An Assessment of Feasibility of Energy Saving Measures

Applied for a Hospital

Cheng-Shu Kuo

1

, Chen-Pu Wang

2

, Fu-Jen Wang

2

, Pei-Yu Yu

1

and Hung-Wen Lin

1

1

Green Energy and Environment Research Laboratories, Industrial Technology Research Institute, Hisnchu, Taiwan

2

Department of Refrigeration, Air Conditioning and Energy Engineering,

National Chin-Yi University of Technology, Taichung, Taiwan

Keywords: Retrofit, Hospital, Energy Saving, EnergyPlus.

Abstract: The objective of this study, including field investigations and simulations, is to evaluate the feasibility of

retrofit for energy performance of a hospital in the midst of Taiwan. This hospital, twelve stories and two

floors of basements, has 37490 m

2

of gross floor area, consuming around 8500000 kWh annually. The

current internal systems of this hospital present relevant signs of degradation and obsolescence. Concerning

this matter, the retrofit plan of internal systems for this hospital is conducted to improve energy

performance. Based on ASHRAE procedures for commercial building energy audits (PCBEA), field study

and energy audits were conducted to collect information of building geometry, building materials, space

types, density and activities of people, capacity of HVAC system, loads and operating schedules of lighting

and internal equipment. Using this information, a hospital energy model with the current internal system

arrangements is established using EnergyPlus software, calibrated by field information of this building as a

baseline. The energy saving potentials of several energy saving measures applied such as high-performance

chillers and lighting devices, window glass with tinted film and energy management resulting from

EnergyPlus simulations have been examined with reference to the cooling energy demand. The retrofit

feasibility has also been evaluated in terms of annual savings and pay-back period of the investment. Those

analyses could be beneficial to establish a feasible retrofit plan for energy saving of this building.

1 INTRODUCTION

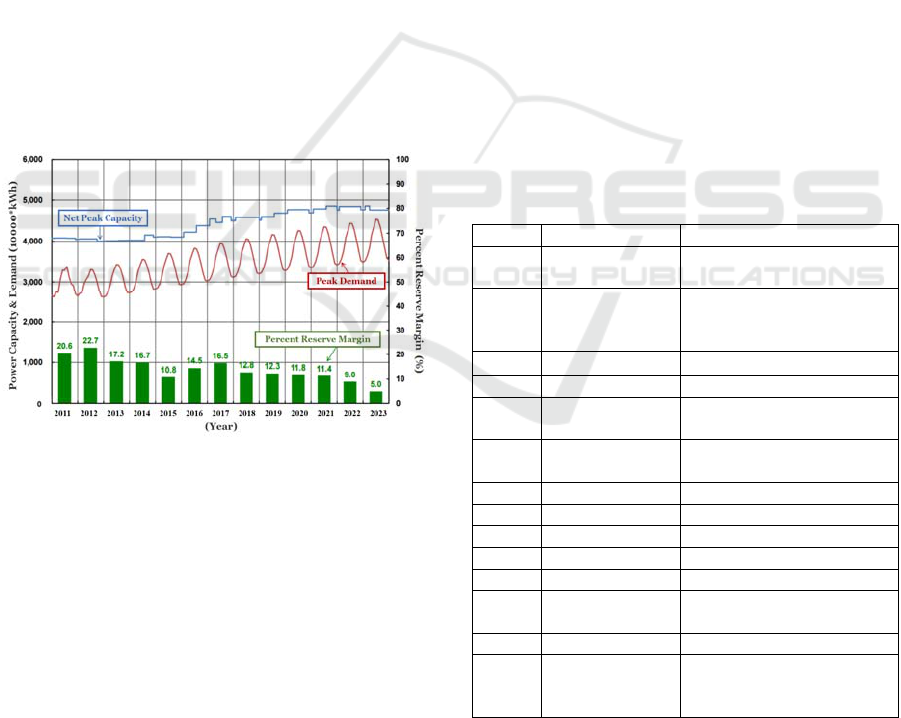

Taiwan is a small island with rare indigenous

energy, 97% of energy imported from overseas.

