Electric-Motion in Romania - Overview

Study on Machining Parameters of EV Charging Station Mechanical Components

Mihaiela Iliescu

1

, Nicolae Bercan

2

and Alexandru Rogojinaru

3

1

Institute of Solid Mechanics, Romanian Academy, 15 Constantin. Mille Street, Bucharest, Romania

2

Lucian Blaga University of Sibiu, 10 Victoriei Street, Sibiu, Romania

3

E-Motion Electric, 73-75 Giugiului Street, Ilfov, Romania

Keywords: Charging Station, Electric Vehicle, Machining, Regression Model.

Abstract: This paper presents some relevant aspects of charging infrastructure for electric vehicles in Romania. It

evidences the charging station and fast charging stations designed and installed by the first Romanian

company dedicated 100% to e-mobility, E-Motion Electric. Also, a study on machining (milling) parameters

of some mechanical components of electric vehicle (EV) charging station is done and, finally, the regression

model for these parameters is determined. This model would be further used for machining process

optimization.

1 INTRODUCTION

Ecological technologies (Eco-Technologies) include

the technologies which does not harm the

environment so hard, when compared to traditional

similar technologies applied to obtain the products

required by the same human need (http://www.insee

.fr/en/ecotechnologies.htm, 2015).

Energy efficiency is "using less energy to provide

the same service" and it is not energy conservation

(http://eetd.lbl.gov/ee/ee-1.html, 2015).

Most of the times, the energy efficiency can be

quatified by comparing the specific energy

consumption for obtaining, in the same condition, the

product, service or, process required. By reducing

these consumptions, wihtout affecting their quality,

represents the increase on energy efficiency

(http://www.utgjiu.ro/revista/ing/pdf/2009-03/35_A

LINA_DANIELA_HANDRA.pdf, 2015).

The concept of energy efficiency, or optimization

of electric energy consumption has become an

essential challenge worldwide, nowadays. In fact,

saving energy does represent the cheapest energy

resource, easy to produce and environmental friendly.

One solution, with highly positive impact on the

environment, is represented by the focus on electric

vehicles (EV). These vehicles have to be charged and,

further, driven, so that to use their required energy in

an effiecient way, as well as an environmental

friendly one. The chargeable electric vehicles, hybrid

ones included, have become more and more popluar,

for person transportation (electric train, electric bus,

electric car, electric bike). There are obvious

advatages, such as: no CO

2

emission, travel comfort,

technology friendly over the environment, low

expenses (http://birdie-electriccar.eu/ro/transport-de-

persoane, 2015).

Based on the asepects mentioned above, it is

estimated a, relatively, high need for good charging

infrastructure for electric vehicles in Romania

2 CONTEXT AND OVERVIEW

In the past 50 years, Europe has changed a lot - just

like the rest of the world. Nowadays, more than ever,

in a constantly evolving world, Europe must face new

challenges. Economy globalisation, demographic

evolution, climate changes, the need for long-lasting

energy sources and modern security threats are the

main challenges of the XXI

st

century.

2.1 Context

National and international relationship of Romania,

member of European Union and the focus on

sustainable development, including friendly

environmental technologies, lead to the increasing

importance of ecological technologies with high

energy efficiency for new generation of vehicles,

448

Iliescu, M., Bercan, N. and Rogojinaru, A.

Electric-Motion in Romania - Overview - Study on Machining Parameters of EV Charging Station Mechanical Components.

In Proceedings of the 5th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2016), pages 448-453

ISBN: 978-989-758-184-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

specially envisaging electric vehicles, more

specifically, electric cars.

Environment degradation because of industrial

development which has mostly been accomplished in

a chaotic way, as well as the consequent hunger of

resources, exhaustion of fossil fuels: oil, gas, coal are

the reason for efficient use of natural resources and

for integrated solution of protection and preservation

of the environment (http://e-motionelectric.ro/sites/d

efault/files/cataloage/Catalog%20general%20produs

e.pdf, 2015).

