Possibility of Modern Humidity Sensor Application in the Studies of

Moisture Transport through the Sports and Outdoor Garments

Andrey Koptyug, Mats Ainegren, Mikael Bäckström, Erika Schieber and Jonas Persson

Sports Tech Research Centre, Mid Sweden University, Akademigatan 1, SE-83125 Östersund, Sweden

Keywords: Sports and Outdoor Garments, Comfort, Moisture Transport, Experimental Studies, Wind Tunnel.

Abstract: Sensor nodes containing pairs of temperature and humidity sensors were assessed as a mean of garment

performance and comfort studies. Modern sensors are small, low weight and produce minimal disturbance

when placed under the garments and in the footwear. Four sensor nodes were used to provide dynamic

information about heat and humidity transfer properties of garments during the tests in realistic conditions.

Pilot studies were carried out for the few models of cross country skiing garments and waders. Main studies

were carried out in the wind tunnel at Mid Sweden University having pivoted treadmill, temperature control

and rain capacity. Additional experiments with the waders were carried out in a large water tank. Studies of

the temperature and humidity dynamics under the garments containing microporous membranes illustrate

the importance of recognizing main features of such materials. In particular, such membranes can only

transport moisture from the side where humidity is higher. It means that garments and footwear containing

such membranes will potentially behave differently when ambient air humidity changes. In particular,

modern garments with incorporated microporous membranes being superior at low ambient air humidity can

be dramatically less effective for moisture transfer from the body in the rain.

1 INTRODUCTION

Modern garments and footwear often incorporate

innovative fabrics and can have quite complex,

multilayer structure. This strongly complicates

possibilities of adequate prediction of the overall

garment or footwear performance and their assess-

ment in targeted environment, even if the fabrics

were tested in the laboratory using standard proce-

dures, and the garment or footwear is individually

fit. When the garment or footwear is designed to

work in extreme conditions (cold, hot, humid

environment) and should provide high degree of

comfort of the person at different physical load

levels, corresponding performance assessment may

be quite challenging. Though modern garment and

footwear research and development strongly de-

pends on traditional ways of subjective assessment,

there is a strong drive towards objective methods

providing more reliable and reproducible data

(Arezes et al., 2013). Present research is aiming at

the assessment of compact temperature and humidity

sensor system applications for the studies relative

humidity and thermal comfort of garments in the

controlled laboratory environment mimicking realis-

tic conditions. Particular research questions were if

such sensor systems can visualize the action of

modern semi-permeable membranes incorporated

into the garments, and if they can be used for the

moisture transport studies.

Human thermoregulation system has a signify-

cant potential to maintain core body temperature in a

comfort zone even with increasing heat production

during work or exercise (e.g. Reilly et al., 2006, Lim

et al., 2008). But this mechanism involves perspire-

tion and thermal comfort is strongly influenced by

the humidity at the skin surface (Jing et al., 2013).

Thus it is quite important for the garments to support

proper heat and humidity control (Gonzalez, 1988,

Sullivan et al., 1992, Rugh et al., 2004,

Senthilkumar et al., 2012, Troynikov et al., 2013,

Nayak et al., 2014). Additional challenge for the

heat and humidity control under the garments and

footwear may be presented by cold (Watson et al.,

2013) and wet (Abreu et al., 2012) environment.

Significant progress in modern garment design is

related to the development of “smart textile” and

“smart garment” concepts (Parkova et al., 2011).

Modern “active” materials can provide needed

proactive heat and humidity control features (Van

Roy, 1992, Chaudhari et al., 2005, Brzeziński et al.,

2005). For example semi-permeable membranes

Koptyug, A., Ainegren, M., Bäckström, M., Schieber, E. and Persson, J.

Possibility of Modern Humidity Sensor Application in the Studies of Moisture Transport through the Sports and Outdoor Garments.

DOI: 10.5220/0006080400510058

In Proceedings of the 4th International Congress on Sport Sciences Research and Technology Support (icSPORTS 2016), pages 51-58

ISBN: 978-989-758-205-9

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

51

facilitating gas and water vapour transfer but

preventing liquid (water) getting through (Metz,

2003, Brzeziński et al., 2005, Frydrych et al., 2009).

Though standards for measuring humidity transfer

through the multi-layer fabric structures containing

such materials do exist (Standard ISO 15496:2004).

Studies on the impact of pro-active materials being

part of the multi-layered structure of the smart

garments in realistic conditions today are carried out

using unique “sweating manikins” (Fukazawa et al.,

2004, Farrington et al., 2005, Bogerd et al., 2012,

Gao et al., 2016), or done with subjects wearing

garments exercising on a treadmill (Roberts et al.,

2007), outdoors or in the climate controlled indoor

environment (Bäckström et al., 2016).

