Direct Observation of the 2D Gain Profile in High Power Tapered

Semiconductor Optical Amplifiers

Rebecca B. Swertfeger

1

, James A. Beil

1

, Stephen M. Misak

1

, Jeremy Thomas

2

, Jenna Campbell

2

,

Daniel Renner

2

, Milan Mashanovitch

2

and Paul O. Leisher

1,2,*

1

Rose-Hulman Institute of Technology, 5500 Wabash Ave, Terre Haute, Indiana, U.S.A.

2

Freedom Photonics, LLC., 41 Aero Camino, Santa Barbara, California, U.S.A.

Keywords: Semiconductor Laser, Diode Laser, Semiconductor Amplifier, Tapered Amplifier, Master-Oscillator Power-

Amplifier (MOPA), High Power, Beam Quality, Single-Mode, Gain Profile, Longitudinal Spatial Hole

Burning, Optical Communication Sources, Free-Space Optical Communication, InGaAsP, InP.

Abstract: A novel experimental approach to permit direct observation of the 2D gain profile in high power tapered

semiconductor optical amplifiers and integrated MOPA devices is reported. A two-dimensional simulation of

the photon, carrier, and gain distributions inside the tapered amplifier demonstrate gain saturation effects that

could be measured by directly viewing the spontaneous emission profile inside of the cavity. Tapered lasers

with a built-in window on the back of the device are fabricated and a SWIR microscope camera is used to

measure the spontaneous emission profile under operation at varying injection levels. The effect of gain

saturation due to stimulated emission is clearly observed and in close agreement with the theoretical model.

1 INTRODUCTION

Modest (watt-class) power levels and diffraction-

limited beam quality are required for a variety of

diode laser applications including optical

communication, narrow linewidth seeding, and

pumping. Conventional ridge waveguide lasers are

not capable of achieving these output levels due to the

low cross-sectional area (high series resistance) and

catastrophic optical mirror damage (in devices

operating at wavelengths below 1100 nm). For

optical communication applications, devices

operating around 1500 nm are particularly important.

Tapered diode laser master oscillator power amplifier

(MOPA) devices grown on InP substrates have shown

promise as a source of watt-class diffraction limited

optical power at 1550 nm (Donnelly, 1998) and

(Selmic, 2002).

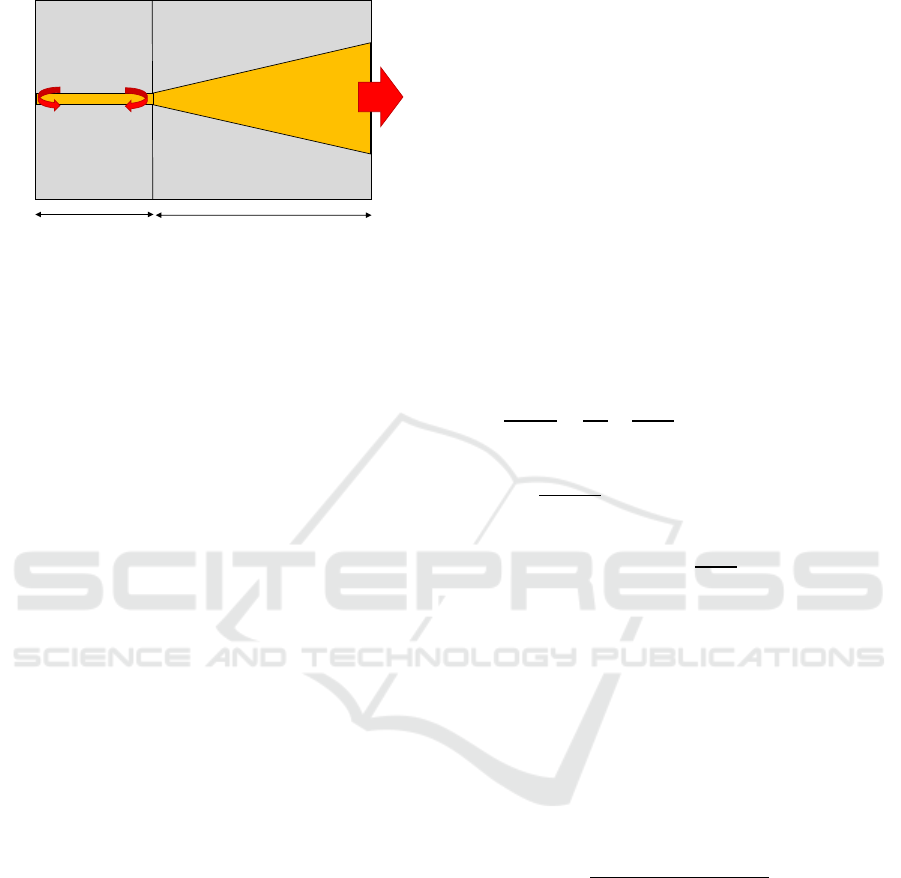

The general concept of the tapered MOPA device

is as follows. Single-mode laser oscillation occurs

within the etched ridge waveguide laser region.

