Avionics Maintenance Ontology Building for Failure Diagnosis

Support

Luis Palacios

1,3

, Gaëlle Lortal

1

, Claire Laudy

1

, Christian Sannino

2

, Ludovic Simon

2

,

Giuseppe Fusco

3

, Yue Ma

3

and Chantal Reynaud

3

1

Thales Research & Technologies, Laboratory of Reasoning and Analysis in Complex Systems, Palaiseau, France

2

Thales Avionics, Toulouse, France

3

Laboratoire de Recherche en Informatique (LRI), Université Paris-Sud - CNRS, 91405 Orsay Cedex, France

Keywords: Ontology Building, Ontology Alignment, Evaluation Prototype, Aeronautics, Predictive Maintenance.

Abstract: In the aviation industry, the delay in maintaining or recovering aircrafts heavily impacts the profit of an

airline company. Consequently the maintenance actions identification and planning of aircrafts is crucial.

However, due to the complexity of the domain in terms of data sources, distributed systems and information

availability, it is hard to provide automatic maintenance support. We propose to use semantic technologies

to model the domain at a conceptual level through ontology, thus abstracting from the data sources and the

maintenancers’uses and jobs. In this manner the information relevant for characterizing failures and

maintenance events is encapsulated and provided to end users via an easier access, which otherwise would

be inaccessible or would require expert analysis to obtain. Such a formal model of the domain can

furthermore enable automated reasoning for maintenance discovery and failure causes detection by

integrating a large amount of background contextual information scattering in different resources. In this

paper we provide the rationale of the Avionics Maintenance ontology i.e. how we built it through expert

knowledge and alignment of different sources and an ontology alignment evaluation tool.

1 INTRODUCTION

In order to profit the most out of flights an airline

operates, both the airline companies as well as the

aircraft manufacturers must plan at best the use of

the planes. Aircraft maintenance is one of the most

important topics to deal with, when referring to keep

or to get back an aircraft able to fly as soon as

possible. Whilst planning and optimization are

topics already heavily handled by airlines, there is a

need to assist in the maintenance actions, i.e. the

forecast of a failure and the support to fault

diagnosis. Both forecasting a maintenance task and

isolating faulty components will reduce the time an

aircraft is unavailable, save money and resources. In

this paper we provide a model for characterizing and

explaining these events.

The aviation domain is a rich, complex and

technical one. As such, it involves a diversity of

locations, companies, services and actors with tight

interaction and interdependence. The diversity of

stakeholders and its distributed nature is reflected on

the systems that compose it. To automate and

support actions on the aeronautic domain requires a

shared and formal representation to model the

domain with its interactions. However, a bottom-up

data-based model is hardly possible due to the

heterogeneity and the recurrence of data

(redundancy of data and systems is compulsory in

aeronautics for security reasons). An approach to

solve this need is to provide a model at a conceptual

level (not only at the data level) and then feed this

model. Such a formalization of this complex domain

will enable automatic reasoning to support failure

forecasting and diagnosis support. Once the core

maintenance ontology is designed, we will use

ontology alignment techniques to enrich and validate

the contents of the model, thus providing more

complete and relevant answers to the final users.

We present first in this paper the aeronautics

maintenance field. Then, we present the design

rationale of the aeronautic maintenance ontology

from several sources (operators, documentation,

data, scenario) and supported by ontology alignment

tool. After an overview of existing works on the

field of avionics, ontology alignment and fusion and

204

Palacios, L., Lortal, G., Laudy, C., Sannino, C., Simon, L., Fusco, G., Ma, Y. and Reynaud, C.

Avionics Maintenance Ontology Building for Failure Diagnosis Support.

DOI: 10.5220/0006092002040209

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 2: KEOD, pages 204-209

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ontology alignment, and guided by our

requirements, we present a first glance at the

ontology alignment tool supporting our approach.

Next, we present the needs of reasoning over the

model in order to discover and refine knowledge. A

set of scenarios are defined, focused on failure

diagnosis, on which the end users validate the

modelling.

2 AERONAUTICS

MAINTENANCE

Airlines define a flight plan, which describes the

usage of the aircrafts they operate. This plan has to

be coordinated with other operators for shared

resources and need to consider several factors as:

destination demand, number of available aircrafts,

state of the aircraft, maintenance, etc. The goal of

the flight plan is to ensure the most efficient

exploitation of the aircraft.

