Light Properties Improvement of Light Emitting Woven Textiles with

Optical Fibres for Photodynamic Therapy

Yesim Oguz

1,2

, Cedric Cochrane

1,2

, Vladan Koncar

1,2

and Serge Mordon

1,3

1

University Lille Nord de France, F-59000 Lille, France

2

ENSAIT, GEMTEX, F-59100 Roubaix, France

3

INSERM 1189 ONCO-THAI, Lille University Hospital, CHRU, Lille, France

Keywords: Light Emitting Fabric (LEF), Plastic Optical Fibres (POF), Photodynamic Therapy (PDT), Doehlert

Experimental Design, Response Surface Method (RSM).

Abstract: For an efficient and less painful photodynamic therapy (PDT), a light emitting fabric (LEF) was woven

from plastic optical fibres (POF) aiming at the treatment of dermatologic diseases such as Actinic Keratosis

(AK). The traditional PDT treatments applied with external light sources deliver a non-uniform light

distribution on the skin surface due to the anatomical particularity of the human body (head vertex, hand,

etc.). Therefore a successful PDT obligates a homogenous and reproducible light delivery. With this

purpose, plastic optical fibres (POF) have been woven in textile in order to create macro-bendings and thus

emit out the injected light directly to the skin. To improve the light intensity and light emitting homogeneity

of the LEF, Doehlert Experimental Design is applied. Fifteen experiments performed to analyze the

response surface. Light properties of the prototypes were evaluated. The proposed models fitted well with

the experimental data and enabled the optimal set up the warp yarns tensions. This study showed that RSM

was a suitable tool to optimize the models of light diffusion properties.

1 INTRODUCTION

Photodynamic therapy (PDT) is a treatment

procedure for localized cancer or pre-cancer that

requires photosensitizer, tumour oxygenation, and

controlled light delivery to provide a treatment

efficient (Mordon et al. 2015). Actinic Keratosis, a

pre-cancerous skin disease, could be treated via PDT

with good cosmetic results.

The traditional PDT modality with external light

sources delivers a non-uniform light distribution on

the skin surface due to the irregularly shaped

cavities or surfaces of the human body (head vertex,

hand, etc.) (Mordon, Cochrane, et al. 2015;

Cochrane et al. 2011; Cochrane et al. 2013).

Therefore, a flexible medical textile was developed

for an adequate and homogenous light coverage of

the entire tumour with the aim of efficient, reliable

and less painful photodynamic therapy for AK

treatment.

In this work, a light emitting fabric (LEF) has

been woven by inserting POF in weft and Polyester

yarns in warp direction. An optimal weaving process

has been set up to predetermine macro-bendings of

the POFs, which introduce side emission of light

when the critical angle is exceeded. By modifying

the weave pattern or modifying the tension on the

warp yarns, it is possible to control the macro-

bendings of POF, so their side emitting property as a

result of weaving process.

A special pattern based on three different satin

weaves has been developed to obtain a good

homogeneity of light emission and regulate the loss

of side emitted radiation intensity along POFs.

Furthermore, Doehlert experimental design is

applied for developing a statistical model to achieve

response surfaces of the effects of the weaving

parameters on the light properties of LEF. First,

fifteen samples were produced with different

tensions on the warp beams calculated by

experimental design to find the optimal tension for a

good light distribution homogeneity and light

intensity of the LEF.

This research work aims at the investigation of

the effects of weaving process, as different warp

yarn tensions, on the light properties of the LEF. To

avoid the high number of experiments and costs with

the traditional one time method, the optimization of

148

Oguz, Y., Cochrane, C., Koncar, V. and Mordon, S.

Light Properties Improvement of Light Emitting Woven Textiles with Optical Fibres for Photodynamic Therapy.

DOI: 10.5220/0005743701460151

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 148-153

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the model performed with the most related technic,

response surface methodology (RSM).