2 MATERIALS AND METHODS

2.1 Sensors and Data Acquisition

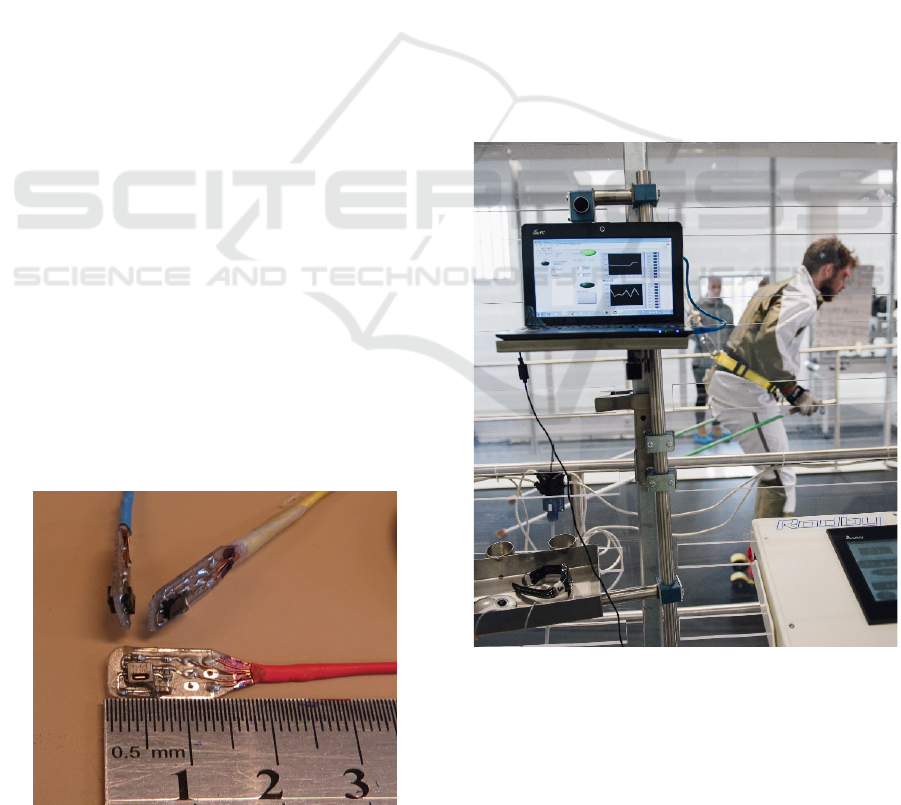

A custom made system with four sensor nodes was

designed and constructed. Each sensor node

consisted of a small printed board with two

temperature (T) and relative humidity (RH) sensors

SHT21 by Sensirion AG, Switzerland (Sensirion

web site, 2016) mounted on opposite sides of the

boards (Figure 1). For better humidity resistance

boards are coated with protection lacquer. The

sensors have a precision of ±3% in RH in the full

range (0 to 100%) and ±0.3

o

C in T in the range of

interest (0 to 60

o

C). Digital interfaces of the sensors

are connected via home-made multiplexer to the

digital serial interface module NI USB-485 (by

National Instruments).

Data acquisition is carried out using the

LabVIEW platform by National Instruments.

Sampling from all nodes simultaneously can be set

to 5 or 10 seconds per sample.

Figure 1: Experimental T and RH measuring nodes.

2.2 Sports Garment Tests

Garments of two different designs from the same

manufacturer were tested. Both garments were the

prototypes designed for the cross-country skiing and

biathlon. Garment 1 is made using: fabric 106402

Vulcano Dry-Storm by Sport wear Argentona (70%

Polyester, 20% Elastan, 10% Polyurethane) in 3

layers with microporous membrane inside, wind

protection GG40; fabric W53798 by Schoeller (60%

Polyacryl, 28% PES-Expand, 12% Lycra) in 2

layers, wind- and water-tight; mesh S-005 by Janmar

Sport (94/ PES, 6% Elastan), single-layer. Garment

2 is made using: fabric 106406 Kanjut Dry-Storm by

Sport wear Argentona (84% PES, 6% Elsatan, 10%

Polyurethane), in 3 layers with microporous

membrane inside, wind- and water- resistant; fabric

S-013/300/DR by Janmar Sport (84% PES, 16%

Elastan); mesh S-005 by Janmar Sport, single layer.

