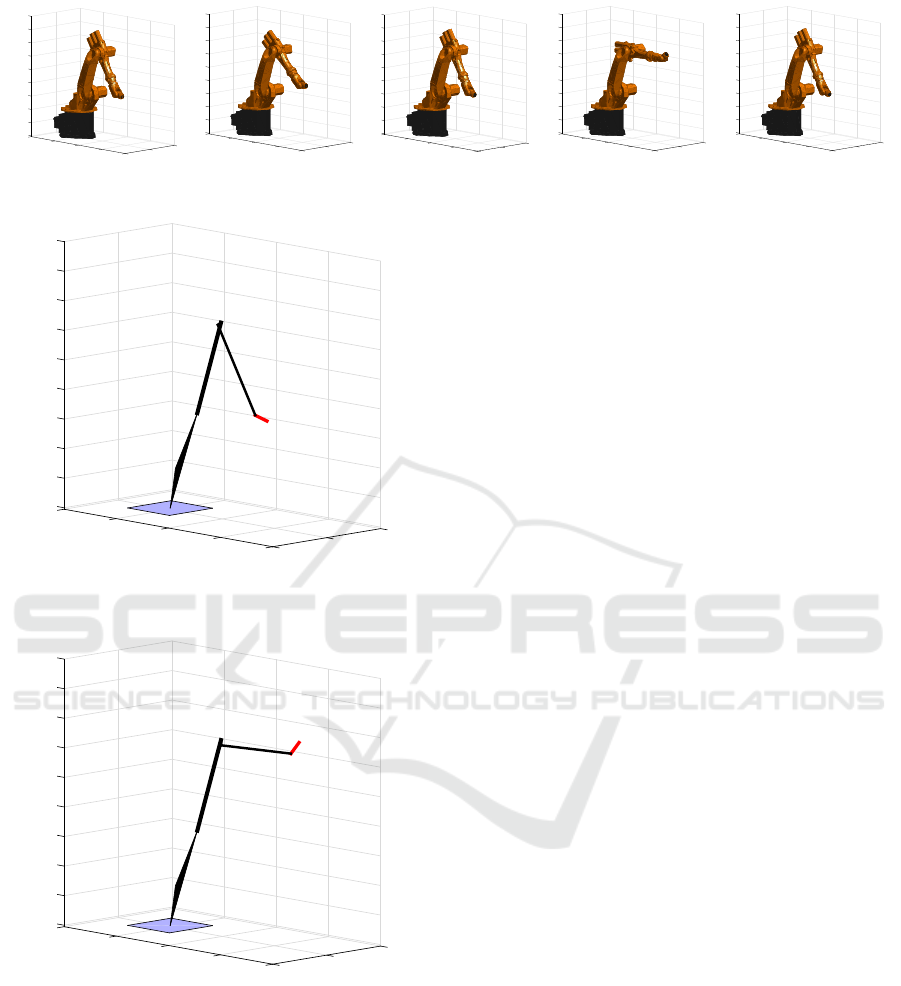

3.4 Testing using Real-time Signals

In order to assess the feasibility of implementing the

designed NIS, the procedures shown in section 2.4

for the signal acquisition, processing, and control was

implemented. The signal processing and control al-

gorithms were executed in real-time detecting the ac-

tivation of the biceps brachii.

The sEMG acquisition device was connected to

the subject. It transmitted each sample through se-

rial port protocol at a baud rate of 115.200 through

an Universal Serial Bus (USB). The samples of the

raw signals were conducted to the signal processing

algorithm and then they were mapped in the control

algorithm.

The real-time experiments carried out on the

healthy subject involved a very simple algorithm to

detect the intended movement of the elbow, since the

purpose of this paper is the proposal of the method-

ology and not presenting a novel algorithm for the

detection of the intended movement through sEMG

signals. The detection of the elbow flexion was done

through a threshold established to the RMS envelope

of the biceps brachii signals. If the change in the

amplitude envelope exceeded the given treshold, the

joint 3 (also labeled input3) of the simplified kine-

matic model of robot was put at a maximum value.