Optical power from this single-mode laser section is

then output into the mode expansion region, where

the fundamental Gaussian beam is free to expand due

to diffraction. A flared, or tapered, contact is

patterned in this region with an angle that is matched

to the natural diffraction angle of the injected beam.

This section operates above saturation intensity and

serves to efficiently amplify the signal. Because the

beam is free to expand, the cross-sectional area of the

device grows with position, keeping the peak

intensity much lower than would occur in a traditional

high power single-mode ridge waveguide laser

(promoting good reliability) and also greatly reducing

the thermal resistance of the device, allowing for

much higher power extraction than would be possible

in a traditional single-mode device. A schematic

drawing is shown in Figure 1.

In an ideal taper, the output optical mode from the

ridge region propagates along the length of the taper,

expanding (due to diffraction) to form a larger version

of the same mode. The mode is amplified as the

tapered region is pumped with electrical current,

leading to high optical output powers. For a fixed

taper angle, the longer the taper, the more the mode is

expanded and the higher the achievable output power.

114

Swertfeger R., Beil J., Misak S., Thomas J., Campbell J., Renner D., Mashanovitch M. and Leisher P.

Direct Observation of the 2D Gain Profile in High Power Tapered Semiconductor Optical Amplifiers.

DOI: 10.5220/0006187301140121

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 114-121

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Schematic diagram of a single spatial mode

tapered master oscillator (MO) power amplifier (PA) laser.

In real tapered lasers, this ability to scale power while

maintaining single-mode performance is limited by

the stability of the lateral optical mode. The onset of

beam filamentation occurs in regions where the gain

is not well-saturated, such as along the edges of the

optical mode where the intensity is lower. Reflection

at the front facet creates a backwards-travelling wave

that can seed laser oscillation, especially in the

regions where the carrier density is high due to poor

gain clamping.

Because tapered amplifiers are edge-emitting

devices, typical measurement techniques do not

permit observation of the gain profile (though the

integrated amplified spontaneous emission can be

measured). In larger laser systems (solid state, fiber,

and gas lasers, for example), the gain can be measured

through the observation of the spontaneous emission

from the side of the laser cavity. High power tapered

semiconductor lasers, however, are bonded junction

down, and the excess solder that pools along the edge

of the device prevents investigation of the gain from

the side of the device. Thus, there exists a need for a

technique which allows for measurement of the gain

profile within the tapered amplifier, and the

demonstration of any such approach would greatly

benefit the development of tapered laser diodes.

In this paper, a method which permits direct

observation of the two-dimensional spontaneous

emission profile, and hence gain profile, within a

tapered optical amplifier is demonstrated. In the next

section, a model which accounts for coupling of the

photon density to the gain profile is developed. The

subsequent sections report the design of the device

and experimental results of the approach.

2 THEORY

2.1 Model Development

Modeling of the 2D photon and carrier distribution in

the tapered power amplifier was based on the

semiconductor laser rate equations and leveraged our

groups’ prior work modeling the effects of

longitudinal spatial hole burning in broad area

semiconductor lasers (Hao, 2014). The standard

semiconductor rate equations are modified to permit

variation of the local carrier density N(z), local

photon density

, and local gain

with

longitudinal position, as described in equations (1)

through (3) In a perfect optical amplifier, feedback

from the emitting facet (and cavity resonance) is

suppressed, thus it is only necessary to track the

forward propagating photon density.

(1)

(2)

(3)

The following parameters are defined as follows.

is the internal quantum efficiency, is the injection

current, and is the electron charge. is the volume

of the active region,

is the photons’ group

velocity, is the optical mode confinement factor,

is the intrinsic optical loss,

is the gain coefficient,

and

is the transparency carrier density. is the

carrier lifetime which includes Auger recombination,

Shockley-Read-Hall recombination, and spontaneous

radiative recombination (Chuang, 1995).

(4)

The finite difference method was used to solve the

simultaneous differential equations along the length

of the cavity. The length of the cavity was divided

into 50 steps and once the photon density was known

for the first point, it was calculated for the second, and

so on. This propagation process was repeated for

many steps in the width of the cavity so that a two-

dimensional model could be created.

