Matching CAD Model and Image Features for Robot Navigation and

Inspection of an Aircraft

Igor Jovan

ˇ

cevi

´

c

1

, Ilisio Viana

1

, Jean-Jos

´

e Orteu

1

, Thierry Sentenac

1,2,3

and Stanislas Larnier

2,3

1

Universit

´

e de Toulouse, CNRS, INSA, UPS, Mines Albi, ISAE, ICA, Campus Jarlard, F-81013 Albi, France

2

CNRS, LAAS, 7 Avenue du Colonel Roche, F-31400 Toulouse, France

3

Universit

´

e de Toulouse, UPS, LAAS, F-31400 Toulouse, France

Keywords:

Computer-aided-inspection, Image Analysis, Feature Matching, PTZ Camera, Hough Transform, EDCircle.

Abstract:

This paper focuses on the navigation of a moving robot equipped with cameras, moving around an aircraft to

perform inspection of different types of items (probes, doors, etc.). Matching CAD model and image features

is useful to provide meaningful features for localization and inspection tasks. In our approach two primitive

sets are matched using a similarity function. The similarity scores are injected in the edges of a bipartite

graph. A best-match search procedure in bipartite graph guarantees the uniqueness of the match solution. The

method provides good matching results even when the location of the robot with respect to the aircraft is badly

estimated. Inspection approaches on static ports and air inlet vent are presented.

1 INTRODUCTION

Airplanes are periodically inspected, either on the air-

port tarmac between flights or in a hangar during

maintenance operations. Today, these inspections are

done by human operators, mainly visually and some-

times with some inspection tools. In order to make

the inspection quicker, more exhaustive and more ac-

curate, as well as for traceability reasons, a multi-

partners research project is being carried on to de-

velop a mobile robot equipped with several sensors

(cameras and 3D scanners) to perform an automatic

inspection of an airplane. The chosen approach is

based on an autonomous mobile robot on the ground,

capable to communicate with human operators and in-

frastructures around the aircraft. In addition to the

long range navigation task, at each checkpoint, the

robot performs an inspection task of several items

(probes, doors, etc.).

Robotic airplane inspection from the ground,

based on computer vision, is a specific application not

enough studied. Previous efforts (Siegel et al., 1998;

Mumtaz et al., 2012) were mainly focused on detailed

airplane skin inspection with robot crawling on the

airplane surface. In most cases, industrial automation

systems (Malamas et al., 2003) are used to inspect

known objects at fixed positions with appropriate illu-

mination necessary to extract meaningful features. In

our application, sensors are mounted on the moving

robot and no additional illumination is used. More-

over, our intention is to enable robot to cover as many

items as possible from one position, i.e. to move as

less as possible.

Firstly, navigation algorithms lead the robot to a

checking position which is localized in the aircraft

model. Secondly, automated image acquisition is

provided by controlling Pan-Tilt-Zoom (PTZ) camera

and pointing it towards the item to be inspected. In-

spection is performed by processing the images. For

each item, integrity or right configuration should be

verified. To perform more accurately, it is required to

obtain a zoomed view of the element to be inspected.

Therefore, the essential step is detection of the region

of interest (ROI) in an image. Detection of items on

the aircraft surface is an important step for navigation

tasks as well. Advantage in the present context is that

the airplane 3D model with the items to be detected is

known (Fig. 1). Therefore, it is possible to project it

onto the image plane to obtain the expected shape and

position of desired items.

Since the shapes on the airplane surface are reg-

ular geometrical shapes such as circles, ellipses or

rounded corners rectangles, our detection approaches

are relying on geometric feature extraction tech-

niques. Extracted primitives are ellipses and straight

line segments. After extraction, each primitive is as-

sociated with an item or part of an item. Our approach

proposes a score for similarity between the projec-

Jovan

ˇ

cevi

´

c, I., Viana, I., Orteu, J-J., Sentenac, T. and Larnier, S.

Matching CAD Model and Image Features for Robot Navigation and Inspection of an Aircraft.

DOI: 10.5220/0005756303590366

In Proceedings of the 5th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2016), pages 359-366