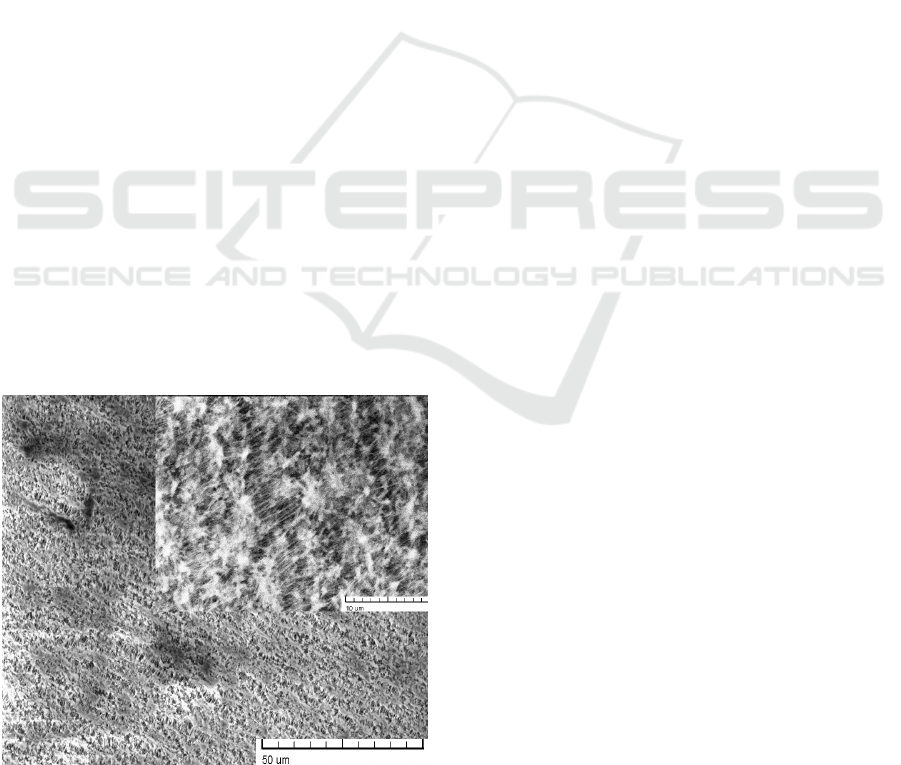

Tests were performed in the wind tunnel (for the

wind tunnel description see Bäckström et al., 2016)

with the subjects roller-skiing on the treadmill

(Figure 2). The air temperature was 3-4

o

C and

relative humidity was 75-80%.

Figure 2: Test subject roller skiing in the wind tunnel.

Sensor nodes were placed over the underwear

(Figure 3 visualizes the sensor node placement-

positions and procedure). Two male cross country

skiers with the experience on national level

participated in this part of the study.

icSPORTS 2016 - 4th International Congress on Sport Sciences Research and Technology Support

52

Figure 3: Sensor node placement- positions and procedure.

Sensor nodes were placed over the underwear

(Figure 3 visualizes the sensor node placement-

positions and procedure). Two male cross country

skiers with the experience on national level

participated in this part of the study.

Each of the skiers performed tests with both

types of garments using roller skis on the treadmill

for 15 minutes at a relative intensity of ~75% of

their maximal heart rate. One of the skiers was using

classical style double poling (15 km/h, 0° treadmill

inclination) and the other was using free style gear 4

(20 km/h, 0° inclination). The wind tunnel created

head wind corresponded to the speed of the

treadmill. Heart rate was recorded along with the

sensor data (T and RH) and the subjects were

interviewed before and after the tests to assess the

perceived comfort. Subjects were wearing small

control box (on the belt) connected with a flexible

cable to the data acquisition PC (Figure 2).

2.3 Waders Tests

In this part of the study three types of commercial

waders were tested, ranging from the least expensive

galon waders (Fladen, PVC-impregnated fabric type,

http://www.jula.se) to the most expensive ones,

using modern semi-permeable membrane materials

(Kaitum and Alta, http://www.guideline.no/).

Kaitum waders use 3-layer fabric sandwiches: outer

layer is nylon, membrane layer is of the

polyurethane (PU) coating type, qualified for 20000

mm Hg water pressure, fabric density 7000 g/m

2

.

From the waist up, Alta waders use 3-layer fabric

sandwiches: outer layer is nylon/spandex, membrane

layer is of the PU coating type, qualified for 15000

mm Hg water pressure, fabric density 3000 g/m

2

.

From the waist down, Alta waders use 4-layer fabric

sandwiches: outer layer is nylon, membrane layer 1

is of the polyurethane coating type, membrane 2 is

PU, qualified for 30000 mm Hg water pressure,

fabric density 5000 g/m

2

.

In each series of tests three subjects were

participating wearing same sample waders. The first

series of tests was performed in the wind tunnel with

the subjects walking on the treadmill (18

o

C and

33% RH). Each of the tests consisted of steady

walking for 10 minutes at 4 km/h followed by

another 10 minutes at 6 km/h. Heart rate of the test

subjects was kept at approximately 60% of

maximum. Head wind was kept at the same speed as

the treadmill one, and treadmill was horizontal

throughout the test.

