Exact Solution of the Multi-trip Inventory Routing Problem using a

Pseudo-polynomial Model

Nuno Braga

1

, Cl

´

audio Alves

1

and Rita Macedo

2

1

Universidade do Minho, 4710-057, Braga, Portugal

2

Institut de Recherche Technologique Railenium, F-59300, Famars, France

Keywords:

Inventory Routing Problem, Integer Linear Programing, Network Flow Models, Multi-trip.

Abstract:

In this paper, we address an inventory routing problem where a vehicle can perform more than one trip in

a working day. This problem was denominated multi-trip vehicle routing problem. In this problem a set of

customers with demand for the planning horizon must be satisfied by a supplier. The supplier, with a set of

vehicles, delivers the demand using pre-calculated valid routes that define the schedule of the delivery of goods

on the planning horizon. The problem is solved with a pseudo-polynomial network flow model that is solved

exactly in a set of instances adapted from the literature. An extensive set of computational experiments on

these instances were conducted varying a set of parameters of the model. The results obtained with this model

show that it is possible to solve instances up to 50 customers and with 15 periods in a reasonable computational

time.

1 INTRODUCTION

The vehicle routing problem can be applied in real

cases on logistics companies in order to reduce trans-

portation costs, which include, among others, costs

associated with drivers, vehicles or fuel. The integra-

tion of this problem with the inventory management

can reflect in considerable savings, since this provides

a more efficient management of the resources than

the one achieved through the local optimization of the

two problems separately.

In the inventory routing problem the goal is to

minimize the total transportation cost from the sup-

plier to the customer, so that the customer maintains

an inventory level that will satisfy the demand in each

period of a given planning horizon, reducing also pos-

sible storage costs.

This problem can incorporate a time horizon infor-

mation, inventory management policies, routes, fleet

type and size (Coelho et al., 2014). Routes are con-

sidered to be direct or not, whether a single customer

or more are visited, respectively (Coelho et al., 2014).

The planning horizon is considered finite if it is de-

fined for a short period, or infinite when the sched-

ule of routes is carried out for a long period of time

(Coelho et al., 2014; Bertazzi and Speranza, 2013).

Typically, the goal is to minimize the overall trans-

portation costs, reducing penalties associated with in-

ventory level, which typically represent storage costs

(Bertazzi and Speranza, 2013).

Several practical applications have been imple-

mented in industry, which enable companies to re-

duce inventory and transportation costs improving the

quality of service. A recent study describes the im-

plementation of this problem in a fuel distribution

company (Hanczar, 2012). Another study describes

an application of the problem in a company with a

fleet of ships that delivers chemicals to warehouses

located throughout the world (Miller, 1987). The

authors describe an integer programming model that

was successfully implemented in this company. The

inventary routing problem was also considered in the

daily strategy of a company that provides calcium car-

bonate throughout Europe and it allowed to achieve

a reduction in millions of dollars of costs per year

(Dauz

`

ere-P

´

er

`

es et al., 2007). In addition, different

approaches of this problem have also been applied

in the maritime industry (Al-Khayyal and Hwang,

2007; Song and Furman, 2013; Persson and G

¨

othe-

Lundgren, 2005; Grnhaug et al., 2010).

The problem explored in this paper is the inven-

tory routing problem that allowed the vehicles to carry

out more than one route in each period of the planning

horizon and therefore it was denominated multi-trip

inventory routing problem. The consideration of mul-

tiple routes can provide advantages, in the sense that

250

Braga N., Alves C. and Macedo R.

Exact Solution of the Multi-trip Inventory Routing Problem using a Pseudo-polynomial Model.

DOI: 10.5220/0006118502500257

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 250-257

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the cost of the vehicle is usually fixed for a period

of the planning horizon, therefore reducing the costs

at this level. On the other hand, the consideration of

this variant with multiple routes makes the problem,

which is already difficult to solve, even more difficult.

Since there is an increasing interest in applying

this problem in practical cases in industry, several

heuristics and exact algorithms have been proposed

by several authors in the literature. The difficulty

of solving the inventory routing problems has been

mostly motivated by the development of heuristics,

which in many cases show good results (Herer and

Levy, 1997; Archetti et al., 2011; Cordeau et al.,

2015; Hemmati et al., 2015). In a recent paper, the

inventory routing problem with multiple products and

vehicles was solved with an exact model (Coelho and

Laporte, 2013). The authors describe an integer pro-

gramming model, to which are also added valid in-

equalities with the objective of strengthening it. In

the model a branch-and-cut is proposed that is able to

solve instances with a maximum of 5 vehicles, 5 prod-

ucts, 7 periods and 50 customers. In another prob-

lem with a constant customers demand the authors re-

sorted to a Lagrangian relaxation method that derives

lower and upper bounds for the model in order to ob-

tain good quality solutions in acceptable times (Zhong

and Aghezzaf, 2012). In another paper it is also pro-

posed a method of Lagrangian relaxation combined

with a subgradient method, able to solve instances up

to 200 customers (Yu et al., 2008). Two integer pro-

gramming models were proposed to solve the inven-

tory routing problem when the inventory is managed

by the supplier and when it is managed by the cus-

tomer, comparing the two approaches (Archetti and

Speranza, 2016).

