Enabling Centralised Management of Local Sensor Data Refinement in

Machine Fleets

Petri Kannisto and David H

¨

astbacka

Department of Automation Science and Engineering, Tampere University of Technology,

P.O. Box 692, FI-33101 Tampere, Finland

Keywords:

Distributed Knowledge Management, Mobile Machinery.

Abstract:

In modern mobile machines, a lot of measurement data is available to generate information about machine

performance. Exploiting it locally in machines would enable optimising their operation and, thus, yield com-

petitive advantage and reduce environmental load due to reduced emissions. However, optimisation requires

extensive knowledge about machine performance and characteristics in various conditions. As physical ma-

chines may be located geographically far from each other, the management of ever evolving knowledge is

challenging. This study introduces a software concept to enable centralised management of data refinement

performed locally in the machines of a geographically distributed fleet. It facilitates data utilisation in end

user applications that provide useful information for operators in the field. Whatever the further data analysis

requirements are, multiple preprocessing tasks are performed: it enables outlier limit configuration, the calcu-

lation of derived variables, data set categorisation and context recognition. A functional prototype has been

implemented for the refinement of real operational data collected from forestry machines. The results show

that the concept has considerable potential to bring added value for enterprises due to improved possibilities

in managing data utilisation.

1 INTRODUCTION

The current era of industrial informatics has brought

ever developing intelligent devices, data processing

methods and sensor technology. Additional value can

be gained from existing devices by collecting data and

analysing it to have new information and knowledge.

The importance of data analysis has been emphasised

not only for business in general (LaValle et al., 2011)

but also in industrial context (Duan and Xu, 2012).

For production, this also applies to mobile machines

such as earthmoving, mining or forestry. Performance

improvements not only bring competitive advantage

but they also save resources and reduce emissions to

the environment.

In this paper, a software concept is introduced –

intended for service architectures – to enable cen-

tralised management of fleetwide sensor data refine-

ment which is performed locally in mobile machines.

The operation of modern machinery typically requires

a high level of expertise, and even a skilled opera-

tor rarely has the technological knowledge required

for optimal operation. That is, various feedback ap-

plications should be utilised to improve performance.

In the data measured during operation, a lot of im-

plicit information is available not only about the ma-

chine itself but also the material or the goods being

processed. In an ecosystem, the number of machines

and the amount of data can be arbitrarily large, and

the machines may be geographically distributed. A

centrally managed data refinement solution facilitates

using all the potential of data as it unifies the infor-

mation available for actual end user applications in

various machines. The applications may, for instance,

provide assistance in machine operation or adjust-

ment. As data processing expertise and requirements

are likely to evolve, frequent updates are expected.

The practical contribution of this work is the im-

plementation of an externally manageable interme-

diary component that refines local machine data. It

accomplishes essential first-hand tasks thus generat-

ing information and facilitating further analysis. The

component can be customised externally by deliver-

ing methods and configuration data that define the lo-

cal refinement process. As several machines can re-

ceive an identical refinement configuration set, cen-

tralised management is enabled.

Kannisto, P. and Hästbacka, D.

Enabling Centralised Management of Local Sensor Data Refinement in Machine Fleets.

DOI: 10.5220/0006045600210030

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 3: KMIS, pages 21-30

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

21

The structure of this paper is as follows. Related

work is discussed in Section 2. Section 3 discusses the

actual problem followed by a solution in Section 4. A

forestry machine related prototype implementation is

introduced in Section 5. Section 6 presents the results

while Section 7 concludes the paper.

2 RELATED WORK

Among the publications in the industrial domain, no

corresponding points of view have been found so this

work is considered novel. None of the discovered pre-

vious studies address a similar data processing work-

flow with the configurability aspect and a similar level

of detail. That is, this section summarises the work

related to either machine data refinement, equipment

data exchange or context awareness as each aspect is

included in this paper.

Farming equipment related data collection or ex-

change has been researched in various papers. In

(Steinberger et al., 2009), farming equipment data is

exposed in a service architecture. In (Iftikhar and

Pedersen, 2011), device data is exchanged bidirec-

tionally between office computers and farming ma-

chines. In (Peets et al., 2012), there is a solution

for data collection from various types of sensors. In

(Fountas et al., 2015), an information system con-

cept is introduced for the management of farming ma-

chines.

There are also other publications related to mo-

bile machine data processing. In (Palmroth, 2011),

the analysis of mobile machine data to assist opera-

tor learning is covered. A knowledge management

solution for operator performance assessment in the

field is considered in (Kannisto et al., 2014). In (Kan-

nisto et al., 2015), a service architecture is introduced

to manage the information and knowledge required to

assist machine parameter optimisation locally in ma-

chines. All of these studies contain machine data re-

finement, and the latter two have an information sys-

tem architecture aspect. However, none of them has a

similar level of detail in configurability.

Fault diagnostics and condition monitoring are

also related as they consider generating information

by processing measured data. Various mathematical

methods can be utilised for diagnostics as presented in

(Yang and Kim, 2006; Basir and Yuan, 2007; Baner-

jee and Das, 2012). Condition-based maintenance

(CBM) is enabled by utilising collected condition data

(Jardine et al., 2006). Recently, even wireless sensor

networks (WSN) have been utilised in diagnostics (Lu

and Gungor, 2009; Hou and Bergmann, 2012). These

studies focus on data processing rather than knowl-

edge management essential in this work.

Context recognition has been researched for a

long time, and various methods as well as applications

have been suggested. In (Khot et al., 2006), there is a

mathematical approach to recognising the context and

the position of a tree planting robot; position infor-

mation from various sources is combined mathemat-

ically to reduce error. Machinery is the domain also

in (Golparvar-Fard et al., 2013) where earthmoving

equipment actions are recognised from video. Human

activities recognition has also been researched includ-

ing hospital work (Favela et al., 2007), car manufac-

turing (Stiefmeier et al., 2008) and general activities

(Choudhury et al., 2008). In this paper, relatively lit-

tle weight is put on context recognition so the method

should not be compared with the advanced context

recognition methods found in literature.