Recently, scales of building in Taiwan such as office

buildings, department stores, hospitals and hotels

were increasing, consuming large amount of

electricity. From the current situation and future

trend of electricity demands and percent reserve

margin of capacity of Taiwan, shown in the Figure

1, it can be found that electricity demands of Taiwan

increase with years while percent reserve margin of

capacity decreases with years. Therefore, how to

reduce the electricity consumption and improve

energy efficiency has become a key issue for energy

management of Taiwan. According to investigations

(Bureau of Energy of Taiwan, 2015) from Bureau of

Energy of Taiwan, there are 145 hospital buildings

with contract capacity above 800 kW, consuming

2.1 billion kWh per year, about 14.9 % of electricity

consumption of non-productive industries in

Taiwan. In addition, average electricity consumption

per unit area of medical centres and regional

hospitals are 245 kWh/m

2

yr and 205 kWh/m

2

yr,

respectively, about 1.47 to 1.75 times of the one of

office buildings. Hospitals provide patients with 24

hours of lighting, air conditioning and healthcare

facilities to meet the requirements of medical care,

thus consuming large amount of electricity. The

Taiwan government has set the energy saving target

that Mega-Watt energy users would have 1% of

energy reduction per year in the following 5 years

(Bureau of Energy of Taiwan, 2015). Concerning

this matter, hospital buildings would have to

implement energy-saving measures in order to

reduce electricity consumption and to reach the

Taiwan government’s energy saving target.

Energy simulation is a useful method to evaluate

influence factors on building energy performance

such as building materials, power densities of

lighting and internal electrical equipment, air

conditioning system, and operation schedules etc.,

especially useful for the early designing or retrofit

planning stage of such large scale hospital buildings.

Kuo, C-S., Wang, C-P., Wang, F-J., Yu, P-Y. and Lin, H-W.

An Assessment of Feasibility of Energy Saving Measures Applied for a Hospital.

DOI: 10.5220/0006293601510157

In Proceedings of the 6th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2017), pages 151-157

ISBN: 978-989-758-241-7

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

151

Energy simulations have been applied to analyze

energy performance of hospital buildings in several

previous works. The building energy simulations

were employed to evaluate the energy-saving

efficiency of HVAC system by studying two green

hospital buildings (Chen and Kan, 2014), to examine

thermal performance of hospital buildings with

various geometries (Shchuchenko et al, 2013), to

calculate heating and cooling loads of the hospital

(Saipi et al, 2014), to assess the feasibility of 50%

energy savings for large hospitals in various climate

zones of USA (Bonnema et al. 2010), and to

evaluate impacts of both envelope renovation and

HVAC system selection for a hospital building

(Ascione et al, 2016) etc. It is indicated that the

building energy software can help to obtain a better

understanding of energy consumption throughout the

whole building. Therefore, EnergyPlus building

energy simulation software developed by

Department of Energy of USA was used in this

report to calculate energy consumptions of energy

saving measures applied on this hospital to evaluate

the feasibility of a retrofit plan for energy saving of

this building, located in the midst of Taiwan.

Figure 1: Trend of net peak capacity, peak demand and

percent reserve margin of Taiwan. (Taipower Company,

2011).

This paper is organized as follows. Section 2 is to

obtain completed information of the hospital

building employing ASHRAE procedures for

commercial building energy audits (PCBEA)

(ASHRAE, 2011) for information of building

geometry, building materials, space types, density

and activities of people, capacity of HVAC system,

loads and operating schedules of lighting and

internal equipment. Based on collected information,

an energy model for this hospital was established

using EnergyPlus software, while this energy model

was calibrated by actual monthly electricity as a

retrofit baseline. Section 3 describes the evaluations

of applied energy saving measures. It will compare

annual energy saving and pay-back period of the

investment among the existing baseline and energy

saving measures to evaluate retrofit feasibility.

Finally, Section 4 presents our conclusions

2 ENERGY MODEL OF THIS

HOSPTIAL BUILDING

2.1 Specification of Building

This hospital building is located in the midst of

Taiwan, built in twelve floors above ground and two

floors underground, with base area 64 meter by 58.6

meter. The front of this hospital building faces

northwest. The first floor is the lobby and

emergency rooms. From the 5th floor to the 11th

floor, all spaces are wards except some spaces in

10th floor are used for negative pressure isolation

rooms. The 12th floor contains an auditorium,

meeting rooms and negative pressure isolation

rooms. The detailed information of area and space

types of each floor of this building is shown in Table 1.

Table 1: Specification of building.

