Fixed-sequence Single Machine Scheduling and Outbound Delivery

Problems

Azeddine Cheref

1,2,3

, Alessandro Agnetis

4

, Christian Artigues

2,3

and Jean-Charles Billaut

1

1

Universit

´

e Franc¸ois-Rabelais Tours / CNRS, 64 av. J. Portalis, 37200 Tours, France

2

CNRS, LAAS, 7 Avenue du Colonel Roche, F-31400 Toulouse, France

3

Univ. de Toulouse, LAAS, F-31400 Toulouse, France

4

Dipartimento di Ingegneria dell’Informazione, Universit

´

a degli Studi di Siena, via Roma 56, 53100 Siena, Italy

Keywords:

Scheduling, Batching and Delivery, Computational Complexity, Dynamic Programming.

Abstract:

In this paper, we study an integrated production an outbound delivery scheduling problem with a predefined

sequence. The manufacturer has to process a set of jobs on a single machine and deliver them in batches to

multiple customers. A single vehicle with limited capacity is used for the delivery. Each job has a processing

time and a specific customer location. Starting from the manufacturer location, the vehicle delivers a set of

jobs which constitute a batch by taking into account the transportation times. Since the production sequence

and delivery sequence are fixed and identical, the problem consists in deciding the composition of batches.

We prove that for any regular sum-type objective function of the delivery times, the problem in NP-hard in the

ordinary sense and can be solved in pseudopolynomial time. A dynamic programming algorithm is proposed.

1 INTRODUCTION

This paper deals with a model for coordinating pro-

duction and delivery schedules. In many produc-

tion systems, finished products are delivered from the

factory to multiple customer locations, warehouses,

or distribution centers by delivery vehicles. An in-

creasing amount of research has been devoted, dur-

ing the last twenty years, to devise integrated models

for production and distribution. These models have

been largely analyzed and reviewed by (Chen, 2010),

who proposed a detailed classification scheme. The

models reflect the variety of issues, including sys-

tems structure, vehicle/transportation system charac-

teristics, delivery modes, various types of time con-

straints. In the large majority of the models in the

literature, the coordination of production and distri-

bution is achieved through the creation of batches,

i.e., several parts are shipped together and delivered

to their respective destinations during a single trip.

When forming batches, one must therefore take into

account both production information (such as pro-

cessing time, release dates etc) and delivery informa-

tion (such as customer location, time windows etc).

Most of the models presented in the literature explic-

itly take into account transportation times to reach the

customers’ location, but there are no proper routing

decisions, since the number of distinct customers is

typically very small. Hence, the focus of the analysis

is often on scheduling and batching.

Many models consider delivery as a separate step

after production, but do not model it in details, e.g. as-

suming that a sufficiently large number of vehicles is

available to deliver the products at any time (Chen and

Lee, 2008) (Agnetis et al., 2014) (Fan et al., 2015), or

assuming that there is a single customer. In (Chang

and Lee, 2004) the jobs have a certain size and the ca-

pacity of a vehicle is a physical space available, and

jobs have to be delivered to a unique customer. NP-

hardness results are given as well as heuristic algo-

rithms with performance guarantee. In (Li and Ou,

2005) and (Wang and Cheng, 2009), delivery con-

cerns the materials as well as finished jobs which must

be transported to a single warehouse. The objective

is to minimize the delivery time of the job delivered

last to this customer. Li and Ou propose a polynomial

time algorithm when the production sequence is fixed.

In the literature, delivery can also be modeled as a

delay after the production completion time. Fan, Lu

and Liu (Fan et al., 2015) consider the join problem of

scheduling and routing with availability constraints of

the machine. The delivery is performed by an unlim-

ited number of uncapacitated vehicles and the objec-

tive is to minimize the total delivery time and total de-

Cheref, A., Agnetis, A., Artigues, C. and Billaut , J-C.

Fixed-sequence Single Machine Scheduling and Outbound Delivery Problems.

DOI: 10.5220/0005701201450151

In Proceedings of 5th the International Conference on Operations Research and Enterprise Systems (ICORES 2016), pages 145-151

ISBN: 978-989-758-171-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

livery cost. Depending on the problem they consider,

the authors propose polynomial time algorithms, an

algorithm with guaranteed performance and a poly-

nomial time approximation scheme.