3 DATA PROCESSING NEEDS

FOR MACHINE FLEETS

This paper introduces a software concept to centrally

manage data refinement performed locally in the ma-

chines of a geographically distributed fleet. The idea

is to process machine data to facilitate further utili-

sation, especially for instant local use. A consider-

able challenge stems from the errors that real-life ma-

chine data typically contains: there is a need to apply

domain expertise by specifying conditions and lim-

its that determine which measurement values should

be considered valid. For instance, measurements are

never completely accurate, and for one reason or an-

other, a sensor may either systematically or randomly

give erroneous output. The physical world rarely

acts ideally. Another essential requirement is context

recognition and consideration – this need comes from

the argument that some domain knowledge is context

dependent. Obviously, the operating environment and

the type of work being performed largely affect what

kind of measures and performance are expected. Fur-

ther requirements are data set categorisation and the

calculation of derived indirect values as they may pro-

vide valuable information.

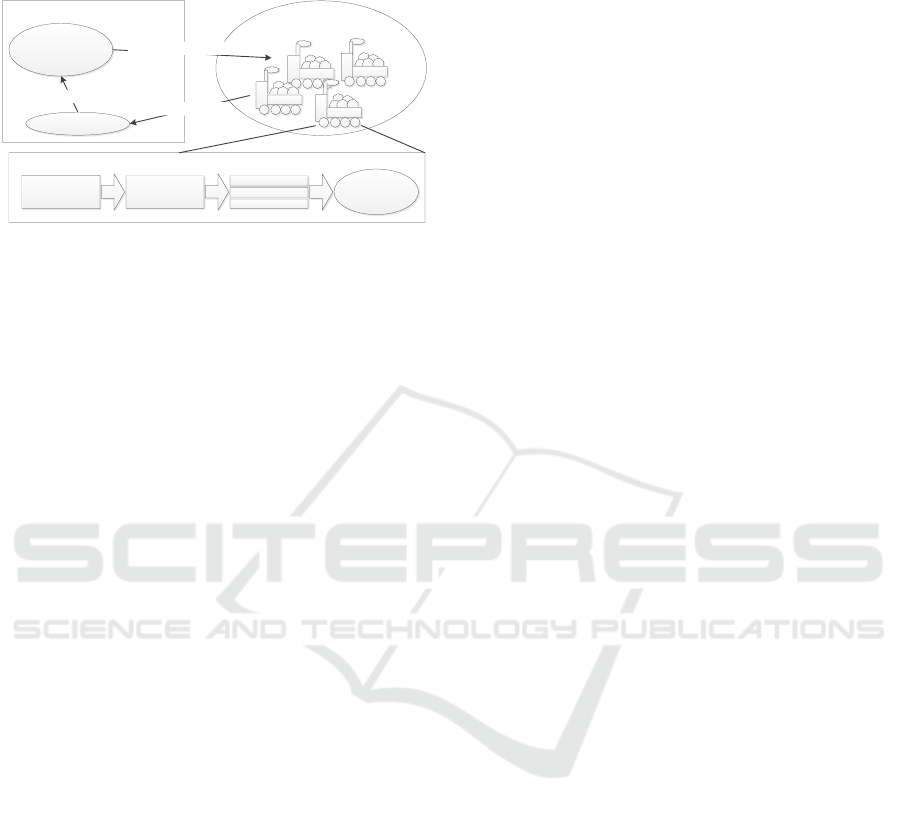

Scalable configurability is essential: it must be

possible to control data refinement even after it has

been taken into use in a large geographically dis-

tributed machine fleet. Figure 1 illustrates this. Ma-

chine data collection enables fleetwide knowledge

generation within the enterprise. The knowledge is

translated to a data refinement configuration to be de-

livered to machines. In each machine, the configu-

ration is utilised in data generation for analysis ap-

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

22

plications that generate added value such as feedback

about machine operation.

Single machine

Data

refinement

Measurement

data provider

Added value

(e.g. feedback)

Fleet data analysis

Enterprise

Central

management of

data refinement

Geographically

distributed machine fleet

Data collection

Refinement config delivery

Refinement knowledge generation

Analysis applications

Figure 1: Data refinement configuration is delivered to ma-

chines so the refinement can be executed locally for analysis

applications.

In this work, data is structured as data item collec-

tions. A data item collection contains measurement

and parameter values saved at a certain point in time

thus providing a snapshot of machine state and per-

formance. Data items are stored as a set of key-value

pairs that enable access to data items using their iden-

tifiers. It is assumed that the machines of the same

type have an identical key set in their data item collec-

tions. Once a data item collection has been retrieved,

its items can be utilised for calculating or inferring

derived data and information or to resolve prevailing

context.

To clarify the concept, let us consider an example

in the forestry domain. As tree stems are processed

with modern equipment, a lot of measured stem data

is available such as the felling diameter, length or how

quickly the stem has been processed with the ma-

chine. For each processed stem, the related measure-

ments will be stored in a data item collection so the

stems can be processed one by one with all related

data available.

Machine type specific data item collection pro-

cessing is likely required. First, there is expected

to be variation in available measurements between

machine types. For instance, as the degree of au-

tomation in tree stem processing keeps improving,

a new machine model likely has more measurement

items available compared to old ones. Second, models

likely have variation in productivity, fuel consump-

tion and other performance values. Third, variation in

machine parametrisation is also expected due to dif-

ferences in components such as hydraulic valves that

control the machine boom. Parameter sets may vary

as well as how a certain parameter affects machine

operation.

Naturally, there are various reasons why a mea-

surement may fail. Even a modern sensor may lack

the ability to indicate if it has succeeded in measuring

a value or not. Even if a sensor were not malfunction-

ing, there is still a possibility that its reading is not

reliable – for instance, the sensor might have come

off its installation position thus measuring something

unexpected. In any case, it must be considered if each

measurement value is reasonable or not. The motiva-

tion of outlier consideration is discussed, for instance,

in (Osborne and Overbay, 2004).

