Development Results of the Intelligent Device for Storage of the

Transfusion Environments Containing Platelets

A. G. Gudkov, V. Yu. Leushin, A. F. Bobrikhin, V. N. Lemondjava and E. N. Gorlacheva

Moscow State Technical University n.a. N.E. Bauman, 2-ya Baumanskaya, Moscow, 105005, Russian Federation

Keywords: Blood, Transfusion, Platelet Concentrates, Storage.

Abstract: Research results directed on creation of the device for safe storage of transfusion environments

containing platelets with the use of thermal stabilization system based on semiconductor thermoelectric

elements, information support of storage process monitoring and radio frequency identification (RFID)

technologies are considered. Сalculation results of the storage modes that differ the initial conditions of the

process are given. Three-dimensional models of a device based on multi-layer walls are elaborated.

Computational experiments with subsequent analysis of the temperature distribution on the computational

domain are described.

1 INTRODUCTION

The transfusion environments containing platelets

include the most important component of the blood-

platelet concentrates. It is widely used in recent

years at program therapy of blood system tumors,

aplastic anemia, transplantation of bone marrow,

courses of intensive chemotherapy with a pre-

planned period f of prolonged agranulocytosis and

thrombocytopenia, and also the performance of

abdominal operations (laparotomy, splenectomy).

There is especially important to provide of

prescribed regimes of platelet concentrate storage,

because the observance of these regimes guarantees

its quality. An integral part of the quality control

system of platelet concentrate is the continuous

monitoring of the storage process and recording its

parameters, and also ensuring the traceability of its

movement along the technological chain from the

donor until use, that can be achieved through the

application of modern information technologies.

2 MAIN PART

According to the Guide to preparation, using and

ensuring quality of blood components platelets

should be stored in such conditions under which

viability and haemostatic activity of cages will be

kept. If it is necessary to store platelets more than 24

hours, for preparation use the closed system of

polymeric containers. Polymeric containers have to

possess good gas permeability to provide oxygen

inflow to platelets. The need for oxygen depends on

the contents in a concentrate of platelets and

leukocytes. Optimum temperature of storage makes

from 20 to 24 ºC. A necessary condition of platelets

viability preservation is their continuous mixing. It

has to be rather effective to provide access of

oxygen during all storage time which under

optimum conditions can be seven days. The complex

of thermohydrodynamic calculations with using of

computer modeling technologies was carried out in

this work. The purpose of computer modeling is

determination of transition process duration of

temperature stabilization of the transfusion

environments containing platelets that is in the

polymeric container.

In the result of three-dimensional scanning of a

container filled with platelet concentrate (PC) was

received a numerical description of the surface

geometry, which was then subjected to computer

processing for receiving three-dimensional solid

model of liquid volume Three-dimensional scanning

was executed by means of the

BreuckmannstereoSCAN 5MP device. Сomputer

data processing was performed.