The second test series was conducted with the

subjects staying waste deep in the water tank (air

temperature 20

o

C, water temperature 14.8

o

C) for 15

minutes. Sensor node placement was same as for the

ski garments tests. Subjects were interviewed before

and after the tests to assess the perceived comfort.

Figure 4 illustrates typical setup of the waders test in

the water tank. In this case control box was placed at

the back of the test subject close to the neck.

Figure 4: Waders test in the water tank.

Possibility of Modern Humidity Sensor Application in the Studies of Moisture Transport through the Sports and Outdoor Garments

53

3 RESULTS AND DISCUSSION

The main target of the study was preliminary

assessment of the method and sensor system

capacity to analyze the temperature and humidity

under the garments, and the possibility to indicate

the humidity flow direction. Thus small number of

test subjects and relatively simple test protocols

were used. So present results can be used as good

indicators only, and more thorough research will be

carried out in the near future.

3.1 Microporous Membranes

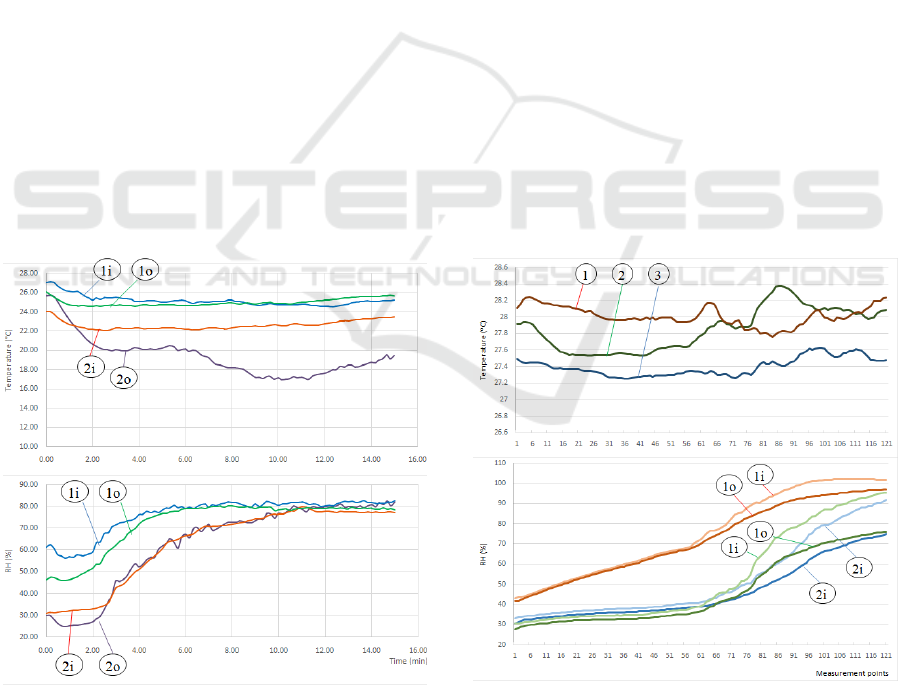

Modern gas and humidity permeable membranes

used in fabric composites are represented by thin

microporous polymer layers (e.g. Gore-Tex, a

microporous PTFE-based material (Gore Tex web

site, 2016). Figure 5 presents a scanning electron

microscopy images of the untreated Gore-Tex

membrane used in standard water vapour

permeability tests (Standard ISO 15496:2004).

Transport rate of water vapour through such

membranes strongly depends on the RH difference

on the sides of membrane, temperature and air

pressure (Metz, 2003). Thus adequately predicting

performance of the full garment containing such

membranes (placed only in certain places in

sections, and also as parts of the composite fabric

sandwiches) in real exercises is quite difficult.

Standard humidity transfer tests done on

relatively small fabric samples (Standard ISO

15496:2004), are essentially static. Expected

dynamic behaviour of the composite fabrics with

such membranes can be explained as follows.

Figure 5: SEM images of the Gore-Tex microporous

membrane. Magnification: x 2200 (x 8800 for insert).

When ambient humidity is lower than the one

under the membrane (towards human body) certain

water vapour transport towards the outer side of the

garment should take place. When humidity under the

garment is becoming higher than the one outside it

water vapour transport towards the body takes place.

During intense exercising humidity under the

garment starts to increase, increasing the water

vapour transport through the garment. Water vapour

transfer rate increases with increasing RH

difference, and the growth of humidity under the

garment will be governed by a competition of the

humidity "production" and humidity transfer. If the

membrane has high transfer capacity humidity under

the garment should be kept almost stable (or at least

should grow very slowly). At some point the

capacity limit of the membrane will be reached

(saturation), and humidity under the garment should

start to grow fast, possibly reaching 100%. Intense

exercising is accomplished by the changes of the

temperature under the garment. And both

temperature and humidity levels matter for the

proper thermoregulation and comfort. So measuring

dynamics of both parameters is important.

