Development of an Intelligent Agent based Manufacturing System

Hong-Seok Park

1

and Ngoc-Hien Tran

2

1

School of Mechanical and Automotive Engineering, University of Ulsan, Ulsan 680-749, South Korea

2

University of Transport and Communications, Lang Thuong Ward, Dong Da District, Hanoi, Vietnam

Keywords: Cognitive Agent, Modern Manufacturing, Self-optimization.

Abstract: The new trend of the manufacturing system development is to apply autonomous behaviours inspired from

biology for the manufacturing systems. In which, the resources of the manufacturing system are considered

as biological organisms, which are autonomous entities so that the manufacturing system has the advanced

characteristics inspired from biology such as self-adaptation, self-diagnosis, and self-optimization. To carry

out these characteristics, the paper presents a paradigm about intelligent agent, called the cognitive agent

and using cognitive agents for adapting to disturbances such as tool wear, machine breakdown that have

happened on the shop floor. Modern manufacturing systems having the distributed control need autonomy

and cooperation in solving problems of agents from agent technology, and cognitive capabilities for agents

from cognitive technology. Cognitive agents combined from these two technologies are necessary for future

manufacturing systems.

1 INTRODUCTION

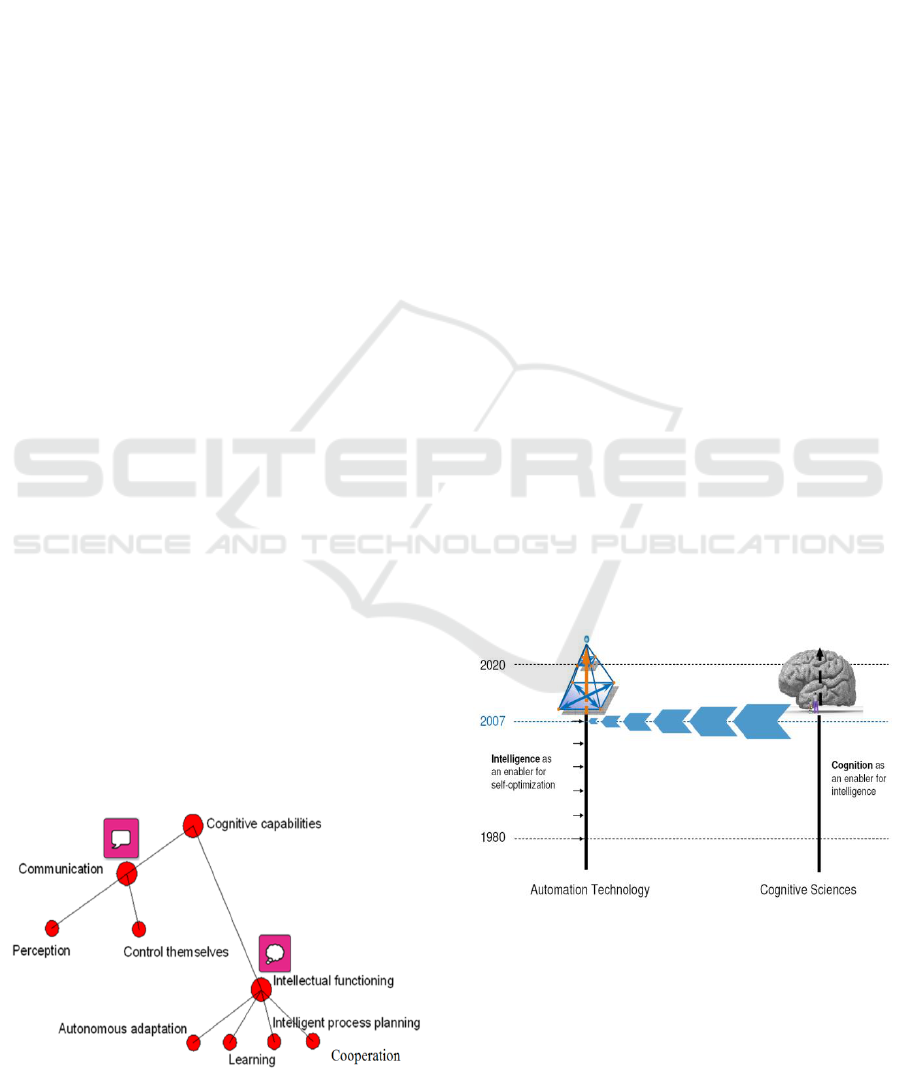

The human beings can adapt to the environmental

changes by the cognitive capabilities such as

perception and intellectual functions as shown in

Figure 1 in which the learning capability allows the

human being to improve the knowledge and skill to

adapt to the changes. Currently, human workers with

their skills and knowledge adapt to changes of

almost activities from design to manufacturing

process. The new trend is to apply the decision

capability, knowledge, and human being capabilities

into the manufacturing system that shows the

combination of cognitive science, automation

technology, and computer science as shown in

Figure 1: Cognitive capabilities of human beings.