At the beginning/end of each flight, scheduled

maintenance takes place. This is composed by a set

of procedures defined in the Aircraft Maintenance

Manual (AMM), given for each aircraft type by the

manufacturer. External factors (like a delayed crew,

or weather conditions) as well as failures (a defect in

a component) may prevent the normal operation of

the aircraft. Moreover, a failure will always imply

unscheduled maintenance, although unscheduled

maintenance may not only be caused by a failure.

Our approach focuses on modelling the latter two

situations: explaining failures and unscheduled

maintenance, to assist the process of ensuring the

best possible exploitation for the aircraft. Such

explanations provide a way to answer questions like:

what are the possible causes (set of causes) of these

set of symptoms, what procedures can be applied to

a situation, what are the causes and effects of a

specific failure, or, which undesired situations are

not captured by any maintenance task. As the

causes, effects, symptoms and actions taken are

extensive, and because of complexity of the domain,

it is difficult to establish all the cause-effect relations

between the above mentioned elements.

3 LITERATURE SURVEY

3.1 Avionics & Ontologies

The avionics and avionics maintenance is largely

studied in industrial research field. It is a key

domain for civil as military industry. However,

publication of works in the field is quite private due

to the economic and safety impacts a published work

could create. However, in (Danping et al., 2012),

authors emphasize on the importance of

development of semantic information systems in

avionics. Other key industries in Europe are working

in the same line. They present an approach for

information extraction on the domain of aviation

products in order to handle the interoperability

issues.

In (Putten et al., 2008) a survey on ontologies

oriented toward Traffic Flow Management (TFM) in

aeronautics is presented, as they aim at providing a

Collaborative and multi-agent TFM system.

However, XCALIBR (Marshall and Morris, 2007)

and AIAA Topic Database (Neff et al., 2007) are of

interest for the aviation domain in general.

Unfortunately, these knowledge sources aim at new

development of component architecture and do not

handle the Maintenance part of the avionics works.

For safety and security reasons, avionics domain

mainly rely on international standards and norms. As

the maintenance field should comply with these

requirements, we can base our ontology building on

(ISO/TS 15926-8:2011, 2011) norm. This part is

providing a OWL implementation. Still it deals with

Industrial automation systems and integration, then

on any industrial maintenance, not in avionics.

Another document of the field, which is of

interest is the (NF EN 13306, 2001), giving the

maintenance terminology in three languages. Again,

it represents the maintenance field in any industrial

domain, including maintenance maagement

processes, but not especially with the terminology of

avionics maintenance.

Backed by these different sources, we have to

align these document contents to build an avionics

maintenance ontology fitting to failure forecast and

diagnosis support. For this task, we used expert

knowledge and an automatic alignment tool.

3.2 Ontology Alignment

The problem of establishing the correspondence

between the components of two or more ontologies

is known as the Ontology Alignment or Ontology

Matching problem (Euzenat and Shvaiko, 2007)..

Several techniques and tools have been developed

for solving it. The various techniques focus on

different specific aspects of the ontology. Following

(Otero-Cerdeira et al., 2015) they can be classified

into: lexicographic, structural, instance based and

reasoning based techniques. The techniques provide

Avionics Maintenance Ontology Building for Failure Diagnosis Support

205

correspondences between elements (concepts or

relations) of different ontologies, together with a

degree of confidence and the type of relation

between them. A set of such correspondences is

called an alignment. There can be many possible

resulting alignments and many incorrect

correspondences, depending on the techniques used

and the ontologies to be aligned.

To establish the most relevant techniques, their

weaknesses and their potential, we have developed a

first prototype for evaluating a set of alignment tools

with different characteristics and developed by

different teams. The goal of the prototype is to have

full control over the alignment process to determine

the causes that lead to a(n) (in)correct

correspondence, and then provide solutions or

improvements for the problems found. Several tools

enable (partially or fully-) automatic alignment

among which we consider the following: H-Match

(Castano et al., 2003), S-Match (Giunchiglia et

al.,2012), TaxoMap (Safar and Reynaud, 2009),

Logmap (Jiménez-Ruiz et al., 2012), (Faria et al.,

2013) for the complementary types of alignment

they provide (Otero-Cerdeira et al., 2015).