As data item collections are persisted for later util-

isation, each measurement value should be stored as

such not to eliminate the possibility to recalculate val-

ues. This applies especially to cases where long-time

historical data is required in analysis. If a measure-

ment value is considered out of outlier limits and au-

tomatically declared a failure, it will be impossible to

reprocess it in case of a later change in outlier con-

ditions. Therefore, in many cases, it is a good prac-

tise not to store any values calculated from measure-

ments as calculation formulas might evolve. Natu-

rally, in some applications, if original values are not

needed for sure, it may also be appropriate to save

storage space by only saving the essential derived val-

ues rather than all raw values.

To run data analyses in a large scale, it is beneficial

if data item collections are categorised. There may be

considerable systematic variation in their values. Not

to treat them as a homogeneous mass (what they cer-

tainly are not), at least rough categorisation is benefi-

cial so each data item collection may be treated within

an appropriate group. In forestry, each stem may be

categorised after its size or tree species as it likely af-

fects productivity – if the processing of large trees is

being optimised, little trees should be ignored. As cat-

egorisation is performed based on measured values, it

is subject to failures; it cannot be performed if some

required value has been measured incorrectly.

Mobile machines may operate in varying environ-

ments so the power of context awareness should be

exploited as the context may significantly affect how

a machine can perform (V

¨

ayrynen et al., 2015). De-

pending on the context, an absolute numeric value

may be relatively high or low. It must be considered

if performance value comparison is appropriate if the

values have been measured in different contexts. For

instance, performance is likely low in unfavourable

conditions: the temperature may affect fuel consump-

tion, rough terrain makes machine movement slower

and so forth. In context classification, its subtleness

and other aspects must be considered depending on

the application area. Another important consideration

is knowledge evolution: it may also be required to up-

date the selected context classification method some-

times.

Enabling Centralised Management of Local Sensor Data Refinement in Machine Fleets

23

Context recognition is essential also in forestry.

Even inside a relatively small geographical region,

there may be a lot of variation between forests: the

type of land may affect machine performance, and

tree species may also vary. Also, the type of work be-

ing performed (final felling, thinning or other) always

affects absolute productivity values.

4 EXTERNALLY MANAGEABLE

DATA REFINEMENT

4.1 Workflow

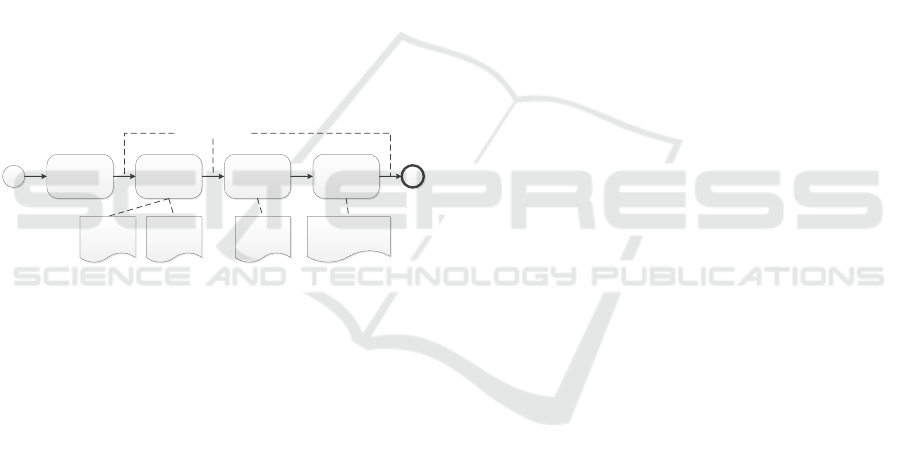

Considering given requirements, a solution can be de-

signed. The flow of the application run locally in

machines is illustrated in Figure 2. There are four

main phases complemented by context consideration.

To enable the utilisation of constantly evolving do-

main expertise, some phases utilise externally defined

methods or configuration files. Each phase is ex-

plained in the coming paragraphs.

Retrieve data

Perform outlier

check

Resolve

derived data

items

Categorise data

item

collections

Consider context?

Data item collection

categorisation

conditions

Data item

outlier

method

Appearance

item

conditions

Data item

outlier

configuration

Figure 2: Data refinement flow.

First, measurement values are retrieved; they are

stored in data item collections realised as key-value

pairs. For a certain machine type, each collection is

expected to have the same key-value pairs. In forestry,

a reasonable data structure is to have a data item col-

lection for each processed tree stem.

Then, an outlier check is performed. Whatever the

utilised method is, it should be applied early as it may

affect forthcoming data processing.

In the next phase, any derived variables are re-

solved. Often, not all desired variables can be di-

rectly measured so calculation may be required. Nat-

urally, a derived variable cannot be calculated if any

required measurement has failed. In this work, de-

rived Boolean values associated to a data item col-

lection are called appearance items: whether some

condition set is fulfilled by the collection or not. For

instance, in forestry data, an appearance item may ex-

press whether a stem is a spruce. The information

may be utilised in further data analysis to determine

which stems are considered interesting – occasional

birches in a spruce forest may not be interesting.

Finally, each data item collection is categorised.

Whatever the categorisation criteria are, technically,

they consist of condition sets on measurement val-

ues. If a data item collection has a failed measurement

value that is required for categorisation, the collection

is ignored in tasks where categories are essential.

Depending on the application, context awareness

may be applied in several phases. Context informa-

tion may even affect the outlier check; for instance,

it may determine which numeric outlier limits are ap-

plied or it may determine what kind of outlier check

method is utilised. Later in the refinement flow, the

context may affect how derived data items are re-

solved. However, some context awareness methods

may require data item collection categorisation results

so they cannot be utilised earlier. In the end, even

though the workflow has a certain phase set, its de-

sign is adaptable in terms of context awareness.

Let us consider the forestry example again. First,

an outlier check is required. For instance, if a mea-

sured value is beyond its reasonable limits, it must

be declared a failure. Second, derived variables are

calculated. Typical effectiveness variables (such as

wood volume productivity while processing a single

stem) are such as they cannot be measured directly.