Floor Floor area (m

2

) Space property

B1 3749

Radiology department;

Morgue; Parking lot

B2 3749

Restaurant; Pharmacy;

Medical records

department

1F 3749

Lobby;

Emergency room

2F 3749 Outpatient Clinic

3F 3749

Intensive care unit;

Operating room

4F 3749

Air conditioning machine

room

5F 1874.5 Ward

6F 1874.5 Ward

7F 1874.5 Ward

8F 1874.5 Ward

9F 1874.5 Ward

10F 1874.5

Ward;

Negative pressure

isolation room

11F 1874.5 Ward

12F 1874.5

Negative pressure isolation

room; Auditorium;

Meeting room

2.2 Construction of the Building

According to the architectural drawing of this

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

152

building, the construction, appearance and interior

partition of the building are established. The roof of

this building is reinforced concrete with regular

insulation (overall heat transfer coefficient U = 0.99

W/m

2

K). Exterior wall is 15 cm reinforced concrete

with tiles (overall heat transfer coefficient U = 3.49

W/m

2

K). Window glass is 8 mm brown colour glass

(overall heat transfer coefficient U = 6.07 W/m

2

K,

solar heat gain coefficient SHGC = 0.82). The

building model is built up following the geometric

dimensions of the building in the architectural

drawing. The complicated geometric dimensions of

the building are simplified without influencing the

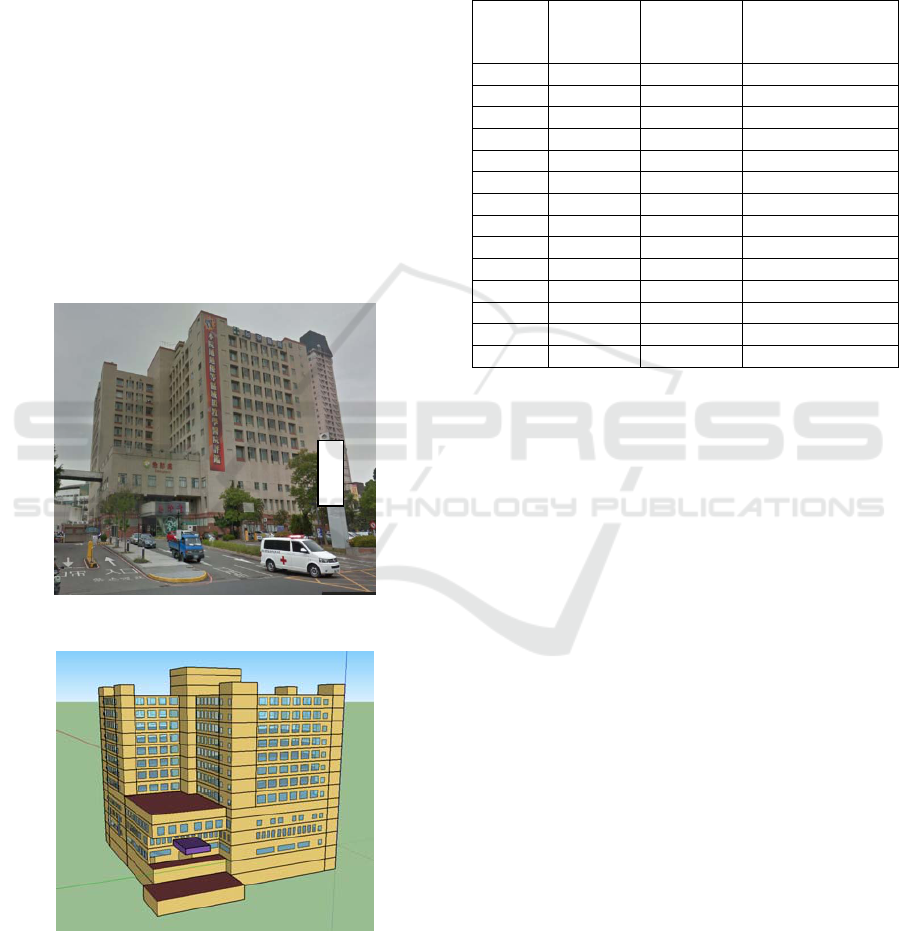

simulations. The actual appearance and 3D model of

the building are shown in Figure 2 and 3. The

interior partitions of each floor of this building are

independently established according to the

architectural drawing. Some spaces without air

conditioning or with the same property are simply

combined into a space to reduce the complexity of

building model.

Figure 2: Actual appearance of the hospital.

Figure 3: 3D model of the hospital.

2.3 Interior Load Parameters

According to field investigation, the average people,

lighting density and internal electrical equipment

density of each floor of this hospital are shown in

the Table 2.