4 AVIONICS MAINTENANCE

ONTOLOGY BUILDING

4.1 General Approach

It is often the case in complex domains, such as

aviation, that the composing sub-systems are highly

specialized and that the interaction between them is

difficult. As a result, the relevant data differs for

each sub-system, depending on their goals and

needs. Some relevant information might not be

accessible, because it is not considered by the

current systems or the links to the sources of

information do not exist. For instance, a shop

repairing a component might focus only on repairing

the components, but not on establishing the

circumstances under which it has failed. Although a

view on both sides allows to determine the causes

and context of a failure. Additionally, the format,

form and representation of the information might

differ as well (text files, Excel files, XML, relational

databases, etc.) moreover this information might not

only be highly technical, but also the meaning may

differ according to the context, thus expert

knowledge is necessary to understand and evaluate

it. All these factors add to the difficulty of providing

a global view of the domain.

In order to support failure diagnosis, we need to

understand the failure mechanism. That involves

establishing the causes, context, effects and related

events that lead to the failure. To this end we

propose to model failure and maintenance in

avionics using an ontology to provide suggestions on

when and which items and events are related to a

failure. These suggestions, subject to a degree of

confidence, can then be presented to the user for

validation and expert knowledge acquisition. These

authoring process lead to knowledge discovery and

revision for failure diagnosis. Likewise, rare events

not considered by the maintenance procedures can

be isolated and characterized for further analysis,

providing support for weak signal detection. It is at

this point, when an ontology is already available,

that we can profit of ontology alignment techniques.

Given that there exist several other sources of

information (other ontologies related to the domain),

aligning them to the maintenance ontology provides

additional inferences, instances and axioms subject

to the same validation/authoring process by the end

user, thus extending the reach of the model beyond

the data sources initially identified, and providing an

additional mechanism for knowledge revision and

ontology design.

The maintenance ontology, along with the

alignment and revision processes is referred here as

the maintenance ontology framework.

4.2 Avionics Maintenance Ontology

After interviewing experts, analysing manuals,

procedures and documents relevant to the field

(norms among others), an ontology has been

designed to capture, at a conceptual level, the

information relevant to failures and maintenance.

That is, when they occur, why they occur and what

are their consequences. In addition contextual

information has been included into the model.

Once the ontology is designed, we also have to

deal with the process of specifying the sources of

data to populate the ontology. As mentioned before,

some of the information comes from reports made

by hand, others from XML files, manuals, etc. This

process involves several considerations: the content

of the sources of data is meant to be used by experts

on the field, the intended information might not be

found in one, but in several sources, and the

availability of the sources. Regarding the latter

point, this is due to the fact that the sources of data

are property of the airlines, the manufacturers and

the service/maintenance providers. Not only this

information might be subject to privacy policies

KEOD 2016 - 8th International Conference on Knowledge Engineering and Ontology Development

206

(intellectual property) but also might be subject to

security policies. When avionics is tightly related to

military, some of this information might not be

disclosed, and thus cannot be included in the model.

This represents an additional task and challenge for

the approach, but also exemplifies the utility of

providing a conceptual model for a domain to

conciliate different sources of data.

European Standards (ISO/TS 15926-8:2011,

2011) (NF EN 13306, 2001), are used as a upper-

leve ontology for building our ontology, since it

provides the industry with a terminology for

referring to the concepts used in maintenance in the

aviation domain among others. We also use specific

documents as the main sources of data for

populating the ontology, like the Post Flight Report

(PFR) the Flight Deck Effect (FDE) or the

Electronic Log Book (ELB).

The core of our model is a subset we call the

maintenance ontology, where two concepts are of

special interest: Resources and Services. A Resource

is a physical item that can be individually identified.

It can be, but is not restricted to, one of the

following: a hardware component, a shop-

replaceable unit, a line-replaceable unit, or a set of

resources. Whereas a Service is a function in the

aircraft (e.g. heating, satellite communications,

altitude measurement, etc.) that is provided by a

Resource. These elements can present Failures,

which are detected by the corresponding reports. A

ResourceFailure is detected by the

PostFlightReport, whereas a ServiceFailure is

detected by the FunctionReport (FDE). Finally,

because Services are provided by Resources, we

establish that a ServiceFailure can be a Symptom of

a ResourceFailure. These elements and its relations

are captured in the model in figure 1:

We also know the sources of the information for

the reports, which are given by some of the

MonitoringSystems of the Aircraft. The BITE (Built-

in Test) system performs tests in the components of

the aircraft and reports their status. The result of

these tests generates messages, known as

BiteMessages, which are associated to a

PostFlightReport for each Flight. Additionally, the

Aircraft Maintenance Manual (AMM) provides one

or more entries for each BiteMessage, where each

entry is a MaintenanceTask designed to isolate and

solve the failure. These maintenance tasks are not

only related to the BITE messages but also to other

events.