2 EXPERIMENTAL

2.1 Weaving Process

In this work weaving process was used to create

macrobends on the optical fibres to emit the injected

light. Optical fibres confine light in the fibre core by

its nature, but bending the optical fibre changes the

incident angle of the injected light, thus radiative

losses occur (see Figure 1). It is possible to modify

the radius of macro-bendings, so the bending losses

by changing the tension on the warp yarns even if

there are other influent factors (textile yarns, weft

and warp density, number of turns etc.) on the side-

emitting properties (Wang et al. 2013; Lee et al.

2009). Adding tension on warp yarns render them

more rigid that effects sharpness of optical fiber

macrobends.

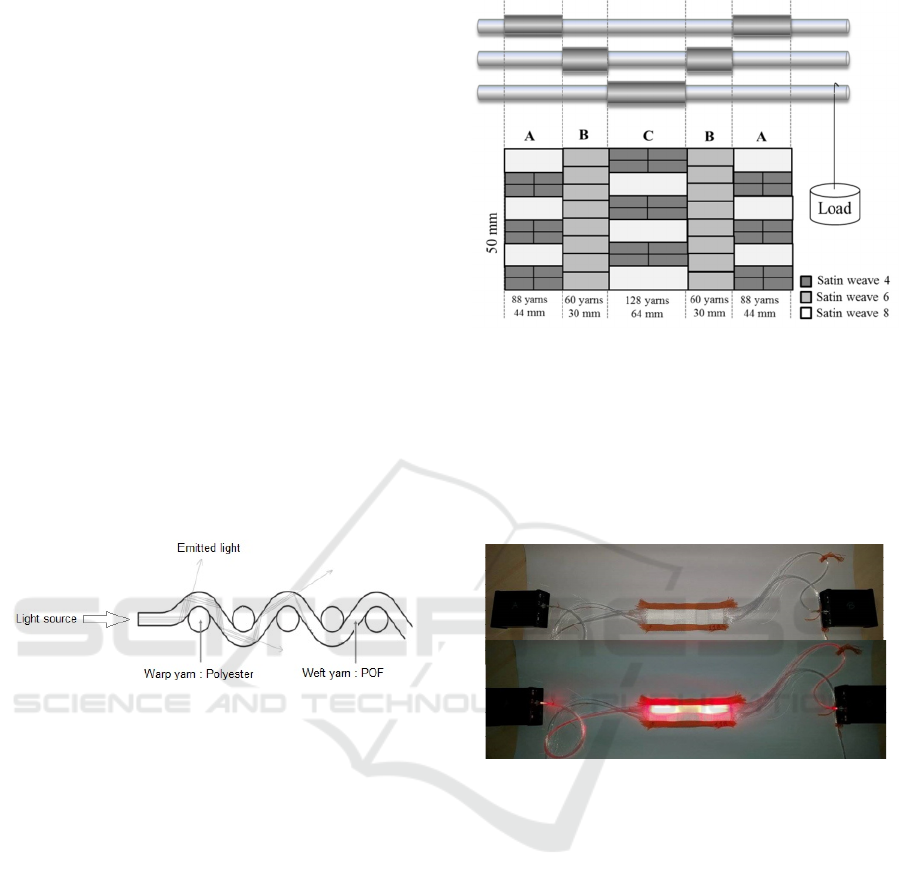

Figure 1: Inserted POF into a textile structure with the

weaving process.

Different weaving patterns were woven to see

their light intensity decay, and then a special

repeating pattern was designed to obtain

homogeneous light emission. This specific repeating

pattern was a composition of three different satin

weaves (SW) and divided in 5 woven areas.

Different zones signify the longitudinal bands with

same weaving patterns; zone A contains the first and

the fifth woven areas, zone B contains the second

and the fourth woven areas and zone C contains the

third woven area. Figure 2 shows the weaving

system with three warp beams that supply the zone

A, B and C on the LEF.

The sample size is chosen 200mm width because

of the morphology and the overall size of the faces.