Table 2: Average interior loads of building.

floor People

number

Lighting

density

(W/m

2

)

Internal electrical

equipment

density(W/m

2

)

B2 100 15 15

B1 200 30 15

1F 300 25 15

2F 160 25 20

3F 160 20 10

4F 5 5 10

5F 160 25 10

6F 160 25 10

7F 160 25 10

8F 160 25 10

9F 160 25 10

10F 160 25 15

11F 160 25 10

12F 100 15 10

2.4 Schedule

During simulations, schedules of people activity,

lighting, internal electrical equipment and air

conditioning system need to be input to represent

time variation of people number and power density

of related equipment. The effect of time variation is

expressed using the number of fraction of peak.

When full load is done, fraction of peak is set to be 1.

On the other hand, fraction of peak is 0 when the

load is off. The value of fraction of peak is between

0 and 1 when it is partial load. In this report,

schedules were derived based on engineering

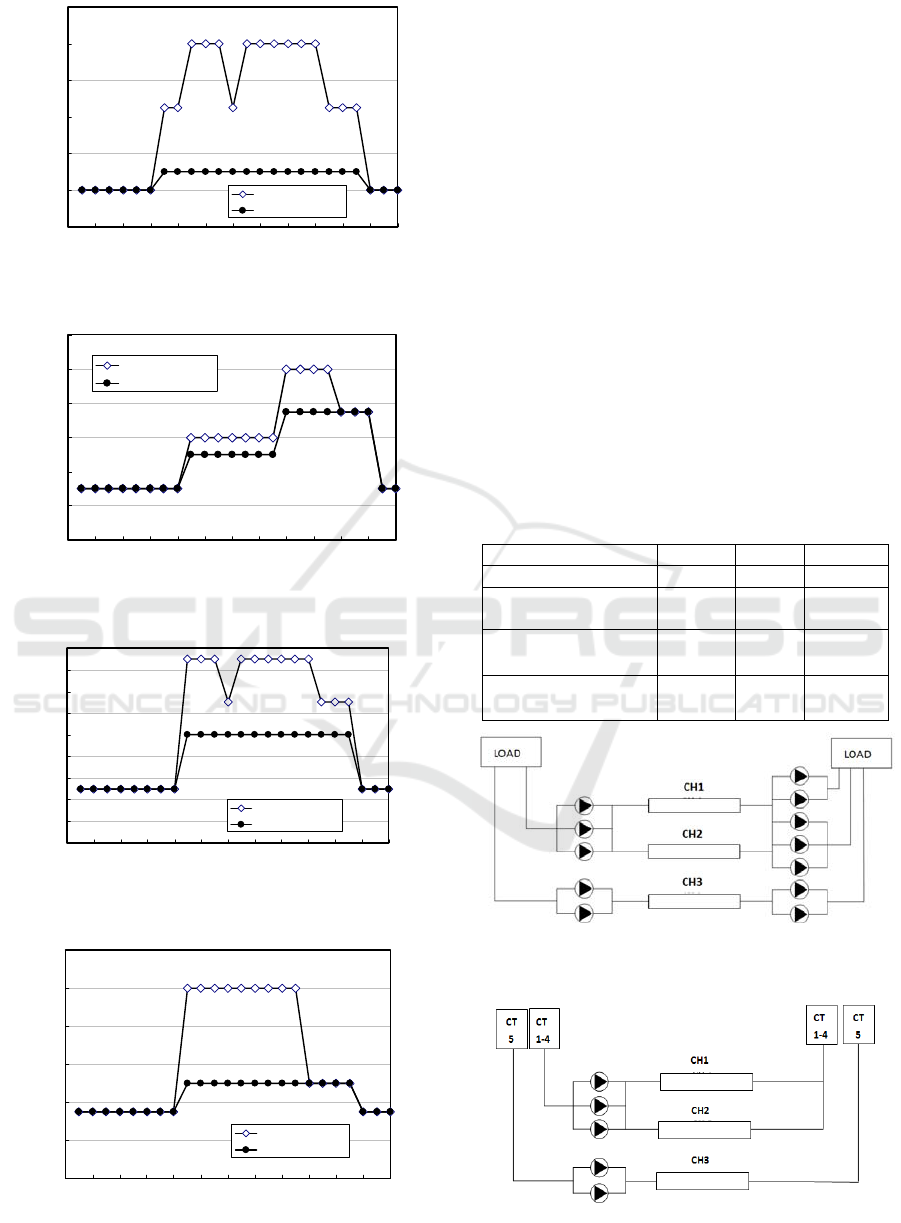

judgment and field investigation. Figure 4 shows the

time variation of people number in the hospital

building. Y-axis represents the ratio of people

number of the current time to the peak people

number. Figure 5, 6, and 7 plot the lighting, internal

electrical equipment, and air conditioning system

schedules in the hospital building. For special spaces

in the hospital such as emergency rooms and

intensive care unit, the fraction of peak of schedules

remains one for 24 hours throughout the whole year.