Also, some derived variables may require consider-

ing multiple data item collections (i.e. stems; such as

the mass of processed wood per working hour dur-

ing a day). Another derived variable could be the

Boolean value (i.e. appearance item) whether a stem

is “large” which involves the comparison of its felling

diameter to a specific limit. Third, data item collec-

tions are categorised according to predefined condi-

tions. Depending on the objective of the categorisa-

tion, stem categories could include tree species, tree

sizes or both. Besides the mentioned phases, context-

awareness may be applied in multiple parts in the

flow. One option is simply to let the predominant tree

stem category determine the prevailing context – this

depends on the implementation of the application.

4.2 Configuration Management

A software component has been designed to imple-

ment the application flow that utilises externally pro-

vided configuration documents (see Figure 3). In

each individual machine, the component retrieves

data from the machine information system and refines

it for further analyses. The number of machines exe-

cuting the flow is arbitrary as well as their geographic

locations compared with each other and the enterprise

office. Several new specification requirements arise

from configuration: the payload enclosed in each doc-

ument, their format, and the way the configuration is

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

24

delivered to machines. Whichever is the way these

requirements are met, a local configuration cache is

likely required as a machine may operate long peri-

ods of time without a connection to any centralised

configuration storage.

Delivery

Machine

Data

refinement

component

Machine

information

system

Enterprise office

Data item

collection

categorisation

conditions

Data item

outlier

method

Appearance

item

conditions

Delivery

Delivery

Masters Local copies

Delivery

Data item

outlier

configuration

Utilisation

Applications utilising

operation data (e.g.

feedback apps)

Context

recognition

configuration

Delivery

Figure 3: Configuration management illustrated.

The modern information technology portfolio pro-

vides several options to deliver configuration doc-

uments from the office environment to mobile ma-

chines. Even widely used standard Internet technolo-

gies can be utilised here: for instance, HTTP (Hyper-

text Transfer Protocol) is suitable for transfering text-

based documents to physical machines. In that case,

a network connection (such as the Internet) is natu-

rally required. Be there no network, the configura-

tion may be delivered using another technology (even

by copying files manually); for instance, regular ma-

chine maintenance could be an occasion suitable for

delivery. Finally, whatever the configuration delivery

method is, regular updates should be enabled so each

machine has as up-to-date a configuration as possible.

5 CONFIGURABLE DATA

REFINEMENT PROTOTYPE

5.1 Implementation

Following the specified concept, a prototype has been

implemented for tree stem data processing in the

forestry domain. Configuration delivery from the en-

terprise office to machines is left as a future task.

Yet the implemented component prototype is config-

urable, and its design allows configuration delivery in

whichever way suits best for the use case. The pro-

totype implementation is not supposed to be a fully

comprehensive solution – it rather illustrates that the

concept is functional in general.

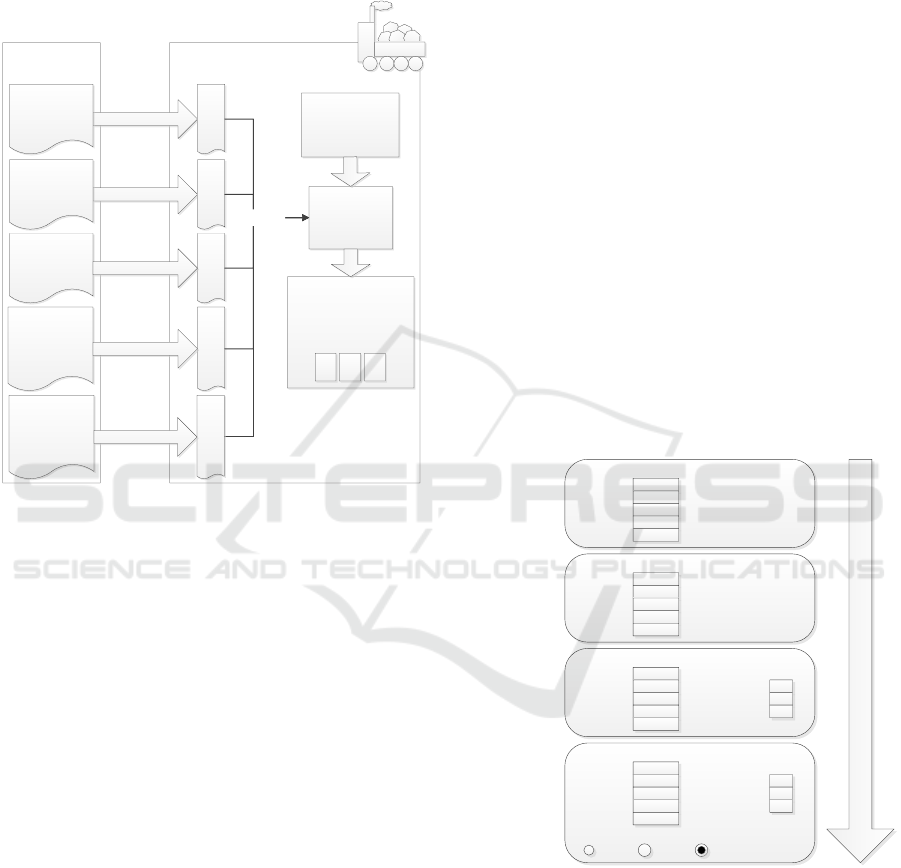

The data item collection refinement flow in the

prototype is illustrated in Figure 4. There will be

a data item collection for each processed tree stem

and the logs made from it. First, measurement values

are retrieved and structured as data item collections.

Then, an outlier check is performed for each mea-

surement value in each data item collection; the data

items that do not match their conditions are marked as

failed. Next, appearance items are resolved by check-

ing whether each data item collection satisfies each

appearance condition set or not. Finally, stem data

item collections are categorised based on their val-

ues. Here, it must be noted that if some measurement

value required for categorisation has failed (per out-

lier check), the category cannot be resolved. Instead,

the stem data item collection (and the related log data

item collections) will not be further processed.