Coupling of the photon population to the carrier

population results in an inverse relationship between

gain and photon density. Thus, as the injected signal

from the master oscillator is amplified along the z-

direction of the amplifier, gain and carrier density are

L

MO

L

PA

Single-Mode

Master Oscillator Tapered Power Amplifier

Direct Observation of the 2D Gain Profile in High Power Tapered Semiconductor Optical Amplifiers

115

necessarily reduced. Spontaneous emission, which is

proportional to the square of carrier density, is used

to extract the gain profile.

The two-dimensional distribution of gain is

calculated following a quasi 1D approach.

Fraunhofer far-field diffraction of the injected optical

mode is assumed, resulting in a linear divergence of

the fundamental Gaussian-like mode along the cavity

length. The diffraction angle is calculated from a 2D

cross-sectional effective index simulation of the

optical mode in the ridge waveguide of the master

oscillator and the unconfined slab which comprises

the power amplifier. The total input photons and

beam width are used as inputs to the amplifier

simulation. At each position z, the local photon and

carrier population distributions are computed. As the

simulation proceeds to the next segment, the beam is

propagated forward and reshaped to follow the

calculated diffraction angle. This process is repeated

to propagate the beam through the entire length of the

amplifier and results in a solved 2D profile of photon

density, carrier density, and gain.

2.2 Simulation Results

A tapered optical amplifier operating at 1550 nm was

simulated subject to the following parameters: taper

length = 2.5 mm, taper angle = 4 , master oscillator

ridge width 4.0 µm, tapered amplifier injection

current I

PA

= 4000 mA, and input power supplied

from the master oscillator P

MO

= 23 µW. Additional

simulation parameters are reported in (Hao, 2014).

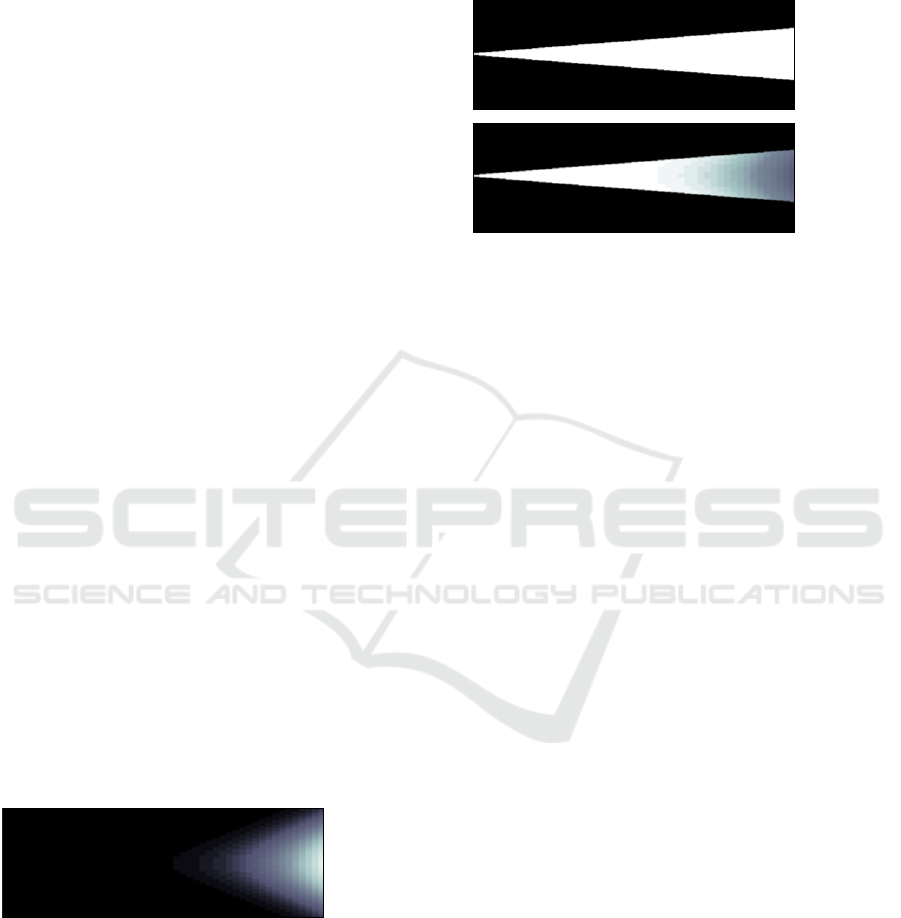

Figure 2 depicts the simulated 2D photon density

profile in the tapered amplifier section of the device.

As shown, the low optical power injected from the

master oscillator leads to small signal amplification

along the first ~65% of the total length of the

amplifier. Gain saturation and linear amplification

take over at this point, increasing the total optical

power to above 500 mW.

Figure 2: Simulated 2D photon density profile for the

tapered MOPA device.

