Characteristics of Phase-Shifted Fiber Bragg Grating Inscribed by

Fusion Splicing Technique and Femtosecond Laser

Yajun Jiang

1,2

, Jian Xu

1,2

, Yuan Yuan

1,2

, Dexing Yang

1,2

, Dong Li

1,2

, Meirong Wang

1,2

and Jianlin Zhao

1,2

1

Key Laboratory of Space Applied Physics and Chemistry, Ministry of Education, Xi’ an, China

2

Shaanxi Key Laboratory of Optical Information Technology, School of Science, Northwestern Polytechnical University

Xi’ an 710072, China

Keywords: Optical Fiber Sensors, Phase-shifted Fiber Bragg Gratings, Femtosecond Laser.

Abstract: Phase-shifted fiber Bragg grating (PS-FBG) inscription in nonphotosensitive single mode fiber (SMF) by

the fusion splicing technique and femtosecond laser is reported. Two SMFs are fusion spliced to introduce a

refractive index modulation point which acts as a phase shift, then exposing the fusion spliced fiber with

femtosecond laser and a uniform phase mask. Two dips can be observed in the transmission spectrum of

inscribed grating, and the max induced refractive index modulation can reach to 4.210

-4

without any fiber

sensitization for a peak power density of 4.510

13

W/cm

2

. The annealing tests show that type I PS-FBG is

successfully inscribed. This type of grating also shows good strain and pressure characteristics. Such PS-

FBGs can be potentially used for optical fiber lasers, filters and sensors.

1 INTRODUCTION

Phase-shifted fiber Bragg gratings (PS-FBGs) show

a very narrow transmission band within its reflection

spectrum, and they have found many applications in

wavelength-division multiplexing systems (Agrawal

and Radic, 1994), optical fiber lasers (Chen et al.,

2005), high finesse transmission filters (Zou et al.,

2013), ultrasonic detectors (Rosenthal et al., 2011;

Liu and Ham, 2012) and optical fiber sensors

(Malara et al., 2015). Many methods have been

presented for PS-FBG inscription, such as

employing a phase-shifted phase mask (PM) (Liu

and Ham, 2012), Moiré method by slightly tuning

the laser wavelength (Malara et al., 2015) or shifting

the fiber perpendicularly to the fiber axis (Reid et al.,

1990), moving fiber-scanning beam technique (Cole

et al., 1995), post-processing technique by exposing

the uniform FBG with focused UV (Canning and

Sceats, 1994) or CO

2

laser (Xia et al., 2005), and

exposing twice process (Chehura et al., 2010), in

which two uniform FBGs with same parameters are

overlapped physically by one grating period. These

methods mentioned above possess good repeatability,

flexibility and quality, but they need the relatively

expensive phase-shifted PM or a high precise control

or the PS-FBGs show poor annealing properties.

In the past decades, femtosecond laser has been

explored for writing complex FBGs in many types

of fibers (Thomas et al., 2008; Marshall et al., 2010;

Williams et al., 2011). PS-FBG has been inscribed

by point-by-point technique with femtosecond laser

by modulating the phase and frequency of

femtosecond laser with two triggers (Marshall et al.,

2010) or an electro-optical modulator (Burgmeier et

al., 2014) in conjunction with a high precise stage,

this technique is versatile and repeatable; however, it

requires the synchronization of pulse train with the

writing position. The PS-FBG has be also inscribed

by introducing an in-grating bubble in the middle of

uniform FBG with femtosecond laser and fusion

splicing technique (Liao et al., 2013), in which the

phase shift is adjusted by filling liquids with

different refractive indices into the bubble, whereas

the fabrication process is complex. Another PS-FBG

inscription technique is proposed by overexposing a

uniform FBG with femtosecond laser and a uniform

PM (He et al., 2015), which is easy to implement,

but an obvious decrease in the transmission loss at

the Bragg wavelength is observed during the

inscription process.

In this paper, a new method for PS-FBG

inscription in nonphotosensitive single mode fiber

358

Jiang, Y., Xu, J., Yuan, Y., Yang, D., Li, D., Wang, M. and Zhao, J.

Characteristics of Phase-Shifted Fiber Bragg Grating Inscribed by Fusion Splicing Technique and Femtosecond Laser.