ISBN: 978-989-758-173-1

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

359

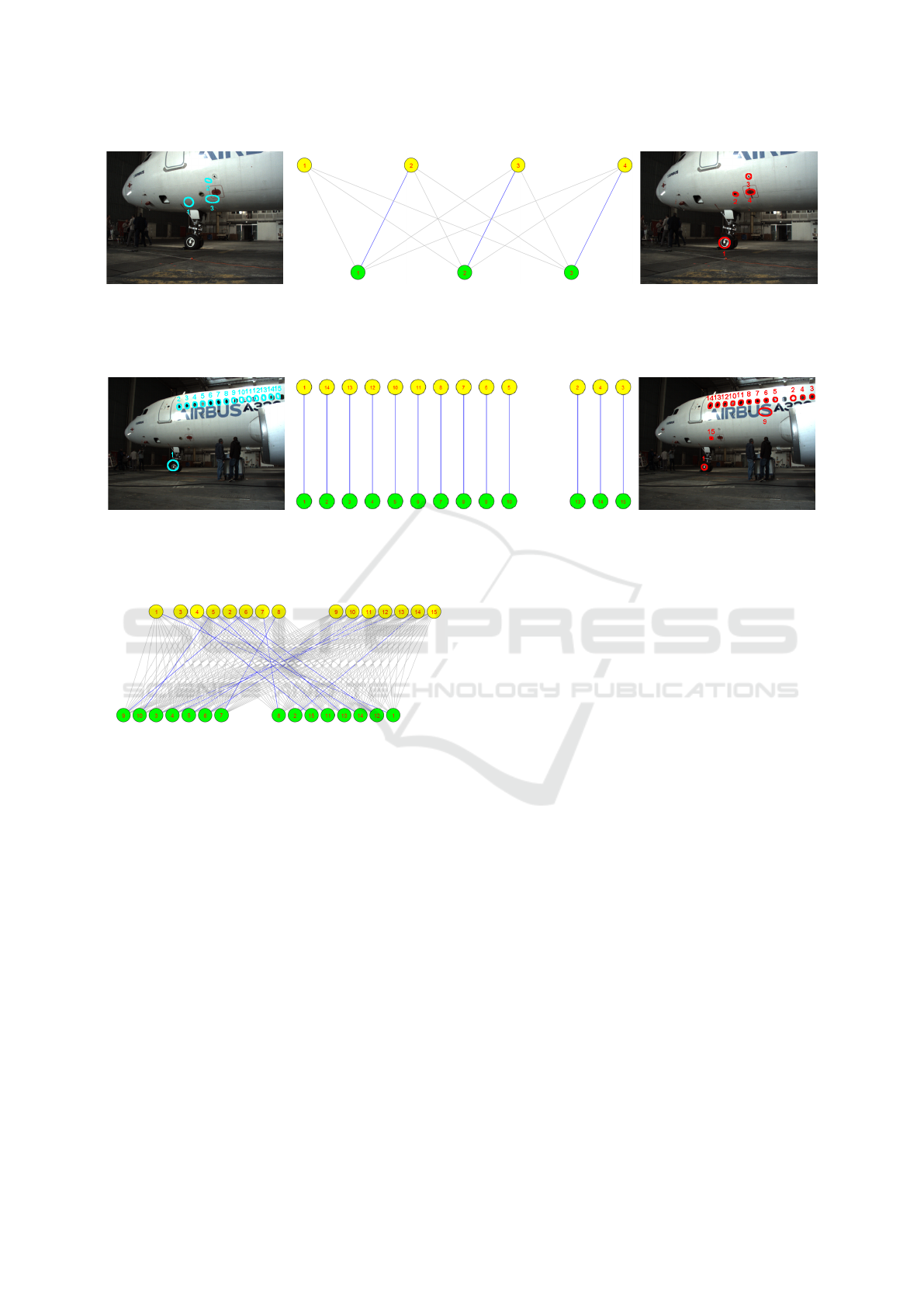

(a) Aircraft model with a far away

view.

(b) Aircraft model near the checking

position.

(c) Aircraft model view from the

checking position.

Figure 1: Screenshots of the 3D aircraft model.

(a) Navigation far from the air-

craft.

(b) Navigation near the aircraft. (c) Inpection of the static port element.

Figure 2: Aircraft views taken by the mobile robot for navigation and inspection. Ellipse feature extraction with EDCircle.

tions and the primitives detected in the real image.

Navigation algorithms around the aircraft rely

firstly on visual servoing (Chaumette and Hutchin-

son, 2006). To perform visual servoing between

checkpoints around an aircraft, the navigation algo-

rithm needs features associated with aircraft visual

elements (windows, tires, trapdoors, company logo,

etc.). Since the aircraft inspection has to be performed

inside or outside, at any time of the day and with dif-

ferent weather conditions, the detection part has to

work even with low contrast images.

Different tracking methods are currently used

such as low contrast, blob, motion edges, template.

The low contrast tracker is a succession of low con-

trast detections. The search zone takes into account

the previous location of the target and the robot move-

ments. The other methods come from the ViSP library

(Marchand and Chaumette, 2005). Our strategy is to

let the robot choose the best tracking method in func-

tion of the aircraft visual element and its status in the

scene. The selection of the best tracking method is

done by taking into account knowledge acquired from

experiments and detection results.

During navigation, robot can switch from vi-

sual servoing to obstacle avoidance (Futterlieb et al.,

2014). In this mode, the plane could dissapear from

the field of view and the robot location is updated only

with odometry. Then a new detection and matching

of the features is needed to restart the visual servoing

and correct the robot location. The visual servoing

algorithm leads the robot to a checking position.

Final step in the process is visual inspection and

making decision on the state of a particular item on

the aircraft. Usual weakness of an inspection system

is being specialized in inspecting one particular type

of object. In that sense, each of the items on the air-

plane could be an isolated, specific, inspection prob-

lem. Our intention is to design more general strate-

gies, applicable to a class of similar items by chang-

ing just parameters and geometry. For instance, there

are many doors and vents on the airplane which can

be closed or open. For more details about inspection,

reader is referred to (Jovan

ˇ

cevi

´

c et al., 2015).