2.2 Measurement of Light Intensity

and Light Emission Homogeneity

Light intensity and light delivery homogeneity of the

LEF samples were measured with a powermeter

Figure 2: Schema of the warp beams disposition and the

designed repeating weave pattern.

(Ophir II, 638nm) while they are connected to lasers

(1W) by their two ends (Figure 3). In a dark room,

the light intensity power was measured on each cm²

by excluding the measures 0,5 cm from the borders

and 1 cm from the ends.

Figure 3: Light emitting fabrics connected to laser by two

ends.

Two mathematical formulas were used to reduce

the number of values to compare the samples among

them. The average of the power per cm², and sum of

square deviations of power per cm² divided to square

of power average were chosen for light intensity (P)

and light emission homogeneity (H), respectively. A

puissant LEF with homogenous light distribution

necessitates a great P value and an H value close to

zero.

Furthermore, to avoid the reinjection in the light

sources, low light output from the brass boxes is

requested. Otherwise reinjection can increase the

temperature of the sources and cause device damage.

It was also observed that when the LEF was

connected to the laser from one side, if the light

output from the other end (connector) was low, light

intensity of the LEF was high.

Light Properties Improvement of Light Emitting Woven Textiles with Optical Fibres for Photodynamic Therapy

149

2.3 Doehlert Experimental Design

Doehlert design was used to optimize the light

intensity and the homogeneity of the LEF woven

with optical fibres. The flexibility of the design

allows adding new points to explore more the

domain without losing quality of the model (Bezerra

et al. 2008; Fauduet et al. 2003; Lee & Hamid 2015).

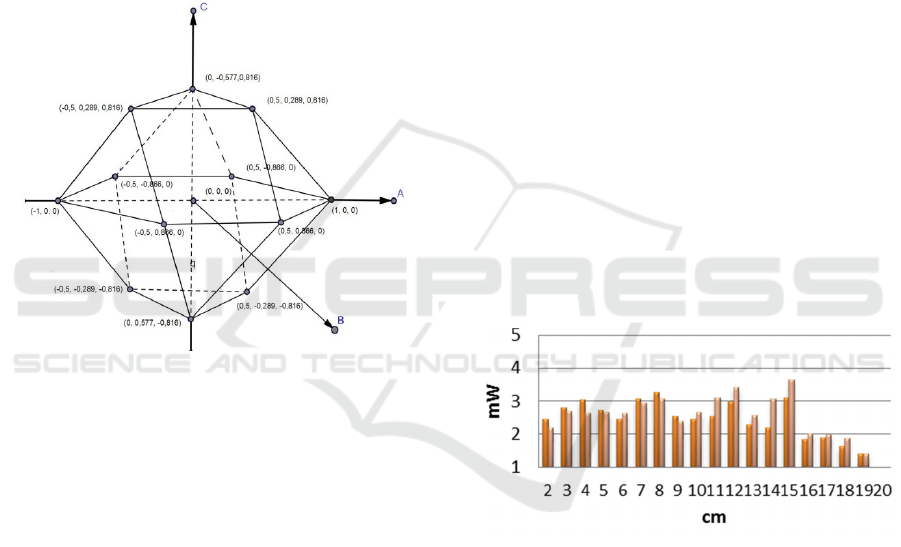

The most influential factors on the responses were

chosen and studied at 3, 5 and 7 levels: A signifies

the added tension on the first zone, B for the second,

and C for the third zone (Figure 4). The critical

points (minimum, centre, maximum point) were

chosen 40, 70, 100 g/warp yarn respectively.

Figure 4: 3D view of the experimental domain. Axis A, B

and C are the coded units of the experimental factors.