An Assessment of Feasibility of Energy Saving Measures Applied for a Hospital

153

0

0.2

0.4

0.6

0.8

1

1.2

0 2 4 6 8 10 12 14 16 18 20 22 24

Time (hour)

Fraction of pea

k

Weekday schedule

Weekend schedule

Figure 4: Occupancy schedule.

0

0.2

0.4

0.6

0.8

1

1.2

024681012141618202224

Time (hour)

Fraction of pea

k

Weekday schedule

Weekend schedule

Figure 5: Lighting schedule.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0 2 4 6 8 1012141618202224

Time (hour)

Fraction of pea

k

Weekday schedule

Weekend schedule

Figure 6: Internal electrical equipment schedule.

0

0.2

0.4

0.6

0.8

1

1.2

0 2 4 6 8 1012141618202224

Time (hour)

Fraction of pea

k

Weekday schedule

Weekend schedule

Figure 7: Air conditioning system schedule.

2.5 Air Conditioning System

This air conditioning system of this hospital contains

two 540 RT chillers in a parallel configuration and a

250 RT chiller, with rated COP of 5.0, 5.0 and 4.0,

respectively. These chillers work using 5 chilled

water pumps and 7 regional chilled water pumps to

cool the rooms inside the building, illustrated in

Figure 8. Also, these chillers employ 5 cooling water

pumps and 5 cooling towers to release heat to the

environment, shown in Figure 9. Specifications of

chillers are indicated in Table 3. The chiller of 250

RT works 24 hours whole year to meet the

requirements of cooling loads of special spaces such

as emergency rooms and intensive care unit. Two

540 RT chillers satisfy the cooling demands for all

regular rooms, operating with the air conditioning

system schedule indicated in Figure 7. The

efficiency of fans used in air conditioning system is

0.6. The room temperature of regular space is set at

25 ℃.

Table 3: Specifications of chillers.

No. CH1 CH2 CH3

Capacity (RT) 540 540 250

Power consumption

(kW)

384 384 198

Inlet/outlet chilled

water temp. (℃)

12/7 12/7 12/7

Inlet/outlet cooling

water temp. (℃)

32/37 32/37 32/37

Figure 8: Chillers, chilled water pumps and regional

chilled water pumps.

Figure 9: Chillers, cooling water pumps and cooling

towers.

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

154

2.6 Baseline Model

A building model with above settings including

construction and materials, internal loads, schedules

and air conditioning system is simulated using

EnergyPlus software. The simulation result of

electricity consumption of this building is compared

with measured electricity consumption in 2015,

listed in Table 4. The deviation of total annual

electricity consumption between simulation and

actual measured data is about 3.64% and the trends

of monthly electricity usages of both are similar and

closed. The allowable difference between predicted

and measured data is that the annual simulated

energy usage should be within 10% of metered data,

while a difference of less than 25% is acceptable on

a seasonal basis (Rahman et al, 2010). From the

simulation result, it is indicated that this building

model can be the baseline for retrofit evaluations in

terms of total annual electricity consumption.

Table 4: Comparison between actual and simulation data.

Month Actual

(kWh)

Simulation

(kWh)

Deviation

(%)

1 595,832 638,165 7.10

2 528,308 566,942 7.31

3 621,872 669,196 7.61

4 620,990 653,532 5.24

5 707,569 739,281 4.48

6 720,664 723,314 0.37

7 855,248 881,724 3.10

8 827,073 799,616 -3.32

9 801,520 752,193 -6.15

10 657,216 715,404 8.85

11 612,632 668,029 9.04

12 590,675 628,319 6.37

Total 8,139,599 8,435,715 3.64

0

100,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

123456789101112

Month

Energy consumption (kWh)

Acutal

Simulated

Figure 10: Simulation result and comparison with

measured data.

3 EVALUATION OF ENERGY

SAVING MEASURES

Based on baseline energy model of this hospital

building, calculations of energy saving and pay-back

period of investment of energy saving measures

applied on air conditioning system, ventilation

system, lighting system, internal electrical

equipment, building materials and energy

management are conducted as follows.

Baseline: The EnergyPlus building model with

current internal system, which has been calibrated

with the monthly electricity consumptions of the

hospital building in 2015.