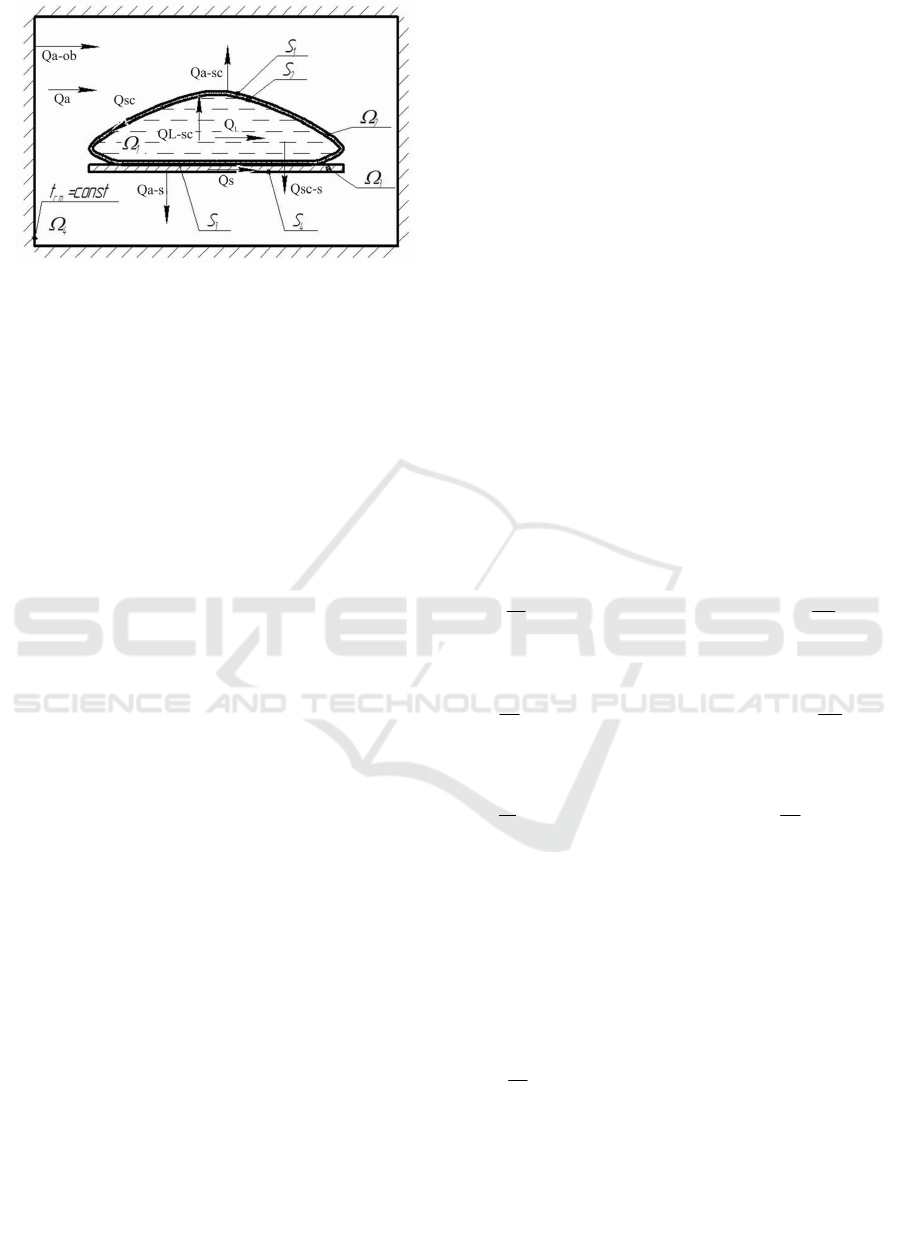

The design scheme of research object including

the following elements (Figure 1): liquid volume

(Ω

1

),a container cover (Ω

2

), a device shelf (Ω

3

), air

108

Gudkov, A., Leushin, V., Bobrikhin, A., Lemondjava, V. and Gorlacheva, E.

Development Results of the Intelligent Device for Storage of the Transfusion Environments Containing Platelets.

DOI: 10.5220/0006036101080115

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 3: KMIS, pages 108-115

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: A design scheme for a polymeric container with

transfusion environments containing platelets.

volume round the container and shelf (Ω

4

) was

made.

The surface section of elements: S

1

–contact

surface of the container shell with the ambient air, S

2

– surface section of the sheath with liquid, S

3

– the

contact surface of the sheath container with a shelf,

S

4

- the surface section of the shelf with the ambient

air are defined in the design scheme. As boundary

conditions it is assumed that the temperature of the

outer boundaries of the air volume is constant and

equal to the initial temperature of the air volume.

In accordance with this scheme during storage in

the present volume the following processes take

place: heat transfer inside the liquid volume (Q

L

);

heat transfer in air volume (Qa); contact heat

transfer by conductivity on the shell polymer

container (Qsc); heat transfer by conductivity on a

shelf (Qs); contact heat transfer between a shell and

a shelf (Qsc-s);convective heat transfer between the

liquid and the shell polymer container

(QL-sc); convective heat transfer between the shell

and the ambient air (Qa-sc); convective heat transfer

between the shelf and the ambient air

(Qa-s);convective heat transfer between the air and

isothermal outer boundary (Qa-ob).

The mathematical model of the physical

processes occurring during storage of PC is

formulated in accordance with the presented design

scheme. A number of assumptions has been

introduced for the correct formulation of the

calculation problem of thermo-hydrodynamic

system: the movement of liquid and air is considered

to be laminar; liquid and air are considered as

Newtonian and incompressible environments

because of the small velocities of motion; all

materials are homogeneous and isotropic on

thermophysical properties; physical parameters of

the liquid medium (PC), gaseous medium (air) and

solids are considered to be independent of

temperature; since the density of the liquid medium

varies insignificantly, we use the Boussinesq

approximation, whereby the liquid density and air

density are linear functions of temperature and are

defined as (1)

()

()

00

1 TT

ρρ β

=−−

(1)

where

ρ

− the density of the liquid medium;

T

− temperature;

β

− coefficient of volume

expansion of the liquid medium;

()

00

T

ρρ

=

−

characteristic value of the density at the temperature

0

T

; thermal radiation is not considered.

Description of motion and heat transfer processes

is based on a system of differential equations.

Convective heat transfer between the system

elements and surrounding air is described by the

dependencies, which include the momentum

conservation equations, the equation of energy

conservation and equation of mass conservation (2)-

(6).