The general quadratic model with n factors and an

experimental response (Y) is given below:

2

0

11

nn n

i i ij i j ii i

iij i

Yb bx bxx bx

(1)

For a process concerning three factors; Tension

of zone 1 (A), Tension of zone 2 (B) and Tension of

zone 3 (C), the model is described as:

P = p

0

+ p

1

A + p

2

B+p

3

C + p

12

AB+ p

13

AC +

p

23

BC+ p

11

A² + p

22

B² + p33C²

(2)

Where, P is predicted response for the average of

LEF’s light intensity (mW/cm²), A, B, C are

independent variables, p

0

is independent term, p1,

p

2

, p

3

are the coefficients of the linear terms, p

11

, p

22

,

p

33

are the coefficients of the squared terms and p

12

,

p

23

, p

13

are interaction terms.

The same equation is also used to find the

predicted response H for the light emission

homogeneity of the LEF, sum of squares of light

puissance deviations divided by the square of

puissance average, with the same independent

variables A, B, C.

H = h0 + h1*A + h2*B + p3*C + h12*A*B +

h13*A*C + h23*B*C + h11*A² + h22*B² +

h33*C²

(3)

3 RESULTS

First of all, fifteen flexible LEFs were produced with

the calculated tension settings in order to predict the

responses of the light intensity and the light delivery

homogeneity of the LEF. The calculated and the

experimental responses are given in the table for the

quadratic model. The experiments were performed

in random order, and the central point (0, 0, 0)

experiments were repeated three times to observe

test repeatability. Then five more samples were

calculated and produced to find the sample with

optimal results (see the values on table 1).

The only sample, which has provided the

compromise of the expected properties, was sample

15 among the twenty samples of experimental

design. The calculated results with the experimental

design were achieved with the experiments. Figure 5

shows the light diffusion per cm² for sample 15.

Figure 5: Light emission of sample 15.

Furthermore the analysis of the variance

(ANOVA) used to verify the fit of the model; p-

value must be compared to chosen significant level

(usually α=0,05). If the p-value is less than or equal

to α, it means the model terms are highly significant.

Otherwise the null hypothesis is accepted. Table 2

demonstrates the model of P has statistically

significant terms.

The following equation 4 and equation 5 were

found by applying multiple regression analysis on

the experimental data. A, B, C correspond to

independent variables of two models.

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

150

P = 2,20 +(-0,32*A) +(0,02*B) +(0,17*C)

+(-0,05*AB) +(-0,02*AC) +(0,32*BC)

+(-0,22*A²) +(0,08* B²) +(-0,41*C²)

(4)

H = 14,45 + (8,20*A)+ (2,12*B)

+(-4,20*C)+ (-5,75*AB)+ (-3,72*AC)

+ (-1,91*BC)+ (8,01*A²)+ (1,52* B²)

+(-3,32*C²)

(5)

Table 1: Three-factors Doehlert experimental design, with the relative responses.

Predicted Results Experimental Results

Experiment A B C P H P H

1.1 0 0 0 2,15 15,61 2,11 12,74

1.2 0 0 0 2,15 15,61 2,28 19,96

1.3 0 0 0 2,15 15,61 2,06 14,12

1.4 0 0 0 2,20 14,45 2,55 13,7

2 1 0 0 1,65 30,66 1,65 31,18

3 -1 0 0 2,30 14,26 2,28 15,06

4 0,5 0,866 0 2,05 21,04 1,97 24,77

5 -0,5 -0,866 0 2,41 9,17 2,27 3,59

6 0,5 -0,866 0 2,04 22,35 1,98 21,38

7 -0,5 0,866 0 2,32 17,82 2,39 18,13

8 0,5 0,289 0,816 1,94 12,85 1,92 7,68

9 -0,5 -0,289 -0,816 2,00 10,28 1,82 13,63

10 0,5 -0,289 -0,816 1,64 23,18 1,71 23,32

11 0 0,577 -0,816 1,65 18,30 1,67 13,78

12 -0,5 0,289 0,816 2,23 9,35 2,17 8,66

13 0 -0,577 0,816 1,95 8,99 2,03 14,47

14 -1 -1 -1 2,21 3,16 2,23 5,0

15 -1 -1 -0,6 2,41 5,86 2,43 3,0

16 -1 -1 -0,7 2,37 5,29 2,44 3,8

17 -1 -1,3 -0,6 2,56 4,04 2,57 6,4

Table 2: ANOVA table for the light intensity and the light delivery homogeneity models.