Electric vehicles are sometimes „accused” that they

do pollute „somwhere else”, because their required

energy for battery charging is obtained using industrial

porcedures that pollute. But, if there were considered

all the emissions, from oil extraction, it would result

that the electric vehicle is significantly more efficient

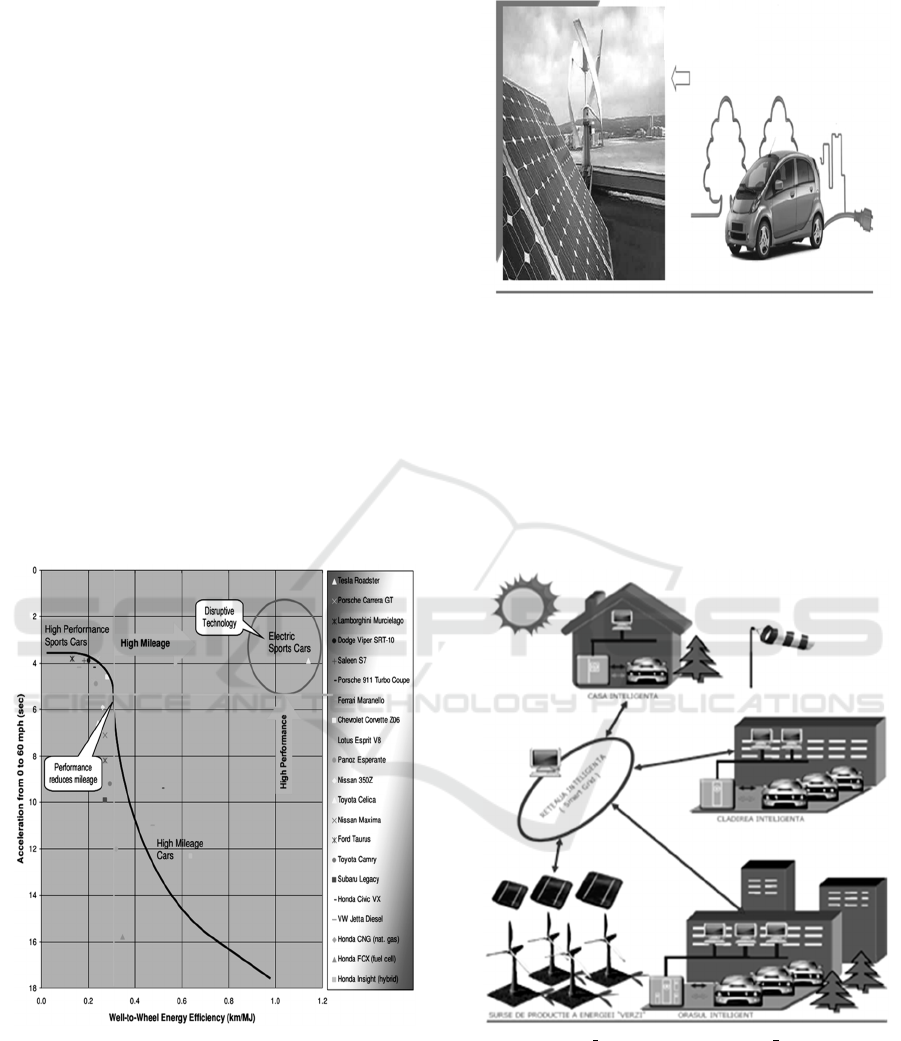

and pollutes less than any other options – see figure 1.

One relevant situation is that where the charging

stations (E-Motion Street Box) are situated in isolated

areas, with no plugin sources to the electricity

distribution network. These stations will be connected

to renewable energy sources so that, the electric vehicle

charging is 100% green, non-pollutiing – see figure 2.

(http://www.evworld.com/library/Tesla_21centuryEV.pdf)

Figure 1: The highest energy efficiency is that of electric

vehicle.

In the context of climate changes and of cities that

turn into sustainable smart cities, high attention is

given to the systems for monitor, analysis and

adjustment to envrionmental changes, energetic

managemnt, etc. The electric transportation and its

(http://e-motionelectric.ro/)

Figure 2: Eco-tehnology for charging the electric vehicle.

charging infrastructure represents components of the

smart grid of the future, so that further development

of the electric vehicles charging stations smart grid is

really important – see figure 3.

This smart grid enables route optimization

depending on the emplacement and performances of

existing charging stations, correlated to roads status

and traffic situations / emergencies.

(http://e-motionelectric.ro/)

Figure 3: Urban transportaton and its infrastructure –

components of the smart city.