Navigation cameras acquire color images at a res-

olution of 480 × 640 pixels. PTZ camera provides

color images at a resolution of 1080 × 1920 pix-

els. Acquisition images of the aircraft and associated

views of the 3D model are presented in Fig. 2 and 1

respectively. The three images present the distance

ranging from far away to a checking position of the

static port element. Fig. 2a is an image coming from

the navigation camera, taken when the mobile robot

is far away from the airplane. Fig. 2b is also an image

coming from the navigation camera, taken when the

mobile robot is near the airplane. Fig. 2c is an image

coming from the PTZ camera, taken when the mobile

robot stopped at the end of the visual servoing and it

should perform inspection.

Paper is organized as follows. Two used fea-

ture extraction algorithms are introduced in Sec. 2.

In Sec. 3 we explain the matching method between

features extracted from the computer-aided design

(CAD) model and the ones detected in the image. The

matching results for the image views from Fig. 2 are

ICPRAM 2016 - International Conference on Pattern Recognition Applications and Methods

360

given in Sec. 4. Two inspection methods relying on

clues such as uniformity of isolated image regions

and convexity of segmented shapes are presented in

Sec. 5.

2 FEATURE EXTRACTION

2.1 Ellipses Extraction

Akinlar and Topal have proposed a robust circle de-

tection method (Akinlar and Topal, 2013), named

EDCircles. The ellipses features in camera images

are obtained after postprocessing of EDCircles results

(Fig. 2). Since it is impossible to have an intersec-

tion of two circles on the airplane, intersected circles

are merged and an ellipse is fitted on them (Prasad

et al., 2013). Sometimes, there is multiple results on

the same location and they are also merged. See the

result of postprocessing in Fig. 4c, 5c and 7c.

Ellipse detector is employed in order to detect nu-

merous elliptical shapes on the airplane skin such as

Air inlet vent (Sec. 5.1).

2.2 Line Segments Extraction

For segments extraction, we are running the progres-

sive probabilistic Hough Transform (PPHT) (Matas

et al., 2000) implementation from OpenCV library.

This method provides set of continuous straight line

segments. It is possible to use other segment detec-

tors such as more recent LSD (von Gioi et al., 2010)

or EDLines (Akinlar and Topal, 2011).

Outputs of all these detectors demand sensitive

postprocessing step of filtering due to the large set of

detected segments (Fig. 3a). First, segments which

are aligned (approximately belong to one ray) are

identified and average ray is calculated. Then, this

set of aligned segments is projected onto the average

ray and the projections are divided into clusters of

overlapping (or nearby) segments. The segments of

each such cluster are finally merged into one segment

(Fig. 3b).

The resulting set of segments is traversed in or-

der to detect some items on the airplane skin. For

example, there is an interest to identify four segments

which make rectangular shape such as static port (Sec.

5.2).

(a) Set of segments ex-

tracted by the PPHT

method.

(b) Set of segments after

postprocessing step.

Figure 3: Line segments extraction.

3 MATCHING OF PRIMITIVES

3.1 Feature Matching using a Similarity

Function

Line segments matching has been a widely studied

topic since segments are used in numerous applica-

tions such as 3D reconstruction (Bay et al., 2005).

This is also the case for primitives like ellipses (Hutter

and Brewer, 2009).

3.1.1 Preliminaries

Given two sets of primitives X and Y , with X rep-

resenting primitives projected from the model and

Y representing primitives in the real image, we will

show how a match score s(X

k

,Y

m

) denoting the simi-

larity between X

k

∈ X and Y

m

∈ Y can be computed.

3.1.2 Basic Graph Theory Concepts

Given a graph G = (V, E), an edge e ∈ E which links

two nodes u ∈ V and v ∈ V is said to be incident to

the nodes u and v. A graph G = (V, E) is said to be

bipartite if V (G) can be partitioned into two disjoint

sets X and Y such that every edge e ∈ E joins a vertex

in X to a vertex in Y .

3.1.3 Similarity Function

Two types of primitives are considered: ellipses and

line segments. A line segment is associated with an

attribute vector composed of the segment mid-point,

the length and the orientation. An ellipse is described

by its center, orientation and area. We divide the at-

tribute vector in two classes (c = [c

1

, c

2

]). Attributes

such as area or length belong to the first group as we

can compute their ratio (Eq. 1). Computing the ra-

tio for attributes such as center coordinates or orien-

tation is, however, not meaningful. Therefore, these

attributes will be in class c

2

. For such attributes, the

similarity score is computed as a distance of the ab-

solute difference from the maximal accepted disparity

Matching CAD Model and Image Features for Robot Navigation and Inspection of an Aircraft

361

between the theoretical and the test primitive (Eq. 2).

Maximal accepted disparity is preset by taking into

account the distance between primitives in the model.