DOI: 10.5220/0005738503560360

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 358-362

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(SMF) by fusion splicing technique and

femtosecond laser is reported. The PS-FBG is

inscribed by fusion splicing two SMFs and then

exposing the fusion spliced fiber with femtosecond

laser and a uniform PM. Its annealing, strain and

pressure characteristics are experimentally studied.

2 EXPERIMENTAL SETUP

The inscription process is divided into three steps.

First, the SMF (Coring SMF-28e+) is cleaved into

two sections by using an optical fiber cleaver after

stripping its coating with a length of about 20 mm.

Then the two sections are spliced by a fusion splicer,

and the typical fusion loss is 0.01 dB. Finally, the

fusion spliced fiber is exposed by femtosecond laser

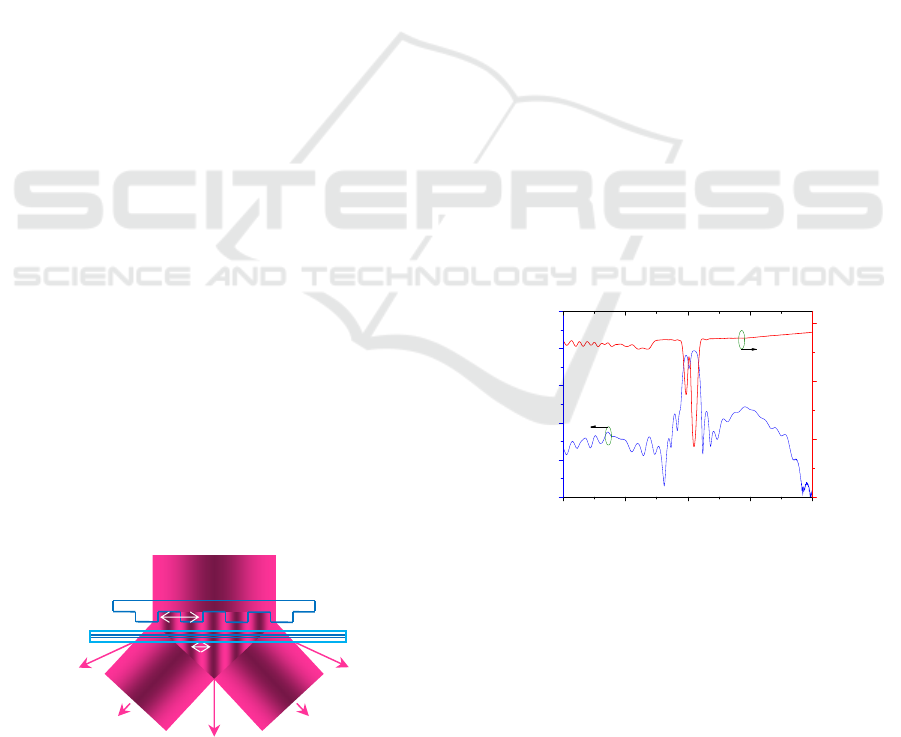

through a cylindrical lens and a uniform PM. Figure

1 shows the schematic diagram of the PS-FBG

inscription by femtosecond laser. The femtosecond

laser pulses have a 35 fs duration and are generated

by a Ti:sapphire amplifier at wavelength of 800 nm

with pulse repetition rate of 1 kHz. The max output

pulse energy of 4 mJ can be adjusted by rotating a

half-wave plate followed by a polarizer. The laser

beam has a radius of 4 mm and is focused by the

cylindrical lens with focal length of 40 mm through

a zero-order nulled PM onto the fiber. The half-

width of the focal line

is 2.5 m according to

=

f/(

0

)

,

where

is the wavelength, f is the focal

length of the cylindrical lens, and

0

is the incident

beam radius. The coating stripped SMF is cleaved

and spliced, and then it is positioned behind the PM

at a distance of about 2 mm in order to produce two-

pure interference (Smelser et al., 2004). The PM is

designed for 800 nm radiation with a period of 2142

nm (Ibsen Photonics) which is twice of the period of

inscribed PS-FBG. Less than 5% of the beam is

diffracted into the 0th order, and more than 70% of

the beam is diffracted into the 1st orders. The

Figure 1: Schematic diagram of the PS-FBG inscription by

femtosecond laser.

during the inscription process by an ASE source and

an optical spectrum analyzer.

