An Architecture for Visualization of Industrial Automation Data

Guillaume Pr

´

evost, Jan Olaf Blech, Keith Foster and Heinrich W. Schmidt

RMIT University, Melbourne, Australia

Keywords:

Industrial Automation, Cloud-based Services, Data Visualization.

Abstract:

We introduce a framework for visualization of data originating from industrial automation devices. Our frame-

work uses cloud-based services to collect data from industrial automation controllers. Clients can subscribe

to the data sources and visualize them in accordance with customer needs. Data from industrial automation

facilities is associated with formal semantic models, such as a mathematical representation of the material

flow in a production plant. The formal models are used to represent interdependencies between entities, their

functionality and other descriptive elements. Ultimately this is used in the visualization and for reasoning

about systems. In addition to the software framework we describe work on our demonstrator: an example

factory with Raspberry Pi-based controllers that are interconnected via standard ethernet technology.

1 INTRODUCTION

Connecting controllers in factories to internet services

comes with a variety of benefits with respect to oper-

ation and maintenance. Recent trends are frequently

summarized under the term Industry 4.0 (Kagermann

et al., 2013). Automation controllers communicat-

ing with centralized cloud-based services can not only

be used for classical supervisory control and data ac-

quisition (SCADA) tasks, but can also be used for

services that are orthogonal to SCADA functionality.

Such tasks can comprise additional data analytics and

visualization functionality (see, e.g., ABB’s service

port framework

1

) as well as remote health monitor-

ing (see, e.g., (Wenger et al., 2016)). In our work, we

are particularly interested in remote monitoring, op-

eration and maintenance of production plants. For ex-

ample supporting mining site operations, e.g., in the

Australian outback is a target area.

In this paper, we introduce a cloud-based frame-

work to gather data from controllers and visualize

the data using a web-based frontend. While a vari-

ety of products already exist for visualizing industrial

facilities such as Dassault Syst

`

emes’ Delmia and En-

ovia(Dassault Systemes Delmia, 2013; Dassault Sys-

temes Enovia, 2013), we focus on the cloud-based

architecture and on a more abstract data visualiza-

tion view. Visualization is based on formal mod-

els. In particular, we are interested in models that

1

http://new.abb.com/process-automation/process-auto

mation-service/advanced-services/serviceport

express spatio-temporal relationships between enti-

ties. A variety of formalisms for spatio-temporal

models have been developed. More process algebra-

like approaches (Caires and Cardelli, 2003; Caires

and Cardelli, 2004) can have benefits when investigat-

ing concurrency. On the modeling side, our approach

is similar to the qualitative predicates of the Region

Connection Calculus (RCC) (Bennett et al.,2002) that

can express inclusion, neighborhood and similar spa-

tial properties. Furthermore, the cardinal direction

calculus (Skiadopoulos and Koubarakis, 2005), the

rectangle algebra (Balbiani et al., 1999), and the cross

calculus (Van de Weghe et al., 2005) use comparable

means of abstracting from concrete geometric objects

in models. On the other hand, semantic descriptions

of services in the industrial automation area have been

discussed (see, e.g., (Loskyll et al. 2011)) as well

as ontologies for factory automation (e.g. (Lin and

Harding, 2007)).

The main contributions of this paper are the use

of semantic data models for industrial automation in

combination with our cloud-based visualization plat-

form. Furthermore, a demonstrator combining these

technologies is presented. The demonstrator can be

used to analyze production plant operations remotely.

Our data modeling language is introduced in Sec-

tion 2. The cloud-based data visualization platform is

presented in Section 3, while the demonstrator is pre-

sented in Section 4. A conclusion and future work are

presented in Section 5.

38

Prévost, G., Blech, J., Foster, K. and Schmidt, H.

An Architecture for Visualization of Industrial Automation Data.

DOI: 10.5220/0006289700380046

In Proceedings of the 12th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE 2017), pages 38-46

ISBN: 978-989-758-250-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 BeSpaceD DATA-MODELS

In our work, semantic models as well as data in

production plants is formalized using the BeSpaceD

framework (Blech and Schmidt, 2014). We briefly in-

troduce the language then describe the data structures

used in the models.

2.1 BeSpaceD

BeSpaceD is a framework for spatio-temporal model-

ing and reasoning. It comprises:

• A language for modeling spatio-temporal systems

and representing data. The language serves as a

domain specific language (DSL) and is realized

using abstract datatype constructors provided by

the Scala programming language. The language

comprises logical operators such as conjunctions,

disjunctions and implications as well as operators

for time and space as basic entities.

• A library-like collection of operations to reason

about the BeSpaceD models as well as import and

export functionality. Typical operations comprise

abstractions and property detection (such as colli-

sions in time and space).

In the past, BeSpaceD was successfully applied to do-

mains such as train systems (Hordvik et al., 2016),

industrial automation (Blech et al., 2015) and smart

energy systems (Blech et al., 2016).