Figure 2. Intelligence in manufacturing systems is

shown by the self-learning, self-adaptation, self-

diagnosis, and self-optimization capability. These

characteristics allow the system to improve the

current capability, to diagnose the status. The

cognitive models have been studied to apply into

manufacturing systems to equip the system with the

cognitive capability.

Figure 2: Cognition for realizing intelligence in

manufacturing (Tobias, 2009).

The cognitive factory was proposed by Zaeh

(2009) in which the advantages of both of automated

systems and cognitive capabilities of human were

inherited. The cognitive architecture namely Beliefs-

Desires-Intentions (BDI) proposed by Zhao and Son

Park H. and Tran N.

Development of an Intelligent Agent based Manufacturing System.

DOI: 10.5220/0006136704450450

In Proceedings of the 9th International Conference on Agents and Artificial Intelligence (ICAART 2017), pages 445-450

ISBN: 978-989-758-220-2

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

445

(2008) was applied for the cognitive factory.

Machines and their process are equipped with

cognitive capabilities to enable the machines for

reacting flexibly to the manufacturing changes.

Figure 3: A cognitive machining system (Zaeh, 2009).

The BDI architecture was based on a decision

making model of human comprising the knowledge

models, perception and control methods, planning

mechanism, and a cognitive perception-action loop.

The information about status of machines and

processes are got from the beliefs module. The states

of tasks that the system will carry out are defined as

desires. The task’s states that the system will work

towards are defined as intentions. Figure 3 illustrates

a vision of a cognitive machining system. The

machines equipped the cognitive abilities can

communicate, cooperate, and negotiate to get the

optimal manufacturing process.