The match function was proposed by (McIntosh and

Mutch, 1988) for line matching. In case of line match-

ing, the metrics used are the ratio of segment lengths,

the absolute difference of the orientation and the eu-

clidean distance, conditioned in such a manner that

the score between two primitives is always ≤ 1. We

extended the concept in order to use it with ellipses

as well. In this case we use the area of the ellipses

instead of the length of the segment.

s

i

=

min(X

k

i

,Y

m

i

)

max(X

k

i

,Y

m

i

)

, i f i ∈ c

1

(1)

δ

i

− abs(X

k

i

−Y

m

i

)

δ

i

, i f i ∈ c

2

(2)

s(X

k

,Y

m

) =

∑

w

i

s

i

(3)

where X

k

stands for a primitive projected from the

CAD model, Y

m

is a primitive in the real image and

i denotes the i

th

attribute for a given primitive. δ

i

is

the maximal accepted disparity for the i

th

attribute in

the class c

2

. The scalar s

i

is the match score between

one theoretical primitive and one test primitive for

the i

th

attribute. Finally, s(X

k

,Y

m

) denotes the match

score between X

k

with Y

m

. As some attributes may be

more relevant than others (Jr. et al., 2005), a priority

weighting function may be suitable (w

i

).

The matching is accomplished by exploring the

entire sets of theoretical and real primitives. A match-

ing matrix containing all the scores (Eq. 3) between

primitives in the set X with primitives in Y is com-

puted (Table 1) then used to construct the bipartite

graph.

Table 1: Matching matrix for the case in Fig. 4.

Test

1 2 3 4

Model

1 -0.407 0.204 -0.424 -0.18

2 -1.147 0.446 0.461 0.193

3 -0.565 0.120 -0.113 0.548

The similarity function is conditioned to be in the

range [0, 1] when i ∈ c

1

. When i ∈ c

2

the score may

be < 0. In our application only candidates having a

match score in the range [0, 1] are considered.

3.2 Search of Mutual Best Match in a

Bipartite Graph

Bipartite graph matching has been widely studied and

has applications in various fields of science (Panda

and Pradhan, 2013), (Fishkel et al., 2006). It is partic-

ularly suitable for a two-class matching problem. For

more details on how this concept is used in our work,

reader is referred to (Viana et al., 2015).

First we keep M occurrences of a score in the

matching matrix meeting a predefined threshold. A

bipartite graph containing M edges is then created.

This graph holds two types of nodes (X, Y ), repre-

senting theoretical and real primitives respectively. A

X-type node in the bipartite graph is linked with a

Y -type node when their similarity score satisfies the

threshold condition. The edge linking these two nodes

is weighted with their similarity score (Eq. 3). De-

pending on the threshold value, one X-type node may

be connected to more than one Y -type node and re-

versely.

Further, best matches are found for all the X-

nodes. Let X

k

be a X-node. We search the edge in-

cident to X

k

, holding the maximal weight. At the end

of this stage, if in the best match list there is more than

one X-node matched to the same Y -node, we proceed

to the second stage. Otherwise, we reached one-to-

one correspondences for all CAD primitives, so the

matching is done. In the second stage, we are search-

ing for best match for each Y -node which was previ-

ously matched with more than one X-node. In these

cases, we are keeping only the mutual best match.

Other edges incident to Y -node are eliminated. There-

fore, some of the X-nodes might stay unmatched. Fig.

6 shows all the possible edges between nodes of two

classes (grey) and the best match for each of the X-

nodes (blue). We have a conflict because Y -node 2 is

chosen as a best match for two X-nodes 12 and 13.

After computing the best match for the Y-node 2, we

are keeping the edge 2 − 13 and eliminating the edge

2 − 12. Final matching result is presented in 5b.

The mutual best match search guarantees the

uniqueness constraint of the matching, i.e. each CAD

primitive is matched to a different real primitive, or it

is not matched at all.

4 MATCHING RESULTS

In this section the matching results are presented.

Fig. 5, 4 and 7 concern ellipse matching. Fig. 8 con-

cerns segments matching. For all, the model features

are in cyan and the image ones are in red. In the graph,

model features are presented as green circles and im-

age ones as yellow circles. From a starting position,

the robot has to detect the airplane then go to a check-

ing area where it can inspect the air inlet vent and the

static port (ellipse features 1 and 2 in Fig. 7c).

In Fig. 5, the robot is at its starting position. The

ICPRAM 2016 - International Conference on Pattern Recognition Applications and Methods

362

(a) Model features projected to

the sensed image.

(b) Bipartite graph with eliminated edges (grey) and matches

(blue).

(c) Ellipse detection in the

sensed image (EDCircles and

our postprocessing step).

Figure 4: Navigation near the aircraft.

(a) Model features projected to

the sensed image.

(b) Bipartite graph with matches (blue) (eliminated edges not

shown).

(c) Ellipse detection in the

sensed image (EDCircles and

our postprocessing step).

Figure 5: Navigation far from the aircraft.

Figure 6: Conflict matches.

aircraft location is roughly known from this position.

The CAD model projection is presented in Fig. 5a.

Only windows and front tire are projected. At this

distance, the other ellipse features of the airplane are

usually not detected. The projection is inaccurate for

the most right windows. The ellipse image features

are given in Fig. 5c. Some windows are not detected

due to light conditions. Undesired ellipses are the air

inlet vent (feature 15) and a part of the logo (feature

9). The bipartite graph in Fig. 5b resumes the match-

ing. The left part is made of 10 good matches and

the right part of 3 bad matches. Last three are inaccu-

rate matches because windows are actually projected

on their precedent neighbors. These three can be ig-

nored by taking into account the distance between the

windows. The robot starts the visual servoing.