2.2 Graphs Representing Industrial

Plants

Most of our models for production plants are repre-

sented as graphs (L, E) comprising a set of locations

L and edges E. Typically L can refer to machines, sen-

sors and actuators in a plant while the elements of E

represent interdependencies such as connections, ma-

terial flow, distances, communication channels. Both

edges and locations can be annotated. To give a look

and feel, we have realized the following constructors

for graphs in BeSpaceD/Scala:

class BeGraphAnnotated[+N, +A]

(terms: List[EdgeAnnotated[N, A]])

extends BIGAND[EdgeAnnotated[N, A]](terms)

class EdgeAnnotated[+N, +A]

(val source : N, val target : N,

val annotation: Option[A])

extends ATOM

For example, we have modeled different aspects

of our factory demonstrator. In the evaluation of our

framework, we are particularly interested in the mate-

rial flow topology. This represents the expected flow

– between sensors and actuators – of material through

the factory. We created a specialized subclass of our

graph. The following provides a small excerpt of our

graph-based formal model. The listing below shows

the definition of an edge in a graph and its use in a

very small graph definition comprising a set of two

edges. The topology does not need to be static, it can

change over time. To represent this, we can annotate

the graphs with time constraints.

def edge(s: FestoSensor, t: FestoSensor) =

EdgeAnnotated(s, t, Some(ProcessSequence))

BeGraphAnnotated[FestoSensor,

TemporalFestoConnection] (

edge(CapDispenser.StackEjectorRetracted,

CapDispenser.StackEjectorExtended) ˆ

edge(CapDispenser.StackEjectorExtended,

CapDispenser.StackEmpty)

)

The nodes (e.g. StackEjectorRetracted) are

objects that uniquely identify a sensor in the demon-

strator.

2.3 Sensor Data

In addition to the static nature of the plant models,

we use BeSpaceD to treat live sensor data. Sen-

sor data comprises a sensor identifier that should

have a corresponding node in the plant model. Fur-

thermore, it is associated with a timestamp and

the actual sensor value. For example, we use

the following construct is used to specify that

the sensor StackEjectorRetracted has the value

Obstructed(High) at a timepoint 1479976418134

INSTATE(StackEjectorRetracted, 1479976418134,

Obstructed(High))

The long integers for the time point are recording

milliseconds since Epoch (12:00am, Jan 1st, 1970).

Sensor data can be sent using the JSON format.

The example above is encoded as follows:

{"type": "IMPLIES",

"premise":{"type": "BIGAND", "terms": [

{"type": "Component",

"id": "Stack Ejector Retracted"},

{"type": "TimePoint",

"timepoint": 1479976418134}

]},

"conclusion": {"type": "Obstructed",

"signal": High}

}

An Architecture for Visualization of Industrial Automation Data

39

3 CLOUD-BASED REPORTING

AND DATA VISUALIZATION

This section describes the software platform for the

visualization of plant data and data-models formal-

ized using the BeSpaceD framework.