2 LITERATURE REVIEW

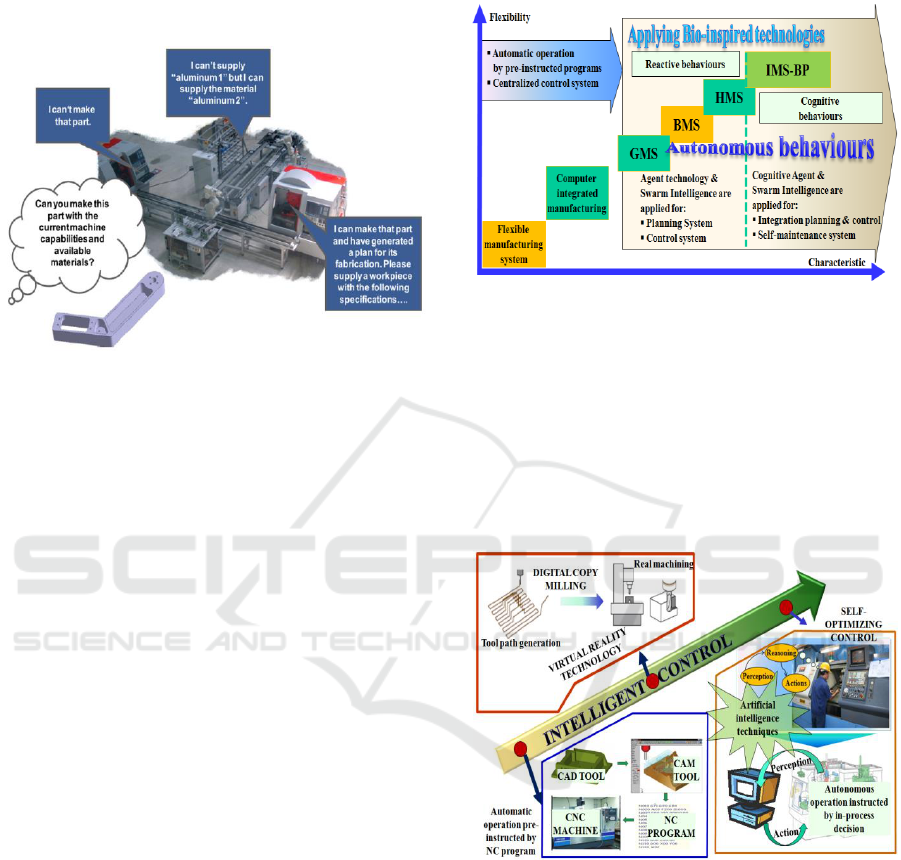

The new trend in manufacturing filed is to apply the

bio-inspired technologies to equip the machines and

processes with autonomous behaviours as shown in

Figure 4. The new concepts in manufacturing have

been proposed such as Genetic Manufacturing

System (GMS) (Christo, 2007), Biological

Manufacturing System (BMS) (Ueda, 2006),

Holonic Manufacturing System (HMS) (Leitao,

2002), and Intelligent Manufacturing System with

Biological Principles (IMS-BP) (Park, 2010).

Autonomy allows the system to recover

autonomously without either upper level aids such as

the Enterprise Resource Planning (ERP), and the

Manufacturing Execution System (MES) or the

operator intervention. In these manufacturing

system, each entity in the manufacturing system is

an autonomous entity so that it can overcome the

disturbances by itself or communicate with the

others to overcome the disturbances.

Figure 4: Evolution of manufacturing systems toward the

autonomous manufacturing.

On the machine level, the evolution of control

techniques toward future machines with intelligent

control is summarized in Figure 5. Technical

innovations in the hardware and software of machine

tools have improved their efficiency, allowing the

application of CNC machine tools in machining

automation that is both highly accurate and

productive (Nakamoto, 2004, Shirase, 2009).

Figure 5: Trend of intelligent control techniques.

3 CORE TECHNOLOGIES

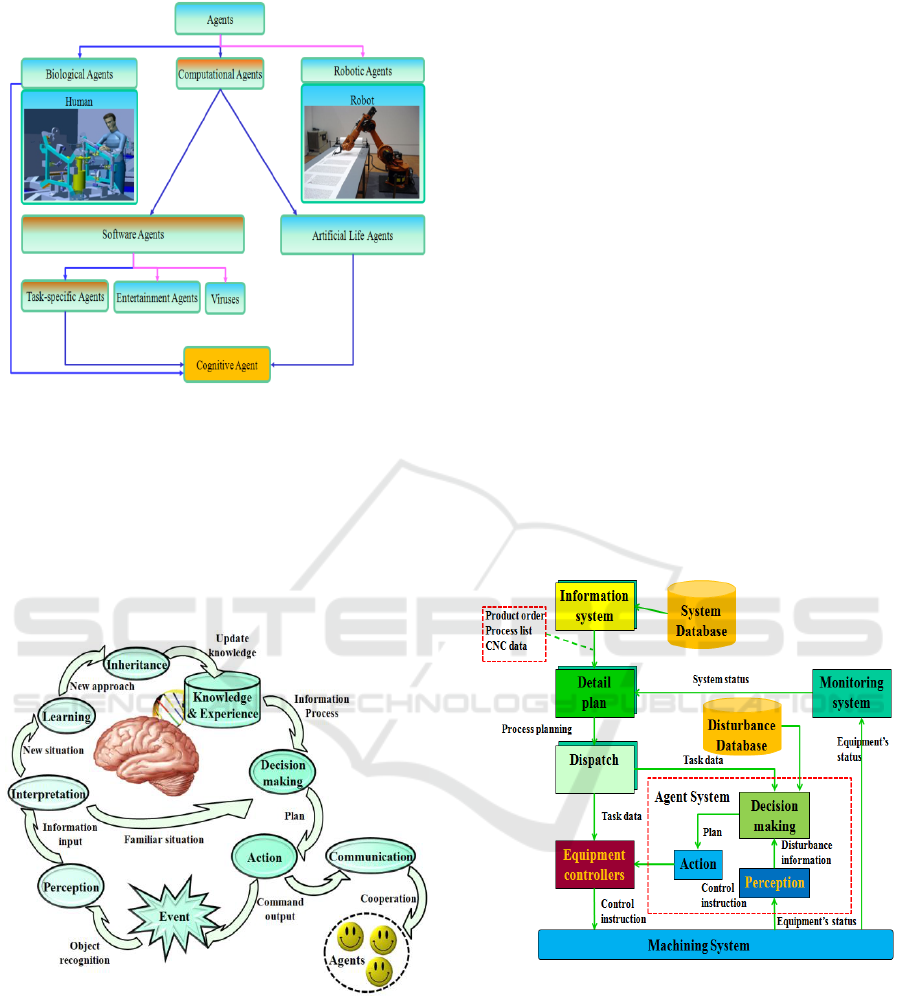

Figure 6 shows the classification of agents including

biological, robotic, and software agents. In this

research, the agents for controlling the

manufacturing system are software agents which are

computer programs. The agents have the advanced

characteristics as autonomy, social ability, reactivity,

and pro-activeness (Monostori, 2006, Leitao, 2009).