Puissance (P) Homogeneity (H)

% D SS MS F- Probability D SS MS F-value Probability

Total 20 20

Constant 1 1

Total 19 1,52 19 1146,38

Regression 9 1,28 0,14 5,871 0,005* 9 957,29 106,37 5,625 0,006*

Residual 10 0,24 0,02 10 189,097 18,91

*Significant at probability value ≤ 0,05,

DF: Degrees of Freedom, SS: Sum of squares, MS: Mean Squares

Light Properties Improvement of Light Emitting Woven Textiles with Optical Fibres for Photodynamic Therapy

151

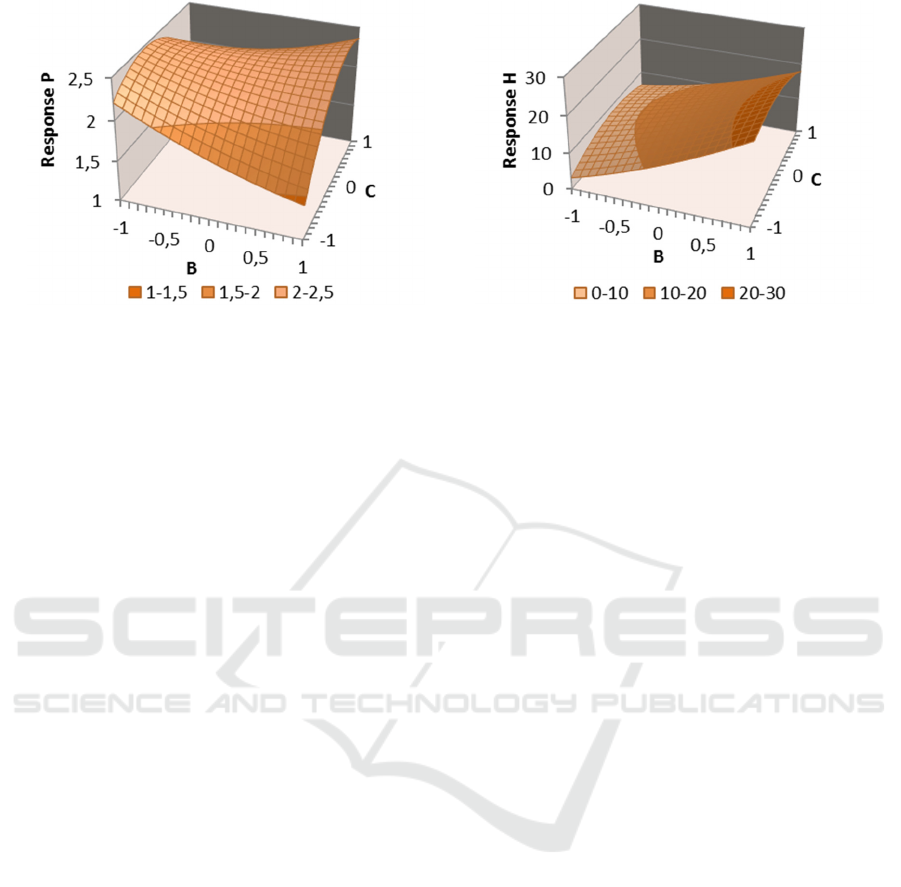

Figure 6: Response surface methodology graphics for the light diffusion models.

Response Surface Methodology (RSM) was used

to optimize the modelling for the light emission

properties of the LEF. Figure 6 presents the three-

dimensional RSM graphics for the light intensity (on

the left) and light diffusion homogeneity (on the

right) responses of the LEF.