Measure 1: The original chiller of 250 RT with

COP = 4.0 is replaced by a new chiller of 250 RT

with COP = 5.0. After this improvement, total

annual energy consumption is 8,115,158 kWh,

saving 3.8% of electricity about reduction of 31,022

USD (US Dollar). If cost of this improvement is

80,646 USD, the return on investment (ROI) will be

2.6 years.

Measure 2: This measure is to increase outlet

chilled water temperature of chillers from 7

o

C to 8

o

C.

According to the required working condition of air

handling units, the apparatus dew point is 13.5

o

C.

Generally, the temperature difference between inlet

and outlet chilled water of the chiller is 5

o

C.

Therefore, when outlet chilled water temperature of

chillers is from 7

o

C to 8

o

C, the apparatus dew point

can reach to 13.5

o

C. It means that this change will

not influence the working condition of cooling coils

of air handling units. This measure can be

implemented easily by changing the temperature

setting value on the control panel of the chiller.

After this setting, total annual energy consumption is

8,345,617 kWh, saving 2.1% of electricity about

reduction of 17,438 USD. Since cost of this

improvement is 0 USD, the return on investment

(ROI) is 0 year.

Measure 3: Decreasing inlet cooling water

temperature of chillers from 32

o

C to 31

o

C is applied

to save energy. Based on the consideration of

capacity of current cooling tower, properties of

chiller and outdoor wet-bulb temperature without

significant deviations from the standard operation

conditions suggested by manufacturers, slightly

decreasing 1

o

C on inlet cooling water temperature of

chillers is proposed to observe the variation of total

energy consumption. This measure can be carried

out by simply changing the setting values of inlet

cooling water temperature on the control panel of

chillers. After this change, total annual energy

consumption is 8,365,667 kWh, saving 1.1% of

An Assessment of Feasibility of Energy Saving Measures Applied for a Hospital

155

electricity about reduction of 8,720 USD. Since cost

of this improvement is 0 USD, the return on

investment (ROI) is 0 year.

Measure 4: Employing the tinted window film on

window glass of the building as thermal insulation,

the solar heat gain coefficient (SHGC) of window

glass with tinted film is reduced from 0.81 to 0.51.

After this improvement, total annual energy

consumption is 8,365,667 kWh, saving 0.8% of

electricity about reduction of 6,780 USD. Since cost

of this improvement is 92,746 USD (total glass area

is 2395.94 m

2

and cost is 38.7 USD/m

2

), the return

on investment (ROI) is 13.7 years.

Measure 5: The original lighting systems for

existing building using T-8 fluorescent lamps are

replaced by T-5 fluorescent lamps. Therefore, by

this energy saving measure, the average lighting

density in all spaces will be 0.85 times of the

original lighting density. After this improvement,

total annual energy consumption is 8,112,018 kWh,

saving 3.8% of electricity about reduction of 31,326

USD. Since cost of this improvement is 222,161

USD, the return on investment (ROI) is 7.1 years.

Measure 6: High-performance appliances are

applied to reduce energy consumption of internal

electrical equipment. By this measure, energy

consumption of internal electrical equipment is

estimated to be 0.94 times of original one. If this

improvement is conducted, total annual energy

consumption will be 8,300,822 kWh, saving 1.6 %

of electricity about reduction of 13,054 USD. Since

cost of this improvement is 70,000 USD, the return

on investment (ROI) is 5.36 years.