In Fig. 4, the robot performed a spiral obstacle

avoidance, to avoid moving humans. The tracking al-

gorithms lost targets. Relying on odometry, the robot

has to detect some features again, taking into account

its estimated location. The CAD model projection is

presented in Fig. 4a. The air inlet vent, the probe area

and the static port are projected (respectively features

1, 2 and 3). The projection is slightly inaccurate. The

ellipse image features are given in Fig. 4c. An un-

desired ellipse is extracted from the tire (feature 1).

Fig. 4b, the bipartite graph resumes the perfect ellipse

matching. The robot restarts the visual servoing.

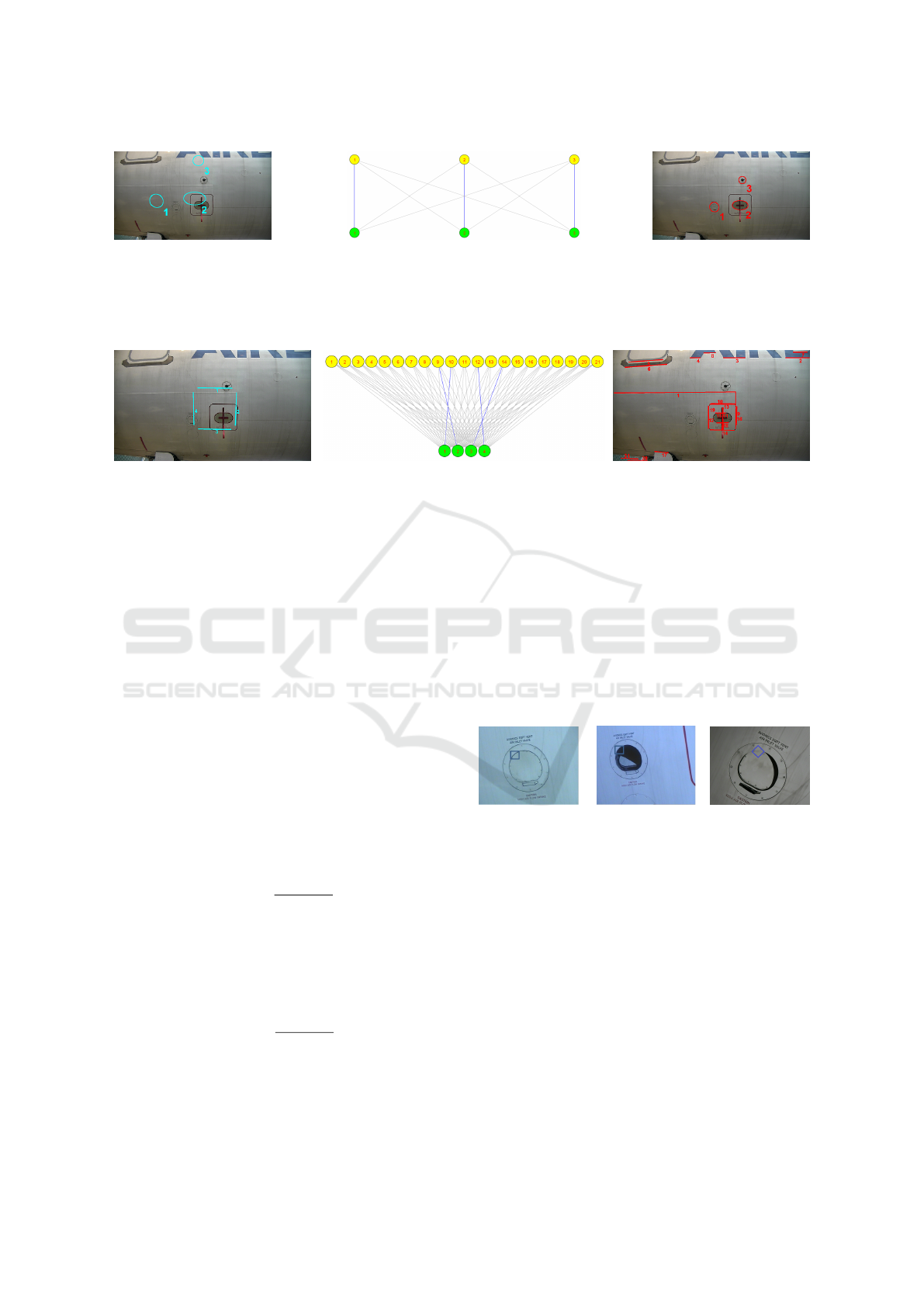

In Fig. 7 and 8, the robot arrives in a checking

area. The CAD model projection is presented in

Fig. 7a and 8a. For the ellipse features, the air in-

let vent, the probe area and the static port are pro-

jected (respectively features 1, 2 and 3). For the seg-

ments, the red warning zone around the static port is

projected. Unfortunately due to bad robot pose esti-

mation, the projection is inaccurate. The ellipse im-

age features are given in Fig. 7c. The segment image

features are given in Fig. 8c. The bipartite graph in

Fig. 7b resumes the perfect ellipse matching.