2.2 Overview

E-Motion Electric is the first Romanian company

dedicated 100% to e-mobility, as producer for electric

vehicle charging stations. It also offers the knowledge

Hybrid

System

Electric-Motion in Romania - Overview - Study on Machining Parameters of EV Charging Station Mechanical Components

449

in developing the best solutions for charging

infrastructure in Romania and e-mobility solutions

in,general.

In 2011 it was installed the first public charging

station in Romania. It has 1 plug 230V and 16A;

controlled acces with RFID; energy meter and is

designed for semi-public use

This EV charging stations meet the IEC standards

and charge the vehicles in mode1, 2 and 3, on Schuko

type 1 or, type 2 plugs. There are also implemented

payment systems with both credit card or prepaied

(http://e-motionelectric.ro/)

Figure 4: Exterior semi-public charging station.

(http://e-motionelectric.ro/)

Figure 5: Interior private charging station.

(http://e-motionelectric.ro/)

Figure 6: Exterior semi-public fast charging station.

One of the exterior semi-public charging station

designed and installed in Romania is presented in

figure 4. It is type 1, with 1 plug 230 V and 32 A;

controlled acces with RFID; energy meter and

designed for semi-public use.

One of the interior private charging stations designed

and installed by the compnay in Romania is shown in

figure 5. It has 1 plug 230 V and 16 A and energy meter.

The first fast charging station designed and

installed in Romania in 2014, for exterior semi-public

use, is evidenced in figure 6. It has 1 plug 230 V and

16 A, 3,6 kW; Type 2 plug 400 V and 32 A, 22 kW.

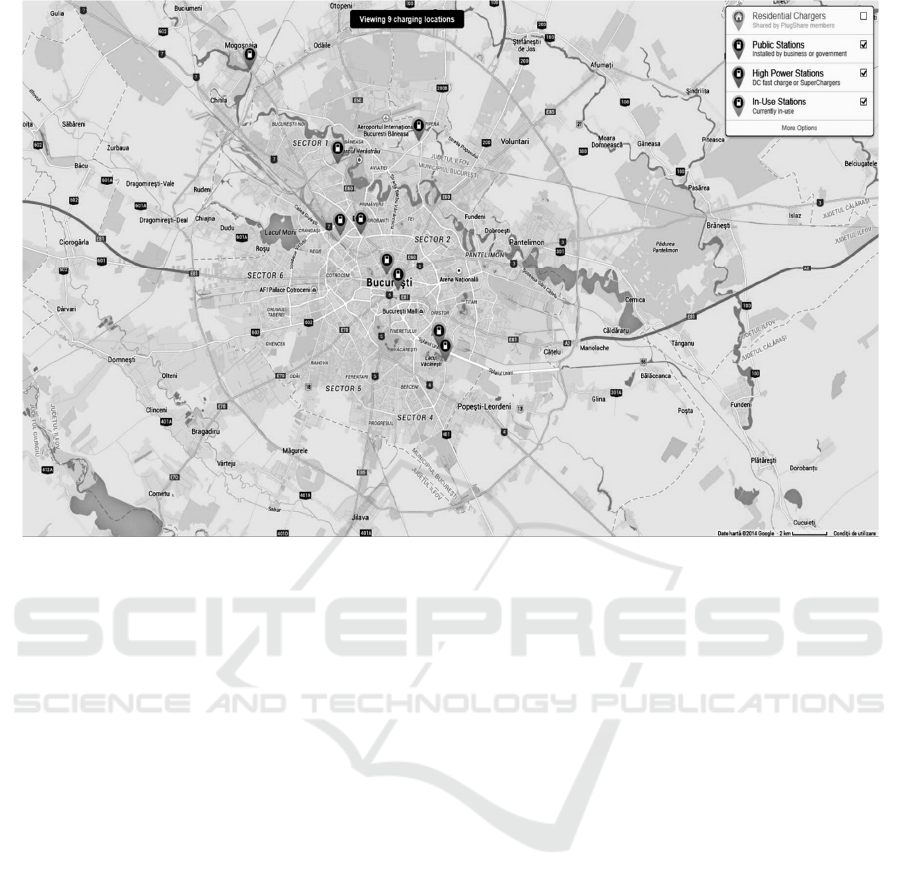

In 2013, in Romania, it was installed only 1 (one)

pulblic charging station. In 2014, in Bucharest

(capital of Romania) there were 9 (nine) public

charging stations – see figure 7.