Figure 3 depicts the simulated 2D gain distribution in

the tapered amplifier for the case of zero input optical

power (amplified spontaneous emission is not

included in the model) and for the case of 23 µW

input optical power. In the case of zero injected

optical power, the 2D gain profile is uniform along

the width and length of the taper. The amplification

of the 23 µW signal injected by the master oscillator

leads to saturation of the gain in the same region

where the photon density is highest, demonstrating

the coupling between these two critical parameters.

Figure 3: Simulated 2D gain profile for a tapered MOPA

device. The asymmetry of the optical photon density leads

to gain reduction due to saturation near the front of the

amplifier.

3 EXPERIMENT

3.1 Device Design and Fabrication

The integrated master oscillator and tapered power

amplifier (MOPA) laser was designed in a manner to

permit direct observation of the 2D spontaneous

emission profile in the cavity. Figure 4 depicts a basic

schematic drawing of the device geometry. The edge-

emitting tapered MOPA structure is designed to be

soldered junction-down to an expansion-matched

heatsink, with separate isolated contacts permitting

individual injection of the master oscillator and power

amplifier sections. A window opening is patterned on

the back (n-side) of the diode to permit viewing of the

spontaneous emission from the quantum well along

the entire length of the device through a microscope.

The InGaAsP-based semiconductor epitaxial

structure was grown by metalorganic chemical vapor

deposition (MOCVD) on InP. The InGaAsP

waveguide is 500 nm thick with InP used for the

cladding layers. The active region comprises two 6.5

nm InGaAsP quantum wells emitting at 1550 nm

surrounded by 10 nm InGaAsP barriers. The tapered

MOPA devices were fabricated using standard

fabrication processes. The single-mode ridge

waveguide master oscillator section is designed for a

lateral width of 4 µm and was dry etched using

chlorine-based reactive ion etching followed by a wet

etch clean-up.

P

MO

= 23 µW

I

PA

= 4000 mA

P

MO

= 0 µW

I

PA

= 4000 mA

P

MO

= 23 µW

I

PA

= 4000 mA

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

116

Figure 4: Schematic drawing of the tapered n-window

device.

Current confinement is provided through

openings lithographically patterned in a SiO

2

insulating layer. The taper angle of 4 corresponds to

the full-width 1/e divergence angle of the lateral beam

in the amplifier section. Laser bars were cleaved to a

total length of 4 mm and anti-reflectance coatings

were deposited on the rear and front facets,

respectively. Feedback at the rear of the master

oscillator section is provided by a narrow trench

which was etched into the waveguide to permit ~30%

reflectance in the waveguide despite the anti-

reflectance coating along the back of the device. The

devices were hard soldered using AuSn to junction-

down to patterned AlN heatsinks which permit

separate injection of the master oscillator and power

amplifier sections of the device.