The equations of momentum conservation for the

liquid medium (2) - (4):

()

()

()

div div grad

ii i

p

uu u

tx

ρρυμ

∂∂

+= −

∂∂

(2)

()

()

()

div div grad

ii i

p

vv v

ty

ρρυμ

∂∂

+= −

∂∂

(3)

()

()

()

div div grad

ii i i

p

ww wg

tz

ρρ

υμ

ρ

∂∂

+= −+

∂∂

(4)

The equation of mass conservation for the liquid

medium (5):

()

div 0

ρυ

=

(5)

The equation of energy conservation for the

liquid medium (6):

()

()

()

div div grad

ii ii i

cT c T T

t

ρρυλ

∂

+=

∂

(6)

The following symbols are in these equations: t−

time; x,y,z− position coordinates; u,v,w − speed in

different projections;

υ

− the velocity vector;

μ

−

dynamic viscosity;

g

− free fall acceleration; c−

specific heat;

λ

– thermal conductivity coefficient

Development Results of the Intelligent Device for Storage of the Transfusion Environments Containing Platelets

109

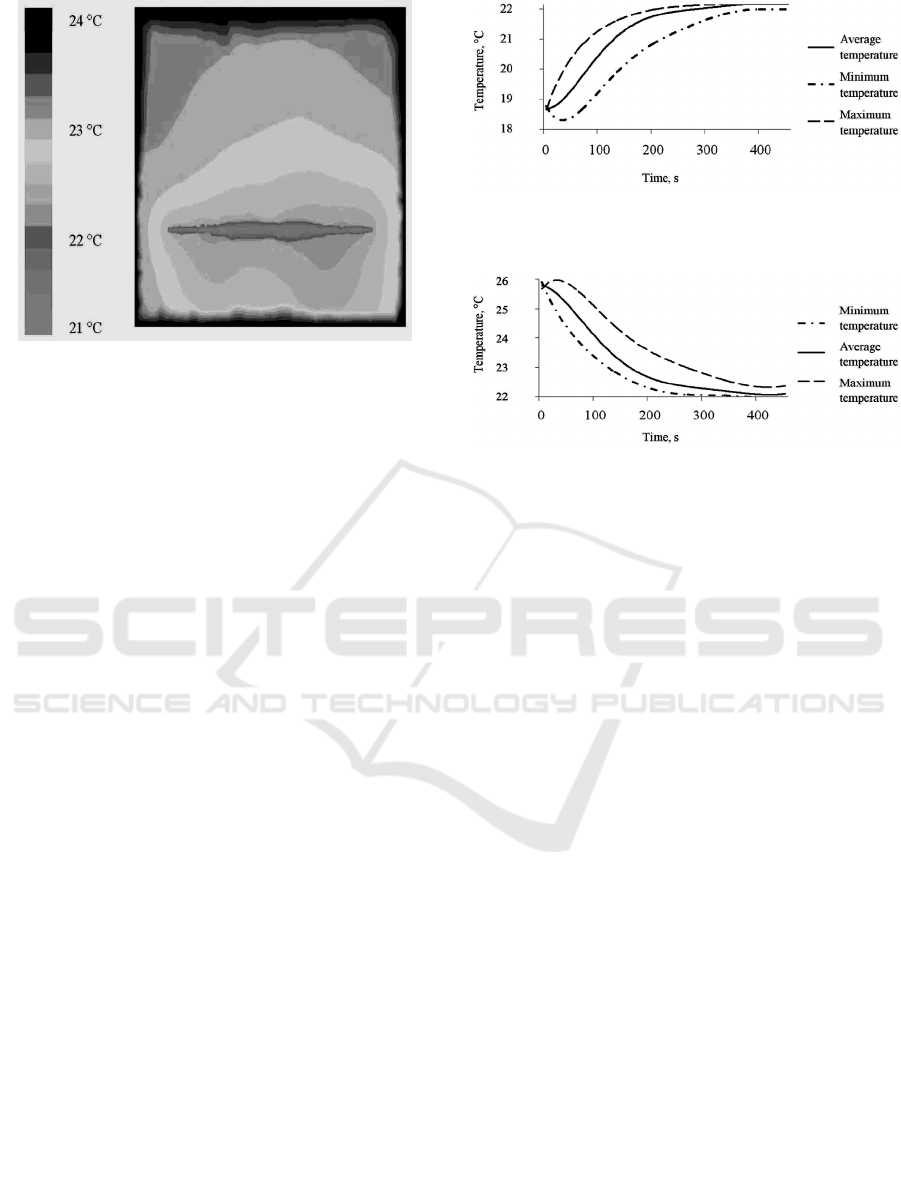

Figure 2: Temperature field in the calculation area at time

t=100 s.

of the liquid medium. Dependencies are considered

to the Boussinesq approximation: density of liquid

medium are accepted everywhere regular, except for

the term describing the buoyancy force, where the

density is assumed to be linear function of

temperature.