3.1 eStoRED

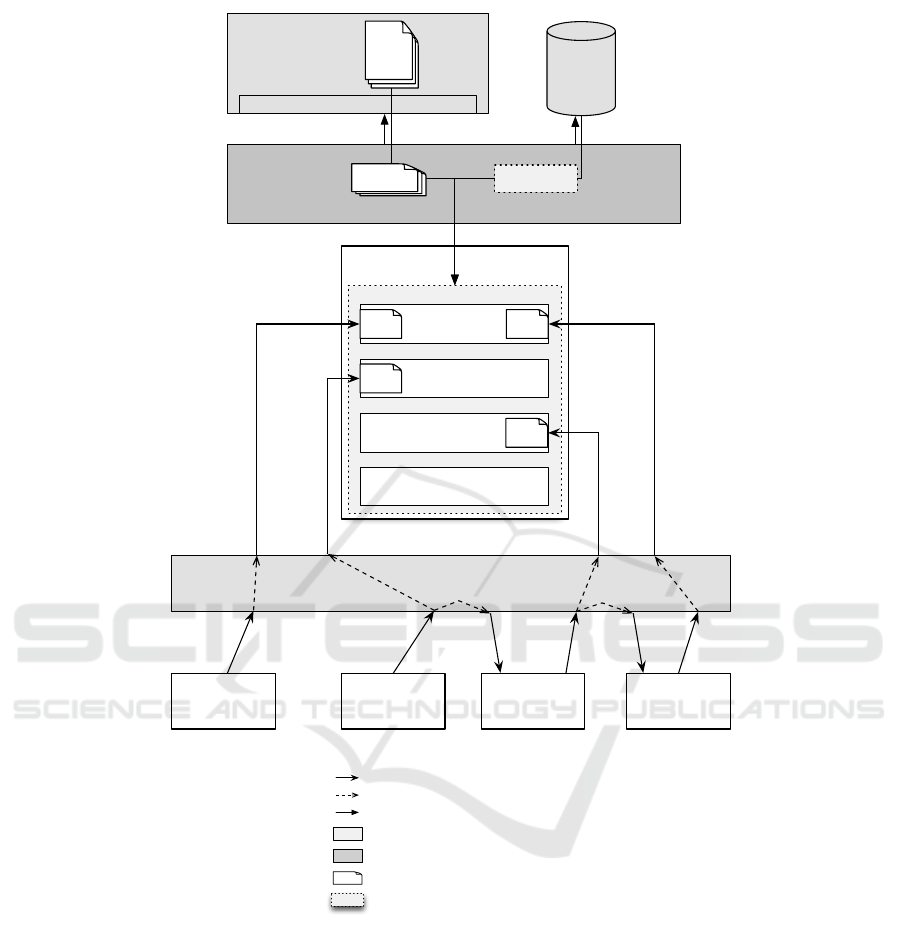

eStoRED is an open source data visualization plat-

form for industrial decision support and risk assess-

ment. Its architecture is shown in Figure 1. It en-

ables the joint-visualization of data from various data

sources or workflows. The visualization is realized

using a centralized platform, to make sense of the var-

ious pieces of data as a whole, and to provide a way

of collaboratively telling a meaningful story about

the data. The eStoRED reporting tool offers a way

to connect to data sources, retrieve data and visual-

ize it along with the possibility to attach metadata.

Possible data sources comprise streamed data (such

as sensor data delivered over a network connection),

web-services, relational databases and file systems. In

eStoRED, users can add their own analysis and risk

definition assessment, thereby enriching and adding

value to the data displayed. This allows building data-

backed comprehensive reports. The eStoRED system

can handle static data extracted from files or databases

as well as live data – such as data coming from sen-

sors – given that there exist a connector to the data

source.

3.2 Architecture

In eStoRED, the main entities created by users are

called Stories. Stories contain different Elements:

Data Elements are the connected elements visualiz-

ing data, Input Elements are the analysis parts written

by the users. At its core, the eStoRED platform is

composed of a web application backed by a relational

database, a message broker and a repository of snip-

pets of code for visualizing data, called Vislets. We

describe eStoRED’s components and how they inter-

act together:

• On one end, the data sources are the processes, ap-

plications and systems that produce the data. They

publish data into messages handled by a publish /

subscribe system that orchestrates and distributes

messages to the processes that have subscribed.

The third-party system chosen for this role is Rab-

bitMQ

2

, an open-source, secure, robust and scal-

2

https://www.rabbitmq.com

able system for software messaging, using the

AMQP protocol

3

.

• The Java web application is using the Spring

MVC framework, Hibernate ORM to map its data

model to a MySQL database storing the internal

eStoRED data (Stories, Data Elements, Input El-

ements, etc.). When working on a Story, a user

can create Data Elements and define one or more

Subscriptions for each of them.

• A Subscription is composed of a subscription ex-

pression, the expected format of the data to be re-

ceived and the snippet of code, called Vislet that

will handle and visualize the data once it is re-

ceived. eStoRED is connected via a REST API

to a curated repository of Vislets and can filter

them according to some metadata attached to each

Vislet. The eStoRED graphical user interface au-

tomatically filters the Vislets to only show those

that can handle the expected data format.

• The topic subscription mechanism of RabbitMQ

is used for subscribing. The mechanism uses rout-

ing keys to match publishers and subscribers. The

subscription expression defined in eStoRED is

used as the RabbitMQ routing key, a sequence of

characters up to 255 bytes, defining dot-separated

words and allowing the wildcards characters *

(star) substituting for exactly one word and #

(hash) substituting for zero or more words. This

enables a powerful and flexible mechanism to

easily create subscription expressions spanning

a wide range of data sources. For example:

australia.2016.rainfall, australia.2016.*, #.rain-

fall are valid routing keys.

Data sources can also use this mechanism to sub-

scribe to each other via the messaging system, and

this way create data workflows. This is illustrated at

the bottom of Figure 1 where Data Source #3 is sub-

scribed to Data Source #2, and Data Source #4 is sub-

scribed to Data Source #3.

Once Data Elements have been defined, when-

ever a Story is loaded, the following steps happen,

as shown in Figure 1 : 1. eStoRED retrieves the

Story and the Data Elements it contains. 2. It con-

nects to the Vislet repository and retrieves the Vislets

defined in the Subscriptions of each Data Element.