In the case of the Services, the FDE registers the

status of the services during the flight, and if the

interruption of any of them is detected. The absence

Figure 1: Core of the Avionics Maintenance Ontology.

or malfunction of a service can be as well reported

by the crew.

Similarly, for each flight an Electronic Log Book

(ELB) entry is generated that registers the status of

the aircraft, its flight departure and destination, its

identification information and

problems/observations and the actions taken, if any.

It differs from the PFR in that the cause-effect-

solution process is expressed in text (as a written

report) rather than related to a specific component,

with a specific failure message and a specific set of

tasks established for solving/isolating the failure.

Figure 2: Failure sub-part of the Avionics Maintenance

Ontology.

Finally, Maintenance takes place for each

Aircraft in each Flight. Depending on the conditions

this can be a ScheduledMaintenance or

UnscheduledMaintenance. By adding these concepts

to the ontology, we can associate causes, effects and

the situations that lead to UnscheduledMaintenance,

providing a better understanding of it (such as

explanations) and thus supporting the process of

diagnosis.

4.3 Ontology Alignment Tool

The creation of our own ontology for the

maintenance domain is not to replace all existing

Avionics Maintenance Ontology Building for Failure Diagnosis Support

207

ones or other pertinent ontological resources.

Instead, our ontology will be used via integration

with external ontologies, achieved via ontology

alignment techniques, in order to explore deeper and

more complete explanations for maintenance tasks.

To evaluate the alignment process and decide the

relevance, accuracy and usefulness of the different

techniques for our approach, we have developed a

prototype integrating the different tools in a single

alignment process. The process receives two

ontologies in OWL (McGuinness and Van

Harmelen, 2004) format as an input, allows to set the

parameters for each tool, and provides the output of

each tool in a unified XML format, along with the

log information, for further analysis.