Autonomy is the ability of agent for achieving its

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

446

Figure 6: Agent classification.

goals without any support from the other agents.

Agent cooperation for getting the global goal of the

system is called the agent’s social ability. The

reactivity is the ability of agents to respond to the

manufacturing changes basing on the relation

between perception and action. The agent’s pro-

activeness is the ability to express the goal-directed

behaviours.

Figure 7: Architecture of cognitive agent.

The cognitive agent is a computer program

which uses the BDI architecture inspired from the

human decision-making model to arm an agent with

artificial cognitive capabilities as shown in Figure 7.

The agent performs cognitive activities such as

perception, reasoning, and execution (Zhao, 2008)

that emulate the human cognitive behaviours. The

cognitive agent inherits all characteristics from the

traditional agent, including the autonomy, social

ability, reactivity and pro-activeness. The different

feature in comparison with the conventional agent,

which is shown by the improvement of the pro-

activeness characteristic, is the intelligence of the

cognitive agent. Intelligence is the ability of the

agent to use its knowledge and reasoning

mechanisms for making a suitable decision with

respect to the environmental changes.

4 COGNITIVE AGENTS BASED

MANUFACTURING SYSTEM

With the traditional manufacturing system, the

information systems such as manufacturing

execution system (MES) keep the main role for

operating the manufacturing system. In the

intelligent agent based manufacturing system, at

normal status, the shop floor is controlled by the

MES. In case the disturbance happen such as tool

wear, machine breakdown and so on, the agent

system controls the operation by agent cooperation.

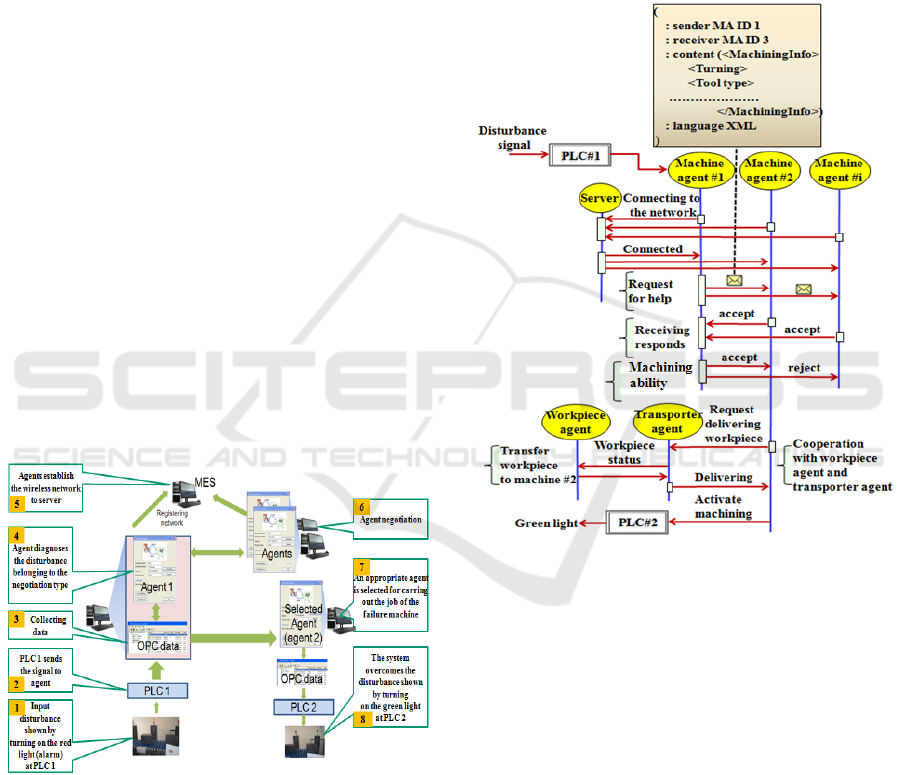

Figure 8 shows the information model of the

intelligent agent based machining system.