The effects of factors were demonstrated that

optimal responses of model P and H could be

achieved if A is at its low level. As a result, when A

is fixed at its low level; the optimum compromise

result for two models is located between -0,4 and -1

(B axis), and between -0,5 and -1 (C axis), while B

is not an influent for the P model as obtained with

the sample 15.

4 CONCLUSIONS

The present study reports the application of the RSM

using the Doehlert experimental design of

experiments to develop a mathematical correlation

between the tension on the warp yarns and the light

diffusion properties of the fabric diffuser.

According to the experimental results of twenty

samples, two models were designed with Doehlert

matrix. The results proved that the optimum trial in

the domain was produced with sample 15, which

showed an average light intensity around 2,5 mW

and uniform light distribution. Furthermore, the

RSM graphs have given more information on the

optimal samples. It is certain that the tension of first

zone was expected to be at its low level (40g/warp

yarn) for the compromise result and there is an

important correlation among the tension of zone A,

B, C.

Predicted values correspond to the experimental

values of the light intensity model, with an

experimental error of the same order as that found in

the experimental design. So the model has been a

powerful tool for optimizing the light intensity of

designed fabric, but it was less suitable for

optimizing the light emission homogeneity.

This design also allowed us to find the optimal

tension settings in few experiences, which was time

consuming and inexpensive.

ACKNOWLEDGEMENTS

This work was supported by the GEMTEX

Laboratory, European Commission grant

PHOSISTOS in the Framework Programme 7, and

INSERM for the development and test of a light

emitting textile for the treatment of skin disease

actinic keratosis.

REFERENCES

Bezerra, M. A. et al., 2008. Response surface

methodology (RSM) as a tool for optimization in

analytical chemistry. Talanta, 76, pp.965–977.

Cochrane, C. et al., 2011. Flexible displays for smart

clothing : Part I — Overview. Indian Journal of Fibre

& Textile Research, 36, pp.422–428.

Cochrane, C. et al., 2013. New design of textile light

diffusers for photodynamic therapy. Materials science

& engineering. C, Materials for biological

applications, 33(3), pp.1170–5. Available at:

http://www.ncbi.nlm.nih.gov/pubmed/23827556

[Accessed September 30, 2014].

Fauduet, H. et al., 2003. Modelling of influential

parameters on a continuous evaporation process by

Doehlert shells. Journal of automated methods &

management in chemistry, 25(1), pp.21–30.

Lee, K. & Hamid, S., 2015. Simple Response Surface

Methodology: Investigation on Advance

Photocatalytic Oxidation of 4-Chlorophenoxyacetic

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

152

Acid Using UV-Active ZnO Photocatalyst. Materials,

8, pp.339–354. Available at:

http://www.mdpi.com/1996-1944/8/1/339/.

Lee, Park, K., 2009. Integration of Plastic Optical Fiber

into Textile Structures.pdf.

Mordon, S., Cochrane, C., et al., 2015. Light emitting

fabric technologies for photodynamic therapy.

Photodiagnosis and Photodynamic Therapy. Available

at: http://dx.doi.org/10.1016/j.pdpdt.2014.11.002.

Mordon, S., Maire, C., et al., 2015. Thérapie

photodynamique en dermatologie. Annales de

Dermatologie et de Vénéréologie, 142(6–7,

Supplement 2), pp.S329–S330. Available at:

http://www.sciencedirect.com/science/article/pii/S015

1963815002811.

Wang, J., Huang, B. & Yang, B., 2013. Effect of weave

structure on the side-emitting properties of polymer

optical fiber jacquard fabrics. Textile Research

Journal, 83(11), pp.1170–1180. Available at:

http://trj.sagepub.com/cgi/doi/10.1177/004051751247

1751 [Accessed September 22, 2014].

Light Properties Improvement of Light Emitting Woven Textiles with Optical Fibres for Photodynamic Therapy

153