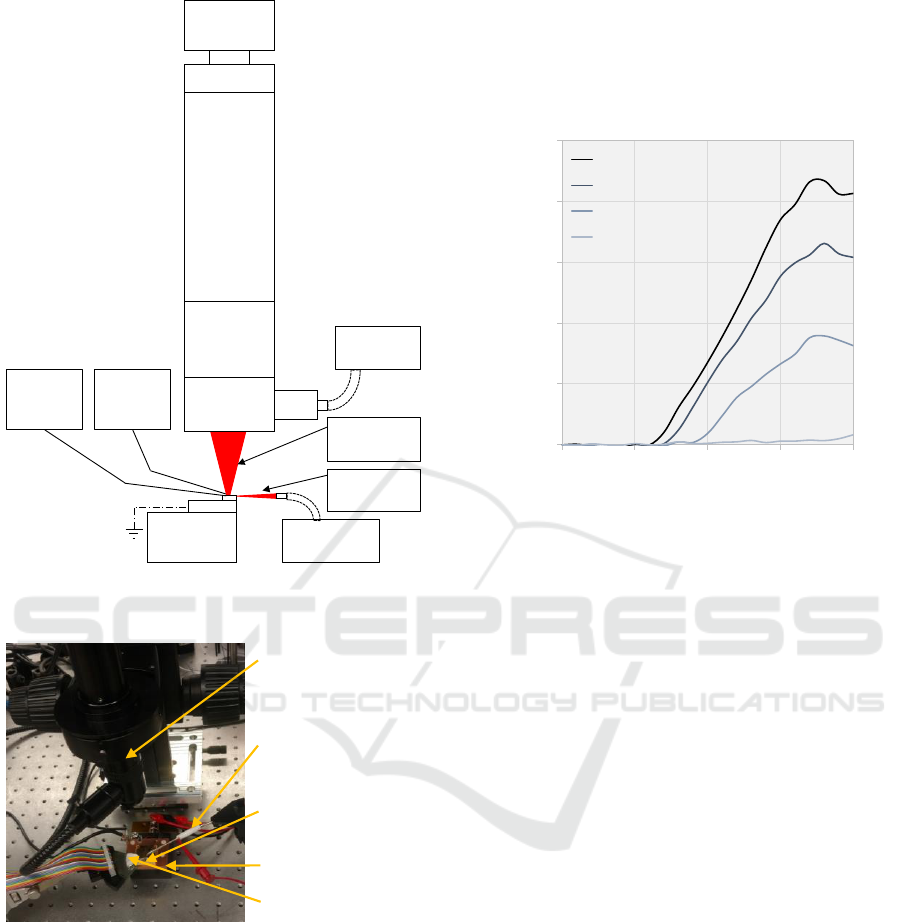

Figure 5 depicts a schematic layout of the

photomask used in the device fabrication. The pink

region represents the dielectric oxide via and hence

pumped active area of the chip. The overlap of the

lateral optical mode with the lateral gain profile is

improved over standard tapered laser designs through

control of the current flow. This technique is

motivated by prior work wherein the gain of the

tapered laser is pixelated (Salet, 1998) and (Walpole,

2000). The blue region shows the window opening in

the backside contact which permits viewing of the

spontaneous emission profile. The window is pulled

back from the injected region of the device by 75 µm.

Figure 6 depicts optical microscope images of the

top-side and bottom-side of three completed chips

prior to device singulation.

Figure 5: Layout of the tapered laser structure showing

several photomask levels.

Figure 6: Optical microscope images of the (top) top and

(bottom) bottom side of fabricated chips prior to bonding.

3.2 Experimental Setup

A schematic diagram of the experimental setup used

to characterize the devices is shown in Figure 7. The

shortwave infrared region (SWIR) microscope is

configured as follows. A 14-bit WiDy model 640U-

S InGaAs camera (640x512 pixel) is mounted to a

Navitar near infrared (NIR) zoom system with a 36

mm working distance and capable of 2X to 20X

adjustable magnification. Co-axial illumination with

a NIR light source is used for initial focusing but

turned off for spontaneous emission measurements.

The tapered master oscillator power amplifier

(MOPA) chip-on-heatsink is attached to a 1 in

2

copper heatsink which is subsequently mounted to a

thermoelectric cooling (TEC)-controlled stage. The

laser output is collected from the edge of the device

by an optical fiber placed near the exit facet, while the

spontaneous emission profile can be simultaneously

recorded by the camera from the top. For optical

power measurements, the fiber is removed from the

front of the device and replaced with a thermopile.

The current and ridge current are separately

controlled and pin probes are used to provide contact

to the associated copper contact pads on the alumina

heat spreader. Figure 8 depicts a photograph of the

experimental setup.

Spontaneous

Emission

Laser Output

Master Oscillator

(MO)

Power Amplifier

(PA)

Direct Observation of the 2D Gain Profile in High Power Tapered Semiconductor Optical Amplifiers

117

Figure 7: Schematic diagram of the SWIR microscope setup

for observation of the 2D spontaneous emission profile.

Figure 8: Photograph of the experimental setup.