The obtained system of equations (2) - (6) has

not analytical solution in the general case. Methods

of the numerical solution were used to obtain an

approximate solution. They include the

discretization step based on the method of control

volumes (MCV) and a specially developed iterative

algorithm. Splitting of the solid model to mesh of

finite volumes was made for the numerical

simulations using the MCV. There were determined

the liquid temperature in the package, the shell,

shelves and air before each calculation.

The characteristic temperature distributions in

the calculation area are shown in Figure 2.

The calculation results of time dependencies of

the temperature PC in the polymer container at the

exit of the storage device of transfusion

environments containing platelets in the mode of

temperature stabilization at different initial

temperatures of transfusion environments containing

platelets are shown in Figure 3 and Figure 4.

It was determined as a result of calculations that

the thermal stabilization duration ranged from 3.7 to

5.8 min (from 220 to 350

s) depending on the initial

conditions, which allows to judge about quick

entering on the thermal stabilization mode. It

ensures high quality and storage safety of

transfusion environments containing platelets under

specified conditions.

You can select the following mandatory

requirements during storage of such media:

Figure 3: The graph of transient on volume in the

calculation area. Initial temperature 19 ºC.

Figure 4: The graph of transient on volume in the

calculation area. Initial temperature 26 ºC.

1. Protection against damage

2. Monitoring of environmental conditions

3. Ensuring stirring platelets

4. Providing the ability to identify the containers

with fluids containing platelets transfusion to

account for them during processing, storage and use

5. Provision of data recording observations

Analysis of the requirements below defines the

requirements for the functional characteristics and

capabilities of the storage device of transfusion

environments containing platelets.

Medical requirements set fairly narrow limits of

storage temperature platelet transfusion containing

media (from + 20 to + 24

о

C), which differ from

normal room temperature, which leads to the use of

special devices maintain a high degree of accuracy

desired temperature of the closed environment of

limited volume, which stores containers with media

containing platelet transfusion. To solve this

problem, a camera, the walls of which have good

insulating properties, is equipped with a cooling

unit. High precision temperature storage transfusion

media containing platelets causes use as a

refrigeration unit thermostatic device with low

inertia. Enhanced security of transfusion media

containing requires the establishment of reliable

systems for thermal stabilization, including

significant positions are occupied by semiconductor

thermoelectric elements (Peltier elements) that

provide both heating and cooling.

Semiconductor thermoelectric elements have

several advantages compared with other devices

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

110

cooling - heating: small size, no moving parts, are

not required to regularly change the refrigerant

(freon charge), ease of operation and maintenance

(no high-pressure systems), there is no sensitivity to

vibrations, the possibility of smooth and precise

control of temperature, environmentally friendly,

quiet, arbitrary orientation in space and gravity field,

low inertia, ease the transition from cooling to

heating mode.