3 RESULTS AND DISCUSSIONS

The fusion spliced fiber is exposed by 600 J laser

pulses for 100 s and the peak power density at the

focus is about 4.110

13

W/cm

2

. Figure 2 gives the

reflection and transmission spectra of the induced

PS-FBG. We can see that there are two main dips in

the transmission spectrum because the PS-FBG is

successfully inscribed. A refractive index

modulation point is introduced by fusion splicing

two SMFs in the fiber core, which acts as a phase

shift during the inscription process. The 2nd order

PS-FBG is inscribed according to the Bragg

condition defined by m

Bragg

=2n

eff

g

, where

Bragg

is

the Bragg wavelength, m is the order number, n

eff

represents the effective index of fiber core, and

g

donates the grating period. The measured Bragg

wavelength

Bragg

=1548.1 nm, so the calculated

n

eff

=1.445. The phase shift is observed during the

whole inscription process which is different from the

PS-FBG formation in stage II (He et al., 2015), and

it is almost unchanged. The cladding modes are also

observed due to the light coupling into the fiber

cladding, which can be suppressed by scanning the

inscription laser beam vertically to maximize

coverage of the fiber core region.

1544 1546 1548 1550 1552

-70

-60

-50

-40

-30

-20

Wavelength (nm)

Reflection (dBm)

-40

-35

-30

-25

Transmission (dBm)

Figure 2: Reflection and transmission spectra of the PS-

FBG inscribed by femtosecond laser.

During the inscription process, the wavelengths

show a nonlinear red shift for about 0.14 nm with

the exposure time (total incident laser fluence). The

transmission losses of the 1st and 2nd dips increase

to -9.3 dB and -4.8 dB, while the wavelengths shift

to 1548.20 nm and 1547.94 nm, respectively. No

obvious saturation is observed within 100 s. The

induced refractive index modulation can be inferred

from the expression for maximum reflectivity

Femtosecond laser

0 order

+1 order -1 order

PM

SMF

g

m

+2 order

-2 order

Characteristics of Phase-Shifted Fiber Bragg Grating Inscribed by Fusion Splicing Technique and Femtosecond Laser

359

R=tanh

2

(

L), where the coupling coefficient

=mn

m

/(2n

eff

m

), L is the grating length, n

m

is

the refractive index modulation of the mth order

grating, and

m

is the PM period. So the induced

refractive index modulation n

m

=3.310

-4

for a dip

of -9.3 dB. The fiber core’s refractive index n

eff

at

the fusion spliced point decreases within few

hundreds of micronmeters due to dopant diffusion,

glass structure change and residual stress relaxation

(Abrishamian et al., 2012), so negative refractive

index change in the fusion spliced point is

introduced to form a PS-FBG during the inscription

process. The insertion loss at 1550 nm is about 0.3

dB.