3.3 Experimental Results

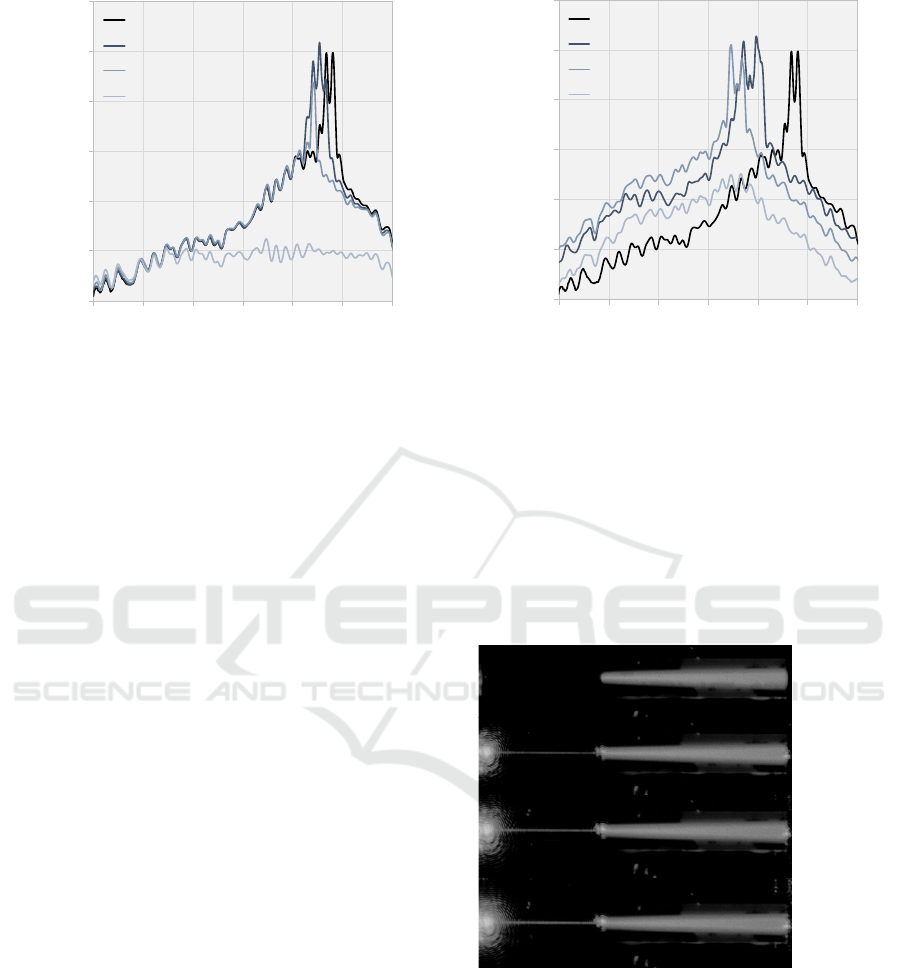

General device characterization of the tapered MOPA

structure occurred as follows. All measurements

were performed continuous wave at a controlled

temperature of 15 C. The device output power was

measured as a function of the injected amplifier

current for four master oscillator (single-mode ridge

section) injection current levels ranging from 0 mA to

300 mA. As shown in Figure 9, a maximum output

power of ~400 mW is achieved at I

MO

= 300 mA and

I

PA

= 4000 mA. The power vs. current characteristics

clearly shows that the tapered amplifier section does

not lase without optical injection from the master

oscillator section. The roll/kink behavior observed

above 3000 mA is attributed to the onset of

multimode oscillation.

Figure 9: CW power vs. tapered amplifier injection current

measured at four master oscillator current values and at a

heatsink temperature T = 15 C.

Figure 10 depicts the measured CW optical

spectra for the case where the amplifier current is held

constant while the master oscillator injection level is

varied. Figure 10 confirms the absence of laser action

when the master oscillator is turned off. As the

master oscillator current is increased, two features are

observed. First, a clear lasing peak appears and red-

shifts with increasing IMO. This behavior is

attributed to self-heating in the master oscillator

section of the device. Second, a large amplified

spontaneous emission pedestal appears around the

lasing peak. This ASE pedestal occurs due to the

excessively high threshold current of the master

oscillator section, which lacks any real feedback from

the front, and only 30% feedback in the rear. It is

clear from this result that the high threshold of the

master oscillator section limits the overall efficiency

of the device.

TEC

Heat Sink

Ridge

Current

Injection

Taper

Current

Injection

Fine Focus

Adjustable

Zoom

IR

Microscope

Adapter

C-mount

Coupler

SWIR

Camera

Microscope

Lamp Fiber

Fiber to OSA

/ thermopile

Spontaneous

Emission

Stimulated

Emission

Probe card (I

PA

)

Current probe (I

MO

)

Tapered laser chip

TEC controlled heatsink

SWIR microscope

0

100

200

300

400

500

0 1000 2000 3000 4000

Output Power (mW)

I

PA

(mA)

I

MO

= 300 mA

I

MO

= 200 mA

I

MO

= 100 mA

I

MO

= 0 mA

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

118

Figure 10: CW optical emission spectrum measured for a

constant power amplifier current of 4000 mA at four

different master oscillator current values at T = 15 C.

Figure 11 depicts the CW optical emission spectra for

the case where the master oscillator injection level is

held constant while the tapered amplifier current is

increased from 1000 mA to 4000 mA. The behavior

of this data series lends insight into the operation of

the tapered MOPA structure. At a current of 1000

mA, no lasing peak in the amplifier is observed – only

the spontaneous emission of the amplifier itself. This

is attributed to injection in the amplifier below the

transparency current density condition. As the

tapered amplifier current increases to 2000 mA, a

strong lasing peak at ~1500 nm is observed (two

longitudinal modes are evident). The background

spontaneous emission profile has also increased due

to the amplified spontaneous emission in the device.

As the current in the tapered amplifier is further

increased, the peak lasing wavelength and broadband

spontaneous emission profile are red-shifted (again

due to self-heating). Less obvious is an apparent

reduction in the total amplified spontaneous emission

due to increased gain saturation.