3. The web application then generates a web page

where the Vislets are included. 4. On the web page,

a JavaScript client for RabbitMQ is executed directly

into the client’s web browser to subscribe to the ex-

pression. 5. When a Data source publishes a message,

if a Data Element is subscribed to it, the message bro-

ker passes it on, and the Vislet code is called to in-

3

https://www.amqp.org/

ENASE 2017 - 12th International Conference on Evaluation of Novel Approaches to Software Engineering

40

Data Source #2

MySQL

Database

REST API

Data Source #3 Data Source #4

Data Element #1

Data Element #2

Data Element #3

Data Source #1

Web Page

from eStoRED

...

eStoRED

Java Web Application

Story structure

Vislets

Vislet Vislet

Vislet

Vislet

Message Broker

RabbitMQ Server

Vislets repository

MyTardis

Vislets

Story

LEGEND:

Messages published/delivered (AMQP protocol)

Message-passing internal to the broker

Web request/response

Third-party entity belonging to the architecture

eStoRED Platform

Visualisers code snippets

eStoRED Story and Data Elements

Figure 1: eStoRED software architecture.

terpret the data contained in the message, and act on

it by displaying it or performing specific computation

on it.

4 DEMONSTRATOR AND

EVALUATION

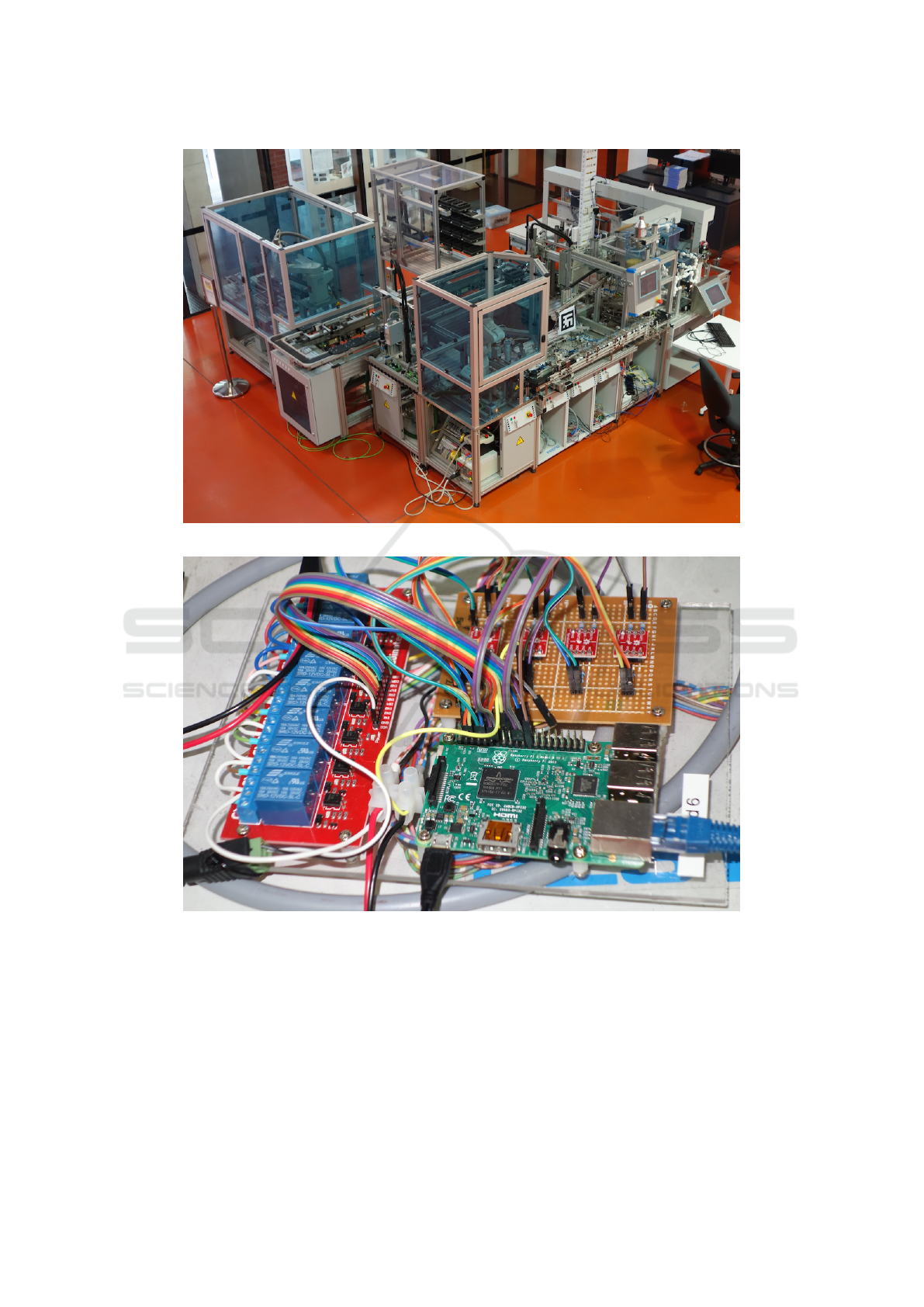

We have created a factory demonstrator and con-

nected it to our framework. Figure 2 shows an

overview of our food-processing factory demonstra-

tor. The conveyor belt circle for pallets in the mid-

dle part and the bottling machinery in the lower left

of the picture are visible. One of our Raspberry Pi-

based controllers is shown in Figure 3. It features a

Raspberry Pi including network connectivity as well

as IO-boards to communicate with the sensor and ac-

tuator world.