The European Comission announced that soon,

there will be rules regarding the development of

public charging station infrastructure for electric

vehicles. For Romania, the Comission estimated an

amount of 10,000 charging stations to be installed by

the year 2020.

MoMa-GreenSys 2016 - Special Session on Modelling Practical Paradigms of Green Manufacturing Systems

450

Figure 7: Public charging stations location in Bucharest district, 2014.

3 STUDY ON MACHINING

PROCESS PARAMETERS

All the above mentioned do evidence the importance

of developing the infrastructure of charging stations

for electric vehicles in Romania. Each of these

stations has a mechanical part – more specifically the

“frame” sustaining all the components for

automation.

In figure 6, one can notice the support – front case

of the fast charging station. It is made of composite

material, machined by milling process so that to

obtain the prescribed (designed) geometrical

precision parameters: dimensions, tolerances, surface

roughness.

The parameters values of the milling process for

obtaining parts’ dimensions are estimated not to have

optimum values, as the milling tool does not last long.

In fact, many times, the tool breaks while machining

the contour. That is why, it has been considered of

benefit a study on milling process parameters, so that

to improve cutting tool (milling) durability.

3.1 Research Method

The study on milling process parameters is done so

that to finally obtain a regression model enabling the

determination of their optimum values for the

process. There are some specific steps for this study.

The first step involves “definition” of material to

be machined. So, it is: 3 m thick sheet made of

composite polymer, PLEXIGLASS (polymethyl

methacrylate, PMMA). The second step is that of

defining the machining equipment. It is an Isel CNC

Router (https://www.isel.com/iselcom_en/, 2015)

and the cutting tool is flat end mill, Sandvik

Coromant. The third step refer to the variables

studied, inputs and output, as well as to the desired

type of mathematical relationship – regression model.

The regression analysis is based on design of

experiments statistical method and, further, on

computer data processing. So, the experiments design

is Central Composite Design (CCD) type (Schmidt,

2005) and the applied software is DOE KISS that

enable polynomial regression analysis, optimization,

plotting 2D and 3D, Pareto diagram, Means Plot etc.

Based on preliminary research and previous work

(Iliescu, 2010), as well as on the experience and

results obtained in practice, the authors have

considered fit the choice of two independent variables

(inputs): cutting speed, v (peripheral speed of the

cutting tool) and radial depth (of the cut), a

r

,. The

speed values were measured in [m/min] and the depth

values were measured in [mm]. The dependent

Electric-Motion in Romania - Overview - Study on Machining Parameters of EV Charging Station Mechanical Components

451

variable considered, due to the interest of this study,

was the tangential cutting force component, F

y

.

Other

milling process parameters were set to: 1200

[mm/min] for the feed speed, v

f

; 3 [mm] for axial the

depth, a

a

and cutting fluid (coolant and lubricant).