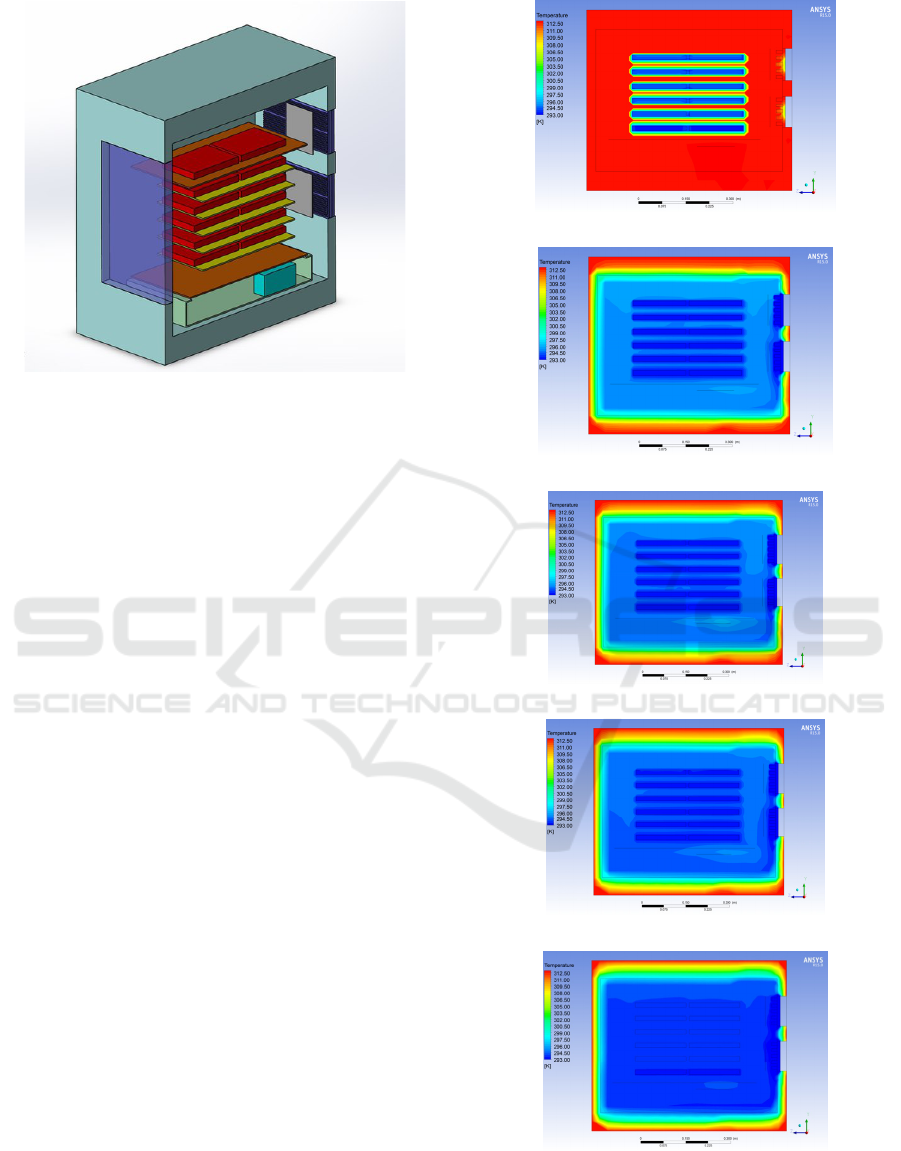

To ensure high accuracy of temperature

maintenance chamber requires the use of high-

precision temperature sensor and a control system

for precisely and smoothly controlling the

temperature inside the chamber. Figure 5 and Figure

6 shows a computer model of the thermopile using

semiconductor thermoelectric elements.

Figure 5: A computer model of the thermo battery using

thermoelectric semiconductor elements (side view).

Figure 6: A computer model of the thermo battery using

thermoelectric semiconductor elements (view from the

external radiator).

To reduce the non-uniformity of temperature

distribution by volume containing platelet transfu-

sion media inside the container used stirring of this

medium. To ensure the agitation of the platelets

transfusion media containing a special device with a

mobile platform and mounted on her shelves for

plastic containers transfusion media containing

platelets.

To reduce the possibility of damage transfusion

media containing platelets due to failure of the

thermostatic device or agitation, use of sound and

light warning of a fault with the fact that the staff

took measures to ensure the necessary conditions of

storage media containing platelet transfusion in any

other way and made emergency repairs device.

Thus, based on the analysis of requirements for

functional performance storage device for

transfusion environments containing platelets, in

principle it should be composed of the following

devices and components:

1. Mixing device transfusion environments

containing platelets;

2. Thermostatic chamber thermally insulated

storage media containing platelet transfusion;

3. Thermostat device of the inner chamber

storage media containing platelet transfusion;

4. System control device temperature control;

5. System sound and light warning of a fault;

6. Registration system (logging) of the

parameters of the device and the process of storage

media containing platelet transfusion;

7. AC power supply with automatic connection

autonomous electric generator.

Figure 7 shows the appearance of intelligent

storage devices containing platelets transfusion

environments.

a) b)

Figure 7: The appearance of intelligent storage devices for

transfusion environments containing platelets. 7a) - heat

insulated chamber with thermostating electronic device

and control system of storage regime parametres and 7b) –

presents electro mechanic module.

The research object is a device for safe storage of

transfusion environments containing platelets,

loaded with 24 polymeric containers, filled with

transfusion environments containing platelets. The

containers are arranged on pallets of an electro-

mechanical module without touching each other by

four packages per pallet. The electromechanical

module is housed within the chamber so as to

provide free access to the cooling air from all sides.

The module is driven by an electric motor connected

via a reduction gear and an eccentric transmission

with the mobile platform. According to preliminary

evaluations the thermal power loss during operation

of the system is 6 watts.

Development Results of the Intelligent Device for Storage of the Transfusion Environments Containing Platelets

111

The device is designed as a metal enclosure that

houses the thermally insulated chamber made of

stainless steel, as well as ventilation, temperature

control system, alarm system and recording

parameters. On the front side of the device is

hermetically sealed the door with a transparent

glazing that allows to control the operation of the

electromechanical module, as well as to monitor the

number of containers filled with filled with

transfusion environments containing platelets

without opening the door and violations of the

thermal regime.