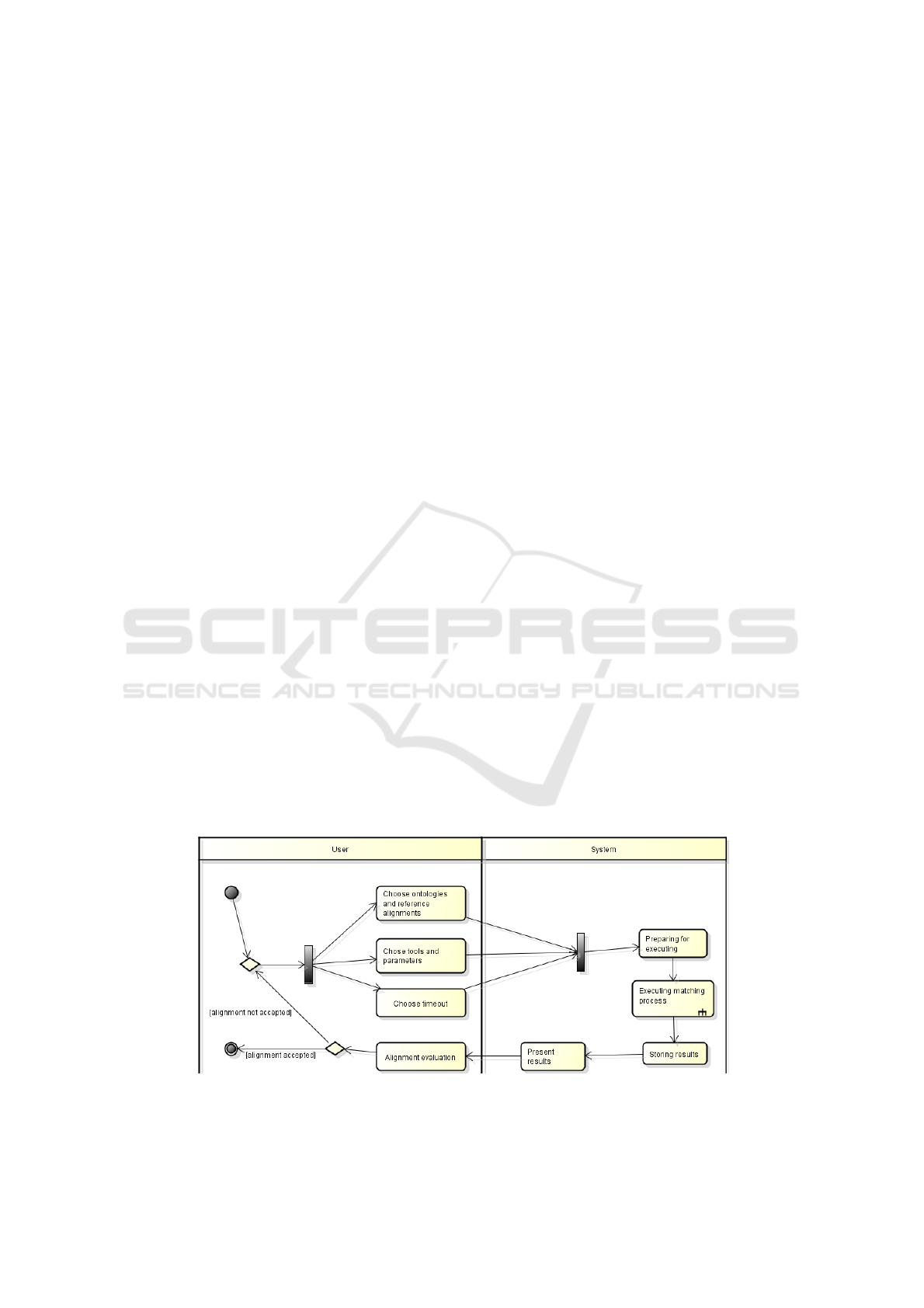

Figure 3 shows the workflow of the prototype

and the activities of the user and the system. The

user provides the input ontologies and sets the tools

and respective parameters to be used in the

alignment process. A timeout might also be

established by the user, because an alignment

process could take a long time to be completed, due

to the size of ontologies. The system receives all

these resources and information to first prepare the

execution (loading matchers and set parameters) and

then execute the alignment process. Once the results

are available, they are stored and presented to the

user for validation.

In the validation process the user identifies the

incorrect/missing correspondences in the resulting

alignment and this information is provided as an

input for a subsequent iteration of the process to

refine the alignment.

The goal of the tool is to explain in detail the

generated alignments to discard or validate the

techniques used, backed up by the results. Given the

reasons why the considered techniques and tools do

not capture all desired answers, we can establish

improvements and algorithms to solve these issues,

and validate/discard them by iterating them in the

tool and running the same process.

The alignment tool consists of two components

allowing us to validate the alignment process,

executing them both in series and in parallel

Configuration component: provides operations

to initialize and maintain the correct

configuration of the entire tool;

Process alignment component: provides

operations to create manage and control the

entire alignment process between two

ontologies.

Since ontologies can be large, a tool could take a

long time for completing the alignment process. A

component allowing us to execute the alignment

process remotely was added to the prototype,

exploiting the REST architectural style. Then, it can

be easily replicated on different servers in order to

create a distributed system, therefore to solve, at

least in part, the problem about execution time.

T he alignment tool allows us to test and validate

manually the selected alignment tools. The need for

further extensions is considered in the design,

resources and architecture of the system, providing

an API to interact with the core of the tool.

Validation measures based on Taxonomy Overlap

(Cimiano et al., 2005), Coverage, Novelty, and

ExtraCoverage (Ponzetto and Strube, 2011) are

planned.

4.4 Scenarios

Our experts validated several avionics maintenance

scenarios, which are representative of a potential

ontology use to support diagnosis and forecast

failures.

Figure 3: Alignment Tool Workflow.

KEOD 2016 - 8th International Conference on Knowledge Engineering and Ontology Development

208

A scenario on scheduled maintenance in

hangar;

A scenario on deferred maintenance in line;

A scenario on unscheduled maintenance in line;

A scenario of in shop repair.

These cases picture the following concepts and

processes: un/planned, un/scheduled maintenance,

condition triggering maintenance (hard time, on

condition, soft-time, deferred correction, condition

monitoring), as well as the types of maintenance

occurring: On aircraft (line or hangar maintenance),

In Shop maintenance/repair (of SRU - Shop

Replaceable Unit), and lastly In Shop

maintenance/repair (of LRU – Line Replaceable

Unit). These scenarios represent the main tasks and

processes of avionics maintenance.