In the paper by (Li et al., 2005), a single vehicle

is used for delivery, and hence the vehicle schedule

has to be synchronized with production and batching

decisions. In particular, one must also take account

of the time that the vehicle will take to deliver a cer-

tain batch of products, and that it will take to be back

at the manufacturing facility. (Li et al., 2005) ana-

lyze the joint problem of production sequencing and

batch formation, in order to minimize total delivery

time, given that delivery is performed by a single ve-

hicle. Total delivery time is a meaningful indicator

of the overall efficiency of the delivery process. They

show that in general the problem is NP-hard, and then

give polynomial time algorithms for the problem with

a fixed number of distinct destinations. In (Tsirim-

pas et al., 2008), the authors consider that all the jobs

are ready for the delivery at the beginning of the time

horizon (no scheduling problem here). The delivery

is performed by a single capacitated vehicle and the

sequence of delivery is predefined. The objective is

to minimize the total travel time and the authors pro-

pose polynomial time algorithms. In (Chen and Lee,

2008), the authors consider the problem with a single

machine where finished jobs must be transported by

an unlimited number of vehicles. There is no vehicle

routing problem, since the vehicle delivers in one trip

only jobs delivered at the same destination.

Using the terminology of (Chen, 2010), the mod-

els presented in this paper concern batch delivery with

routing, i.e., orders going to different customers can

be delivered together in the same shipment (batch).

A distinctive feature of the problems we address

here is that the jobs must be delivered in the same

order in which they are produced (we can simply as-

sume that the delivery sequence is fixed and in this

case, there is always an optimal production sequence

which is the same as the delivery sequence). Ex-

amples of situations in which the customer sequence

is fixed are reported by (Armstrong et al., 2008),

(Viergutz and Knust, 2014) and include a fixed se-

quence of customers and a single round trip for the

delivery, as well as the objective is to maximize the

total demand without violating the product lifespan.

This problem is proved NP-hard by (Armstrong et al.,

2008). In (Lent

´

e and Kergosien, 2014), the authors

consider that the production sequence is fixed as well

as the delivery sequence. The authors search for a

batching of jobs minimizing the makespan, the maxi-

mum lateness and the number of tardy jobs. The prob-

lems are modeled by a graph and polynomial time al-

gorithms are proposed for these objective functions.

In this paper, we will mainly focus on the problem

of deciding how to form batches with a given pro-

duction sequence (problem P1). We completely char-

acterize the complexity of Problem P1, showing that

when the objective function is to minimize the total

delivery time it is NP-hard in the ordinary sense, and

that it can be solved in pseudopolynomial time for any

sum-type function of the delivery times.

The paper is organized as follows. In Section 2

we present the problem formally and show that the

problem is NP-hard when Z is the total delivery time,

and that it can be solved in pseudopolynomial time

when Z is any sum-type objective function. Finally,

some conclusions and future research directions are

presented in Section 4.

2 PROBLEM DEFINITION AND

COMPLEXITY

2.1 Problem Definition and Notation

The problem considered in this paper can be de-

scribed as follows. A set of n jobs is given and

their production sequence is known. Each job J

j

,

j = 1, ...,n, requires a certain processing time p

j

on

a single machine, and must be delivered to a certain

location site. We assume w.l.o.g. that the production

sequence is (J

1

,J

2

,...,J

n

). For the sake of simplicity,

when it does not create confusion, we use j to refer to

the destination of job J

j

. We denote by t

i, j

the trans-

portation time from destination i to destination j. For

analogy with vehicle routing problems, we refer to the

manufacturer’s location as the depot. We use M to de-

note the depot (manufacturer), hence t

M,j

= t

j,M

is the

transportation time between the depot and destination

j. Unless otherwise specified, we assume that trans-

portation times are symmetric and satisfy the triangle

inequality.

Deliveries are carried out by a single vehicle. The

vehicle loads a certain number of jobs which have

been processed and departs towards the correspond-

ing destinations. Thereafter, it returns to the depot,

hence completing a round trip. The set of jobs de-

livered during a single round trip constitutes a batch.

The capacity c of the vehicle is the maximum num-

ber of jobs it can load and hence deliver in a round

trip. The jobs must be delivered in the order in which

they are produced, hence the production sequence

also specifies the sequence in which the customers

have to be reached.

The problem consists in deciding a partition of

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

146

all jobs into batches, i.e., a batching scheme. Each

batch will be routed according to the manufacturing

sequence. In general, the performance of the sys-

tem depends on all the concurrent decisions: produc-

tion scheduling, batching and vehicle routing. This

requires therefore an integrated model, allowing the

coordination of all these aspects. A solution to our

problem with fixed sequence, is the specification of a

batching scheme. Given a solution, we denote by C

j

the completion time of job J

j

on the single machine,

which is also the time at which the job is released for

delivery, i.e., the batch including job J

j

cannot start

before C

j

. We denote by D

j

the delivery time of J

j

,

i.e., the time at which the job J

j

is delivered at its des-

tination. The performance measures we consider in

this paper depend on such delivery times. In particu-

lar, denoting with Z the performance measure, in this

paper we consider:

• the total delivery time, i.e., Z =

∑

n

j=1

D

j

• a general sum-type performance index, i.e., Z =

∑

n

j=1

f

j

(D

j

), where f

j

(D

j

) is a general, nonde-

creasing function of D

j

, j = 1,...,n.