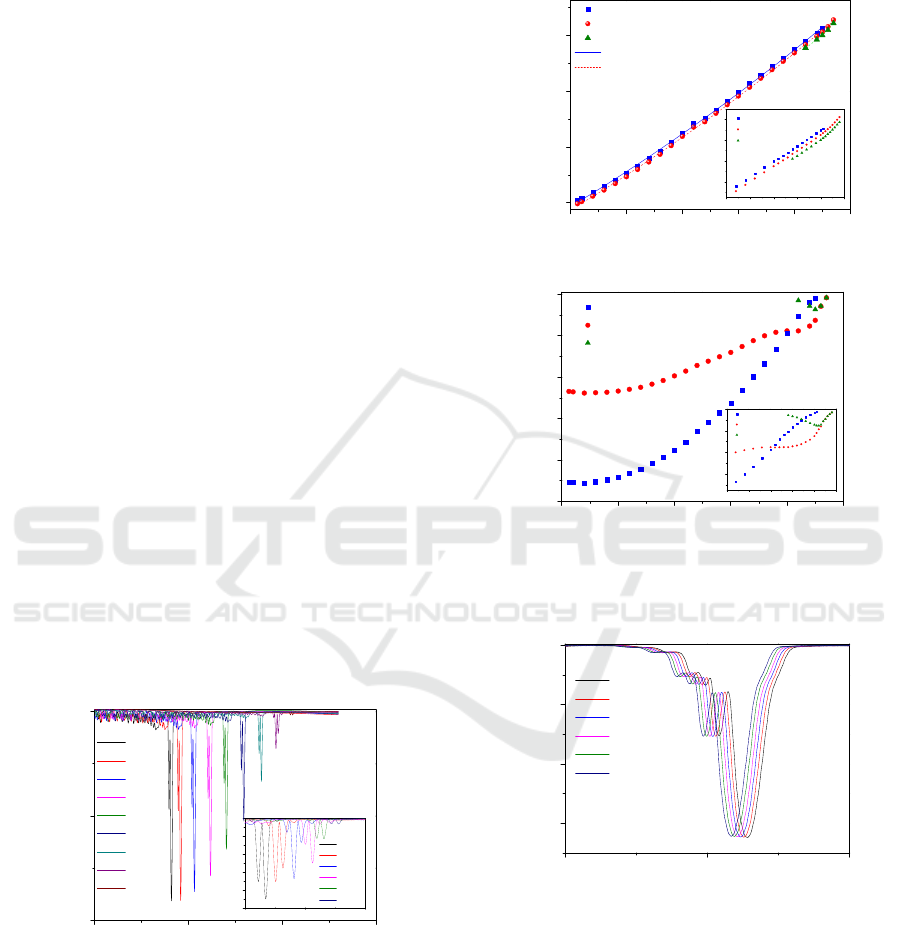

The annealing tests are conducted in a tube

furnace. The evolution of the transmission spectra of

PS-FBG form 24

°

C to 940

°

C are shown in Fig. 3. It

can be seen that the transmission spectrum of PS-

FBG shifts to long wavelength, at the same time, it

transmission decreases with increase the

temperature. The change of the central wavelengths

and the transmission losses with the temperature are

given in Fig 4 (a) and (b), respectively. It can be

seen that the central wavelengths of the two dips

shift almost with the same speed according to the

polynomial fit results. But the transmission loss of

the 2nd dip changes slowly compared with the 1st

dip. There is a turning point near the temperature of

800

°

C at which the loss of the 2nd dip is larger than

the 1st one. At the same time a new third dip can be

observed, its loss increases firstly and approaches to

the 2nd one at the temperature of 920

°

C, and then

they decrease at the same speed. The experimental

results show that type I PS-FBG has been inscribed.

Figure 3: Evolution of the transmission spectra of PS-FBG

under different temperature.