The multi-trip inventory routing problem is typi-

cally more difficult to resolve as compared with the

usual vehicle routing problem. This variant was re-

viewed elsewhere (S¸en and Blbl, 2008). Since this is

not a trivial problem, several heuristic methods have

been proposed. A tabu search algorithm is also de-

scribed to solve this problem (Taillard et al., 1996).

The same problem was addressed with a heuristic al-

gorithm also using tabu search (Brando and Mercer,

1998). The use of constructive heuristic with three

phases was also proposed (Petch and Salhi, 2003). An

adaptive memory procedure was described (Olivera

and Viera, 2007), and the results were compared with

those obtained with others from the literature (Tail-

lard et al., 1996; Brando and Mercer, 1998; Petch and

Salhi, 2003). A genetic algorithm was also proposed,

for the first time, to solve this problem (Salhi and

Petch, 2007). A vehicle routing problem with multi-

ple routes and additional accessibility constraints was

studied using a tabu search algorithm that involved in-

stances up to 1000 customers (Alonso et al., 2008).

An exact integer programming method was pro-

posed for the problem of routing with a single vehi-

cle with time windows and multiple routes (Azi et al.,

2007). The algorithm is divided in two phases: first,

all valid routes are generated and in the second phase

routes are affected at different periods of the plan-

ning horizon. The authors further generalize the al-

gorithm for the case of multiple vehicles (Azi et al.,

2010). The authors resorted to a column generation

algorithm able to solve instances with a number of

customers between 25 and 50.

A pseudo-polynomial network flow model was

used to solve the vehicle routing problem with time

windows and multiple routes (Macedo et al., 2011).

In the model, the underlying graph vertices corre-

spond to instants of time of the planning horizon, and

the arcs define valid routes. It is proposed an exact al-

gorithm that considers an iterative disaggregation of

the vertices of the graph, which are first aggregated

to obtain a smaller model, and thus easier to solve.

The model proposed in this article is similar to the

one here described (Macedo et al., 2011) in the sense

that it uses a pseudo-polynomial network flow model,

the arcs define valid routes and the vertices also cor-

respond to instances of time.

In section 2 we present the definition of the prob-

lem, showing also an example. On section 3 it is for-

mally presented the pseudo-polynomial network flow

model to solve this problem. In section 4 the com-

putational results are shown and finally, some conclu-

sions are presented in section 5.

2 MULTI-TRIP INVENTORY

ROUTING PROBLEM

2.1 Definition

The class of inventory routing problems considers a

context in which one or more types of products are

shipped from a supplier to a set of customers through

a fleet of vehicles.

In this problem the customers demand should be

satisfied during several periods of a planning horizon.

What differentiates this class of problems, from the

vehicle routing problem is the fact that the supplier

manages the inventory of the customer, i.e., the prod-

uct amount supplied to each customer in each period

is not necessarily equal to their demands. The prod-

ucts deliveries must be carried out in such a way that

the customers have available at each period, the re-

Exact Solution of the Multi-trip Inventory Routing Problem using a Pseudo-polynomial Model

251

quired amount of product.

In this paper, a variant of this problem is addressed

that considers the vehicle routing problem with mul-

tiple routes, which means that each vehicle can be al-

located to more than one route in each period of the

planning horizon.

We consider that a fleet of vehicles is located in a

warehouse, which supplies a set of customers with a

single type of product.

The objective of this problem is to determine the

optimal set of routes that minimize the total trans-

portation cost, and any storage costs in the customer.

That is, whenever an order is delivered before the set

period, incurs in a penalty proportional to the costs

of storage of products in the customer. On the other

hand, it is considered that customers have an unlim-

ited storage capacity. With regard to anticipated de-

liveries, they can not be phased. This means that all

demand for a period is delivered in a single visit to the

corresponding customer, whether made on the same

period or in previous periods.

In this problem, the number of available vehicles

is limited, as well as the capacity of each vehicle, and

the load in each route can not exceed its capacity. It

is assumed that each unit of the product transported

occupies a unit of volume on the vehicle and the time

spent on transportation is equivalent to the distance

traveled. Each vehicle can carry out various routes

per period, so that, the sum of their lengths does not

exceed the duration of a working day.

2.2 Data and Parameters

To clarify the formal presentation of the problem, we

provide below an exhaustive list of parameters that

characterise it:

− D = {0}: warehouse;

− S = {1, . . . , N}: customers;

− T = {1, . . . , τ}: time periods of the planning hori-

zon.