To ensure a predetermined temperature two

thermopile thermoelectric module based on Peltier

elements are set at the back wall of the chamber.

As containers for transfusion environments

containing platelets there are widely used special

packages - products of company MacoPharma

(France) in Russian hospitals. The container is

produced of a soft polypropylene. In frames of

presented research the volume of container is

assumed to be 0.35 liters.

Thermal processes in solids are described by the

heat equation, known an equation of energy

conservation. The heat equation for a solid is

obtained from the energy equation for the liquid

medium in the absence of movement (

0v

→

=

)

The heat equation is:

()( )

ii i

cT div gradT

t

ρλ

∂

⋅⋅ = ⋅

∂

(7)

In order to account heat transfer by means of

radiation, the present mathematical model of thermal

processes comprises radiation model (surface-to-

surface), by means of which the radiant heat

exchange between surface segments, which are the

boundaries of individual regions is calculated.

The calculation of the total density of radiation flow

on the surface is performed by the matrix method.

The boundary terms are:

-

the condition of constant temperature at the

outer edge of a device chamber

_CT OKP CP

TT= that

is equal to ambient air temperature (is settled by

regime parameters);

-

the velocity of air flow on input and output

faces of the ventilator is orthogonal to the input

flatness and is constant

vent

v const= ;

-

on the cold side of the thermoelectric module

the heat flow is settled equal to a thermoelectric

cooling module;

-

radiant flow of thermal energy from the camera

window is evenly distributed over the surface of the

window. The integral value of the heat flow is equal

to 5 W;

-

heat dissipation from the engine module

electromechanical uniformly is distributed over the

surface of the engine. The integral value of the heat

flow is equal to 6 watts;

-

the ideal contact condition allows us to take the

same temperature in the border areas on both sides

of the interface.

As initial conditions the following are accepted:

-

the same temperature of all objects in a design

scheme, with the exception of container temperature

are equal to the ambient air temperature;

-

container temperatures are equal to temperature

loads;

-

the pressure inside the chamber is uniformly

distributed and equal to atmospheric pressure.

In general, this equation system has no analytical

solution. In order to get an approximate solution the

numerical solution methods were used. To sample

initial differential equations the method of finite

volume was used.

The SIMPLE-like iterative algorithm was used

for solving a system of differential equations.

SIMPLE is derived from the Semi-Implicit Method

for Pressure-Linked Equations (semi-implicit

method for pressure bonding equations).

A simplified three-dimensional model of the

device in accordance with the previously developed

design has been developed to carry out the thermal

design shown in figure 8.

As a boundary condition it is assumed that the

temperature of the outer boundary of the chamber is

constant and equal to the characteristic temperature

for the selected thermal regime.

The thermopile is represented as a three-layer

wall, through the middle layer of which is held

constant heat flow, equal to the cooling capacity of

the thermoelectric element. The maximum

temperature difference between the hot and cold side

is 69 ° C. Each of the inner presented as a

parallelepiped, on one face of which is defined a

velocity of suction flow, while the other is the

velocity of injection.

Each of the containers for storage of the

transfusion environments containing platelets is

presented as a uniform medium parallelepiped,

placed on the flat shelf. For each interface between

the liquid and solid phases the process of convective

heat transfer is considered.

Each homogeneous object design scheme the

conduction heat transfer process is considered.

Between each pair of segments of surfaces is

considered the presence of radiant heat transfer,

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

112

Figure 8: Cross-section of three-dimensional model of

device for storage of the transfusion environments

containing platelets.

which depends on the surface temperature. In case of

shadowing the radiation heat transfer between the

two segments is not considered.

To carry out the necessary calculations the

material properties were selected on standard bases

materials.

The change of the temperature distribution of the

computational domain is shown in Figure 9. Each

figure corresponds to a different time: 9a - the

beginning of the calculation; 9b - 1min; 9c - 10min;

9d - 15min; 9e - 60min.

According to Fig. 9 it can be seen that the

warmest air masses are concentrated in the top of the

device for safe storage, and the coldest - in the

region of the radiator of the thermoelectric module

sensor.

The heat from the engine electromechanical

module does not lead to a significant redistribution

of temperatures.

As a result of this work has been developed a

mathematical model of the thermogashydrodynamic

processes during the incubation of biological objects

in their storage devices.

In general, difference in temperatures between

different zones of the cavity is small, and therefore

the containers should have thermostated uniformly

regardless of the position on the shelves of the

electromechanical module.

To improve the reliability of the device and

reduce the likelihood of a sudden its failure

developed a system of registration of all of its

settings and thus keep a record of the process of

storage media containing platelets transfusion.

a)

b)

c)

d)

e)

Figure 9: Temperature distribution in calculation domain.