Figure 8: Architecture of cognitive agent based

manufacturing system.

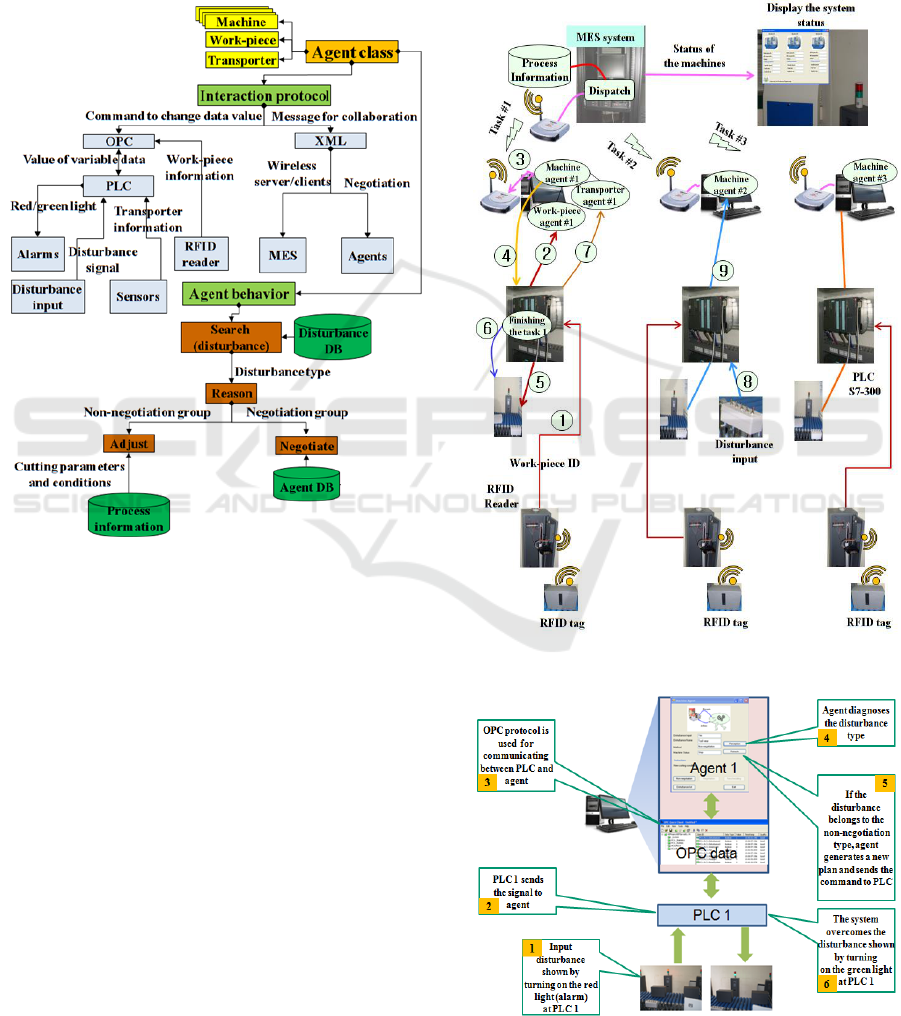

The .NET platform and C# were used for

programming intelligent agents. Figure 9 show he

system architecture with information flow of the

intelligent based machining system. For carrying out

the system, three kernel issues such as the

interaction protocol, agent behaviours, and database

(DB) must be focused on. The extensible markup

language (XML) messages are used for interacting

between agent with MES as well as with other

Development of an Intelligent Agent based Manufacturing System

447

agents. Communication among agents with the

programmable logic controllers (PLC) is established

using the process control protocol (OPC) for linking

and embedding objects. The physical devices on the

machining system such as sensors, alarm device, and

the controlled machine connect to PLCs. SQL

Server

TM

2005 was used for programming database

(DB).

Figure 9: System architecture of the autonomous

machining shop.

The functionality of the developed agent system

was tested successfully on the test-bed. Model of the

test-bed is shown in Figure 10. The working method

of the test-bed is explained as follows:

- RFID Reader sends the work-piece ID to PLC

(denoted by 1).

- Work-piece agent gets the work-piece ID from

PLC and sends to the machine agent (denoted by

2).

- The machine agent requires the task from MES

(denoted by 3).

- The machine agent sends the task to PLC

(denoted by 4).