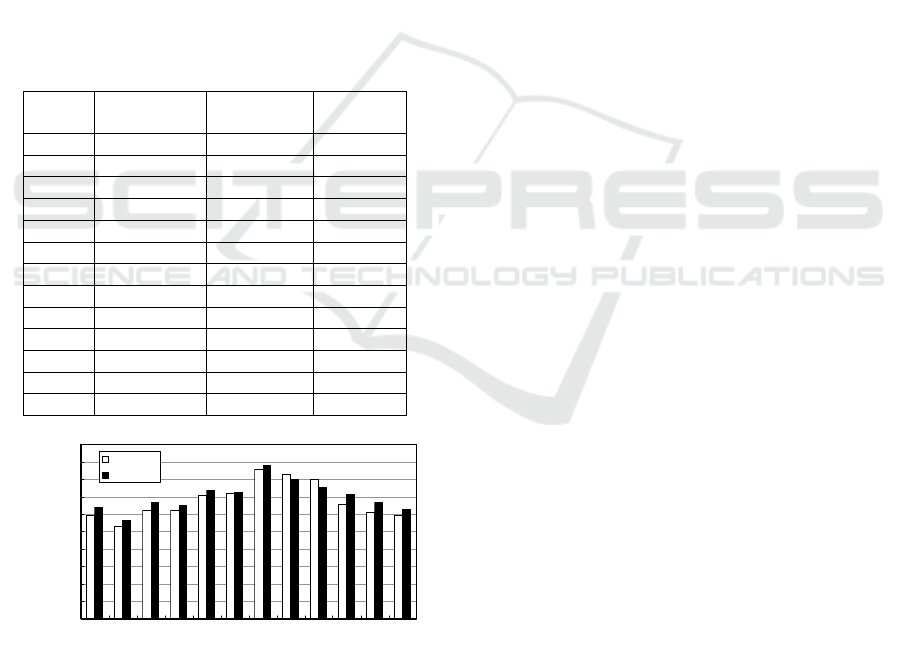

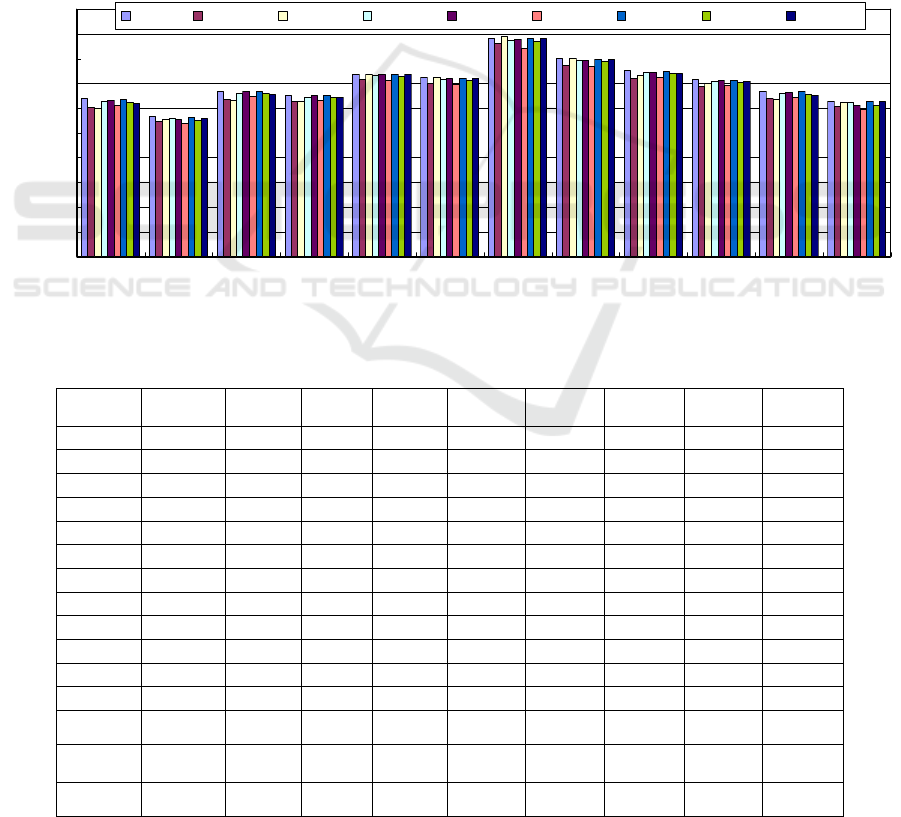

Figure 11: Simulation results of energy saving measures and comparison with baseline data.

Table 5: Results of energy saving measures.

Month

Baseline

(MWh)

Measure

1(MWh)

Measure

2(MWh)

Measure

3(MWh)

Measure

4(MWh)

Measure

5(MWh)

Measure

6(MWh)

Measure

7(MWh)

Measure

8(MWh)

1 638.17 605.07 598.83 628.38 630.55 611.38 636.33 624.65 621.67

2 566.94 544.17 554.79 558.89 554.14 540.88 565.18 553.55 560.57

3 669.20 636.65 632.63 660.16 667.35 647.42 667.89 659.46 654.75

4 653.53 624.92 627.20 646.13 651.03 633.43 652.22 643.97 643.18

5 739.28 716.11 736.84 732.91 736.11 713.28 737.91 728.77 736.13

6 723.31 701.41 725.10 716.68 719.20 697.67 721.97 713.00 721.03

7 881.72 859.65 889.26 874.86 877.68 840.54 880.37 871.29 879.43

8 799.62 775.21 800.33 792.46 794.21 769.42 798.22 788.71 796.02

9 752.19 722.16 733.26 743.80 745.46 724.79 750.84 741.66 740.47

10 715.40 686.17 699.36 709.06 711.67 691.73 714.05 705.13 709.56

11 668.03 637.07 635.45 659.73 666.20 645.88 666.76 658.57 653.79

12 628.32 606.59 622.48 622.55 612.08 595.60 626.08 612.08 625.89

Total 8435.72 8115.16 8255.52 8345.62 8365.67 8112.02 8417.82 8300.82 8342.48

Energy

saving (%)