Otherwise, it stayed at the minimum value. The tresh-

old used was 75% of the range of the RMS envelope

signal.

The test consisted on five activations of the muscle

separated approximately by two seconds. The simpli-

fied model of the robot moved correctly after each ac-

tivation. Figures 7 and 8 show the status of the robot

without and with an activation respectively.

BIOSIGNALS 2016 - 9th International Conference on Bio-inspired Systems and Signal Processing

84

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

1000

1200

1400

1600

1800

400

0

600

200

800

-500

Z (mm)

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

0

400

600

1600

200

1400

1800

1200

1000

800

-500

Z (mm)

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

200

0

400

1000

1200

1600

600

1800

800

1400

-500

Z (mm)

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

800

600

400

200

0

1800

1600

1200

1000

1400

-500

Z (mm)

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

1600

1800

0

200

400

600

800

1000

1200

1400

-500

Z (mm)

a

b

c

d

e

Figure 6: Movement using prerecorded signals.

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

200

400

600

800

1600

1400

1200

1000

1800

0

-500

Z (mm)

Figure 7: Simplified 3D model during the real-time experi-

ment with the elbow extended.

500

Y (mm)

0

-500

1500

1000

X (mm)

500

0

200

400

600

800

1600

1400

1200

1000

1800

0

-500

Z (mm)

Figure 8: Simplified 3D model during the real-time experi-

ment with the elbow flexed.

3.5 Discussion

After the tests developed in Subsections 3.3 and 3.4,

it can be stated that the simulation of the robot can be

successfully implemented and controlled by means of

a biosignal. The tests yielded three tools useful for

future projects:

The first one is the kinematic simulation of the

robotic arm KUKA KR6. This tool gives the re-

searcher the ability to recreate the movement of the

robot without interacting directly with a real device,

and its performance is suitable compared to the real

movement of the KUKA KR6. Additionally, it en-

ables the inclusion of accessories or more detailed

characteristics using the same instructions presented

in Section 2. For instance, if there is any change in

the design of the robot, it is only necessary to update

its D-H parameters and CAD model. Furthermore, as

the researcher checks the movement of the robot in the

screen, the tool enables the test and assessment of tra-

jectories of the different actuators and end-effectors

of the robot.

The second useful tool is the simplified model. It

may be useful to check the kinematic behavior of the

links of the robot’s mechanism, while enabling real-

time analysis.

A third and last tool is the sEMG acquisition and

processing system, which completes the Neural In-

terface System. sEMG signals are particularly (but

not exclusively) useful in the field of prosthetics, as

they can be measurable on the residual muscles of

amputees, allowing the patient to control a prosthetic

device.

It is important to note that the amplitude of the ac-

quired signals shown in Figure 5 is different, depend-

ing on some anatomic and physiologic characteristics

of muscle and the force applied in the movement. For

the case of the KUKA KR6, which is a serial robot

with a similar structure to a human arm, the correla-

tion with the human movement was straightforward.

For instance, the movement produced by the flexion

of the elbow, as a result of biceps brachii activation,

was visualized in the joint 3 of the robot.

We highlight that this paper does not present re-

sults with a real-life robot, only with a computational

model. Future works include a realistic test with the

industrial serial robot KUKA KR6 and, subsequently

with a mechatronic device that our laboratory is de-

veloping for a specific application in rehabilitation.

In that way we will be able to compare the results of

the robot movement presented in the simulation ap-

plying our methodology and the results with the real-

life neural interface system. Moreover, this test with

a real-life robot and a real-life neural interface system

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems

85

will enable to develop a comparative evaluation with

other approaches.

4 CONCLUSION

The proposed methodology can be implemented in

the design stage of a NIS that involve a robotic de-

vice, since it can influence important decisions before

building the robotic system. Taking these decisions

before manufacturing processes may signify an eco-

nomical benefit for the designer.