Processes of moisture transfer by such

membranes can be better understood using analogies

with the microporous membranes used in osmosis

(Zhao et al., 2012, Nicoll, 2013). In this case

membrane attempts to level the osmotic pressures on

both of its sides. In simplest cases with water salt

solutions these membranes attempt to level the salt

concentrations on two sides of the membrane. From

this analogy point of view one can treat humidity as

moisture concentration in the air, and microporous

membrane working to level such concentrations on

both sides of it. This analogy is also useful to stress

the presence of strong temperature and air pressure

dependence of moisture transport through

microporous membranes. Indeed, relative humidity

is not a simple concentration of the water vapour in

the air: "the relative humidity of an air-water

mixture is defined as the ratio of the partial pressure

of water vapour in the mixture to the equilibrium

vapour pressure of water over a flat surface of pure

water at a given temperature" (Relative humidity

definition, Wikipedia). Simply speaking it is the

ratio of the water amount that is now in the air, to

the maximum amount of water the air at this

temperature and pressure can hold without forming

condensation droplets (fog). And this maximum

amount is significantly temperature and pressure

dependent. And even though absolute amount of

water in the air can be constant, RH is changing

when air temperature and pressure changes.

icSPORTS 2016 - 4th International Congress on Sport Sciences Research and Technology Support

54

3.2 Ski Garment Tests

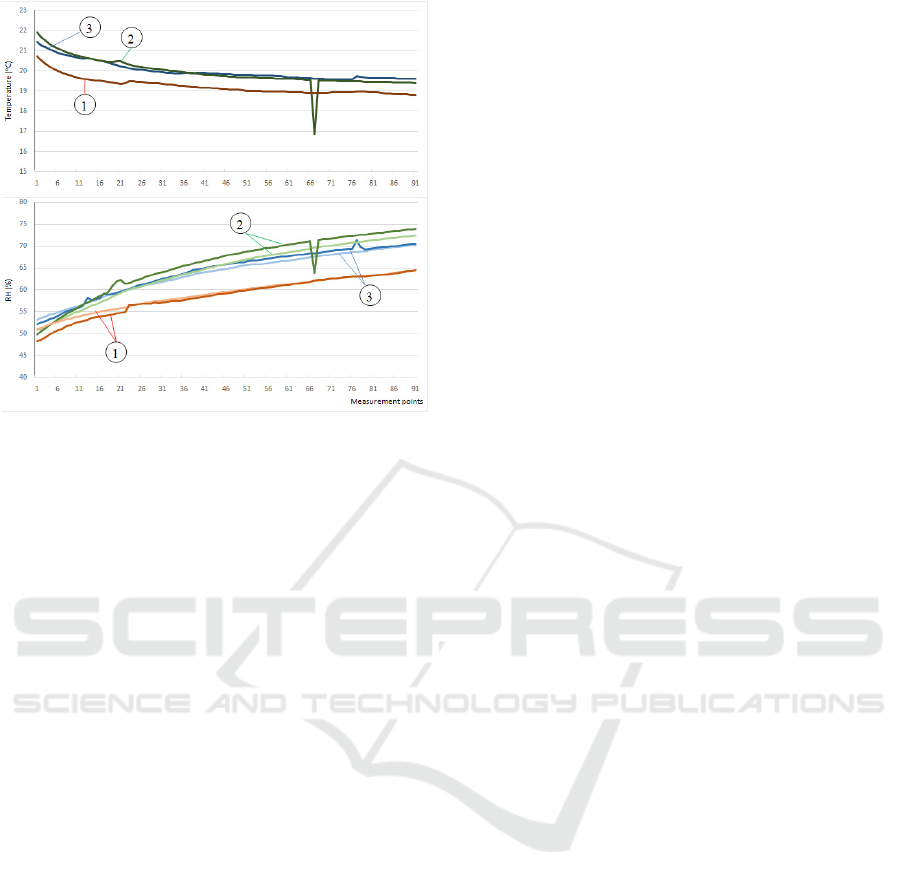

Figure 6 presents typical data from the posterior

thigh sensor node (ski garment tests, skating style)

when testing two different garments by the same test

subject.