Note that the latter case includes total (weighted)

delivery time, total (weighted) tardiness, etc.

We consider the following problem:

Problem P1(Z). Given n jobs of length p

j

, j =

1,... ,n, transportation times t

i, j

for all i, j, and a se-

quence σ, find a batching scheme B such that Z is

minimized.

2.2 Complexity

Since the production sequence is given, and since

jobs are delivered to the respective customers in the

same given order, we assume that the job sequence

is σ = (J

1

,J

2

,...,J

n

). Only travel times t

j, j+1

are rel-

evant, as well as times t

j,M

= t

M,j

, representing the

travel time between customer j and the manufacturer

or vice-versa.

Let us first consider the problem when the objec-

tive to minimize is the total delivery time, i.e., prob-

lem P1(

∑

n

j=1

D

j

). For our purposes, we introduce the

following problem.

EVEN-ODD PARTITION (EOP). A set of n pairs

of positive integers (a

1

,b

1

),(a

2

,b

2

),... , (a

n

,b

n

) is

given, in which, for each i, a

i

> b

i

. Letting K =

∑

n

i=1

(a

i

+ b

i

), is there a partition (S,

¯

S) of the index

set I = {1,2,... ,n} such that

∑

i∈S

a

i

+

∑

i∈

¯

S

b

i

= K/2? (1)

EOP is NP-hard in the ordinary sense (Garey et al.,

1988). In the following, we will actually use the fol-

lowing slightly modified version of the problem.

MODIFIED EVEN-ODD PARTITION (MEOP). A

set of n pairs of positive integers (a

1

,b

1

),(a

2

,b

2

),

..., (a

n

,b

n

) is given, in which, for each i, a

i

> b

i

. Let-

ting Q =

∑

n

i=1

(a

i

−b

i

), is there a partition (S,

¯

S) of the

index set I = {1,2,. ..,n} such that

∑

i∈S

(a

i

− b

i

) = Q/2? (2)

Note that the two problems are indeed equiva-

lent. In fact, suppose that EOP has a partition (S,

¯

S).

The corresponding instance of MEOP also admits the

same partition. In fact, subtracting

∑

n

i=1

b

i

=

∑

i∈S

b

i

+

∑

i∈

¯

S

b

i

from both sides of (1), one obtains

∑

i∈S

(a

i

− b

i

) = K/2 −

n

∑

i=1

b

i

(3)

Now, from the definitions of K and Q it turns out that

Q = K − 2

n

∑

i=1

b

i

and hence (3) is indeed (2). We next show the follow-

ing result.

Theorem 2.1. P1(

∑

n

j=1

D

j

) is NP-hard.

Proof. The problem is obviously in NP. Given an in-

stance of MEOP, we build an instance of P1 as fol-

lows. There are 3n + 3 jobs. The processing times of

the jobs are defined as follows:

• p

1

= p

2

= p

3

= 0.

• for each i = 0, 1, ..., n − 1, one has

– p

3i+1

= p

3i+2

= 1,

– p

3i+3

= 4x

i

+ b

i

− 2.

• p

3n+1

= 4x

n

+ b

n

+ Q/2.

• p

3n+2

= p

3n+3

= 0,

where the x

i

are defined by

x

i

= (3a

i

−2b

i

+3(n −i)(a

i

−b

i

))/2 ∀ i = 1 . . .n (4)

and x

n+1

= 0.

In the following, we refer to the set of jobs

(J

3i+1

,J

3i+2

,J

3i+3

), i = 0,..., n, as the triple T

i+1

.

For what concerns the travel times, we let:

• for each i = 0, 1, ..., n − 1, one has

– t

M,3i+1

= t

3i+1,M

= t

M,3i+2

= t

3i+2,M

= t

M,3i+3

=

t

3i+3,M

= x

i+1

,

– t

3i+1,3i+2

= a

i+1

,

– t

3i+2,3i+3

= b

i+1

,

– t

3i+3,3i+4

= x

i+1

+ x

i+2

.

• t

M,3n+1

= t

3n+1,M

= t

M,3n+2

= t

3n+2,M

= t

M,3n+3

=

0.

• t

3n+1,3n+2

= t

3n+2,3n+3

= 0.

Fixed-sequence Single Machine Scheduling and Outbound Delivery Problems

147

Finally, vehicle capacity is c = 2. The problem

consists in determining whether a solution exists such

that the total delivery time does not exceed

f

∗

=

n

∑

i=1

(3C

3i

+7x

i

+b

i

)+C

3n+1

+C

3n+2

+C

3n+3

−Q/2.

(5)

For shortness, we call feasible a schedule satisfy-

ing (5). The proof has the following scheme.