The warehouse is associated with the index 0.

Customers are located within a certain distance from

the warehouse, distributed according to their cartesian

coordinates. The planning horizon defines the time

period for which deliveries to customers will have to

be made. This period will subsequently be divided

into units of time referred to as work day.

We consider that a customer cannot be visited

more than once in each time period and there is a

single type of product. Furthermore, we assume that

a visit to a customer at a time t requires the deliv-

ery of the demand for that period, and eventually the

later periods. Stock-outs are not allowed, i.e., all cus-

tomers must imperatively have at their disposal, in

each period, the required quantities of products. Fi-

nally, it is considered that there is no initial stock in

customers, i.e., at time period 0 of the planning hori-

zon the customers do not have at their disposal any

stock.

Below we present the problem data:

− C: vehicle capacity (homogeneous fleet);

− F: number of available vehicles;

− W : duration of a working day;

− d

t

i

: demand of customer i on time period t;

− N

max

: maximum number of customers visited by

route.

Some additional settings:

− Ψ

t

: set of valid routes in the period t;

− N

r

: set of customers visited by route r;

− α

t

0

irt

: equal to 1 if the route r delivers the demand

of the customers i in the period t, or equal to 0

otherwise;

− a route r is characterised by a set of customers

(visited by the route) and the periods of demands

that are delivered as part of the same route.

The costs considered in this problem are:

− C

v

: fixed cost for using a vehicle in a working day;

− C

r

: transportation cost associated with the route r;

− C

h

i

: storage cost of a unit of product on the cus-

tomers i for a period of time;

− C

H

t

r

: total cost of storage associated with the route

r (C

H

t

r

=

∑

i∈N

r

C

h

i

t

i

r

, being t

i

r

the total waiting time

until the product is consumed on the customer i

delivered through the route r).

2.3 Example of a Problem Instance

Example 1. Consider the example of an instance for

the inventory routing problem.

The Table 1 indicates all the parameters that de-

fine it. Table 1a defines the location of the warehouse,

and Table 1b defines the capacity of the vehicles (C),

the fleet size (F), the duration of a working day (W ),

the number os periods of the planning horizon (τ) and

the number of customers (N). In Table 1c are repre-

sented the customer cartesian coordinates (x, y), as

well as the storage costs for each customer (C

h

i

). Fi-

nally, Table 1d defines the demands d

t

i

in the period t

for the customer i.