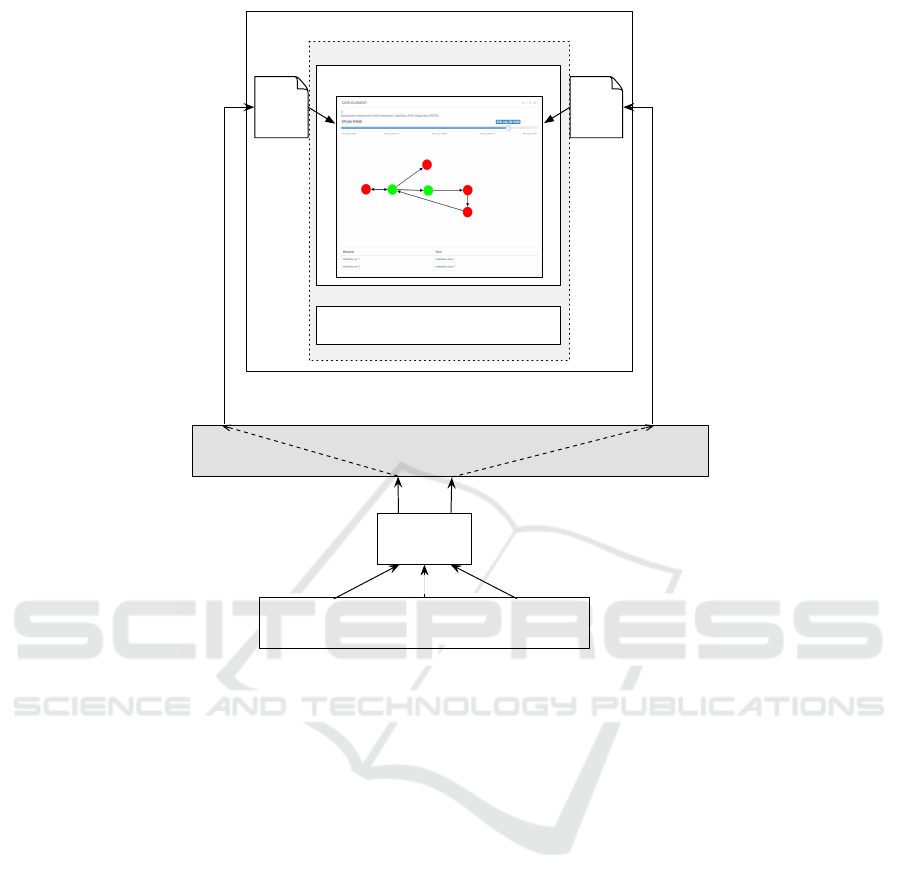

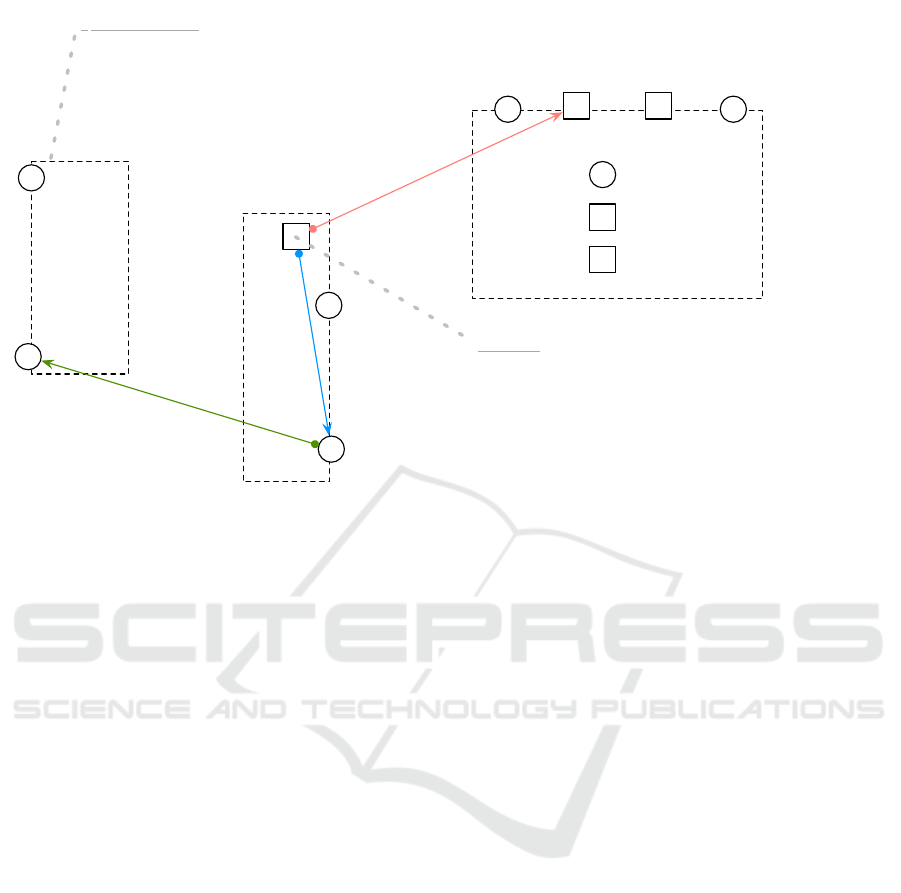

The Figure 4 shows how the eStoRED architecture

is used in the context of visualizing that demonstrator.