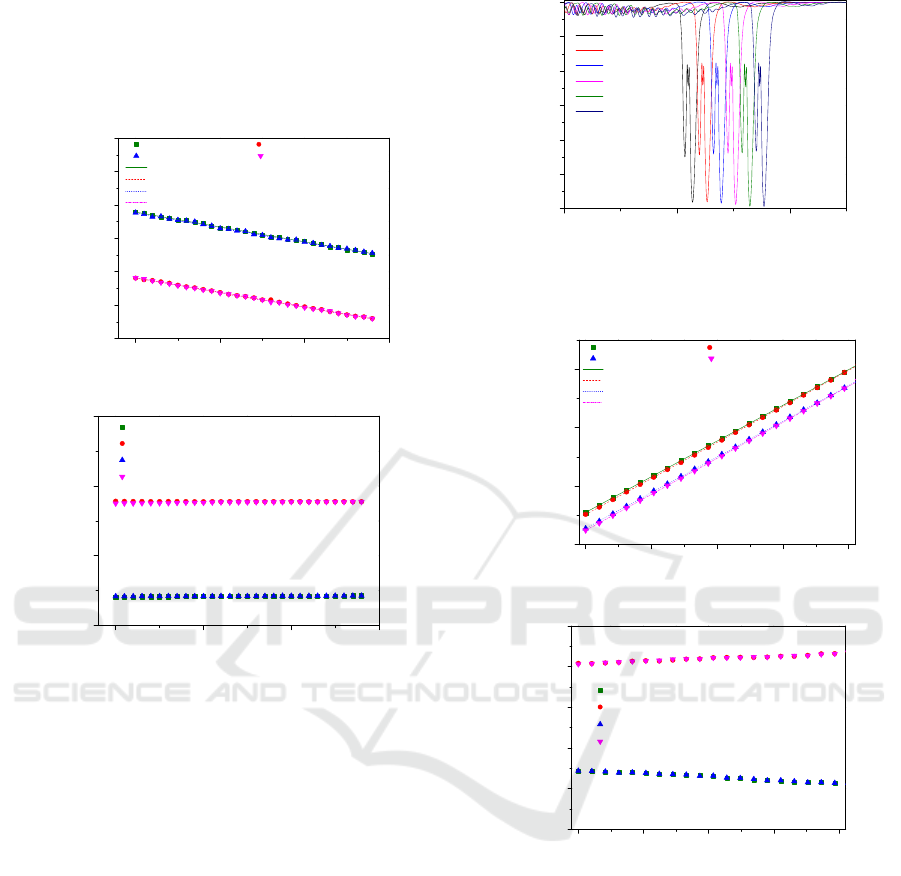

The hydrostatic pressure test of the PS-FBG was

performed in a sealed stainless steel tube filled with

water. The transmission loss of the PS-FBG is about

-13 dB, so the induced refractive index modulation

n

m

=4.210

-4

. Figure 5 gives the evolution of the

transmission spectra of PS-FBG under different

pressures in the range from 0 MPa to 25 MPa with a

step of 5 MPa. It can be seen that the transmission

Figure 4: Change of the (a) central wavelengths and (b)

transmission losses for two dips with the temperature.

1547 1548 1549

-12

-8

-4

0

Transmission (dB)

Wavelength (nm)

0 MPa

5 MPa

10 MPa

15 MPa

20 MPa

25 MPa

Figure 5: Evolution of the transmission spectra of PS-FBG

under different pressures.

spectrum has a blue shift and its shape is not

distorted during increasing the pressure. Figure 6

depicts the central wavelengths and transmission

losses for the two dips under different pressures.

From Fig. 6 (a), we can see that the central

wavelengths for two dips decrease linearly with the

pressure at a same sensitivity of -4.4 pm/MPa, which

is slightly higher than that of the UV laser induced

0 200 400 600 800 1000

-10

-8

-6

-4

-2

0

1st dip

2nd dip

3rd dip

Transmission (dB)

Temperature (

0

C)

(b)

700 750 800 850 900 950

-3

-2

-1

0

1st dip

2nd dip

3rd dip

700 750 800 850 900 950

1558

1559

1560

1561

1st dip

2nd dip

3rd dip

0 200 400 600 800 1000

1548

1552

1556

1560

1st dip

2nd dip

3rd dip

Polynomial fit of the 1st dip

Polynomial fit of the 2nd dip

Wavelength (nm)

Temperature (

0

C)

Y1=2.5*E-6X1^2+0.012*X1+1547.73

Y2=2.6*E-6X2^2+0.012*X2+1547.48

(a)

1558 1560 1562

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

780

0

C

820

0

C

860

0

C

900

o

C

920

o

C

940

o

C

1540 1550 1560 1570

-10

-5

0

Transmission (dB)

Wavelength (nm)

24

0

C

120

0

C

240

0

C

360

0

C

480

0

C

600

0

C

720

0

C

840

0

C

940

0

C

OSENS 2016 - Special Session on Optical Sensors

360

FBG in standard SMF. There is no hysteresis for

both increasing and decreasing cycles. In Fig. 6 (b),

the transmission losses of the two dips are almost

unchanged under different pressures, and the

fluctuation is only about 0.1 dB.

0 10 20 30

1547.9

1548.0

1548.1

1548.2

1548.3

1548.4

1548.5

Increase of the 1st dip Increase of the 2nd dip

Decrease of the 1st dip Decrease of the 2nd dip

Linear fit of increase of the 1st dip

Linear fit of increase of the 2nd dip

Linear fit of decrease of the 1st dip

Linear fit of decrease of the 2nd dip

Wavelength (nm)

Pressure (MPa)

The 1st dip

Increase: Y1=1548.279-0.0044*X1

Decrease: Y2=1548.277-0.0044*X2

The 2st dip

Increase: Y3=1548.082-0.0044*X3

Decrease: Y4=1548.082-0.0044*X4

(a)

0 10 20 30

-15

-10

-5

0

Increase of the 1st dip

Increase of the 2nd dip

Decrease of the 1st dip

Decrease of the 2nd dip

Transmission (dB)

Pressure (MPa)

(b)

Figure 6: Changes of the (a) central wavelengths and (b)

transmission losses for two dips under different pressures.