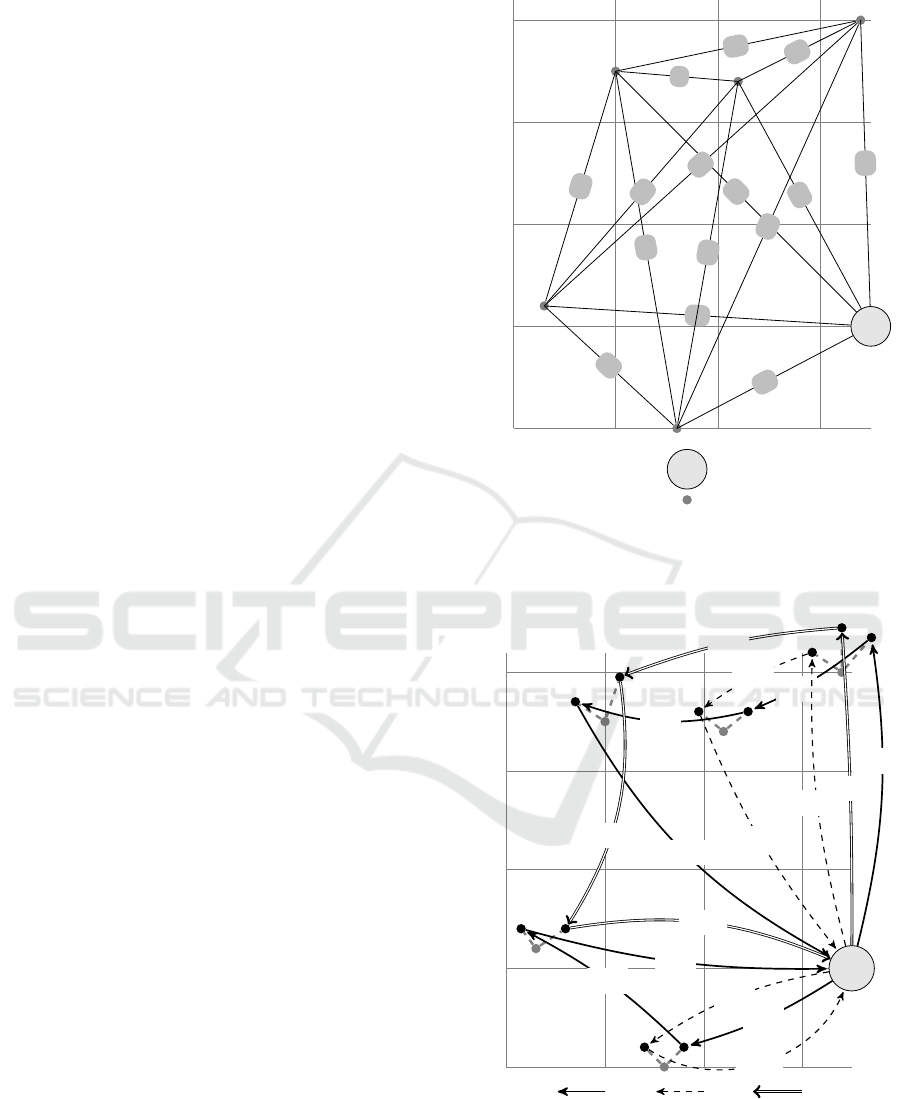

The graphical representation of this instance can

be observed in Figure 1, showing the warehouse and

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

252

Table 1: Example of an instance of the inventory routing

problem. (a) Warehouse location data, (b) general data of

the problem, (c) customer data and (d) customer demands.

A 10 20

(a)

C 10

C

v

20

F 5

W 120

T 3

N 5

(b)

x y C

h

i

9 50 24

-9 10 15

-22 22 3

-15 45 9

-3 44 12

(c)

t i d

t

i

1 1 4

1 2 2

1 3 2

1 4 2

1 5 2

2 1 2

2 2 2

2 3 2

2 4 2

2 5 2

3 1 4

3 2 2

3 3 2

3 4 2

3 5 3

(d)

the customers distributed according to their cartesian

coordinates. All connections between customers and

warehouse (supplier) are also represented, as well

as the corresponding distances to be traveled in this

route.

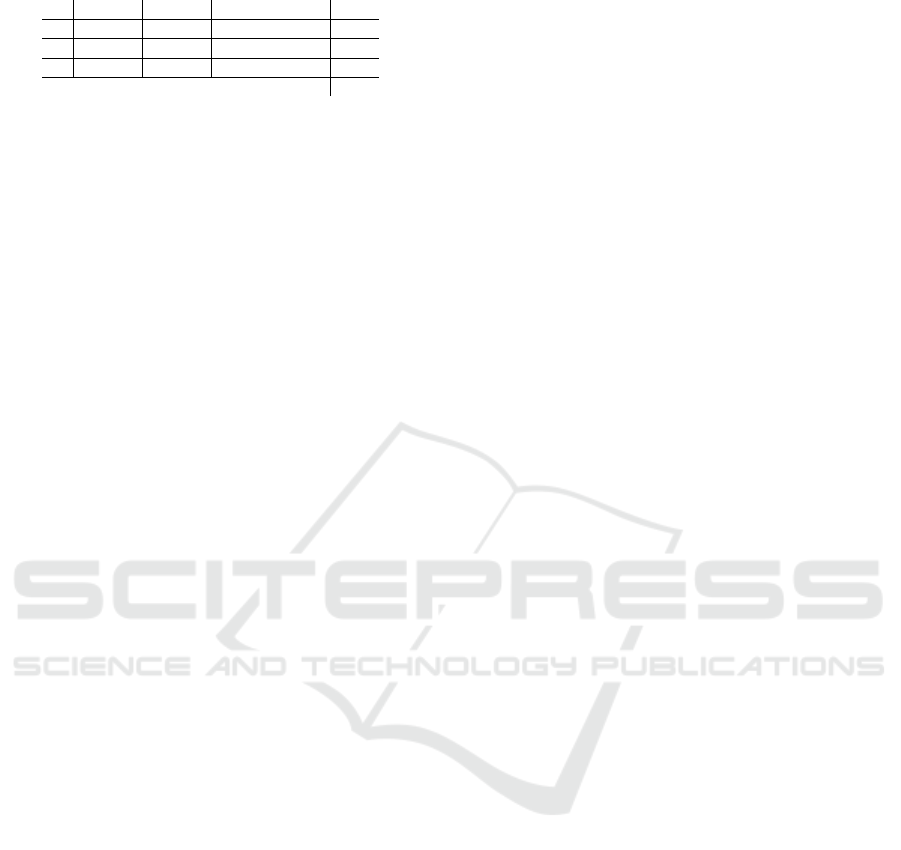

Figure 2 represents a valid solution for this in-

stance, which has in the first period a cost of 214,

in the second 198 and in the third and last 131, with

a total cost of 543. In this case, it is not possible to

use a single vehicle in the first period, since the dis-

tance that the vehicle would have to travel to deliver

all customer demands is greater than 120 (length of a

work day). Thus, two vehicles are scheduled for the

routes for the first period, and in each of the routes it

is delivered the demand for further periods, in partic-

ular customers 3 and 4. These deliveries in later peri-

ods incur in a penalty for each unit in storage. In the

second period, it may resort to a single vehicle that

performs two routes. In the third period, a single ve-

hicle performs the remaining deliveries to customers

where the demands have not yet been satisfied, mak-

ing use of a single route. In this latter period there is

no storage costs since all demands are satisfied and

consumed in this period. In this figure, the informa-

tion relative to the demand is denoted by d

t

i

, and can

exist for later periods. The information about the dis-

tance (l) traveled and the volume (v) occupied on the

vehicle in the route is defined in the arcs as [l|v]. Ta-

ble 2 discriminates the objective function values for

the three periods shown in Figure 1.