The topology of the food processing plant demonstra-

tor is formalized in BeSpaceD as part of the configu-

ration of the program monitoring the plant. It is con-

verted into the JSON format and sent to the message

An Architecture for Visualization of Industrial Automation Data

41

Figure 2: Food processing plant demonstrator.

Figure 3: Raspberry Pi-based controller.

broker at initialization. Whenever the sensors’ sta-

tuses change over time, the sensors send signals to

their respective Raspberry Pi-based controller. A pro-

gram to monitor this is deployed on the Raspberry Pi.

After converting these into the BeSpaceD language,

the corresponding events are sent to the message bro-

ker via a simple AMQP client.

At the other end, a Data Element is created in the

eStoRED platform, with two Subscriptions: one for

the topology, and one for the sensor events. The spe-

cific visualizers are retrieved and loaded into the web

browser. Being in the same data element, both visual-

izers are acting on the same graph visualization. The

topology visualizer draws the nodes and edges of the

graph representing the process, and the sensors visu-

alizer re-draws the status of the sensors by colouring

the nodes whenever they get updated.

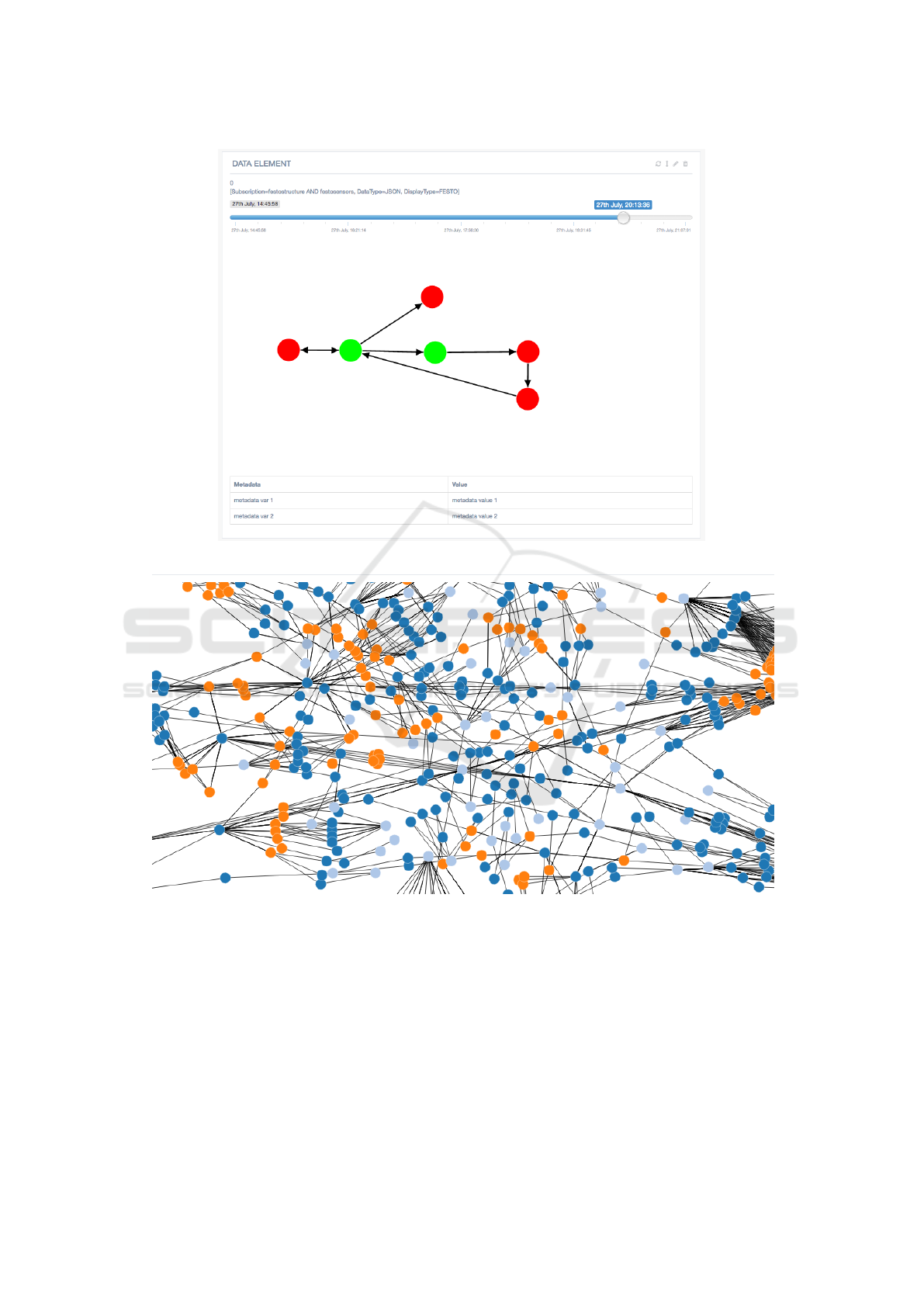

Figure 5 shows an eStoRED Data Element which

ENASE 2017 - 12th International Conference on Evaluation of Novel Approaches to Software Engineering

42

BeSpaceD

eStoRED Platform

...

Topology

Visualiser

Sensors

Visualiser

Message Broker

RabbitMQ Server

Story

Food processing factory demonstrator

Sensors data

Data Element

Topology data

Sensors data

Figure 4: eStoRED in the factory data visualization context.

has received both topology data and sensor data. A

timeline control can be observed at the top of the Data

Element, which is updated when receiving new sen-

sor data. Since each sensor signal encompasses the

exact time when it happened, the visualizer enables

scrolling through signals received in the past, using

this timeline control. At the bottom of the Data El-

ement are displayed metadata that can optionally be

added to AMQP messages as key-value pairs. Here

it only shows metadata as an example, but this could

be important data such as the factory location or staff

responsible for it. To provide a look and feel, Figure 6

shows a larger graph visualized using eStoRED.

An excerpt of the semantic model represented as

a topology in the JSON format is shown below:

{"type":"BIGAND","terms":[ {

"type" : "EdgeAnnotated",

"source" : {"type":"Component",

"id":"Stack Ejector Retracted"},

"target" : {"type":"Component",

"id":"Stack Ejector Extended"},

"annotation" : "ProcessSequence"

} , {

"type" : "EdgeAnnotated",

"source" : {"type":"Component",

"id":"Stack Ejector Extended"},

"target" : {"type":"Component",

"id":"Stack Empty"},

"annotation" : "ProcessSequence"

} , ...

Two edges representing material flow are shown