1. We first establish that if a feasible schedule exists,

then there is one having a certain structure, called

triple-oriented,

2. We analyze some properties of this structure,

3. We show that a triple-oriented schedule of value

f

∗

exists if and only if EOP is a yes-instance.

Lemma 2.2. If a feasible schedule exists, then there

exists one satisfying the following property: for all

i = 1,.. .,n+1, jobs J

3i

and J

3i+1

are NOT in the same

batch.

Proof. Suppose that a feasible schedule exists in

which, for a certain i (1 ≤ i ≤ n), jobs J

3i

and J

3i+1

are in the same batch. Since c = 2, the batch contains

no other job. As a consequence, after delivering J

3i+1

,

the vehicle must go back to M in order to load the next

jobs and start a new trip. If we denote by τ the start

time of the round trip of jobs J

3i

and J

3i+1

, job J

3i

is

delivered at time D

3i

= τ + t

M,3i

and job J

3i+1

is de-

livered at time D

3i+1

= τ + t

M,3i

+ t

3i,3i+1

. Therefore

we have D

3i

= τ + x

i

and D

3i+1

= τ + x

i

+ (x

i

+ x

i+1

).

The vehicle is back at M at time τ + 2x

i

+2x

i+1

. Now,

if we replace this batch with two batches of one job

each, the delivery times of both jobs as well as the

time at which the vehicle is back at M are unchanged.

Therefore, there is an equivalent solution where J

3i

and J

3i+1

are not in the same batch.

We call triple-oriented a schedule satisfying

Lemma 2.2. The reason of this name is that

the schedule is decomposed according to triples.

More precisely, since c = 2, for each triple T

i+1

=

(J

3i+1

,J

3i+2

,J

3i+3

), i = 0,. ..,n − 1, there are exactly

two batches, and only two possibilities, namely:

• either the first batch is {J

3i+1

,J

3i+2

} and the sec-

ond is {J

3i+3

},

• or the first batch is {J

3i+1

} and the second is

{J

3i+2

,J

3i+3

}.

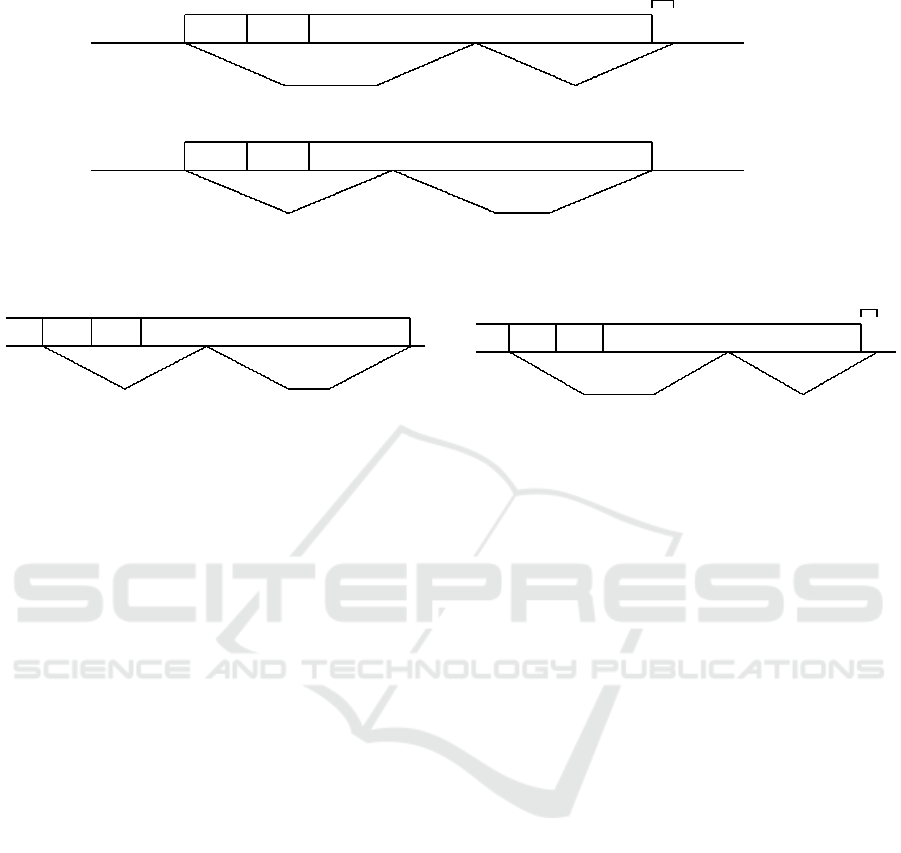

We call these two possibilities option A and option

B respectively (see Fig. 1). Namely, let us view option

B as the Base option, and A as a variant to it.