Due to the amount of line segments in a scene, the

line segment features are only used with the PTZ cam-

era at the checking position, Fig. 8. The PTZ cam-

era is directed towards the aircraft surface so the seg-

ments set is decreased. The line segments are used

for the static port because sometimes the detection of

the corresponding ellipse fails. The bipartite graph

resumes the perfect segment matching, see Fig. 8b.

Matching CAD Model and Image Features for Robot Navigation and Inspection of an Aircraft

363

(a) Model features projected

to the sensed image.

(b) Bipartite graph with eliminated edges

(grey) and matches (blue).

(c) Ellipse detection in the

sensed image (EDCircles

with the proposed postpro-

cessing step).

Figure 7: Inspection mode.

(a) Model features projected to the

sensed image.

(b) Bipartite graph with eliminated edges (grey)

and matches (blue).

(c) Segment detection in the sensed

image.

Figure 8: Inspection mode.

5 INSPECTION APPROACHES

In this section, the inspection approaches and numer-

ical results will be provided for the air inlet vent and

the static port.

Detection phase is evaluated by counting images

on which the approach was able to isolate ROI suc-

cessfully enough that the zooming is possible. In-

spection approaches are evaluated by calculating false

positive rate (FPR) and false negative rate (FNR). In-

put image in terms of the tested approach is classified

as false positive (FP) in the case when the defect is not

present and the approach reported a defect. It is clas-

sified as false negative (FN) in the case when there is

a defect and the method reports no defect.

False positive rate: ratio between number of false

positive images and total number of images with no

defect.

FPR =

FP

FP + T N

where TN is the number of images with no defect on

which the method reported no defect. FPR is the mea-

sure of false alarms.

False negative rate: ratio between number of false

negative images and total number of images with de-

fect.

FNR =

FN

FN + T P

where TP is the number of images with defect on

which the method reported a defect. FNR is the mea-

sure of missed defects. This measure is considered

critical in our application.

5.1 Air Inlet Vent

The objective is to verify that the vent is closed

(Fig. 9a). Challenging case is when the inlet is par-

tially open (Fig. 9c). For a detailed inspection, a small

sliding window is moved along the border of ROI

(Fig. 9) and uniformity of the sliding window is es-

timated by the binarization.

(a) Closed vent

(negative).

(b) Open vent

(positive).

(c) Partially open

vent (positive).

Figure 9: Air inlet vent - sliding window inspection.

In the case of open vent, there are two different

regions within sliding window, while in the case of

closed vent, the sliding window is uniform.

Matching algorithm was evaluated on a dataset of

23 low zoom images. It detected the vent in 100%

of the cases. Inspection was evaluated on 32 high

zoom (ex. Fig. 9) images (13 negative and 19 positive

cases) of two different kinds of vent. On this dataset,

the sliding window method performed with both FNR

and FPR equal to 0%.

ICPRAM 2016 - International Conference on Pattern Recognition Applications and Methods