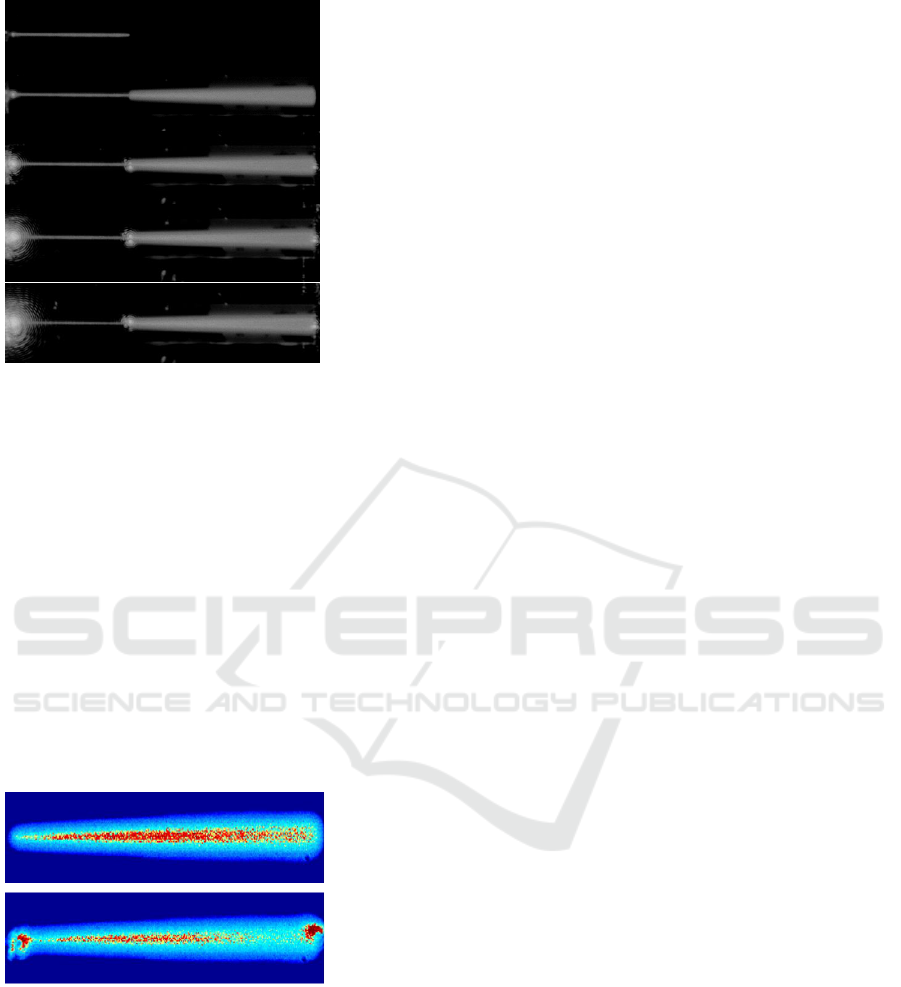

Figures 12 and 13 depict the SWIR microscope

images taken for the cases where the tapered

amplifier current is held constant and where the

master oscillator current is held constant,

respectively. The apparent blurring of the tapered

gain section is not caused by defocus; as previously

discussed the current injection is pixelated in this

region in order to create a lateral gain profile which

better matches the fundamental optical mode

amplified in this section. A significant amount of

light is seen to scatter off the rear facet of the power

amplifier and is caused by the etched trench which

serves to provide feedback to the master oscillator.

Figure 11: CW optical emission spectrum measured for a

constant master oscillator current of 300 mA at four

different power amplifier current values at T = 15C.

Scattering of the laser emission can also be seen

where the master oscillator and power amplifier

intersect and is caused by mode effective index

mismatch at this location. A small amount of laser

light can be seen scattering at the front facet of the

amplifier – this scattered light is attributed to

imperfections in the facet cleave or antireflection

coating.

Figure 12: SWIR microscope image of the spontaneous

emission measured at a constant tapered amplifier injection

current of 4000 mA and varying master oscillator injection

current values.

The simulation of this device predicted the low

output power of the single-mode master oscillator

section would make it difficult to observe the gain

saturation effects in the amplifier section. In the

analysis of the microscope images taken at I

PA

= 4000

mA, a nonlinear color map was applied

in order to investigate the gain saturation effects.