Round trip length. Letting M

A

i

and M

B

i

denote the

round trip length of the jobs of T

i

in the two cases.

One has:

M

A

i

= 4x

i

+ a

i

(6)

M

B

i

= 4x

i

+ b

i

(7)

Since a

i

> b

i

, option A implies a longer round trip

length than the Base option. The difference between

the two lengths M

A

i

− M

B

i

is precisely equal to a

i

− b

i

.

Lemma 2.3. In any triple-oriented schedule, the ve-

hicle is never idle, except possibly before loading

J

3n+1

.

Proof. The lemma is proved by an induction argu-

ment. Let consider the first triple T

1

. The vehicle

starts at time 0 (to deliver batch {J

1

} or {J

1

,J

2

}), and

is back at time 4x

1

+ b

1

or at time 4x

1

+ a

1

. The

production completion time of the jobs of T

2

is pre-

cisely equal to C

6

=

∑

6

j=1

p

j

= 1 + 1 +4x

1

+b

1

−2 =

4x

1

+b

1

. Therefore, the vehicle can immediately start

the delivery of the jobs of T

2

. For the same reasons,

the delivery time of the jobs of T

i

cannot be smaller

than the duration of the processing of the jobs of T

i+1

,

and the vehicle will be able to start immediately the

delivery of the jobs of T

i+1

. This reasoning stops for

the last triple T

n+1

because the duration of J

3n+1

is

particular.

In view of Lemma 2.3, one can compute the total

delivery time in the Base scenario, i.e., when option

B is always chosen. From (7), one has that the vehicle

always returns to M exactly at time C

3i

. Therefore, the

last time the vehicle arrives at M (before delivering

the jobs of T

n+1

) is C

3n

+ 4x

n

+ b

n

. Because of the

definition of p

3n+1

, and because J

3n+1

starts at time

C

3n

, this time is equal to C

3n+3

− Q/2. In this case,

the vehicle will stay idle from C

3n+1

− Q/2 to C

3n+1

,

when job J

3n+1

can be finally loaded (see Fig.2) and

delivered (the two reminder jobs have a duration of 0

and travel times equal to 0). Hence, we have:

f

BASE

=

n

∑

i=1

(3C

3i

+ 7x

i

+ b

i

) +C

3n+1

+C

3n+2

+C

3n+3

(8)

Contribution to total delivery time. Before com-

puting the contribution of a certain triple to the to-

tal delivery time, let us consider schedules in which

the last three jobs J

3n+1

, J

3n+2

and J

3n+3

start exactly

their transportation at their release time, i.e., at time

C

3n+1

= C

3n+2

= C

3n+3

(options A and B are equiva-

lent). Let us call regular a schedule in which such a

condition holds.

Expression (8) refers to the scenario in which for

all triples, the option B is chosen. We want now to

compute the objective function of an arbitrary solu-

tion. Let us first consider the contribution of triple T

i

to the objective function in the Base schedule, i.e., as-

suming that the delivery of T

i

started at time C

3i

, and

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

148

3(i-1)+1 3(i-1)+2 3(i-1)+3

b

i

3(i-1)+1 3(i-1)+2 3(i-1)+3

a

i

3i+1 3i+2 3i+3

3i+1 3i+2 3i+3

option A

option B

a

i

− b

i

Figure 1: Round trips with options A and B.

...

3(i-1)+1 3(i-1)+2 3(i-1)+3

b

i

3i+1 3i+2 3i+3

x

i

x

i

x

i

x

i

T

i+1

T

i

Figure 2: The base schedule (i.e., B is always chosen).

let us denote such piece of contribution as T DT

A

i

and

T DT

B

i

in the two cases. One has:

T DT

A

i

= (C

3i

+ x

i

) + (C

3i

+ x

i

+ a

i

) + (C

3i

+ 3x

i

+ a

i

)

= 3C

3i

+ 5x

i

+ 2a

i

(9)

T DT

B

i

= (C

3i

+ x

i

) + (C

3i

+ 3x

i

) + (C

3i

+ 3x

i

+ b

i

)

= 3C

3i

+ 7x

i

+ b

i

(10)

Note that

T DT

B

i

− T DT

A

i

= 2x

i

+ b

i

− 2a

i

= (3a

i

− 2b

i

+ 3(n − i)(a

i

− b

i

)) + b

i

− 2a

i

= a

i

− b

i

+ 3(n − i)(a

i

− b

i

) (11)

which is positive, remembering that a

i

> b

i

. This

means that choosing option A over B brings a bene-

fit in terms of total delivery time. However, such fa-

vorable situation for option A is mitigated by the fact

that, with option A, one has a longer round trip time

than with option B, by the amount (a

i

−b

i

) (Fig.3). In

a regular schedule, such increased round trip time will

be ”paid” by all subsequent jobs, except the last jobs

J

3n+1

, J

3n+2

and J

3n+3

. Hence, in a regular schedule

the total effect (in favor of option B) on the subse-

quent jobs of choosing option A for T

i

is given by

3(n − i)(a

i

− b

i

) (12)