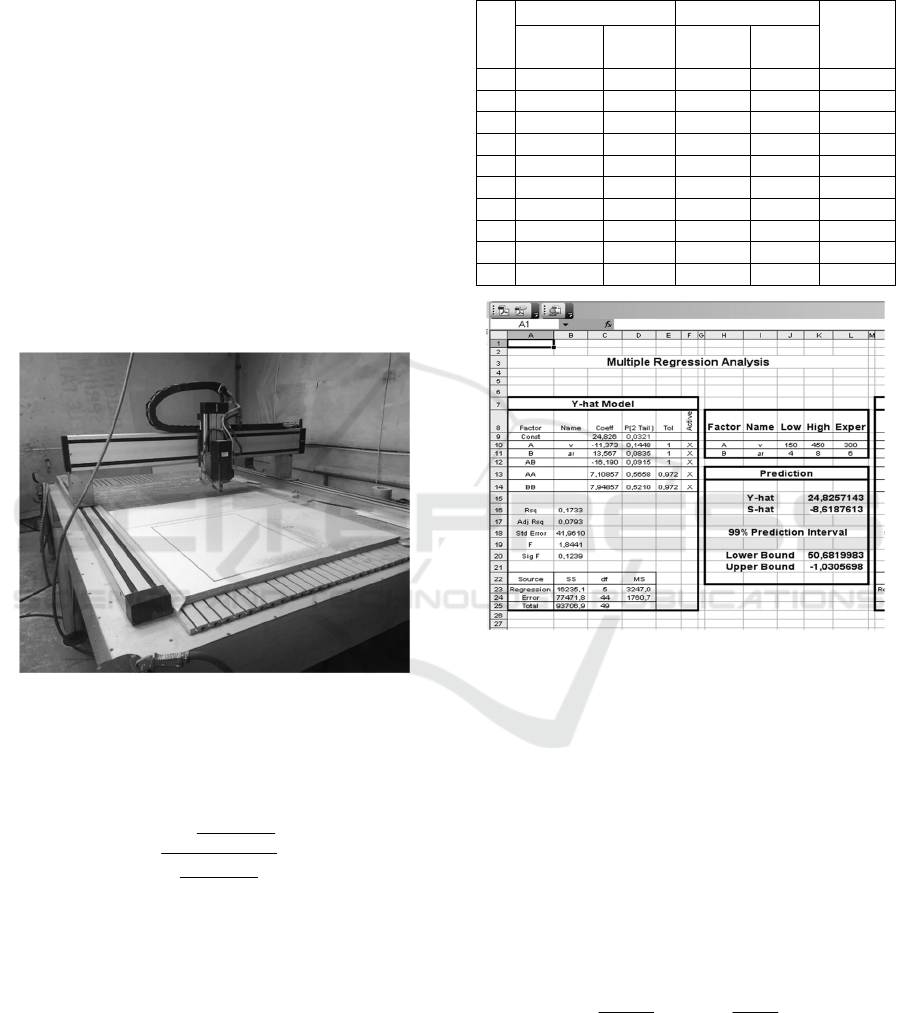

3.2 Experiments and Data Processing

Experiments were done at the Production Department

of E-Motion Electric Company – see figure 8. For

measuring milling forces’ components, along each of

the OX, OY and Oz axes, it was used a dynamometric

system with 6 resistive transducers positioned along

each axis and connected in a complete Wheastone

electronic bridge; a 6 channels tension bridge and a

data acquisition system, with DAQPad-6020E type

data acquisition component; according to the

experimental program applied, each experience was

repeated 5 times.

Figure 8: Cylindrical face milling experiments.

The independent variables, are conventionally

named z

j.

Coding their values, results in, x

j.

Their

relationship is expressed by equation (1).

2

2

minmax

maxmin

zz

zz

z

x

j

j

−

+

−

=

(1)

Where: z

min

is the minimum value of the variable;

z

max

- the maximum value of the variable.

For this study, the inputs values are the ones

mentioned in relation (2) and relation (3):

z

1

= v; v

min

= 150 m/min; v

max

= 450 m/min (2)

z

2

= a

r

; a

rmin

= 4 mm; a

rmax

= 8 mm (3)

The obtained results for the tangential cutting

force, F

y,

as arithmetic mean values, are presented in

Table 1. Results of the DOE KISS regression analysis

are shown in Figure 9.

Table 1: Experimental results.

v [m/min] a

r

[mm]

F

y

[daN]

Real

value

Coded

value

Real

value

Coded

value

1 150 -1 4 -1 26.16

2 150 -1 8 +1 33.85

3 450 +1 4 -1 23.60

4 450 +1 8 +1 28.36

5 300 0 6 0 26.50

6 300 0 6 0 26.42

7 150 -1 6 0 26.58

8 450 +1 6 0 25.82

9 300 0 4 -1 23.28

10 300

0 8 +1

28.80

Figure 9: DOE KISS regression analysis results.

Based on regression analysis results, and further

processing data – by neglecting the factors that do not

have significant influence on the output values, there

was obtained the regression model for milling process

parameters interaction.

The regression model for coded variables, x

j

, is

given by equation (4).

21

21

190.16

567.13373.11826.24

xx

xxy

⋅⋅−

−⋅+⋅−=

(4)

Considering the variables’ values considered for

this study, relation (1) turns into relation (5).

150

300

1

−

=

v

x

;

2

6

2

−

=

r

a

x

(5)

So, based on all the above, there is obtained the

regression model for real variables, z

j

, expressed by

equation (6).