−25 −15 −5 5

10

20

30

40

50

Wharehouse

Customers

i = 1

i = 2

i = 3

i = 4

i = 5

30

21

32

35

27

44

42

25

13

18

36

35

24

29

4

Figure 1: Instance graphical representation with a ware-

house, customers and their distances located in midway of

the connections.

−25 −15 −5 5

10

20

30

40

50

[d

3

1

]

[d

2

1

]

[d

1

1

]

[d

2

2

, d

3

2

]

[d

1

2

]

[d

1

3

, d

2

3

]

[d

3

3

]

[d

1

4

, d

2

4

]

[d

3

4

]

[d

2

5

, d

3

5

]

[d

1

5

]

[30|10]

[43|6]

[47|4]

[82|0]

[21|6]

[39|4]

[71|0]

[30|7]

[43|5]

[70|0]

[91|4]

[112|0]

[30|8]

[55|4]

[79|2]

[111|0]

Period 1

Period 2

Period 3

Figure 2: Valid solution to the inventory routing problem

instance of Example 1. In the middle of the connection

between each customers is shown the distance traveled, as

well as the volume of the goods on the vehicle in the route.

Exact Solution of the Multi-trip Inventory Routing Problem using a Pseudo-polynomial Model

253

Table 2: Objective function values for the three periods.

T C

r

C

v

C

h

i

total

1 82 + 71 20 + 20 9 × 2 + 3 × 2 214

2 112 20 12 × 3 + 15 × 2 198

3 111 20 0 131

543

3 A NETWORK FLOW MODEL

FOR THE MULTI-TRIP

INVENTORY ROUTING

PROBLEM

In this section, we describe a new integer program-

ming model for the multi-trip inventory routing prob-

lem.

This network flow model is defined in a set of

acyclic and direct graphs, one for each period of the

planning horizon, denoted by G

t

= (V, A

t

), t ∈ T and

V is a set of vertices V = {0, . . . , W + 1}, and A

t

is

the set of arcs that represent the set of all valid routes

in the period t ∈ T , as well as the waiting time in the

warehouse. A flow that runs through the graph repre-

sents a working day of a vehicle, i.e., the sequence of

routes and waiting times this performs from the mo-

ment 0 until time instant w of a given planning hori-

zon. A route is defined by a sequence of customers

to visit, as well as the respective product amounts to

deliver to each customer. In order for a route to be

valid, the sum of the quantities of products to be de-

livered to each customer must not exceed the capacity

of the vehicle, and the necessary travel time cannot

exceed a working day (a period of the planning hori-

zon). Note that the same route can start at different

instants, keeping it valid. The set of all valid routes is

generated in advance, and the variable x

t

uvr

represents

the route r that starts at the instant u and ends at time

v of period t ∈ T . Routes are generated through a re-

cursive process that will exclude routes violating the

vehicle capacity (C) and/or a maximum duration (W )

of the route.

min

∑

t∈T

∑

(u,v)

r

∈Ψ

t

C

r

x

t

uvr

+C

v

∑

t∈T

∑

(0,v)

r

∈Ψ

t

x

t

0vr

+

∑

t∈T

∑

(u,v)

r

∈Ψ

t

C

H

t

r

x

t

uvr

(1)

s.t.

∑

t∈T,t≤t

0

∑

(u,v)

r

∈Ψ

t

|i∈N

r

α

t

0

irt

x

t

uvr

= 1, ∀i ∈ S, t

0

∈ T, (2)

∑

(0,v)

r

∈Ψ

t

x

t

0vr

≤ F, ∀t ∈ T, (3)

−

∑

(u,v)

r

∈Ψ

t

x

t

uvr

+

∑

(v,y)

s

∈Ψ

t

x

t

vys

=

0, if v = 1, . . . , W − 1,

−

∑

(0,v)

r

∈Ψ

t

x

t

0vr

, if v = W,

∀t ∈ T, (4)

x

t

uvr

∈ {0, 1}, ∀(u, v)

r

∈ Ψ

t

, ∀t ∈ T. (5)

The objective function (1) represents the sum of

the transportation costs of the traveled routes C

r

, the

cost of the vehicles used C

v

, and daily storage costs

per item C

H

i

.