In conclusion, the net benefit of choosing option

A over B for T

i

in terms of objective function value

is obtained subtracting (12) from (11), and in view of

the definition of x

i

(4), one has therefore that

NetBene f it

i

= (2x

i

+ b

i

− 2a

i

) − 3(n − i)(a

i

− b

i

)

= a

i

− b

i

(13)

...

a

i

− b

i

3(i-1)+1 3(i-1)+2 3(i-1)+3

a

i

x

i

x

i

x

i

x

i

T

i+1

T

i

3i+1 3i+2 3i+3

Figure 3: T

i

is the first triple choosing option A.

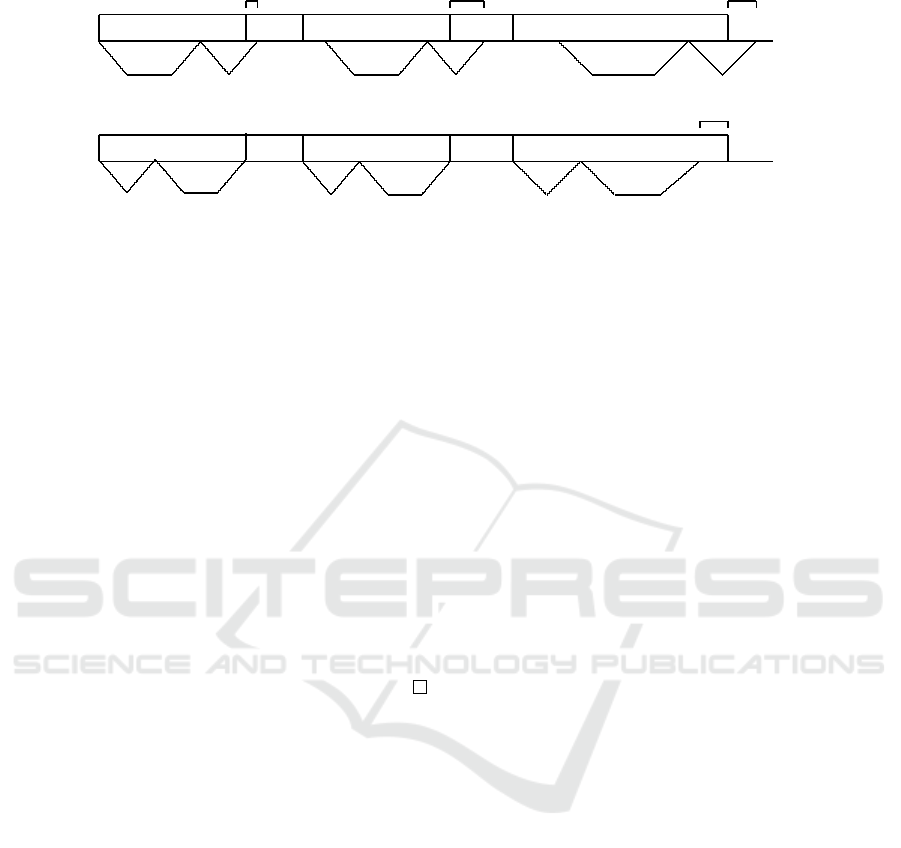

In conclusion, it turns out that, when A is chosen

over the Base option, one has a larger round trip time,

by (a

i

− b

i

), but also a smaller contribution to total

delivery time (also by the amount (a

i

− b

i

))(see Fig.

4). So, given any regular triple-oriented schedule in

which the last three jobs depart at their completion

time, let T

A

be the set of triples for which the option

A is chosen. Then, from the above considerations, the

value f of the objective function is given by

f = f

BASE

−

∑

i∈T

A

(a

i

− b

i

) (14)

On the other hand, the time at which the vehicle re-

turns to M before loading the last three jobs (J

3n+1

,

J

3n+2

and J

3n+3

) is given by

C

3n

+ 4x

n

+ b

n

+

∑

i∈T

A

(a

i

− b

i

) (15)

Now, in a regular schedule job J

3n+1

(and also

J

3n+2

and J

3n+3

) starts at time C

3n+1

= C

3n

+ 4x

n

+

b

n

+ Q/2. Hence, from (15), in a regular schedule, it

must hold:

∑

i∈T

A

(a

i

− b

i

) ≤ Q/2

On the other hand, comparing (5), (8) it turns out

that

f

∗

= f

BASE

− Q/2

and hence, from (14), a regular schedule is feasi-

ble precisely if a subset T

A

of indices exists such that

∑

i∈T

(a

i

−b

i

) = Q/2, i.e., if and only if a feasible par-

tition exists in the instance of EOP. To conclude the

proof, it is left to show that f

∗

can be attained only by

a regular schedule. In fact, if a schedule is not regular,

Fixed-sequence Single Machine Scheduling and Outbound Delivery Problems

149

.... ....