5 CONCLUSIONS AND FURTHER

WORKS

The aeronautics domain is a large domain, in which

the maintenance is unfortunately considered as a

non-central topic. Then, we had to build our avionics

maintenance ontology and validate it. The building

is based on ontology reuse and then ontology

alignment as well as expert knowledge for

validation. Still we have to work automatic

validation of aligned concepts and automating the

ontology building based on ontology alignment.

The ontology is a basis for further reasoning

works to support maintenance users in diagnosis.

We plan to focus on providing the maintenance

analysts with two capabilities: the discovery of links

between causes and failures and the highlighting of

unexplained failures. In order to provide these

capabilities, we propose to use automatic pattern

matching. A graphical pattern describing the

observed failure is extracted from the populated

maintenance ontology, and completed with generic

graph structures expressing a generic link to a

generic cause. We propose to use a semantic graph

matching approach as in (Laudy, 2015) and relying

on the use of conceptual graphs (Sowa, 1984),

formalism and algorithms (Chein and Mugnier,

2008).

ACKNOWLEDGEMENTS

Part of this work is a PhD funded by the French-

ANRT.

REFERENCES

Castano, S., Ferrara, A., and Montanelli, S. (2003). H-

match: an algorithm for dynamically matching

ontologies in peer-based systems. In Proc.1

st

Int.Conf.

on Semantic Web and DB (pp. 218-237).

Chein, M. and Mugnier, M.-L. (2008). Graph-based

Knowledge Representation: Computational

Foundations of Conceptual Graphs. Springer.

Cimiano, P., Hotho, A., and Staab, S., 2005, Learning

concept hierarchies from text corpora using formal

concept analysis. J. Artif. Int. Res., 24(1):305–339.

Danping Z, Youyuan W, Qi Z, Hongsheng J, Xianming D

(2012). The Design of the Aviation Products Semantic

Information System Based on Ontology. 2012 Int.

Workshop on Information and Electronics Engineering

Euzenat, J., and Shvaiko, P. (2007). Ontology matching

(Vol. 18). Heidelberg: Springer.

Faria, D., Pesquita, C., Santos, E., Cruz, I. F., and Couto,

F. M. (2013). Agreement maker light results for OAEI

2013. In Proceedings of the 8th Int. Conf.e on

Ontology Matching-Volume 1111 (pp. 101-108).

Giunchiglia, F., Autayeu, A., and Pane, J. (2012). S-

Match: an open source framework for matching

lightweight ontologies. Semantic Web, 3(3), 307-317.

ISO/TS 15926-8:2011 http://www.iso.org/

catalogue_detail.htm?csnumber=52456

Jiménez-Ruiz, E., Grau, B. C., Zhou, Y., and Horrocks, I.

(2012). Large-scale Interactive Ontology Matching:

Algorithms and Implementation. In ECAI (Vol. 242,

pp. 444-449)

Laudy, C. (2015). Hidden relationships discovery through

high-level information fusion. FUSION 2015: 916-923

Marshall, J. R., and Morris, A. T. (2007). Organization’s

Orderly Interest Exploration: Inception, Development

and Insights of AIAA’s Topics Database. 20pages.

McGuinness, D. L., and Van Harmelen, F. (2004). OWL

web ontology language overview. W3C

recommendation, 10(10), 2004.

Neff, J. M., Some, R., and Lyke, J. (2007). Lessons

Learned in Building a Spacecraft XML Taxonomy and

Ontology. 16 pages.

NF EN 13306, http://maint.t.i.b.free.fr/Files/Other/

NF%20EN%2013306.pdf

Otero-Cerdeira, L., Rodríguez-Martínez, F. J., and

Gómez-Rodríguez, A. (2015). Ontology matching: A

literature review. Expert Sys. App., 42(2), 949-971.

Ponzetto, S. and Strube, M.,. Taxonomy induction based

on a collaboratively built knowledge repository.

volume 9 of 175, pages 1737–1756. 2011.

Putten van BJ, Wolf SR, Dignum V (2008). An Ontology

for Traffic Flow Management. 26th Congress of

International Council of the Aeronautical Sciences

Safar, B., and Reynaud, C. (2009). Alignement

d'ontologies basé sur des ressources complémentaires :

TaxoMap. TSI, 28(10), 1211-1232.

Sowa, JF (1984) Conceptual Structures - Information

Processing in Mind and Machine. The Systems

Programming Series, Addison-Wesley

Avionics Maintenance Ontology Building for Failure Diagnosis Support

209