Restrictions (2) ensure that deliveries of demands

of all periods, for each of the customers are met by

one and only one of the traveled routes. This deliv-

ery can take place on the same period or in previous

periods.

Restrictions (3) impose that more than F vehicles

in each period t are not used. Conservation flow is

ensured by the restrictions (4).

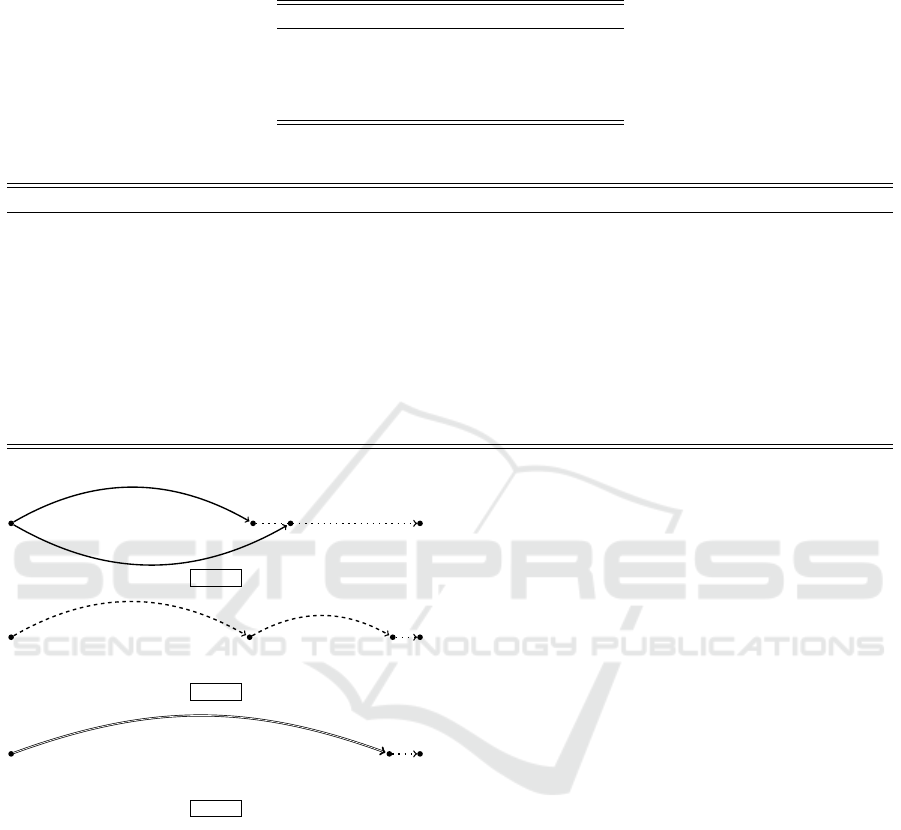

Example 2. The graph from Figure 3 represents a

valid solution from Figure 2 of Example 1.

These graphs have a dimension W = 120 which

represents the duration of a working day, being 0 the

beginning and W the end. The set of arcs corresponds

to the represented traveled routes. Each vertice de-

fines a time instant and each arch represents a route

traveled to visit a series of customers. These flows

are the arcs defined for the three periods, in the first

one two vehicles perform a route each, in the second

period a single vehicle performs two routes and in

the third and final period a vehicle performs a single

route. This is a valid solution for instance Example 1.

4 COMPUTATIONAL RESULTS

To evaluate the performance of the model, it was used

a set of instances adapted from the literature (Moin

et al., 2010).

A set of 32 instances was generated, and in all

the duration of the planning horizon the working day

is W = 140. There are two instances for each com-

bination of parameters: number of customers N ∈

{10, 20, 40, 50} and number of periods of the plan-

ning horizon τ ∈ {3, 5, 10, 15}.

With this set of instances, different tests were per-

formed varying the capacity of the vehicles. It is con-

sidered C ∈ {10, 13, 20}, so that, for all instances all

the demands are higher than 20%, 15% and 10% of

vehicle capacity, respectively. It was also considered

an additional constraint on the maximum number of

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

254

Table 3: Summary of instances solved to optimality / instances in which the model found a solution / number of instances to

solve.

N

max

C = 10 C = 13 C = 20

3 12/32/50 12/30/50 12/20/40

4 12/22/50 8/20/20 8/12/20

5 12/18/40 11/12/20 -

10 12/18/40 10/12/20 -

Table 4: Average values of instances solved with different parameters.