Development Results of the Intelligent Device for Storage of the Transfusion Environments Containing Platelets

113

Protocol analysis parameters of the device reveals

how repetitive unstable fault and mismatch control

system temperature readings actual values.

Conclusion protocol for printing entails the use of a

switching system or directly with the printer, or a

personal computer to which it is connected. In order

to implement additional storage capabilities of

protocols in electronic form for a long time it is

advisable to connect the device to store

environments containing platelets transfusion to a

personal computer. For this purpose a corresponding

interfaces.

One of the main criteria of quality assessment of

transfusion environments containing platelets are the

parameters of storage process that reflect the time

dependence of storage temperature and allow to

control observance of the temperature rates.

Ensuring traceability of the movement and

temperature control of these blood components at all

stages of their storage and transportation in real

climatic conditions of the environment from the

moment of receipt in the blood bank to the transfer

to the consumer is difficult, but actual task at the

present stage of medicine development. It can be

solved using radio frequency identification.

The development level of RFID technology

allows to use for this purpose special tags using

radio frequency electromagnetic radiation with a

frequency of 13.56 MHz. Labels are fixed on the

polymer containers with transfusion environments

containing platelets and can be used for reading and

writing of information up to 10 Mb (a bar code -

about 100 bytes) with multiple overwrites. A

donation number, a product code and temperature

regimes of storage are fixed in the label. This

information can be used in a central information

system with the subsequent registration of all

movements of the container with transfusion

environments containing platelets.

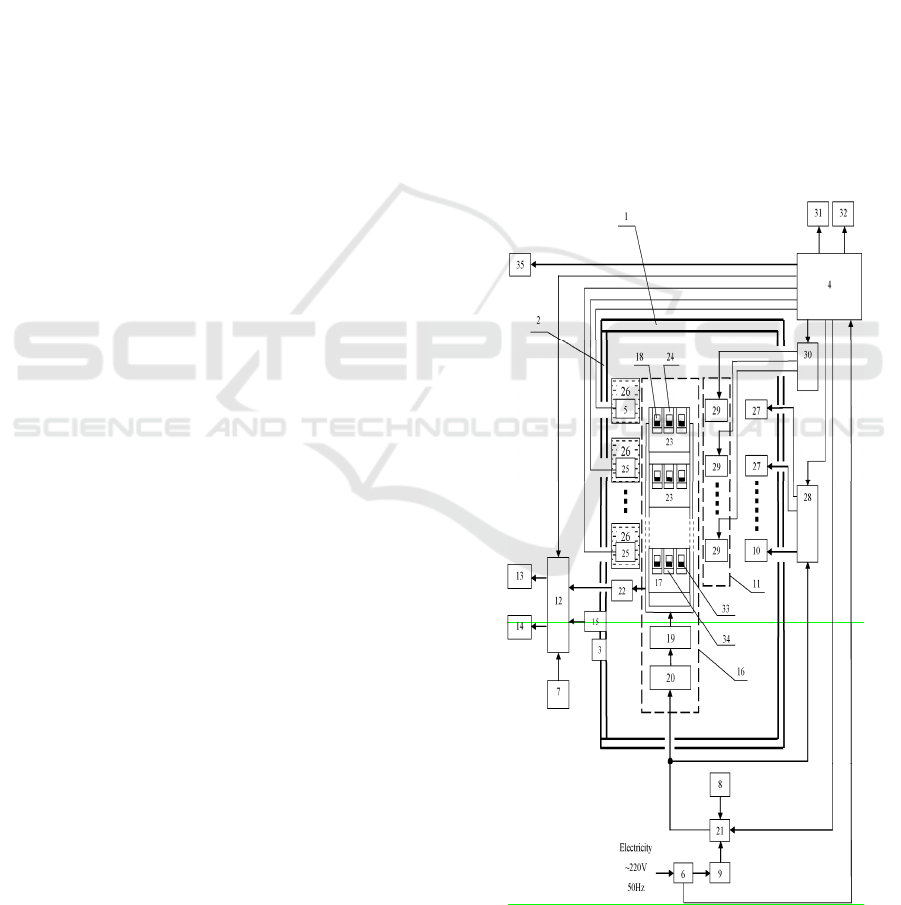

The fig. 10 shows the structural scheme of the

intelligent device for storage of the transfusion

environments containing platelets.