5.3

-2.1

-0.5

3.3

9.8

Measurements

M1

M2

M3

M4

M5

5.3

-2.1

-0.5

3.3

9.8

Measurements

M1

M2

M3

M4

M5

5.3

-2.1

-0.5

3.3

9.8

Measurements

M1

M2

M3

M4

M5

5.3

-2.1

-0.5

3.3

9.8

Y

Appearance items

A1

A2

A3

Measurements

M1

M2

M3

M4

M5

N

Y

After retrieval

After outlier

check

After resolving

appearance

items

After

categorisation

Refinement of data item collection

FAIL

FAIL

FAIL

FAIL

FAIL

FAIL

Category

C1 C2 C3

Y

Appearance items

A1

A2

A3

N

Y

Figure 4: Data refinement in the prototype implementation.

The method utilised for the outlier check is

straightforward. For each measurement, an arbitrary

number of conditions may be specified. In a typical

case, there will be a lower and an upper bound. While

the utilised outlier detection method is simple, various

more advanced methods exist as discussed in (Hodge

and Austin, 2004), for example. An XML format has

been designed to capture the outlier limits for each

data item. The documents specifying the limits may

Enabling Centralised Management of Local Sensor Data Refinement in Machine Fleets

25

be managed anywhere; fresh versions will be deliv-

ered to machines for utilisation. That is, even though a

machine fleet may be geographically distributed, cen-

tralised outlier limit management is enabled.

To enable configurability, conditions for appear-

ance items are defined with the same XML format as

the outlier limits. For each appearance item, an ar-

bitrary set of data items may be inspected. For each

data item, there can be an arbitrary number of condi-

tions (similar to each data item that may have multiple

outlier conditions).

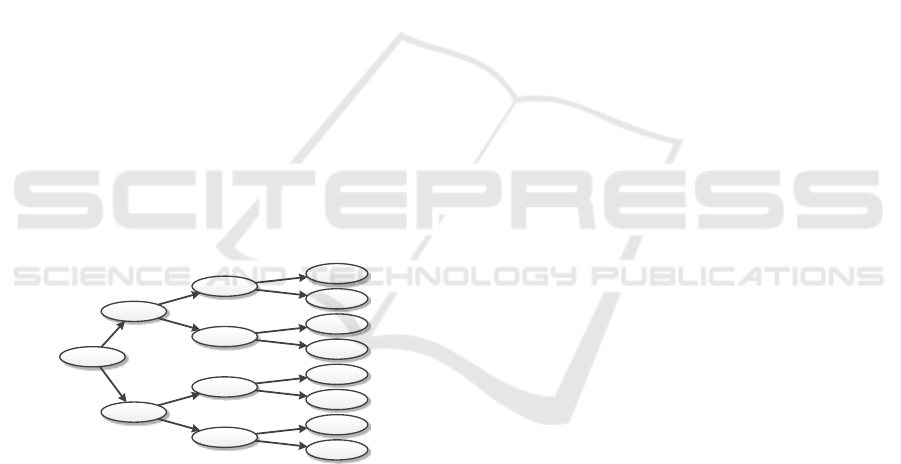

While various context recognition methods exist,

the prototype utilises a simple though configurable

way. The prevailing context is determined by find-

ing the most typical stem data item collection cate-

gory. That category is considered the context; any

other data item collections are excluded from further

processing as they are considered exceptions in the

current environment. Categories are defined using a

tree-like condition set (see Figure 5): the categorisa-

tion tree may inspect any data items to resolve the

category of a data item collection. The categorisation

tree is stored in a structured text document; it has been

generated by a data analysis software in the enterprise

office. The prototype parses the categorisation tree so

it is available in the application during machine op-

eration. Similar to outlier and appearance condition

definitions, even the categorisation tree is delivered

as a configuration file to each machine.

Ctg 8

Ctg 7

Ctg 6

Ctg 5

Ctg 4

Ctg 3

Ctg 2

Ctg 1

1.3

0.70

0.34

0.085

0.19

0.94

0.50

<

<

<

<

<

<

<

>=

>=

>=

>=

>=

>=

>=

Figure 5: An example of categorising a tree stem after its

volume in m

3

(though there could be multiple variables ob-

served in the conditions). Here, the categories have indices

from 1 to 8, a high index indicating a large stem. For in-

stance, category 4 has the stems with a volume within range

[0.34-0.50[.