Analysis of the dynamic temperature curves

(Figure 6, top graph) indicates that garment 1 is

warmer than garment 2: temperatures of the sensors

on the surface of the underwear (1i, “inner” T

sensor) and towards the garment inner surface (2i)

have rather small difference of the values. For the

garment 2 the sensor facing towards the inner

garment surface (2o, “outer” sensor) shows much

lower temperatures as compared to the values from

“inner” one. Also temperatures of both sensors in the

node during all 20 minutes of test are lower for the

garment 2 indicating higher hear loss. This also can

be explained by potentially looser fit of garment 2

for the same test subject. Looser fit can lead to the

intake of cooler ambient air into the gap between the

underwear and the garment. It is interesting to note

that steady state temperature is reached in about 1

minute from the beginning of the test for the “inner”

sensor, and in about 3 minutes for the “outer”

sensor. Heart rate dynamics of the test subject shows

that steady state value is reached during the first

three minutes of the test, corresponding to the

“warming up” period.

Figure 6: Dynamic data from the posterior thigh sensor

node, ski garment test, skating style. (1o) and (1i) mark

the data from the test on type 1 garment, (2o) and (2i)- on

type 2 garment correspondingly. (1o) and 2(o)- outer, (1i)

and (2i) -inner sensors of the node.

Analysis of the dynamic humidity curves (Figure

6, bottom graph) indicates that garment 2 provides

much better humidity control than garment 1 almost

through the whole duration of the test. Even at the

beginning of the test humidity under the garment 1 is

higher (it took some time to rig the measurement

system and test subjects were already wearing the

garments for about 5 minutes before the test started).

For 2 minutes there is no significant change in

the humidity detected by both sensors in the node for

both garments. After that humidity starts to increase,

more rapidly for garment 1, reaching saturation at

about 6th and 11th test minutes for garments 1 and 2

correspondingly. So it indicates that humidity

control in garment 2 is more effective. It is also

supported by the larger difference between the RH

values detected by “inner” and “outer” node sensors.

3.3 Waders Tests

Figures 7 and 8 present typical data from the

posterior thigh sensor node in waders tests. Same

subject was testing three different waders in the

wind tunnel walking (Figure 7) and water tank tests

(Figure 8) correspondingly.

Sample waders 1 are made of traditional

waterproof materials (galon, impregnated fabric),

samples 2 and 3 are using the modern composite

fabrics incorporating microporous membranes.

Figure 7: Dynamic data from the posterior thigh sensor

node, wader walking test. (1), (2) and (3) - waders samples

##1-3; (i)- "inner" sensor placed towards underwear, (o)-

"outer" sensor towards the waders. 10 seconds between

data points.

Possibility of Modern Humidity Sensor Application in the Studies of Moisture Transport through the Sports and Outdoor Garments

55

Figure 8: Dynamic data from the posterior thigh sensor

node, wader "water tank" test. (1), (2) and (3) – waders,

samples ##1-3. 10 seconds between data points.

In walking tests the heart rate of the subjects was

stabilizing after about 3 minutes. Similarly, the

temperature on the node sensors was also stabilizing

in about 2-3 minutes (Figure 7, top graphs).

As expected, temperature under the old style

waders (sample 1) was generally higher, as compa-

red to the modern style ones (samples 2 and 3). It

can be also expected that humidity under the old

style waders should be generally higher as well

(which is confirmed), but humidity dynamics is

quite interesting (Figure 7, bottom graphs).

Humidity under the old style waders is steadily

growing straight from the beginning of the test

increasing the rate after about 10 minutes from the

start as the treadmill speed was increasing from 4 to

6 km/h. But new style waders with microporous

membranes are capable of maintaining close to

constant humidity within comfortable range up to 12

minutes of the walking test and some longer. And

even towards the end of the test humidity transport

in modern style waders is not reaching saturation.

During the water tank test temperature under the

old style waders (sample 1) was generally lower, as

compared to the modern style waders (samples 2 and

3), as illustrated in Figure 8 (top graphs). This can

be explained by the fact that modern materials

provide better heat insulation. But counter intuitively

the humidity under the old style waders in the water

tank test was also generally lower, as compared to

the modern style ones (Figure 8, bottom graphs).

Both tendencies are opposite to the ones acquired

in the walking tests. There are few spurious

disturbances on the graphs corresponding to the "out

of trend" T and RH values. So far we were not able

to attribute these to any issue, but these are not

changing any trends. Also, there are temperature

instabilities in the second half of the test. Most

probably it can be attributed to the relatively loose

fit of the waders. At higher treadmill speed during

the second half of the test ambient air was probably

starting to get under the waders.

The counter intuitive humidity results can be

explained through the basic property of microporous

membranes. In these membranes direction and rate

of humidity transport depends on the RH difference

on the membrane sides: transport always goes from

higher to lower humidity. In the walking test

ambient humidity is lower than that under the

garments, and membranes work to decrease the

humidity inside. In the water tank test humidity

outside the garments is 100% (water) and the

membranes will always tend to increase the

humidity under the garments, even though water

droplets are not getting through the microporous

membrane. This fact is worth taking into account

when designing garments and footwear that will be

working in different ambient humidity conditions

and occasionally wet environments. Also, moisture

transport properties of such membranes are

generally temperature dependent, and thorough

garment and footwear tests in realistic conditions are

advisable in such cases.