- PLC turns on the green light (denoted by 5).

- After finishing the task, PLC turns off the light

(denoted by 6).

- PLC sends the signal to the transporter agent to

transfer the work-piece to the next machine

(denoted by 7).

- Inputted disturbance (denoted by 8).

- PLC sends the signal to the machine agent

(denoted by 9).

- Agent overcomes the disturbance by itself or

cooperation with the other machine agents.

Figure 10: System architecture of the machining shop.

Figure 11: Reaction of the agent in the case of tool wear.

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

448

The reaction of the developed system in the case

of tool wear is shown in Figure 11. Steps of this case

are explained as follows:

- Input disturbance shown by turning on the red

light (alarm) at PLC 1.

- PLC 1 sends the signal to agent.

- OPC protocol is used for communicating

between PLC and agent.

- Agent diagnoses the disturbance type.

- If the disturbance belongs to the non-negotiation

type, agent generates a new plan and sends the

command to PLC.

- The system overcomes the disturbance shown by

turning on the green light at PLC 1.

The reaction of the developed system in the case

of machine breakdown is shown in Figure 12. Steps

of this case are explained as follows:

- Input disturbance shown by turning on the red

light (alarm) at PLC 1.

- PLC 1 sends the signal to agent.

- Collecting data.

- Agent diagnoses the disturbance belonging to the

negotiation type.

- Agents establish the wireless network to server

- Agent negotiation as shown in Figure 13.

- An appropriate agent is selected for carrying out

the job of the failure machine.

- The system overcomes the disturbance shown by

turning on the green light at PLC 2.

Figure 12: Reaction of the agents in the case of machine

breakdown.

5 CONCLUSIONS

Cognitive agents enable the manufacturing system to

adapt flexibility to changes and disturbances without

upper level aids or a total planning modification. In

the cognitive agent based manufacturing, the

cognitive capabilities such as perception, reasoning,

and cooperation are equipped for resources on the

shop floor. In order to prove the efficiency of the

proposed cognitive agent concept, the test-bed was

implemented and focused on the self-adjustment

mechanism in the case of the disturbances. The

experimental results show that the mechanism of the

proposed system enables the system to adapt to the

disturbances successfully.

Figure 13: Agent negotiation process.

REFERENCES

Christo, C., Cardeira, C., 2007. Trends in intelligent

manufacturing systems, Proceedings of the IEEE

International Symposium on Industrial Electronics,

pp.3209-3214.

Leitao, P., 2009. Agent-based distributed manufacturing

control: A state-of-the-art survey, Engineering

Applications of Artificial Intelligence, 22(7): 979-991.

Leitao, P., Restivo, F., 2002. Agent-based holonic

production control, Proceedings of the 13th

International Workshop on Database and Expert

Systems Applications, 589-596.

Monostori, L., Váncza, J., Kumara, S.R.T., 2006. Agent –

based system for manufacturing, CIRP Annals -

Manufacturing Technology, 55(2):697-720.

Nakamoto, K., Shirase, K., Wakamatsu, H., Tsumaya, A.,

Arai, E., 2004. Development of an innovative

Development of an Intelligent Agent based Manufacturing System

449

autonomous machine tool for dynamic product

planning, Science and Technology of Advanced

Materials, 5:283-291.

Park, H.S, Tran, N.H., 2010. An intelligent manufacturing

system with biological principles, International

Journal of CAD/CAM, 10(1):39-50.

Shirase, K., Fujii, S., 2009. Machine tool automation,

Handbook of Automation, Springer, pp. 837-857.

Tobias, K., Werner, H., Christian, B., 2009. SOAR-based

sequence control for a flexible assembly cell,

Proceeding ETFA'09 Proceedings of the 14th IEEE

international conference on Emerging technologies &

factory automation, 2009.

Ueda, K., Kito, T., Fujii, N., 2006. Modeling biological

manufacturing system with bounded-rational agents,

Annals of the CIRP, 55(1):469-472.

Zaeh, M.F., Beetz, M., Shea, K., et al., 2009. The

cognitive factory. In: EIMaraghy, H.A (ed)

Changeable and reconfigurable manufacturing

systems, Springer, pp.355-371.

Zhao, X., Son, Y., 2008. BDI-based human decision-

making model in automated manufacturing systems,

International Journal of Model and Simulation,

28(3):347-356.

ICAART 2017 - 9th International Conference on Agents and Artificial Intelligence

450