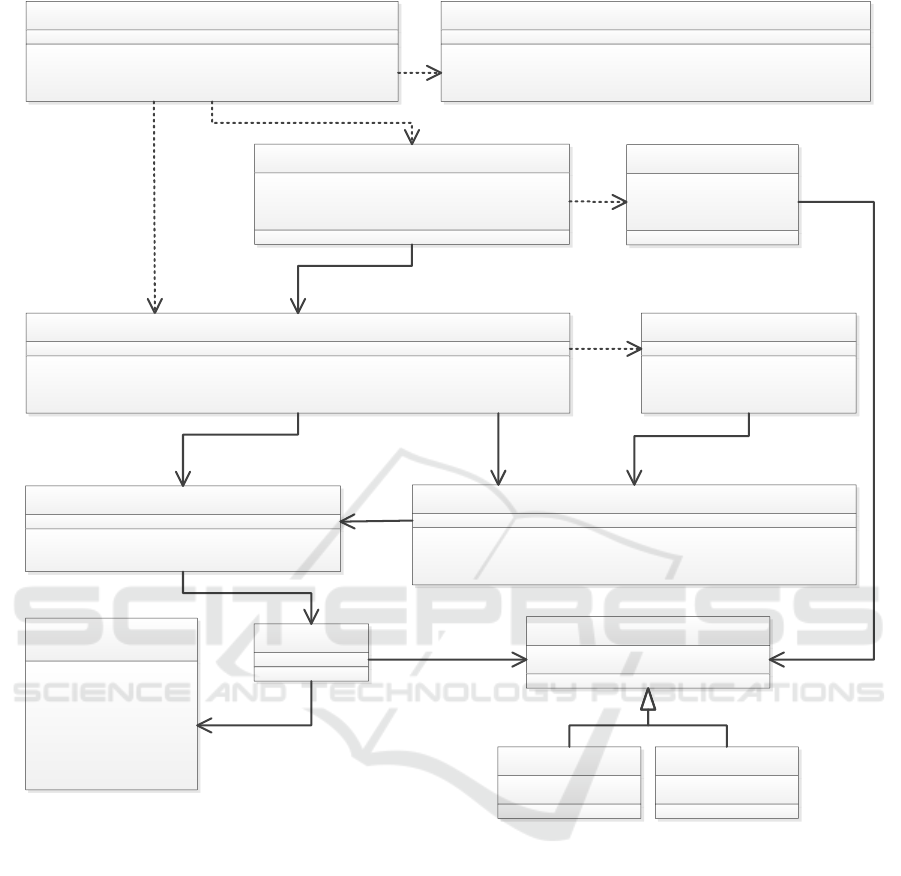

The classes of the prototype are illustrated in Fig-

ure 6. In the prototype, an abstraction called item con-

dition is essential: it defines a condition for a data

item (such as a measurement). Item conditions are

utilised for both outlier checking and specifying ap-

pearance items. Each item condition is a part of an

item condition definition (as a value may have mul-

tiple boundaries), and each item condition definition

is a part of an item condition definition set (such as

the conditions of an appearance item). Item condi-

tions are stored in an XML configuration file parsed

by the item condition XML reader class. Appearance

resolver class resolves which appearances are true for

each data item collection. The conditions for data

item collection categorisation are parsed by the cat-

egorisation tree parser class.

The prototype has been implemented with Java

though any other platform could be used as well. As

long as component interfaces (such as configuration

formats) are as specified, even heterogeneous plat-

forms are possible within an enterprise.

5.2 Practical Experiment

The prototype has been utilised in the refinement of

real operational forestry data. It has been included in

a workflow that estimates machine performance and

suggests machine parameter tuning in case the pa-

rameters seem non-optimal; the same scenario has al-

ready been considered in (Kannisto et al., 2015). As

the number of machine parameters may reach hun-

dreds in a modern machine, their optimisation is too

difficult for a typical operator. That is, such informa-

tion refinement has considerable added value to the

operating enterprise. The actual parameter optimisa-

tion application utilises the outcome of the data pre-

processing introduced in this paper. The software has

been executed on a desktop computer with a data re-

trieval interface identical to a physical forestry ma-

chine. As real operating data is utilised, the setup is

almost identical as if the application were run in the

field.

Parameter optimisation is not a simple task as it

requires multiple factors to be considered. The oper-

ating context and the type of work being performed

may affect both which parameter values result in a

good performance and the actual performance values.

Large amounts of historical data should be analysed to

generate reference sets of performance values and op-

timal parameter values. As machines keep operating,

data should be continuously collected to refresh pa-

rameter related knowledge; as knowledge updates are

delivered to multiple machines, ease in management

becomes beneficial. Knowledge generation actions

require both extensive domain expertise and advanced

data refinement methods so they should be performed

by a dedicated group of skilled personnel. The knowl-

edge may be managed by, for instance, machine man-

ufacturer or fleet operator.

Here, the function under parameter optimisation

is automatic tree stem positioning in a wood process-

ing implement. Stems are positioned to be cut into

logs. Such a case suits well for parameter optimisa-

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

26

ItemCondition

ItemConditionDefinition

+dataItemMatches(di : DataItem) : boolean

ItemConditionDefinitionSet

+dataItemCollectionMatches(dic : DataItemCollection) : boolean

+dataItemMatches(itemId : String, item : DataItem) : boolean

ItemConditionChecker

+checkMeasurementSuccess(dic : DataItemCollection)

+dataItemCollectionMatchesAppearance(appr : String, dic : DataItemCollection)

ItemConditionXmlReader

+startElement(...)

+endElement(...)

AppearanceResolver

+MatchingAppearanceItems : Collection

+UnmatchingAppearanceItems : Collection

DataRefiner

+init()

+treatDataItemCollection(DataItemCollection : dic)

CategorisationTreeParser

+parse()

+getCategoryForDataItemColl(dic : DataItemCollection) : String

DataItemCollection

+Timestamp : Calendar

+Items : Collection

DataItem

+MeasuredSuccessfully : boolean

BooleanDataItem

+Value : boolean

NumericDataItem

+Value : double

<<enumeration>>

OperatorType

EQUAL

NOT_EQUAL

LESS

LESS_OR_EQUAL

GREATER

GREATER_OR_EQUAL

value

operator

parsed

1

*

*

1

*

11

*

1

1

*

0..1

1

0..1

*

1

1

1

Figure 6: The classes of the prototype implementation.

tion as automatic positioning is controlled entirely by

machine parameters rather than by the operator – the

most of other machine functions are largely affected

by operator skills.

The outliers of two measurements are observed

in the experiment. Positioning error describes how

close to its optimal cutting position a stem has been

stopped. In contrast, feed speed does not determine

positioning performance but it is an important mea-

sure as the overall machine performance is estimated

in further data processing (more speed results in a

higher productivity value). The outlier conditions are

as follows: feed speed cannot be negative, and the ab-

solute value of positioning error must be within 30 cm

of the desired position.

Stem categorisation is important in the experi-

ment. According to stem volume, each stem is put

into one of eight categories. As little trees are not of

interest in this felling scenario, there is an additional

condition that each stem with a felling diameter of

less than 15 cm is excluded. The context recognition

method also uses the outcome of the categorisation.

It is simplistic: for each category, there is a directly

mapped context class. The stems in any other cate-

gory are considered irrelevant and excluded from fur-

ther processing.

In the experiment, appearance items have an infor-

mative function. They are generated using conditions

that specify if a stem represents a long spruce or a

long pine (that is, both tree species and stem length

are observed). For the resulting Boolean true val-

Enabling Centralised Management of Local Sensor Data Refinement in Machine Fleets

27

ues, percentages are calculated how large their sec-

tion is within the relevant stem category (or context;

e.g. ”64% of stems are long spruces”). While the

parameter analysis application does not utilise these

percentage values, the machine operator might want

to observe himself if tree species or lengths actually

affect optimal parameter values. If there are such fac-

tors, they should actually be discovered in fleet level

data analyses. Then, they could be utilised by the pa-

rameter optimisation application in the field.