The strain test of another PS-FBG with the dip of

-11.6 dB inscribed under the same condition was

performed by fixing it on two manual translating

stages with a resolution of 0.01 mm, and the space

between the two fixed points was 483 mm. The

strain was applied on the FBG by adjusting one of

the translating stages up to 1 mm with a step of 0.05

mm. Figure 7 shows the evolution of the

transmission spectra under different strains in the

range from 0 to 2070 . We can see that the

transmission spectrum has a red shift and there is no

distortion during increasing the strain. Figure 8 (a)

and (b) depict the wavelengths shift for two dips

under different strains. We can see that the strain

response of the PS-FBG shows good linearity and

repeatability, and the strain sensitivity is 1.2 pm/,

which is the same with that of the UV laser induced

FBG. But the transmission loss of the 1st dip

decreases when increasing the strain, while it

increases for the 2nd one.

1544 1548 1552

-12

-10

-8

-6

-4

-2

0

Transmission (dB)

Wavelength (nm)

0

414

828

1242

1656

2070

Figure 7: Evolution of the transmission spectra under

different strains.

0 500 1000 1500 2000

1548

1549

1550

1551

Increase of the 1st dip Increase of the 2nd dip

Decrease of the 1st dip Decrease of the 2nd dip

Linear fit of increase of the 1st dip

Linear fit of decrease of the 1st dip

Linear fit of increase of the 2nd dip

Linear fit of decrease of the 2nd dip

Wavelength (nm)

Strain ()

The 1st dip

Increase:Y1=1548.551+0.0012*X1

Decrease:Y2=1548.515+0.0012*X2

The 2nd dip

Increase:Y3=1548.278+0.0012*X3

Decrease:Y4=1548.243+0.0012*X4

(a)

0 500 1000 1500 2000

-13

-12

-11

-10

-9

-8

Increase of the 1st dip

Increase of the 2nd dip

Decrease of the 1st dip

Decrease of the 2nd dip

Transmission (dB)

Strain ()

(b)

Figure 8: Change of the (a) central wavelengths and (b)

transmission losses for two dips under different strains.

4 CONCLUSIONS

In conclusion, PS-FBGs have been successfully

inscribed in nonphotosensitive SMFs by fusion

splicing technique and femtosecond laser through a

uniform PM. Two main dips can be observed due to

the formation of PS-FBG and its transmission

spectrum of PS-FBG shows a nonlinear red shift

during the inscription process. The max induced

refractive index modulation of 4.210

-4

is achieved

for a PS-FBG with a dip of -13 dB for a peak power

Characteristics of Phase-Shifted Fiber Bragg Grating Inscribed by Fusion Splicing Technique and Femtosecond Laser

361

density of 4.510

13

W/cm

2

. The annealing, strain

and pressure characteristics of the PS-FBG are

experimentally studied. These PS-FBGs inscribed in

SMFs by femtosecond laser will find applications in

optical fiber lasers, two wavelength filters and

optical fiber sensors.

ACKNOWLEDGEMENTS

This work was supported by the National Natural

Science Foundation of China (Grant No. 61405163),

the Fundamental Research Funds for the Central

Universities (Grants No. 3102014KYJD025,

3102014JCQ01100 and 3102015BJ(Ⅱ)ZS015) and

the Northwestern Polytechnical University

Foundation for Fundamental Research (Grant No.

JC20110272).

REFERENCES

Agrawal, G & Radic, S 1994, ‘Phase-shifted fiber Bragg

gratings and their application for wavelength

demultiplexing’, IEEE Photonics Technology Letters,

vol. 6, no. 8, pp. 995-997.

Chen, X, Yao, J & Deng, Z 2005, ‘Ultranarrow dual-

transmission-band fiber Bragg grating filter and its

application in a dual-wavelength single-longitudinal-

mode fiber ring laser’, Optics Letters, vol. 30, no. 16,

pp. 2068-2070.

Zou, X, Li, M, Pan, W, Yan, L, Azaña, J & Yao, J 2013,

‘All-fiber optical filter with an ultranarrow and

rectangular spectral response’, Optics Letters, vol. 38,

no. 16, pp. 3096-3098.

Rosenthal, A, Razansky, D & Ntziachristos, V 2011,

‘High-sensitivity compact ultrasonic detector based on

a -phase-shifted fiber Bragg grating’, Optics Letters,

vol. 36, no. 10, pp. 1833-1835.