4 CONCLUSIONS

Sensor nodes containing pairs of temperature and

relative humidity sensors are well suited for the

indoor and field applications. These sensors are

small, low weight and produce minimal disturbance

when placed under the garments or inside the

footwear. Multiple sensor nodes can provide the

information about heat and humidity transfer

properties of garments and footwear during work or

exercising in realistic conditions. There are clear

indications that such sensor nodes can provide

information about not only the rate of moisture

transfer, but also its direction. Such systems can be

effectively used for the assessment and comparison

of the garment and footwear performance, especially

the ones containing modern active and "smart"

materials. Application of arrays of such sensors

allows for the analysis of temperature and humidity

dynamics under the garments and footwear during

outdoor and indoor tests. Preliminary studies of the

temperature and humidity dynamics under the

icSPORTS 2016 - 4th International Congress on Sport Sciences Research and Technology Support

56

garments containing microporous membranes

carried out in realistic conditions illustrate the

importance of recognising main features of such

materials. In particular, such materials can only

transport moisture from the side where humidity is

higher. This means that garments and footwear

containing such membranes will potentially behave

quite differently when ambient air humidity

dramatically changes. Additional work is now in

progress to better adapt sensor nodes for the

footwear comfort studies.

ACKNOWLEDGEMENTS

The work was carried out with the financial support

from the EU and Swedish Agency for Economic and

Regional Growth (Tillväxtverket) within the project

"Focus Outdoor" (Grant nr. 163382).

REFERENCES

Abreu, M., Catarino, A., Cidália C. and Kueblbeck, S.

(2012). Influence of Water-repellent Finishing on

Outer Water Sportswear regarding Thermal Insulation.

In: The Fiber Society 2012 Spring Conference, St.

Gallen, Switzerland, 23-25 May 2012, pp. 40-42.

Arezes, P., Neves, M., Teixeira, S., Leão, C. and Cunha, J.

(2013). Testing thermal comfort of trekking boots: an

objective and subjective evaluation. Applied

Ergonomics, 44(4), pp. 557-65.

Bäckström, M., Carlsson, P., Danvind, J., Koptyug, A.,

Sundström, D. and Tinnsten, M. (2016). A new wind

tunnel facility dedicated to sports technology research

and development. Procedia Engineering, 147, pp. 62–

67.

Bogerd, C., Brühwiler, P. and Rossi, R. (2012). Heat loss

and moisture retention variations of boot membranes

and sock fabrics: A foot manikin study. International

Journal of Industrial Ergonomics, 42(2), pp. 212-218.

Brzeziński, S., Malinowska, G. and Nowak, T. (2005).

High-Tech Sports Clothing with a High Comfort of

Use from Multi-layer Composite Materials. Fibres &

Textiles in Eastern Europe, 13(4/52), pp. 55-58.

Brzeziński, S., Malinowska, G., Nowak, T., Schmidt, H.,

Marcinkowska, D. and Kaleta, A. (2005). Structure

and Properties of Microporous Polyurethane

Membranes Designed for Textile-Polymeric

Composite Systems. Fibres & Textiles in Eastern

Europe, issue 13(6/54), pp. 53–58.

Chaudhari, S., Chitnis R. and Ramkrishnan, R. (2004).

Waterproof Breathable Active Sports Wear Fabrics.

Man-made textiles in India, 5, pp. 166-171.

Farrington, R., Rugh, J., Bharathan, D., Paul, H., Bue, G.

and Trevino, L. (2005). Using a Sweating Manikin,

Controlled by a Human Physiological Model, to

Evaluate Liquid Cooling Garments. SAE Technical

Paper 2005-01-2971. Available at http://www.nrel.

gov/transportation/pdfs/38103.pdf [Accessed 23 Aug.

2016].

Frydrych, I., Sybilska, W. and Wajszczyk, M. (2009).

Analysis of Selected Physical Properties of Membrane

Fabrics Influencing the Utility Comfort of Clothing.

Fibres & Textiles in Eastern Europe, 17(6/77), pp. 50-

55.

Fukazawa, T., Lee, G., Matsuoka, T., Kano, K. and

Tochihara, Y. (2004). Heat and water vapour transfer

of protective clothing systems in a cold environment,

measured with a newly developed sweating thermal

manikin. European Journal of Applied Physiology,

92(6), pp. 645-648.

Gao, W., Emaminejad, S., Nyein, H., Challa, S., Chen, K.,

Peck, A., Fahad, H., Ota, H., Shiraki, H., Kiriya, D.,

Lien, D.-H., Brooks, G., Davis R. and Javey A.