MoMa-GreenSys 2016 - Special Session on Modelling Practical Paradigms of Green Manufacturing Systems

452

r

ry

av

avF

⋅⋅−

−⋅+⋅+−=

054.0

974.22248.0269.90

(6)

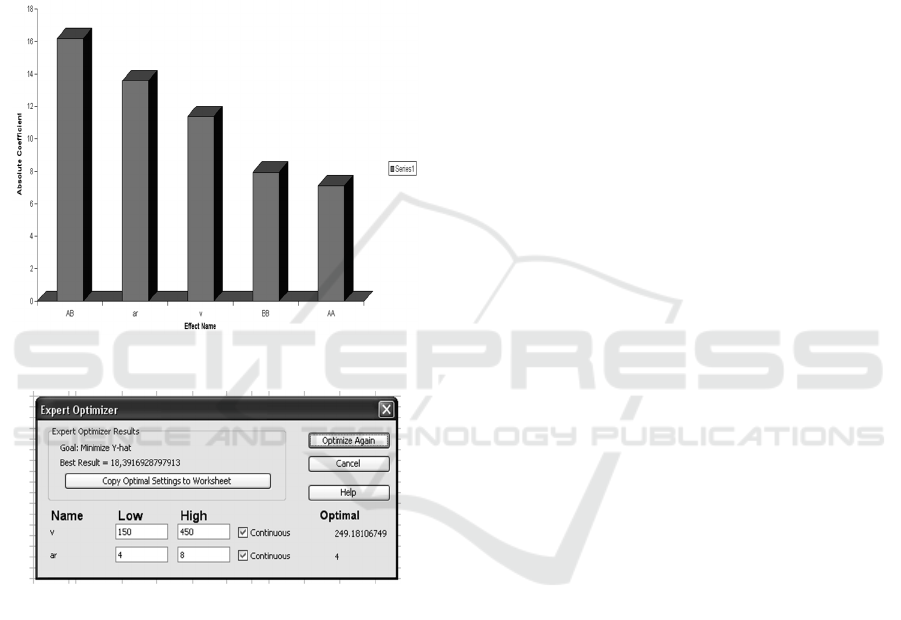

DOE KISS software enables the plot of Pareto

charts of coefficients – see figure 10. This charts

points out how strong the influence of each input, as

well as of inputs interactions, is on the output values.

Also, the software enables the use of Expert

optimizer, so that to optimize (minimize for this

study) the values of the output (tangential cutting

force component, F

y

) – see figure 11.

Figure 10: Pareto chart of coefficients.

Figure 11: Expert optimizer.

4 CONCLUSIONS

This paper was aimed to present aspects of the

development of charging station infrastructure for

electric vehicles, in Romania.

Due to importance and need for this development,

high attention was given to the machining process

(milling) of the mechanical parts components of the

charging station. Parameters values of the milling

process for obtaining parts’ dimensions were

estimated not to have optimum values, as the milling

tool does not last long.

Regression analysis results showed that the radial

depth, a

r

, variable influences the values of tangential

cutting force component, F

y

, while the cutting speed,

v, does not significantly influence these values. There

is also, the influence of inputs interaction on the

output, that should be given attention to. Finally, the

regression model would be further used for

machining process optimization.

REFERENCES

Iliescu, M., Vlădăreanu, L., Spânu, P., Modeling and

Controlling of Machining Forces when Milling

Polymeric Composites. In Plastic Materials 2/2010,

pag. 231-235, ISSN 0025 / 5289.

Schmidt, L., et al., 2005, Understanding Industrial

Designed Experiments. In Academy Press, USA.

http://www.insee.fr/en/ecotechnologies.htm, Accessed on

November, 10, 2015.

http://www.utgjiu.ro/revista/ing/pdf/2009-03/35_ALINA_

DANIELA_HANDRA.pdf, 2015.

http://e-motionelectric.ro/, Acccessed on July, 27,2015.

http://www.evworld.com/library/Tesla_21centuryEV.pdf,

2015.

https://www.isel.com/iselcom_en/, Accessed on

November, 7, 2015.

Electric-Motion in Romania - Overview - Study on Machining Parameters of EV Charging Station Mechanical Components

453