364

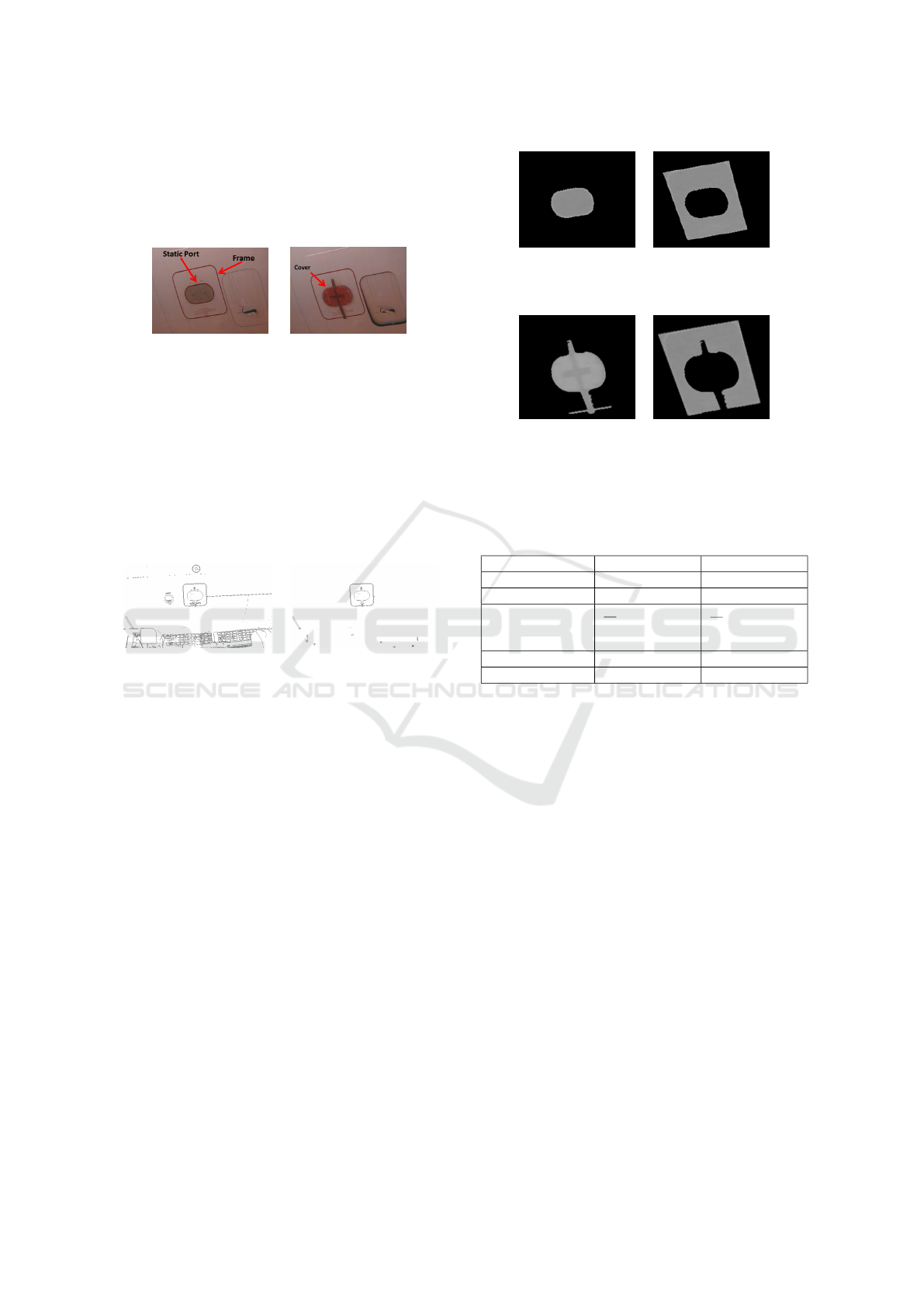

5.2 Static Ports

The aim is to verify that the protecting cover is re-

moved from the static ports (Fig. 10).

(a) Uncovered (nega-

tive).

(b) Covered (posi-

tive).

Figure 10: F/O and CAPT static ports. Wrong situation is

when protecting cover is still present (Fig. 10b).

Since there are red regions on the image, original

RGB image is converted to CIELAB color space. A*

channel of this color space is suitable for segmenting

red regions. Further, from the input edge set, only

edges corresponding to red regions are kept. The im-

provement can be seen in Fig. 11.

(a) All the edges of the in-

put image.

(b) Edges corresponding

to red regions.

Figure 11: Significant reduction of edge set by rejecting

edges of non-red regions.

On the zoomed image, segmentation based on re-

gion growing technique is employed on the static

ports region, by setting the seed pixel in the mean po-

sition of the previously segmented rectangular ROI.

Convexity of the detected static port region is used

for making a decision. The region is convex in un-

covered case (Fig. 12a) and concave in covered case

(Fig. 12c). The convexity is estimated by the ratio of

the segmented region area and the area of its convex

hull.

The detection approach followed by the matching

step was tested on a dataset of 75 images of two dif-

ferent kinds of static ports and it was successful in the

97% of the cases. The inspection method was eval-

uated on a dataset of 96 images (37 negative and 59

positive cases) with different cover shapes. The ap-

proach has shown accuracy with both FNR and FPR

equal to 0%. Detection and inspection results for both

items are summarized in the Table 2.

(a) Uncovered case:

static ports region.

(b) Uncovered case:

frame without static

ports region.

(c) Covered case:

static ports region.

(d) Covered case:

frame without static

ports region.

Figure 12: Static ports - uncovered: both regions are not

red; covered: region 12c is red, region 12d is not red.

Table 2: Evaluation results.

Item: Air inlet vent Static port

Detection dataset 23 75

Detection accuracy 100% 97%

Inspection dataset 32

13 negative

19 positive

96

37 negative

59 positive

Inspection FPR 0% 0%

Inspection FNR 0% 0%

6 CONCLUSION

Similarity measure is used to match projected ge-

ometric primitives from CAD model with detected

ones in real camera images. Existing similarity mea-

sure for segments is adapted to ellipses. This match-

ing step facilitates the detection and data association

processes for navigation and inspection tasks. In navi-

gation mode, features are provided to the visual servo-

ing and tracking algorithms. When robot is in check-

ing area, location of the desired item is forwarded to

the inspection algorithm. Results prove that even with

an inaccurate robot location estimation, good match-

ing results are still obtained so robot location can be

corrected. It is important because the robot can switch

from visual servoing to obstacle avoidance where the

robot pose could be updated only with odometry.

Minor problem has been noticed in some windows

matching. The inclusion of distance information be-

tween features is in development. When the robot

is really near the aircraft, ellipse extraction algorithm

are not precise on the detection of the static port due

Matching CAD Model and Image Features for Robot Navigation and Inspection of an Aircraft

365

to the fact that the shape is a superellipse. Superel-

lipse feature extraction is under consideration.