6 RESULTS AND DISCUSSION

The objective of this work was to design a software

concept to enable centralised management of data re-

finement in an arbitrarily large geographically dis-

tributed machine fleet. Outlier inspection for mea-

surements was required as well as data set categori-

sation and the possibility to specify variables derived

from original data. Context recognition and consider-

ation were also required.

The concept meets its requirements well. The ease

of management of the application workflow was con-

sidered paramount: it is possible to configure not only

outlier limits but also data set categorisation and the

context determination method. As an enterprise may

have machines in arbitrary geographic locations, the

delivery of configuration data has also been consid-

ered. In addition, it is possible to specify variables

for information that has been inferred from explicit

measurement data. Such data may be numeric (calcu-

lated) or Boolean values resulting from the assertion

of multiple conditions.

A functional data refinement component proto-

type has been implemented. It implements the spec-

ified data refinement flow. First, an outlier check is

performed on measurement values followed by the

calculation of derived variables. Then, each data

item collection (a data set of key-value pairs) is cate-

gorised according to specified conditions, and finally,

the prevailing context is determined using categori-

sation information. The configurability requirement

is fulfilled by getting outlier conditions, derived vari-

able calculation conditions and categorisation defini-

tion from externally defined configuration files.

The concept was experimented with real operative

data from 11 forestry machines. For each machine,

the data of thousands of stems was processed so it can

be said there has been a lot of repetition in application

cycles. The outcome of the software component (i.e.

refined data) was utilised to optimise the parameters

of automatic tree stem positioning in a wood process-

ing implement. The data refinement results are in Ta-

ble 1. In each data set, the number of stems in the

context was relatively low. The context recognition

method returned the same operating context for each

data set (stems with volume within 0.19-0.34 m

3

) so

it is not included in the table.

The outlier results provided by the component

seem useful. For positioning error values, the exclu-

sion percentage is relatively low – mostly less than

1%, at most 1.4%. However, the highest exclusion

percentage due to feed speed value is 9.7%. If these

values were not excluded from further processing,

they could cause significant errors in further calcula-

tions performed by other applications. Still, depend-

ing on error magnitudes, even a 1% section of erro-

neous values may cause misleading results.

18-54% of all stems were excluded from further

processing as their felling diameter was less than 15

cm. The percentages are relatively high. As the

parameter optimisation goal was concerned with the

processing of large stems, such large amounts of rel-

atively little stems might distort further calculations.

However, it may also be asked if the processing of lit-

tle stems should also be considered in optimisation.

In that case, their data should be passed through dis-

tinguished from large stems.

The percentages of long spruces and pines are also

included in the results table. In most cases, spruce ap-

pears the dominant species. The parameter analysis

application did not utilise this information for any-

thing so it is purely informative.

The context recognition method appeared to be in-

effective as its result was the same context class for

each test run. More context recognition and classifi-

cation related research should be performed. The goal

of context recognition should be reconsidered; that

would specify which variables and what kind of meth-

ods should actually be included as the context is deter-

mined. However, the task is more related to domain

expertise and data analysis rather than the knowledge

management concept relevant in this study. In the end,

it might be beneficial if the entire context recognition

method could be updated along with the configura-

tion.

The experiments made with the prototype indicate

that the data refinement concept is functional. It has

potential business value in real-life data processing: it

would be easier to manage the refinement of the data

consumed by various end user applications. Such ap-

plications may, for instance, assist in more effective

machine operation. However, the prototype also has

room for further development. It does not address the

delivery of configuration documents – at least a loose

framework might be beneficial. Still, the prototype

provides a baseline for the delivery by having a spe-

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

28

Table 1: Data refinement results with real forestry machine operation data.

Stems excluded

Mach Feed speed Pos. error (felling diam Stems in Long spruces Long pines

ID Stems Logs outlier (logs) outlier (logs) <15 cm) context (in context) (in context)

1 11,000 27,000 4.0% 0.33% 54% 1,400 40% 52%

2 6,300 19,000 1.8% 1.1% 23% 1,200 60% 26%

3 14,000 39,000 4.1% 0.93% 36% 2,500 61% 22%

4 6,600 18,000 3.9% 0.56% 48% 1,100 61% 5.6%

5 5,900 18,000 2.9% 0.27% 31% 1,000 60% 8.7%

6 7,800 26,000 5.1% 0.36% 30% 1,100 75% 9.1%

7 8,000 27,000 1.6% 0.39% 26% 1,400 72% 7.9%

8 10,000 28,000 4.9% 0.76% 32% 2,000 33% 33%

9 12,000 38,000 4.9% 1.4% 34% 1,600 64% 20%

10 6,800 25,000 9.7% 0.93% 18% 1,100 55% 4.2%

11 6,500 20,000 4.9% 1.0% 29% 1,400 62% 13%

cific XML format for some configuration items. Also,

derived variables can only be Boolean values – nu-

meric values are not currently supported though they

would offer significantly more potential for various

uses cases.

7 CONCLUSION

This paper introduces a software concept for centrally

manageable data refinement run locally in the ma-

chines of an arbitrarily large fleet. As machine data is

utilised locally in end-user applications (such as feed-

back generation to improve machine operation and

productivity), it is beneficial if the required data pre-

processing is configurable and managed on the fleet

level. Configurability covers multiple actions: outlier

checks detect erroneous sensor output, derived vari-

ables can be calculated from original data, and data

sets are categorised according to predefined condi-

tions. Further, determining the operating context is

also configurable. Context awareness is utilised as the

context may affect how data should be interpreted.

A functional prototype has been implemented.

Utilising externally defined configurations, it pro-

cesses operational data retrieved from an interface

similar to a physical production machine. The solu-

tion showed its potential as a part of an added-value

data refinement concept by enabling centralised man-

agement.