In this work, the methodology was tested using

a KUKA KR6 robot. However, any serial robotic

device can be used. It is possible to implement the

methodology with robots that help people, such as

exoskeletons or upper limb prostheses. The only re-

quirement is to have their CAD files, which is usual

in the design process of any machine nowadays, and

convert them to STL format. Although sEMG sig-

nals were used in the presented experiments, EEG,

ECG, EOG and even electrocorticogram (ECoG) sig-

nals may be used as well as an input for the NIS. It is

recommended to follow the proper protocol to acquire

the signals.

In this paper a basic control algorithm was used to

map the angles from human joints to robot joints. It is

possible to include in the simulations more advanced

control algorithms according to the capabilities of the

real robot. Some of these algorithms may include dy-

namic analysis. Therefore, an interesting follow up

for the project is the development of force models in-

side the methodology.

Finally, we also propose that the presented

methodology has a potential use in the field of

biofeedback for musculoeskeletal and neurologic re-

habilitation, since the movement of the robot is an in-

dicator of muscular activation in real-time tests. Nev-

ertheless, in order to assess this proposition clinical

tests have to be carried out.

ACKNOWLEDGEMENTS

The authors would like to thank Cristian D. Mart

´

ınez

for the design and development of a Low-Cost sEMG

signal acquisition device.

REFERENCES

Asghari Oskoei, M. and Hu, H. (2007). Myoelectric control

systems-A survey. Biomedical Signal Processing and

Control, 2(4):275–294.

Corke, P. (2011). Robot Arm Kinematics. In Robotics, Vi-

sion and Control: Fundamental Algorithms in MAT-

LAB (Springer Tracts in Advanced Robotics), chap-

ter 7, pages 137–170. Springer.

Corke, P. I. (2007). A simple and systematic approach to as-

signing Denavit-Hartenberg parameters. IEEE Trans-

actions on Robotics, 23(3):590–594.

Correa, J. C., Ram

´

ırez, J. A., Taborda, E. A., Cock, J. A.,

G

´

omez, M. A., and Escobar, G. A. (2010). Imple-

mentation of a Laboratory for the Study of Robot Ma-

nipulators. In Proceedings of the ASME 2010 Inter-

national Mechanical Engineering Congress & Expo-

sition, pages 23–30.

Crane, C. D. and Duffy, J. (1998). Kinematic Analysis of

Robot Manipulators. Cambridge University Press.

Delis, A. L., Carvalho, J. L. a. J., and Rocha, A. F. (2006).

Myoelectric Knee Angle Estimation Algorithms for

Control of Active Transfemoral Leg Prostheses. Self

Organizing Maps - Applications and Novel Algorithm

Design, (1977):401–424.

Eurostat (2014). Disability statistics - prevalence and de-

mographics.

Florimond, V. (2010). Basics of Surface Electromyography

Applied to Physical Rehabilitation and. 1(March):1–

50.

Fu, K. S., Gonzalez, R. C., and Lee, C. S. (1987). Robotics:

control, sensing, vision and intelligence. McGraw-

Hill.

Garc

´

ıa Quiroz, F., Villa Moreno, A., and Casta

˜

no Jaramillo,

P. (2007). Interfaces neuronales y sistemas m

´

aquina-

cerebro: fundamentos y aplicaciones. Revisi

´

on. Re-

vista Ingenier

´

ıa Biom

´

edica, (1):14–22.

Hatsopoulos, N. and Donoghue, J. (2009). The science

of neural interface systems. Annual review of neuro-

science, 32:249–266.

Hon Wah, W. (1999). Introduction to STL format.

Kiguchi, K., Tanaka, T., and Fukuda, T. (2004). Neuro-

fuzzy control of a robotic exoskeleton with EMG

signals. IEEE Transactions on Fuzzy Systems,

12(4):481–490.