T

i+1

3(i-1)+1 3(i-1)+2

3i

b

i

.... ....

T

i+1

∑

i

j=1

a

j

− b

j

3(i-1)+1 3(i-1)+2

3i

a

i

T

2

1 2

3

a

1

T

2

1 2

3

b

1

3n+1, 3n+2, 3n+3

3(n-1)+1 3(n-1)+2

3n

a

n

Q/2

3n+1, 3n+2, 3n+3

3(n-1)+1 3(n-1)+2

3n

b

n

Q/2

a

1

− b

1

Figure 4: Round trips with option A only and option B only.

the departure time of the last batch is delayed by the

amount (

∑

i∈T

A

(a

i

− b

i

) − Q/2) with respect to C

3n+1

.

As a consequence, the expression of f in (14) must

be modified to take account of such delay of the last

three jobs, i.e. it comes

f = f

BASE

−

∑

i∈T

A

(a

i

− b

i

) + 3(

∑

i∈T

A

(a

i

− b

i

) − Q/2)

= f

BASE

+ 2

∑

i∈T

A

(a

i

− b

i

) − 3Q/2 (16)

Since, in a nonregular schedule,

∑

i∈T

A

(a

i

− b

i

) > Q/2,

from (16) one has

f > f

BASE

+ Q − 3Q/2 = f

BASE

− Q/2

and hence it cannot be feasible.

3 PSEUDOPOLYNOMIAL TIME

ALGORITHM FOR P1(

∑

j

f

j

(D

j

))

Theorem 2.1 implies that no optimal polynomial time

algorithm can be found for P1(

∑

n

j=1

D

j

), and hence

for more general objective functions, unless P=NP.

In what follows, we show that P1(

∑

j

f

j

(D

j

)) can be

solved in pseudopolynomial time, hence settling the

complexity status of P1.

In what follows we denote by {i, j} the batch con-

sisting of jobs J

i

,... ,J

j

. As usual, C

j

is the com-

pletion time of job J

j

(known because σ is known),

and hence the release time for delivery. We denote by

M(i, j) the duration of the round trip of batch {i, j},

and, if the batch starts at time t, we call K(i, j,t) its

contribution to the objective function. Also, we as-

sume that at the beginning, the vehicle is at the man-

ufacturing location.

We denote by F(i, j,t) the value of the optimal

solution of the problem restricted to the first j jobs,

in which the first job of the last batch is J

i

, and such

that the batch starts at time t. Then, F(i, j,t) can be

computed by means of a simple recursive formula. In

the optimal solution of the subproblem, if the second

last batch is {p,i − 1}, and if it starts at time s, then

we have:

F(i, j,t) = F(p,i − 1,s) + K(i, j,t)

Note that, if the vehicle starts at time s, it must be

back before or at time t, i.e., the following constraint

must hold:

C

i−1

≤ s ≤ t − M(p,i − 1)

In conclusion, the problem is solved by means of:

F(i, j,t) = min

max(i−c,1)≤p≤i−1

C

i−1

≤s≤t−M(p,i−1)

{F(p,i−1, s)}+K(i, j,t)

(17)

Let T be an upper bound on the latest possible de-

parture time for the last batch. As long as the triangle

inequality holds, this is given, for instance, by:

T = max

max

1≤i≤n−1

{C

i

+ 2

n−1

∑

h=i

t

hM

},C

n

!

The optimal solution is given by:

z

∗

= min

n−c+1≤i≤n,C

n

≤t≤T

F(i,n,t)

(18)

A few boundary conditions must be imposed:

F(i, j,t) = +∞ for all j < i (19)

F(1, j,t) = K(1, j,t) for all j,t (20)

Condition (19) is obvious. Condition (20) allows

to initialize the algorithm.

Let us turn to complexity. First, consider the com-

putation of values M(i, j) and K(i, j,t). Both can be

simply computed adding the contribution of the next

job in the batch either to the round trip time (for

M(i, j)) or to the objective function (for K(i, j,t)).