(2016). Fully integrated wearable sensor arrays for

multiplexed in situ perspiration analysis. Nature, 529,

pp. 509–514.

Gonzalez, R. (1988). Biophysics of Heat Transfer and

Clothing Considerations. In Human Performance

Physiology and Environmental Medicine at Terrestrial

Extremes. KB Pandolf, MN Sawka and RR Gonzalez

Eds.: Benchmark Press, Indiana, pp. 45-95.

Gore Tex web site. 2016. Available at: http://www.gore-

tex.com/en-us/technology/what-is-gore-tex [Accessed

23 Aug. 2016].

Jing, S., Li, B. Tan, M. and Liu, H. (2013). Impact of

Relative Humidity on Thermal Comfort in a Warm

Environment. Indoor and Built Environment, 22(4),

pp. 598-607.

Lim, C., Byrne, C. and Lee, J. (2008). Human Thermo-

regulation and Measurement of Body Temperature in

Exercise and Clinical Settings. Annals Academy of

Medicine, 37 (4), pp. 347-353.

Metz, S., (2003). Water vapour and gas transport through

polymeric membranes. PhD Thesis, University of

Twente, Enschede, The Netherlands, 133 pages.

Nayak, R., Houshyar, S. and Padhye, R. (2014). Recent

trends and future scope in the protection and comfort

of fire-fighters’ personal protective clothing. Fire

Science Reviews, 3(1), pp. 1-19.

Nicoll, P. (2013). Forward osmosis- a brief introduction.

In: The International Desalination Association World

Congress on Desalination and Water Reuse 2013 /

Tianjin, China, IDAWC/TIAN13-445 http://idadesal.

org/wp-content/uploads/2014/10/140824-Nicoll-IDA-

Whte-Paper-Forward-Osmosis-A-Brief-

Introduction.pdf [Accessed 23 Aug. 2016].

Parkova, I. and Vilumsone, A. (2011). Microclimate of

Smart Garment. Material Science, 6, pp. 99-104.

Reilly, T., Drust, B. and Gregson, W. (2006).

Thermoregulation in elite athletes. Curr Opin Clin

Nutr Metab Care., 9(6), pp. 666-671.

Relative humidity definition. Wikipedia: Relative

humidity. https://en.wikipedia.org/wiki/Relative_humi

dity [Accessed 23 Aug. 2016].

Roberts, B., Waller, T. and Caine, M. (2007). Thermo-

Possibility of Modern Humidity Sensor Application in the Studies of Moisture Transport through the Sports and Outdoor Garments

57

regulatory Response to Base-layer Garments During

Treadmill Exercise. International Journal of Sports

Science and Engineering, 1(1), pp. 29-38.

Rugh, J., Farrington, R., Bharathan, D., Vlahinos, A.,

Burke, R., Huizenga and Zhang, H. (2004). Predicting

human thermal comfort in a transient nonuniform

thermal environment. European Journal of Applied

Physiology, 92(6), pp 721–727.

Sensirion web site, SHT 2x family, digital temperature and

humidity sensors, 2016. Available at: https://www.sen

sirion.com/products/humidity-sensors/humidity-tempe

rature-sensor-sht2x-digital-i2c-accurate/ [Accessed 23

Aug. 2016].

Senthilkumar, M., Sampath, M. and Ramachandran, T.

(2012). Moisture Management in an Active Sports-

wear: Techniques and Evaluation - A Review Article.

Journal of the Institution of Engineers (India): Series

E., 93(2), pp. 61-68.

Standard ISO 15496:2004, Textiles - Measurement of

water vapour permeability of textiles for the purpose

of quality control. International Organization for

Standartization, Geneva.

Sullivan, P. and Mekjavić, I. (1992). Temperature and

humidity within the clothing microenvironment. Aviat

Space Environ Med., 63(3), pp. 186-192.

Troynikov, O., Nawaz, N. and Yermakova, I. (2013).

Performance and Protection in Extreme Hot Condi-

tions. Materials and Engineering Design for Human

Advanced Materials Research, 633, pp.169-180.

Van Roy, M. (1992). Water resistant breathable fabrics. J

Ind Fabr., 22(1), pp. 20–31.

Watson, C., Nawaz, N. and Troynikov, O. (2013). Design

and evaluation of sport garments for cold conditions

using human thermoregulation modeling paradigm.

Procedia Engineering, 60, pp. 151-156

Zhao, S., Zou, L., Tang, C., and Mulcahy, D. (2012).

Recent developments in forward osmosis: Opportuni-

ties and challenges. Journal of Membrane Science,

396, pp. 1–21.

icSPORTS 2016 - 4th International Congress on Sport Sciences Research and Technology Support

58