-90

-80

-70

-60

-50

-40

-30

1430 1450 1470 1490 1510 1530 1550

Relative Intensity (dB)

Wavelength (nm)

I

PA

= 4000 mA

I

MO

= 300 mA

I

MO

= 200 mA

I

MO

= 100 mA

I

MO

= 0 mA

-90

-80

-70

-60

-50

-40

-30

1430 1450 1470 1490 1510 1530 1550

Relative Intensity (dB)

Wavelength (nm)

I

MO

= 300 mA

I

PA

= 4000 mA

I

PA

= 3000 mA

I

PA

= 2000 mA

I

PA

= 1000 mA

I

MO

= 0 mA

I

PA

= 4000 mA

I

MO

= 100 mA

I

PA

= 4000 mA

I

MO

= 200 mA

I

PA

= 4000 mA

I

MO

= 300 mA

I

PA

= 4000 mA

Direct Observation of the 2D Gain Profile in High Power Tapered Semiconductor Optical Amplifiers

119

Figure 13: SWIR microscope image of the spontaneous

emission measured at a constant master oscillator injection

current of 300 mA and varying tapered amplifier injection

current values.

Figure 14 depicts the rescaled color map images of

the measured spontaneous emission profiles at I

MO

=

0 and 300 mA. As shown, there is a clear decrease in

the spontaneous emission, and hence gain, in the final

~35% of the device, just as predicted in the numerical

simulations. It is worth noting that the photon density

due to stimulated emission is many orders of

magnitude higher in this region at 300 mA than at 0

mA. Despite this, a reduction in the light captured by

the microscope in this region clearly indicates that the

optical signal being measured is spontaneous

emission from the quantum well (as opposed to

scattered stimulated emission).

Figure 14: Rescaled color map image comparing the

measured spontaneous emission profiles at zero and 300

mA master oscillator injection currents. Suppression of the

spontaneous emission near the exit of the facet of the

tapered amplifier is a clear indicator of gain reduction due

to local saturation.

4 DISCUSSION

The development of high power, high-efficiency

tapered amplifiers stands to benefit from

measurement techniques which enables a better

understanding of the internal device physics. This

work, for the first time, enables direct observation of

and mapping of the gain saturation effect in a

semiconductor optical amplifier. The technique relies

on the incorporation of a window in the back-side of

the device so that the spontaneous emission profile

can be directly observed for devices bonded junction

down. This first demonstration utilized a separately

addressable tapered MOPA device exhibiting an

unusually high master oscillator threshold current

attributed to antireflection coatings applied to both

sides of the device. Nevertheless, the effects of gain

saturation are clearly observed in the images taken.

Subsequent work in this area will first focus on

applying the technique to devices which operate at

much greater output levels. It is expected that this

technique will then be used to improve the gain

pixelation design to ensure more uniform gain

extraction over the entire area of the device.

ACKNOWLEDGEMENTS

The authors acknowledge support by NASA under

award number NNX16AD20G.

REFERENCES

J. P. Donnelly, J. N. Walpole, S. H. Groves, R. J. Bailey, et

al., "1.5-um tapered-gain-region lasers with high-CW

output powers," IEEE Photonics Technology Letters,

vol. 10, pp. 1377-1379, 1998.

S. R. Selmic, G. A. Evans, T. M. Chou, J. B. Kirk, et al.,

"Single frequency 1550-nm AlGaInAs-InP tapered

high-power laser with a distributed Bragg reflector,"

IEEE Photonics Technology Letters, vol. 14, pp. 890-

892, 2002.

T. Hao, J. Song, and P. O. Leisher, "Rate equation analysis

of longitudinal spatial hole burning in high-power

semiconductor lasers," Proc. of SPIE, pp. 91340S-

91340S-7, 2014.

T. Hao, J. Song, R. Liptak, and P. O. Leisher,

"Experimental verification of longitudinal spatial hole

burning in high-power diode lasers," Proc. SPIE. pp.

90810U-90810U-9, 2014.

S. L. Chuang, Physics of optoelectronic devices. New York:

Wiley, 1995.

P. Salet, F. Gerard, T. Fillion, A. Pinquier, et al., "1.1-W

continuous-wave 1480-nm semiconductor lasers with

I

MO

= 300 mA

I

PA

= 0 mA

I

MO

= 300 mA

I

PA

= 1000 mA

I

MO

= 300 mA

I

PA

= 2000 mA

I

MO

= 300 mA

I

PA

= 3000 mA

I

MO

= 300 mA

I

PA

= 3000 mA

I

MO

= 0 mA

I

PA

= 4000 mA

I

MO

= 300 mA

I

PA

= 4000 mA

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

120

distributed electrodes for mode shaping," IEEE

Photonics Technology Letters, vol. 10, pp. 1706-1708,

1998.

J. N. Walpole, J. P. Donnelly, L. J. Missaggia, Z. L. Liau,

et al., "Gaussian patterned contacts for improved beam

stability of 1.55-um tapered lasers," Photonics

Technology Letters, IEEE, vol. 12, pp. 257-259, 2000.

Direct Observation of the 2D Gain Profile in High Power Tapered Semiconductor Optical Amplifiers

121