C N

max

¯

t

r

¯

t

m

¯

t

total

¯n

r

¯var

¯

Lim

in f

¯

Lim

up

¯

gap % #opt

10 20 6,28 59,64 65,92 13561,08 21970,00 2680,50 2680,50 0 12

13 20 538,65 196,46 735,17 51020,08 62688,58 2499,22 2507,67 0,17 10

10 3 0,51 31,71 32,21 8479,33 16844,25 2738,50 2738,50 0 12

10 4 2,90 90,23 93,13 12961,50 21370,42 2685,00 2685,00 0 12

10 5 6,20 57,88 64,08 13561,08 21970,00 2680,50 2680,50 0 12

13 3 1,25 45,52 46,78 17398,92 28893,67 2672,17 2672,17 0 12

13 4 12,20 390,00 402,22 38345,67 50014,17 2560,10 2576,83 0,61 8

13 5 66,44 151,35 217,80 49527,67 61196,17 2503,21 2507,33 0,09 11

20 3 4,51 36,00 40,53 53169,92 73678,50 2634,42 2634,42 0 12

20 4 95,99 399,87 495,92 209121,33 230754,58 2480,53 2514,42 1,44 8

0 12082

71

r

1

r

2

Period 1.

0 12070

112

r

3

r

4

Period 2.

0 120

111

r

5

Period 3.

Figure 3: Solution of multi-trip inventory routing problem

for three periods.

customers to visit in a route. In Tables 3 and 4, this

parameter takes on values that do not restrict, or only

limit slightly, the number of customers to consider in

a route.

Computational tests were performed using a PC

with i7 processor with 3.5 GHz and 32 GB of RAM.

The optimization routines resorted to version 12.6.1

of CPLEX. The time limit for resolution of the inte-

ger programming model was 900 seconds. For the

total time of model generation (including generation

of routes) and its resolution it was set a time limit of

9500 seconds.

Tables 3 – 4 report the results obtained and their

respective columns have the following meaning:

N

max

: maximum number of customers to visit on

a route;

t

r

: generation time of routes;

t

m

: execution time of the integer programming

model (1) – (4);

t

total

: total execution time (t

m

+t

m

);

n

r

: number of routes generated;

var: number of variables of the integer program-

ming model (1) – (4);

Lim

in f

: best lower bound;

Lim

up

: best upper bound;

gap %: gap (percentage);

In tests carried out without limit of customers to

visit (N

max

), where the vehicle capacity is 10 and 13

it was possible to solve, until the optimality, 24 of 18

and 10 of 12 instances, respectively. In this set of

tests, where there is no restriction on the maximum

number of customers to visit in a route, it was only

possible to find a solution for instances with N ≤ 40.

As expected, increasing the capacity of the ve-

hicles hinders the generation and resolution of the

model, since this variation increases the number of

valid routes and, consequently, the number of vari-

ables. Instances for which it was not possible to find

an optimal solution it was however possible to reduce

the optimality gap. However, the maximum gap for

all the parameters considered was equal to 8.85%.

Table 3 summarises the results obtained for all the

instances and aggregates them by the different param-

eters. Each field in the table reflects the number of in-

Exact Solution of the Multi-trip Inventory Routing Problem using a Pseudo-polynomial Model

255

stances solved to optimality, the number of instances

for which the model found a solution and the number

of instances to solve for this combination.

Note that a company that solves this problem will

just have to generate all the valid routes once for each

set of customers considered, and what will change in

practice are the demands.

5 CONCLUSIONS

The multi-trip inventory routing problem has a great

practical interest in the industrial field, but on the

other hand, it is quite challenging in terms of reso-

lution.

In this paper, we propose a network flow model for

multi-trip inventory routing problem, which is solved

exactly for a set of adapted instances in the literature.

The model was able to solve instances up to 50 cus-

tomers and 15 time periods in reasonable computa-

tional times. Several instances were solved to opti-

mality when set to different parameters. The average

gap obtained was relatively low.

ACKNOWLEDGEMENTS

This work was supported by FEDER funding through

the Programa Operacional Factores de Competitivi-

dade - COMPETE and by national funding through

the Portuguese Science and Technology Founda-

tion (FCT) in the scope of the project PTDC/EGE-

GES/116676/2010.

REFERENCES

Al-Khayyal, F. and Hwang, S.-J. (2007). Inventory con-

strained maritime routing and scheduling for multi-

commodity liquid bulk, part i: Applications and

model. European Journal of Operational Research,

176:106–130.

Alonso, F., Alvarez, J. M., and Beasley, E. J. (2008). A

tabu search algorithm for the periodic vehicle routing

problem with multiple vehicle trips and accessibility

restrictions. Journal of the Operational Research So-

ciety, 59:963–76.

Archetti, C., Bertazzi, L., Hertz, A., and Speranza, M. G.

(2011). A hybrid heuristic for an inventory routing

problem. INFORMS Journal on Computing, 24:101–

16.

Archetti, C. and Speranza, M. G. (2016). The inventory

routing problem: the value of integration. Interna-

tional Transactions in Operational Research, 23:393–

407.