More precisely, the delivery time d

h

of job J

h

with

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

150

respect to the departure time of the batch is simply

given by:

d

h

=

d

h−1

+t

h−1,h

, if i < h ≤ j

t

M,h

, if h = i (in this case the

vehicle starts from M)

Hence, M(i, j) is simply given by d

j

+ t

j,M

. Note

that M(i, j +1) = M(i, j) −t

j,M

+t

j, j+1

+t

j+1,M

. This

means that all M(i, j) can be computed in O(nc) as-

suming j ≤ i + c − 1. Similarly, if batch {i, j} starts

indeed at time t, the contribution of job J

h

to the ob-

jective function is given by:

f

h

(t + d

h

),∀i ≤ h ≤ j

Clearly, K(i, j,t) is given by

∑

j

h=i

f

h

(t + d

h

).

Again, assuming that f

j

(·) can be computed in con-

stant time, note that d

j+1

= d

j

+ t

j, j+1

and K(i, j +

1,t) = K(i, j,t) + f

j+1

(d

j+1

). So, all values K(i, j,t)

can be computed in O(ncT ).

Once all values M(i, j) and K(i, j,t) are known,

one can compute formula (17) for all feasible triples

(i, j,t). Each such computation requires comparing

nT values. Finally, O(cT ) values are compared to

find the optimal solution. Since the feasible triples are

O(ncT ), the computation of all values F(i, j,t) clearly

dominates the other phases, and the following result

is proved.

Theorem 3.1. Problem P1(

∑

j

f

j

(D

j

)) can be solved

in pseudopolynomial time in O(nc

2

T

2

).

4 CONCLUSION AND FUTURE

RESEARCH DIRECTIONS

The problem treated in this paper takes place in a Sup-

ply Chain environment, where a manufacturer (mod-

eled as a single machine) has to organize the delivery

of the items (performed by a single capacitated ve-

hicle). The sequence of production is given, and is

supposed to be the same as the sequence of delivery.

The problem is to form batches of jobs, so that the

total delivery time is minimised. We prove that the

problem is NP-hard for a capacity equal to 2, and a

pseudopolynomial time dynamic programming algo-

rithm is proposed.

We are going to investigate the case where the se-

quence is not fixed. Several polynomial cases can

be proposed as well as dynamic programming algo-

rithms for non-polynomial cases.

ACKNOWLEDGEMENTS

This work was supported by the financial sup-

port of the ANR ATHENA project, grant ANR-13-

BS02-0006 of the French Agence Nationale de la

Recherche.

REFERENCES

Agnetis, A., Aloulou, M. A., and Fu, L.-L. (2014). Co-

ordination of production and interstage batch deliv-

ery with outsourced distribution. European Journal

of Operational Research, 238(1):130 – 142.

Armstrong, R., Gao, S., and Lei, L. (2008). A zero-

inventory production and distribution problem with a

fixed customer sequence. Annals of Operations Re-

search, 159(1):395–414.

Chang, Y.-C. and Lee, C.-Y. (2004). Machine scheduling

with job delivery coordination. European Journal of

Operational Research, 158(2):470 – 487. Method-

ological Foundations of Multi-Criteria Decision Mak-

ing.

Chen, B. and Lee, C.-Y. (2008). Logistics scheduling with

batching and transportation. European Journal of Op-

erational Research, 189(3):871 – 876.

Chen, Z.-L. (2010). Integrated production and outbound

distribution scheduling: Review and extensions. Op-

erations Research, 58(1):130–148.

Fan, J., Lu, X., and Liu, P. (2015). Integrated scheduling

of production and delivery on a single machine with

availability constraint. Theoretical Computer Science,

562:581 – 589.

Garey, M. R., Tarjan, R. E., and Wilfong, G. T. (1988).

One-processor scheduling with symmetric earliness

and tardiness penalties. Mathematics of Operations

Research, 13(2):330–348.

Lent

´

e, C. and Kergosien, Y. (2014). Probl

`

eme de livrai-

son a s

´

equence fix

´

ee. In 10

`

eme conf

´

erence inter-

nationale de mod

´

elisation, optimisation et simulation

(MOSIM’14), Nancy.

Li, C.-L. and Ou, J. (2005). Machine scheduling with

pickup and delivery. Naval Research Logistics (NRL),

52(7):617–630.

Li, C.-L., Vairaktarakis, G., and Lee, C.-Y. (2005). Ma-

chine scheduling with deliveries to multiple customer

locations. European Journal of Operational Research,

164(1):39 – 51.

Tsirimpas, P., Tatarakis, A., Minis, I., and Kyriakidis, E.

(2008). Single vehicle routing with a predefined cus-

tomer sequence and multiple depot returns. European

Journal of Operational Research, 187(2):483 – 495.

Viergutz, C. and Knust, S. (2014). Integrated production

and distribution scheduling with lifespan constraints.

Annals of Operations Research, 213(1):293–318.

Wang, X. and Cheng, T. (2009). Production scheduling

with supply and delivery considerations to minimize

the makespan. European Journal of Operational Re-

search, 194(3):743 – 752.

Fixed-sequence Single Machine Scheduling and Outbound Delivery Problems

151