As the current prototype does not cover all con-

cept aspects, a few future tasks remain. A concrete

solution for the delivery of configuration data from

office to machines should be designed. Also, the cur-

rent context recognition method appeared to be too

simple.

REFERENCES

Banerjee, T. P. and Das, S. (2012). Multi-sensor data fusion

using support vector machine for motor fault detec-

tion. Information Sciences, 217:96 – 107.

Basir, O. and Yuan, X. (2007). Engine fault diagnosis based

on multi-sensor information fusion using dempster-

shafer evidence theory. Information Fusion, 8(4):379

– 386.

Choudhury, T., Consolvo, S., Harrison, B., Hightower, J.,

Lamarca, A., Legrand, L., Rahimi, A., Rea, A., Bor-

dello, G., Hemingway, B., Klasnja, P., Koscher, K.,

Landay, J., Lester, J., Wyatt, D., and Haehnel, D.

(2008). The mobile sensing platform: An embed-

ded activity recognition system. Pervasive Comput-

ing, IEEE, 7(2):32–41.

Duan, L. and Xu, L. D. (2012). Business intelligence for

enterprise systems: A survey. Industrial Informatics,

IEEE Transactions on, 8(3):679–687.

Favela, J., Tentori, M., Castro, L. A., Gonzalez, V. M.,

Moran, E. B., and Mart

´

ınez-Garc

´

ıa, A. I. (2007). Ac-

tivity recognition for context-aware hospital applica-

tions: Issues and opportunities for the deployment of

pervasive networks. Mob. Netw. Appl., 12(2-3):155–

171.

Fountas, S., Sorensen, C., Tsiropoulos, Z., Cavalaris, C.,

Liakos, V., and Gemtos, T. (2015). Farm machin-

ery management information system. Computers and

Electronics in Agriculture, 110:131–138.

Golparvar-Fard, M., Heydarian, A., and Niebles, J. C.

(2013). Vision-based action recognition of earthmov-

ing equipment using spatio-temporal features and sup-

port vector machine classifiers. Advanced Engineer-

ing Informatics, 27(4):652 – 663.

Hodge, V. and Austin, J. (2004). A survey of outlier de-

tection methodologies. Artificial Intelligence Review,

22(2):85–126.

Hou, L. and Bergmann, N. (2012). Novel industrial wire-

less sensor networks for machine condition monitor-

ing and fault diagnosis. Instrumentation and Measure-

ment, IEEE Transactions on, 61(10):2787–2798.

Enabling Centralised Management of Local Sensor Data Refinement in Machine Fleets

29

Iftikhar, N. and Pedersen, T. B. (2011). Flexible exchange

of farming device data. Computers and Electronics in

Agriculture, 75(1):52 – 63.

Jardine, A. K., Lin, D., and Banjevic, D. (2006). A review

on machinery diagnostics and prognostics implement-

ing condition-based maintenance. Mechanical Sys-

tems and Signal Processing, 20(7):1483 – 1510.

Kannisto, P., H

¨

astbacka, D., Palmroth, L., and Kuikka, S.

(2014). Distributed knowledge management architec-

ture and rule based reasoning for mobile machine op-

erator performance assessment. In Proceedings of the

16th International Conference on Enterprise Informa-

tion Systems, pages 440–449.

Kannisto, P., H

¨

astbacka, D., Vilkko, M., and Kuikka, S.

(2015). Service architecture and interface design

for mobile machine parameter optimization system.

IFAC-PapersOnLine, 48(3):848 – 854. 15th IFAC

Symposium on Information Control Problems in Man-

ufacturing INCOM 2015.

Khot, L. R., Tang, L., Blackmore, S., and Nørremark, M.

(2006). Navigational context recognition for an au-

tonomous robot in a simulated tree plantation. Trans-

actions of the ASABE, 49(5):1579–1588.

LaValle, S., Lesser, E., Shockley, R., Hopkins, M. S., and

Kruschwitz, N. (2011). Big data, analytics and the

path from insights to value. MIT sloan management

review, 52(2):21–31.

Lu, B. and Gungor, V. (2009). Online and remote motor en-

ergy monitoring and fault diagnostics using wireless

sensor networks. Industrial Electronics, IEEE Trans-

actions on, 56(11):4651–4659.

Osborne, J. W. and Overbay, A. (2004). The power of out-

liers (and why researchers should always check for

them). Practical assessment, research & evaluation,

9(6).

Palmroth, L. (2011). Performance Monitoring and Oper-

ator Assistance Systems in Mobile Machines. PhD

thesis, Department of Automation Science and Engi-

neering, Tampere University of Technology, Tampere,

Finland.

Peets, S., Mouazen, A. M., Blackburn, K., Kuang, B.,

and Wiebensohn, J. (2012). Methods and procedures

for automatic collection and management of data ac-

quired from on-the-go sensors with application to on-

the-go soil sensors. Computers and Electronics in

Agriculture, 81:104 – 112.

Steinberger, G., Rothmund, M., and Auernhammer, H.

(2009). Mobile farm equipment as a data source in

an agricultural service architecture. Computers and

Electronics in Agriculture, 65(2):238 – 246.

Stiefmeier, T., Roggen, D., Ogris, G., Lukowicz, P., and

Tr

¨

oster, G. (2008). Wearable activity tracking in car

manufacturing. IEEE Pervasive Computing, 7(2):42–

50.

V

¨

ayrynen, T., Peltokangas, S., Anttila, E., and Vilkko, M.

(2015). Data-driven approach for analysis of perfor-

mance indices in mobile work machines. In DATA

ANALYTICS 2015, The Fourth International Confer-

ence on Data Analytics, pages 81–86.

Yang, B.-S. and Kim, K. J. (2006). Application of demp-

stershafer theory in fault diagnosis of induction mo-

tors using vibration and current signals. Mechanical

Systems and Signal Processing, 20(2):403 – 420.

KMIS 2016 - 8th International Conference on Knowledge Management and Information Sharing

30