Liu, T & Han, M 2012, ‘Analysis of -phase-shifted fiber

Bragg gratings for ultrasonic detection’, IEEE Sensors

Journal, vol. 12, no. 7, pp. 2368-2373.

Malara, P, Campanella, C, De Leonardis, F, Giorgini, A,

Avino, S, Passaro, V & Gagliardi, G 2015, ‘Enhanced

spectral response of pi-phase shifted fiber Bragg

gratings in closed-loop configuration’, Optics Letters,

vol. 40, no. 9, pp. 2124-2126.

Reid, D, Ragdale, C, Bennion, I, Buus, J & Stewart, W

1990, ‘Phase-shifted Moiré grating fibre resonators’,

Electronics Letters, vol. 26, no. 1, pp. 10-12.

Cole, M, Loh, W, Laming, R, Zervas, M & Barcelos, S

1995, ‘Moving fibre/phase mask-scanning beam

technique for enhanced flexibility in producing fibre

gratings with uniform phase mask’, Electronics

Letters, vol. 31, no. 17, pp. 1488-1490.

Canning, J & Sceats, M 1994, ‘π-phase-shifted periodic

distributed structures in optical fibres by UV post-

processing’, Electronics Letters, vol. 30, no. 16, pp.

1344-1345.

Xia, L, Shum, P & Lu, C 2005, ‘Phase-shifted bandpass

filter fabrication through CO

2

laser irradiation’, Optics

Express, vol. 13, no. 15, pp. 5878-5882.

Chehura, E, James, S & Tatam, R 2010, ‘A simple and

wavelength-flexible procedure for fabricating phase-

shifted fibre Bragg gratings’, Measurement Science &

Technology, vol. 21, no. 9, pp. 094001-1-7.

Thomas, J, Voigtländer, C, Schimpf, D, Stutzki, F,

Wikszak, E, Limpert, J, Nolte, S & Tünnermann, A

2008, ‘Continuously chirped fiber Bragg gratings by

femtosecond laser structuring’, Optics Letters, vol. 33,

no. 14, pp. 1560-1562.

Marshall, G, Williams, R, Jovanovic, N, Steel, M &

Withford, M 2010, ‘Point-by-point written fiber-Bragg

gratings and their application in complex grating

designs’, Optics Express, vol. 18, no. 19, pp. 19844-

19859.

Williams, R, Voigtländer, C, Marshall, G, Tünnermann, A,

Nolte, S, Steel, M & Withford, M 2011, ‘Point-by-

point inscription of apodized fiber Bragg gratings’,

Optics Letters, vol. 33, no. 15, pp. 2988-2990.

Burgmeier, J, Waltermann, C, Flachenecker, G & Schade,

W 2014, ‘Point-by-point inscription of phase-shifted

fiber Bragg gratings with electro-optic amplitude

modulated femtosecond laser pulses’, Optics Letters,

vol. 39, no. 3, pp. 540-543.

Liao, C, Xu, L, Wang, C, Wang, D, Wang, Y, Wang, Q,

Yang, K, Li, Z, Zhong, X, Zhou, J & Liu, Y 2013,

‘Tunable phase-shifted fiber Bragg grating based on

femtosecond laser fabricated in-grating bubble’,

Optics Letters, vol. 38, no. 21, pp. 4473-4476.

He, J, Wang, Y, Liao, C, Wang, Q, Yang, K, Sun, B, Yin,

G, Liu, S, Zhou, J & Zhao, J 2015, ‘Highly

birefringent phase-shifted fiber Bragg gratings

inscribed with femtosecond laser’, Optics Letters, vol.

40, no. 9, pp. 2008-2011.

Smelser, C, Grobnic, D & Mihailov, S 2004, ‘Generation

of pure two-beam interference grating structuresin an

optical fiber with a femtosecond infrared source and a

phase mask’, Optics Letters, vol. 29, no. 15, pp. 1730-

1732.

Abrishamian, F, Dragomir, N & Morishita, K 2012,

‘Refractive index profile changes caused by arc

discharge in long-period fiber gratings fabricated by a

point-by-point method’, Applied Optics, vol. 51, no.

34, pp. 8271-8276.

OSENS 2016 - Special Session on Optical Sensors

362