Inspection approaches were presented for air inlet

vent and static ports. Image processing approaches

were evaluated on real airplane exterior images. On

our dataset, inspection approaches could reach 0%

FPR and FNR. For the moment, the approaches

are adapted to the items and are based on heuris-

tics. Comparison with binary classification methods

is planned once the training data is sufficient.

Testing dataset is obtained in hangar with constant

illumination. Some artificial illumination is added to

make the dataset more representative. Next acquisi-

tion on tarmac with more various conditions (other

airplanes present, weather, etc.) is planned.

ACKNOWLEDGEMENT

This work is part of the AIR-COBOT project

(http://aircobot.akka.eu) approved by the Aerospace

Valley world competitiveness cluster. The authors

would like to thank the French Government for

the financial support via the Single Inter-Ministry

Fund (FUI). The partners of the AIR-COBOT

project (AKKA TECHNOLOGIES, Airbus Group,

ARMINES, 2MoRO Solutions, M3 SYSTEMS and

STERELA) are also acknowledged for their support.

REFERENCES

Akinlar, C. and Topal, C. (2011). EDLines: A real-time

line segment detector with a false detection control.

Pattern Recognition Letters, 32(13):1633 – 1642.

Akinlar, C. and Topal, C. (2013). EDCircles: A real-time

circle detector with a false detection control. Pattern

Recognition, 46(3):725 – 740.

Bay, H., Ferrari, V., and Gool, L. V. (2005). Wide-baseline

stereo matching with line segments. Proceedings of

Computer Vision and Pattern Recognition, 1:329–336.

Chaumette, F. and Hutchinson, S. (2006). Visual servo con-

trol, part i: Basic approaches. IEEE Robotics and Au-

tomation Magazine, 13(4):82–90.

Fishkel, F., Fischer, A., and Ar, S. (2006). Verification of

engineering models based on bipartite graph matching

for inspection applications. Springer-Verlag Berlin

Heidelberg. LNCS 4077, pages 485–499.

Futterlieb, M., Cadenat, V., and Sentenac, T. (2014). A nav-

igational framework combining visual servoing and

spiral obstacle avoidance techniques. In Proc. of the

11th International Conference on Informatics in Con-

trol, Automation and Robotics, Volume 2, Vienna, Aus-

tria, 1 - 3 September, 2014, pages 57–64.

Hutter, M. and Brewer, N. (2009). Matching 2-d ellipses

to 3-d circles with application to vehicle pose identifi-

cation. Proc. of International Conference Image and

Vision Computing, pages 153 – 158.

Jovan

ˇ

cevi

´

c, I., Larnier, S., Orteu, J.-J., and Sentenac, T.

(2015). Automated exterior inspection of an aircraft

with a pan-tilt-zoom camera mounted on a mobile

robot. Journal of Electronic Imaging, 24(6):061110.

Jr., R. M. C., Bengoetxea, E., Bloch, I., and Larra

˜

naga,

P. (2005). Inexact graph matching for model-based

recognition: Evaluation and comparison of opti-

mization algorithms. Elsevier, Pattern Recognition,

38:2099–2113.

Malamas, E. N., Petrakis, E. G., Zervakis, M., Petit, L., and

Legat, J.-D. (2003). A survey on industrial vision sys-

tems, applications and tools. Image and Vision Com-

puting, 21(2):171 – 188.

Marchand, E. and Chaumette, F. (2005). Feature track-

ing for visual servoing purposes. Robotics and Au-

tonomous Systems, 52(1):53–70.

Matas, J., Galambos, C., and Kittler, J. (2000). Robust

detection of lines using the progressive probabilistic

hough transform. Computer Vision and Image Under-

standing, 78(1):119 – 137.

McIntosh, J. H. and Mutch, K. M. (1988). Matching straight

lines. Computer Vision, Graphics and Image Process-

ing, 43:386–408.

Mumtaz, R., Mumtaz, M., Mansoor, A. B., and Masood, H.

(2012). Computer aided visual inspection of aircraft

surfaces. International Journal of Image Processing

(IJIP), 6(1):38–53.

Panda, B. and Pradhan, D. (2013). Minimum paired-

dominating set in chordal bipartite graphs and perfect

elimination bipartite graphs. Journal of Combinato-

rial Optimization, 26:770 – 785.

Prasad, D. K., Leung, M. K., and Quek, C. (2013). Ellifit:

An unconstrained, non-iterative, least squares based

geometric ellipse fitting method. Pattern Recognition,

46(5):1449 – 1465.

Siegel, M., Gunatilake, P., and Podnar, G. (1998). Robotic

assistants for aircraft inspectors. Instrumentation

Measurement Magazine, IEEE, 1(1):16–30.

Viana, I., Bugarin, F., Cornille, N., and Orteu, J.-J. (2015).

Cad-guided inspection of aeronautical mechanical

parts using monocular vision.

von Gioi, R. G., Jakubowicz, J., Morel, J.-M., and Randall,

G. (2010). LSD: A fast line segment detector with a

false detection control. IEEE Transactions on Pattern

Analysis and Machine Intelligence, 32(4):722–732.

ICPRAM 2016 - International Conference on Pattern Recognition Applications and Methods

366