with their annotations. Another graphical depiction

of a factory element is shown in Figure 7. Only a lim-

ited number of edges are shown for readability pro-

poses The dashed lines represent parts of the factory

and these correspond to their relative spatial position

and size. Squares represent actuators and circles rep-

resent sensors.

Some meta data is shown that is used for config-

uration, debugging and automatic decision support.

Of note is the General Purpose Input Output (GPIO)

Pin number of the Raspberry Pi-based PLC that is

mapped to the actuator that controls and actuator: it

extends a stack ejector. The signal mapping defines

the binary voltage level (e.g. zero or 24 volts) that

the actuators or sensors accept or emit. This relates to

sensor states in our model (e.g. [de]activate actuator;

[un]obstructed light sensor). Spatial measurements

for a tube that holds bottling caps are shown to il-

An Architecture for Visualization of Industrial Automation Data

43

Figure 5: Example of an eStoRED data element including topology and sensor data.

Figure 6: Larger graph visualized with eStoRED.

lustrate the annotation of geometric information. The

symbols are reference points and intermediate values

used to formulate absolute measurements.

There are three different qualitative topological

aspects that can be distinguished in our factory model.

One edge from each aspect is added to the diagram to

illustrate them.

• Material Flow Topology (green)

In the example, this edge is asserting that the stack

empty sensor becomes obstructed exactly one sec-

ond before the stack ejector extended sensor be-

comes unobstructed. In other words, it takes one

second to eject the last cap from the stack.

• Interdependency aspects (blue)

This edge is asserting that the stack ejector ex-

tended sensor becomes unobstructed between 200

to 300 milliseconds after the stack ejector extend

actuator is inactivated (passive). In other words,

it takes 200–300 ms for the light sensor to indi-

cate retraction after the actuator starts retracting

ENASE 2017 - 12th International Conference on Evaluation of Novel Approaches to Software Engineering

44

Stack Ejector Retracted

Stack Ejector Extended

Stack Ejector

Tube

Stack Full

Stack Empty

Workpiece Gripped

Loader Picked Up Loader Dropped Off

Loader

Vacuum Grip

Eject Air Pulse

Stack Ejector Extend

Loader

Pick Up

Loader

Drop Off

-500..1000ms

Active

Passive

Passive

Unobstructed

200..300ms

Unobstructed

Obstructed

-1sec

Spatial META DATA

x = Station1EdgeLeft + 68

y = StackEjectorFront + 55

= Station1EdgeFront + 76 + 55

z = Base + 34

width = Diameter.Tube = 60

depth = Diameter.Tube = 60

height = Z.TubeTop - Z.TubeBottom

= Base + 230 - StackEjectorPlatform

= Base + 230 - Base + 34

= 264

META DATA

Category = Actuator

Type = Solenoid

GPIO = 4

SignalMapping = (High -> Active, Low -> Passive)

Figure 7: Partial model of a factory element.

the stack ejector.