The described device includes heat-insulated

corpus 1 with transparent door of multi-layer glass

with air space 2, door lock 3, control system 4,

connected with (n+1) temperature sensors 5 and

25 and with voltage sensor 6, first 7 and second 8

independent power supply, secondary power supply

9, that by means of voltage sensor is connected with

electric power system, (n+1) units of semiconductor

thermopiles 10 and 27, forced air circulation system

11, consisting of (n+1) ventilators 29, unit of alarm

system and registration system of storage process

parameters 12, connected with control system, with

first independent power supply, with alarm light and

sound system 13, interface box with personal

computer 14 and sensor of door position 15, stirring

system 16, including (n+1) mobile netted or

perforated platforms 17 and 23 with nests for

distribution of polymeric containers with transfusion

environments containing platelets 18 and connected

through movement interface box 19 with electro

engine 20, switching unit of power supply facilities

21, the first entrance of it plugged into secondary

power supply, control input of it is plugged into

control system, and output – to electric engine,

movement sensor 22, that is connected with mobile

platform by optic or electromagnetic connection and

is plugged into alarm system and registration system

of storage process parameters, (n+1) simulators of

polymeric containers (tubes with liquid) with

transfusion environments containing platelets 26,

inside of which temperature sensors are disposed,

first commutator 28, connected with outputs with

Figure 10: Structural scheme of the intelligent device for

storage of the transfusion environments containing

platelets.

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

114

(n+1) units of semiconductor thermopiles, input

with switching unit of power supply facilities,

second commutator 30, connected with outputs with

(n+1) ventilators 29 of forced air circulation system,

input with switching unit of power supply sources

(at fig.1 the connection doesn’t show), and control

input with control system, bar-code reader 31,

connected with control system, printer of RFID

marks 32, connected with control system, RFID

identification marks 32, connected with control

system, RFID identification marks 33, anchored on

polymeric containers with transfusion environments

containing platelets, readers of RFID identification

marks 33, disposed on platform nests for arranging

polymeric containers with transfusion environments

containing platelets and connected with control

system, alphameric or graphic display 34, connected

with control system.

3 CONCLUSIONS

Physical processes research of safe storage of

biological objects under the temperature control

conditions at high requirements to the temperature

accuracy and temperature uniformity on the volume

within +1 °C was carried out. The simulation of

thermal processes in polymeric containers with PC

was realized. These theoretical and experimental

studies, as well as the development of new

mathematical models of thermophysical processes

will allow to create a scientific-methodical base for

development of the optimizing technique of the

device design for safe storage the transfusion

environments containing platelets.

The results of these studies were used to create

the experimental sample of the device for safe

storage of transfusion environments containing

platelets in which provides WHO requirements to

PC storage modes , and remote monitoring and

logging of PC storage modes using a personal

computer.

This work was supported by the Ministry of

Education and Science of the Russian Federation in

the framework of the Federal Target Program

"Research and development on priority directions of

scientific-technological complex of Russia for 2014 -

2020 years", grant agreement № 14.577.21.0138,

unique identifier of applied research and

experimental development (project)

RFMEFI57714XO138.

REFERENCES

Gudkov, A. G., Gorlacheva, E. N. and Leushin, V. Yu.

(2007), Complex technological optimization of

medical equipment, Biotechnology: state and

prospects of development: Materials of the fourth

Moscow international congress, Moscow, Russia,

2007, pp. 67-68.

Gudkov A .G. and Leushin V. Yu (2008), Domestic

equipment for service of blood, Hematology and

transfusiology, pp. 43-44.

Borodavko, V. I., Gudkov, A. G. and Leushin, V. Yu.

(2010), Possibilities of innovative development of

production of the medical equipment for service of

blood, Biomedical radio electronics, pp.54-64.

Gudkov, A. G., Leushin, V. Yu., Pozdin, S. V., Bobrikhin,

A.F. and Petrov, V.I. (2012), A Termostating Device

for Storage of Thrombocyte-Containing Media,

Biomedical Engineering, vol. 46, № 3, pp. 104-105.

Gudkov A. G., Bobrikhin A. F., Zelenov M. S., Leushin

V. Yu., Lemondzhava V. N., Marzhanovskiy I. N.,

Chernyshev A. V. (2016) Modelling of storage

processes of transfusion environments containing

platelets in polymeric containers, Medical

Technique,#3, pp. 53-55.

Gudkov A. G., Popov V. V., Leushin V. Yu., Bobrikhin A.

F., Lemondzhava V. N. (2014), Complex approach in

design electronic devices for thermal conditioning and

storage of blood components and products, Biomedical

radioelectronics, #8, pp.54-60.

Bobrikhin A. F., Gudkov A. G., Leushin V. Yu.,

Lemondzhava V. N., Petrov V. I., Tschukin S. I.

(2015), Equipment for thermal conditioning and

storage pf blood components and products, Medical

Technique, #2, pp.40-43.

Development Results of the Intelligent Device for Storage of the Transfusion Environments Containing Platelets

115