-- 3.8 2.1 1.1 0.8 3.8 1.6 0.2 1.11

ROI (year) -- 2.6 0 0 13.7 7.1 5.36 37.3 0

0

100,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

123456789101112

Month

Energy consumption (kWh)

Baseline Measure 1 Measure 2 Measure 3 Measure 4 Measure 5 Measure 6 Measure 7 Measure 8

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

156

Measure 7: This measure is to improve the fan

efficiency in the ventilation systems from 0.6 to 0.7.

If this improvement is conducted, total annual

energy consumption will be 8,417,819 kWh, saving

0.2% of electricity about reduction of 1,732 USD.

Since cost of this improvement is 64,516 USD, the

return on investment (ROI) is 37.3 years.

Measure 8: The temperatures of regular spaces

such as offices, lobby, outpatient clinic and general

wards inside the hospital building are increased from

25

o

C to 26

o

C. The room temperatures of special

spaces remain unchanged. Therefore, by this energy

saving measure, energy consumption will be

8,342,484 kWh, saving 1.11% of electricity about

reduction of 9,022 USD. Since cost of this

improvement is 0 USD, the return on investment

(ROI) is 0 years.

4 CONCLUSIONS

In this study, the building energy software

EnergyPlus was used to calculate annual energy

consumptions of the hospital building under various

energy saving measures. The feasibilities of energy

saving measures have been evaluated in terms of

annual savings and pay-back period of the

investment. The pay-back periods of the investment

of energy saving measures such as replacement of a

high-performance chiller of 250 RT, increasing

outlet chilled water temperature of chillers by 1

o

C,

decreasing inlet cooling water temperature of

chillers by 1

o

C, and increasing room temperature of

regular spaces by 1

o

C are less than 5 years, which

are recommended to implement first. By simulations,

those analyses could be beneficial to establish a

feasible retrofit plan for energy performance of this

hospital building.

ACKNOWLEDGEMENTS

The authors would like to thank the Bureau of

Energy of the Ministry of Economic Affairs of

Taiwan for sponsoring this research work.

REFERENCES

Ascione, F., Bianco, N., De Masi, R.F., de Rossi, F., De

Stasio, C., Vanoli, G.P., 2016. Energy audit of health

care facilities: dynamic simulation of energy

performances and energy-oriented refurbishment of

system and equipment for microclimatic control.

American Journal of Engineering and Applied

Sciences, in press.

ASHRAE, 2011. Procedures for commercial building

energy audit.

Bonnema, E., Studer, D., Parker, A., Pless, S., Torcellini,

P., 2010. Large hospital 50% energy savings: technical

support document. National Renewable Energy

Laboratory, U.S. Department of Energy.

Bureau of Energy of Taiwan, 2015. Energy audit annual

report for non-productive industries.

Chen, P.H., Kan, M.S., 2014. Integrating energy

simulation in energy saving analysis of Taiwan’s

green hospital buildings. In 2014 Proceedings of the

31

st

International Symposium on Automation and

Robotics in Construction and Mining, Sydney,

Australia. pages 561-567.

Rahman, M.M., Rasul, M.G., Khan, M.M.K., 2010.

Energy conservation measures in an institutional

building in sub-tropical climate in Australia. Applied

Energy, 87: 2994-3004.

Saipi, N., Schuss, M., Pont, U., Mahdavi, A., 2014.

Comparison of simulated and actual energy use of a

hospital building in Austria. Advanced Materials

Research, 899: 11-15.

Shchuchenko, V., Lie, B., Harsem, T.T., 2013. Influence

of building form of hospital on its energy

performance. European Scientific Journal, 3: 286-295.

Taipower Company, 2011. Report of electricity

development of Taipower company in Taiwan.

U.S. Department of Energy, 2014. EnergyPlus engineering

reference, version 8.1.

An Assessment of Feasibility of Energy Saving Measures Applied for a Hospital

157