• Safety aspects (red)

This edge is asserting a constraint that we want the

loader to move to the pick-up position from half a

second before to one and a half seconds after the

stack ejector starts extending in order to avoid a

collision.

5 CONCLUSION

This paper described our cloud-based data collec-

tion and visualization framework for industrial au-

tomation. We presented the incorporation of spatio-

temporal models into the framework and discussed

some detailed examples. In addition, we introduced

a demonstrator and a visualization application. The

cloud-based software framework and the example fac-

tory are integrated and serve as a demonstrator plat-

form for our lab. The presented work facilitates

monitoring, operation and maintenance of production

plants. In particular remote plants such as mining

sites in the Australian outback are a targeted appli-

cation area. Future work will connect additional ser-

vices to the AMQP server in order to establish a com-

mon interchange platform for factory data.

REFERENCES

P. Balbiani, J.-F. Condotta, and L. F. del Cerro. A new

tractable subclass of the rectangle algebra. In Proceed-

ings of the 16th International Joint Conference on Ar-

tifical Intelligence - Volume 1, pages 442447, 1999.

B. Bennett, A. G. Cohn, F. Wolter, M. Zakharyaschev.

Multi-Dimensional Modal Logic as a Framework

for Spatio-Temporal Reasoning. Applied Intelligence,

Volume 17, Issue 3, Kluwer Academic Publishers,

November 2002.

J. O. Blech, L. Fernando, K. Foster, Abhilash G and

Sudarsan Sd. Spatio-temporal Reasoning and Deci-

sion Support for Smart Energy Systems. Emerging

Technologies and Factory Automation (ETFA), IEEE,

2016.

J. O. Blech, I. Peake, H. Schmidt, M. Kande, A. Rahman,

S. Ramaswamy, Sudarsan SD, V. Narayanan. Efficient

Incident Handling in Indus- trial Automation through

Collaborative Engineering. Emerging Technologies

and Factory Automation (ETFA), IEEE, 2015.

J. O. Blech, H. Schmidt. BeSpaceD: Towards a Tool Frame-

work and Methodology for the Specification and Ver-

ification of Spatial Behavior of Distributed Software

Component Systems, http://arxiv.org/abs/1404.3537.

arXiv.org, 2014.

L. Caires and L. Cardelli.A Spatial Logic for Concurrency

(Part I). Information and Computation, Vol 186/2

November 2003.

L. Caires and L. Cardelli. A Spatial Logic for Concurrency

(Part II). Theoretical Computer Science, 322(3) pp.

517-565, September 2004.

DS DELMIA V6R2013x – Fact Sheet: 3DEXPERIENCES

An Architecture for Visualization of Industrial Automation Data

45

of Global Production Systems for all stakeholders in

the extended supply chain. Dassault Syst

`

emes 2013.

ENOVIA V6R2013x – Fact Sheet. Dassault Syst

`

emes 2013

S. Hordvik, K. Oseth, J. O. Blech, P. Herrmann. A Method-

ology for Model-based Development and Safety Anal-

ysis of Transport Systems.Evaluation of Novel Ap-

proaches to Software Engineering, 2016.

H. Kagermann, W. Wahlster, J. Helbig (eds.). Recommen-

dations for implementing the strategic initiative IN-

DUSTRIE 4.0 – Final report of the Industrie 4.0

Working Group. Acatech, 2013.

H. K. Lin and Jenny A. Harding. A manufacturing system

engineering ontology model on the semantic web for

inter-enterprise collaboration. Computers in Industry

58, no. 5 (2007): 428-437.

M. Loskyll, J. Schlick, S. Hodek, L. Ollinger, T. Gerber,

& B. Pirvu. Semantic service discovery and orches-

tration for manufacturing processes., 16th Confer-

ence on Emerging Technologies & Factory Automa-

tion (ETFA). IEEE, 2011.

S. Skiadopoulos and M. Koubarakis. On the consistency of

cardinal direction constraints. Artificial Intelligence,

163(1):91135, 2005.

N. Van de Weghe, B. Kuijpers, P. Bogaert, and P. De

Maeyer. A qualitative trajectory calculus and the com-

position of its relations. In Proceedings of the 1st

International Conference on GeoSpatial Semantics,

pages 6076. Springer, 2005.

M. Wenger, A. Zoitl, J. O. Blech, I. Peake. Remote Mon-

itoring Infrastructure for IEC 61499 Based Control

Software. 8th International Congress on Ultra Mod-

ern Telecommunications and Control Systems, IEEE,

2016.

ENASE 2017 - 12th International Conference on Evaluation of Novel Approaches to Software Engineering

46