Kyrylova, A., Desplenter, T., Escoto, A., Chinchalkar, S.,

and Trejos, A. L. (2014). Simplified EMG-driven

Model for Active-Assisted Therapy. In IROS 2014

Workshop on Rehabilitation and Assistive Robotics:

Bridging the Gap Between Clinicians and Roboticists,

page 6.

Lasso, I. L., Masso, M., and Vivas, O. A. (2010). Ex-

oesqueleto para reeducaci

´

on muscular en pacientes

con IMOC tipo diplej

´

ıa esp

´

astica moderada. pages

1–88.

Lenzi, T., De Rossi, S. M. M., Vitiello, N., and Carrozza,

M. C. (2012). Intention-based EMG control for pow-

ered exoskeletons. IEEE Transactions on Biomedical

Engineering, 59(8):2180–2190.

Lucas, M. F., Gaufriau, A., Pascual, S., Doncarli, C., and

Farina, D. (2008). Multi-channel surface EMG clas-

sification using support vector machines and signal-

based wavelet optimization. Biomedical Signal Pro-

cessing and Control, 3(2):169–174.

Merletti, R. (1999). Standards for reporting EMG data.

BIOSIGNALS 2016 - 9th International Conference on Bio-inspired Systems and Signal Processing

86

Merletti, R. and Parker, P. A. (2004). Electromyography:

Physiology, Engineering, and Non-Invasive Applica-

tions. John Wiley & Sons.

Mon, Y. and Al-Jumaily, A. (2013). Estimation of Up-

per Limb Joint Angle Using Surface EMG Signal.

International Journal of Advanced Robotic Systems,

page 1.

National Limb Loss Center Information (2008). Amputa-

tion statistics by cause. Limb loss in the United States.

Pan, D., Gao, F., Miao, Y., and Cao, R. (2015). Co-

simulation research of a novel exoskeleton-human

robot system on humanoid gaits with fuzzy-PID/PID

algorithms. Advances in Engineering Software,

79:36–46.

Revilla, L. M., Delis, A. L., and Olaya, A. F. R. (2013).

Evaluation of the Hilbert-Huang Transform for my-

oelectric pattern classification: Towards a method to

detect movement intention. Pan American Health

Care Exchanges, PAHCE, pages 1–6.

Ruiz, A. F., Rocon, E., and Forner-Cordero, A. (2009).

Exoskeleton-based robotic platform applied in biome-

chanical modelling of the human upper limb. Applied

Bionics and Biomechanics, 6(2):205–216.

Schultz, A. E. and Kuiken, T. A. (2011). Neural interfaces

for control of upper limb prostheses: the state of the

art and future possibilities. PM & R : the journal of

injury, function, and rehabilitation, 3(1):55–67.

The Seniam Project. SENIAM. http://www.seniam.org.

Tsai, L.-W. (1999). Robot analysis: the mechanics of serial

and parallel manipulators. John Wiley & Sons.

Wojtczak, P., Amaral, T. G., Dias, O. P., Wolczowski, A.,

and Kurzynski, M. (2009). Hand movement recogni-

tion based on biosignal analysis. Engineering Appli-

cations of Artificial Intelligence, 22(4-5):608–615.

World Health Organization (2011). World Report on Dis-

ability.

Yepes, J. C., Yepes, J. J., Mart

´

ınez, J. R., and P

´

erez, V. Z.

(2013). Implementation of an Android based teleoper-

ation application for Controlling a KUKA-KR6 robot

by using sensor fusion. Health Care Exchanges.

Ziegler-Graham, K., MacKenzie, E. J., Ephraim, P. L.,

Travison, T. G., and Brookmeyer, R. (2008). Estimat-

ing the Prevalence of Limb Loss in the United States:

2005 to 2050. Archives of Physical Medicine and Re-

habilitation, 89(3):422–429.

A Simulation-based Methodology to Test and Assess Designs of Mechatronic Neural Interface Systems

87