Azi, N., Gendreau, M., and Potvin, J.-Y. (2007). An exact

algorithm for a single-vehicle routing problem with

time windows and multiple routes. European Journal

of Operational Research, 178:755–66.

Azi, N., Gendreau, M., and Potvin, J.-Y. (2010). An ex-

act algorithm for a vehicle routing problem with time

windows and multiple use of vehicles. European Jour-

nal of Operational Research, 202:756–63.

Bertazzi, L. and Speranza, M. G. (2013). Inventory routing

problems with multiple customers. EURO Journal on

Transportation and Logistics, 2:255–75.

Brando, J. C. S. and Mercer, A. (1998). The multi-trip ve-

hicle routing problem. Journal of the Operational Re-

search Society, 49:799–805.

Coelho, L. C., Cordeau, J.-F., and Laporte, G. (2014).

Thirty years of inventory routing. Transportation Sci-

ence, 48:1–19.

Coelho, L. C. and Laporte, G. (2013). A branch-and-cut al-

gorithm for the multi-product multi-vehicle inventory-

routing problem. International Journal of Production

Research, 51:7156–69.

Cordeau, J.-F., Lagan, D., Musmanno, R., and Vocaturo,

F. (2015). A decomposition-based heuristic for the

multiple-product inventory-routing problem. Comput-

ers & Operations Research, 55:153–66.

S¸en, A. and Blbl, K. (Universidade Bilgi, Istambul, Turquia,

2008). A survey on multi trip vehicle routing problem.

Dauz

`

ere-P

´

er

`

es, S., Nordli, A., Olstad, A., Haugen, K.,

Koester, U., Per Olav, M., Teistklub, G., and Reistad,

A. (2007). Omya hustadmarmor optimizes its supply

chain for delivering calcium carbonate slurry to euro-

pean paper manufacturers. Interfaces, 37:39–51.

Grnhaug, R., Christiansen, M., Desaulniers, G., and

Desrosiers, J. (2010). A branch-and-price method

for a liquefied natural gas inventory routing problem.

Transportation Science, 44:400–415.

Hanczar, P. (2012). A fuel distribution problem application

of new multi-item inventory routing formulation. Pro-

cedia - Social and Behavioral Sciences, 54:726–735.

Hemmati, A., Stlhane, M., Hvattum, L. M., and Ander-

sson, H. (2015). An effective heuristic for solving

a combined cargo and inventory routing problem in

tramp shipping. Computers & Operations Research,

64:274–82.

Herer, Y. T. and Levy, R. (1997). Raising the competitive

edge in manufacturingthe metered inventory routing

problem, an integrative heuristic algorithm. Interna-

tional Journal of Production Economics, 51:69–81.

Macedo, R., Alves, C., Valrio de Carvalho, J., Clautiaux,

F., and Hanafi, S. (2011). Solving the vehicle rout-

ing problem with time windows and multiple routes

exactly using a pseudo-polynomial model. European

Journal of Operational Research, 214:536–45.

Miller, D. M. (1987). An interactive, computer-aided ship

scheduling system. European Journal of Operational

Research, 32:363–379.

Moin, N., Salhi, S., and Aziz, N. (2010). An efficient hybrid

genetic algorithm for the multi-product multi-period

inventory routing problem. International Journal of

Production Economics, 133:334–343.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

256

Olivera, A. and Viera, O. (2007). Adaptive memory pro-

gramming for the vehicle routing problem with multi-

ple trips. Computers & Operations Research, 34:28–

47.

Persson, J. A. and G

¨

othe-Lundgren, M. (2005). Shipment

planning at oil refineries using column generation and

valid inequalities. European Journal of Operational

Research, 163:631–652.

Petch, R. J. and Salhi, S. (2003). A multi-phase constructive

heuristic for the vehicle routing problem with multiple

trips. Discrete Applied Mathematics, 133:69–92.

Salhi, S. and Petch, R. J. (2007). A ga based heuristic for the

vehicle routing problem with multiple trips. Journal of

Mathematical Modelling and Algorithms, 6:591–613.

Song, J. H. and Furman, K. C. (2013). A maritime inventory

routing problem: Practical approach. Computers &

Operations Research, 40:657–665.

Taillard, xc, ric, D., Laporte, G., and Gendreau, M.

(1996). Vehicle routeing with multiple use of vehi-

cles. The Journal of the Operational Research Society,

47:1065–70.

Yu, Y. G., Chen, H. X., and Chu, F. (2008). A new model

and hybrid approach for large scale inventory rout-

ing problems. European Journal of Operational Re-

search, 189:1022–40.

Zhong, Y. and Aghezzaf, E.-H. (2012). Modeling and solv-

ing the multi-period inventory routing problem with

constant demand rates. Ghent University, Department

of Industrial management.

Exact Solution of the Multi-trip Inventory Routing Problem using a Pseudo-polynomial Model

257