Simulation of Copper Thin Film Thickness Optimization for Surface

Plasmon using the Finite Element Method

Tanaporn Leelawattananon

1

, Kitsakorn Locharoenrat

1

and Suphamit Chittayasothorn

2

1

Department of Physics, Faculty of Science, King Mongkut’s Institute of Technology Ladkrabang, Thailand

2

Department of Computer Engineering, Faculty of Engineering, King Mongkut’s Institute of Technology Ladkrabang,

Bangkok, Thailand

Keywords: Surface Plasmon Wave, Kretschmann Configuration, Finite Element Method, Simulation.

Abstract: This paper presents a computer simulation of optical activations based on the Kretschmann configuration

using a prism for the observation of the surface plasmon wave. This is according to the condition of the

dispersion relation. The analysis of the electric field of the surface plasmon wave which appears at the

interface between the metal layer and the air layer is done by using the Finite Element Method (FEM). The

simulation is performed using the COMSOL Multiphysics software which supports the FEM. The objective

of our experiment is to find the most suitable thickness of the metal thin film which is most suitable for the

surface plasmon excitation when activated by 632.5 nm red laser light source. The red laser light source is

commonly available and also very economical. The metal used in our work is copper which is an

economical noble metal and gives better conductivity than gold. The findings from the simulation will be

used in the future high precision physical experiments. The outcome of this research project, the surface

plasmon wave on copper thin film, is expected to be used in bio-molecular detectors or high speed THz

communications.

1 INTRODUCTION

During the past decades, the need to verify and

process data by using optics have been growing and

developing rapidly. Optical sensors which are able

to detect bio-molecular objects such as DNA protein

are widely available. They have both sensitivity and

size advantages over non-optical sensors (Anker et

al., 2008). These optical sensors use the Surface

Plasmon Resonance (SPR) principle which works by

the optical excitation at the interface between the

metal thin film layer and dielectric layer (or the test

sample layer). The most widely used noble metals

for the metal layer is gold. Gold has less oxidation

and is very resistant to atmospheric contaminants

(G. Boisde, A. harmer, 1996). However, gold is very

expensive. It has been recently found that copper has

better conductivity than gold. It is also cheaper. The

main disadvantage of copper is the ease of having

oxidation. However, copper is better in term of

diffusion. Copper does not diffuse into the silicon

substrate when gold does. Copper is therefore used

in the standard silicon manufacturing process such

as CMOS technology (G.V. Naik, et al., 2013).

Furhermore, there is a research result which reports

that copper is an excellent plasmonic material (P.

Robusto, R. Braunstein, 1981). Also, according to a

research work (V.G. Kravets, et al., 2014), the

application of Graphene layer over copper layer can

significantly reduce the oxidation; thus the copper

layer is slowly deteriorated and improves plasmonic

characteristic.

Recently, surface plasmon wave find

applications in high speed communications and high

frequency electronic technology since they have

frequencies in the THz ranges (H. Sakai et al.,

2016).

The thickness of the metal film has direct effects

to the excitation of the surface plasmon wave, both

from the consistency of the waves and the

amplitudes of the electric fields of the waves. In

order to find the optimum waves for the given metal

and the given optical source, this project models the

excitation using the Kretschmann configuration. We

also analyze the result electric field of the surface

plasmon wave which take place at the interface

between the metal thin film layer and the sample test

layer using the finite element method (FEM). We

intend to use the economical 632.5 nm red laser light

source with thin film copper. The COMSOL

188

Leelawattananon, T., Lorchalearnrat, K. and Chittayasothorn, S.

Simulation of Copper Thin Film Thickness Optimization for Surface Plasmon using the Finite Element Method.

DOI: 10.5220/0006395601880195

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 188-195

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Multiphysics software (COMSOL Inc., 2017) which

supports the FEM is employed.

2 THEORETICAL

BACKGROUNDS OF THE

SURFACE PLASMON

RESONANCE (SPR)

Surface plasmon waves or surface plasmon

polaritons (SPPs) are generated at the surface

between metal-dielectric interfaces when excited by

the incoming light with an appropriate frequency.

The excitation of surface plasmon waves can be

done by having light beams contact prisms and the

phase of the light at the metal-dielectric interface is

matched to the phase of the surface plasmon waves.

In the early years of the research in this area Otto

(Y. Suzuki et al., 1989) and Kretschmann (T.A.

Leskova et al., 2000) developed an experimental

optical excitation which created SPs waves by using

a prism and coated a metal thin film on the surface

of the prism. Attenuated total reflection (ATR) is a

technique to observe the plasmons. The reflected

light intensity are measured by changing the incident

angles of the incoming light to various degrees. At a

certain angle which is referred as the "resonance

angle", the reflected ATRs from the prism signifies

the light absorption by the electrons in the metal and

their resonance which in turn creates the surface

plasmon wave at the metal–dielectric interface.

Apart from this, there are also researches which use

the grating (A. Iadicicco et al., 2005) and optical

waveguides (Wei Du and Feng Zhao, 2014) for the

optical excitations of surface plasmons.

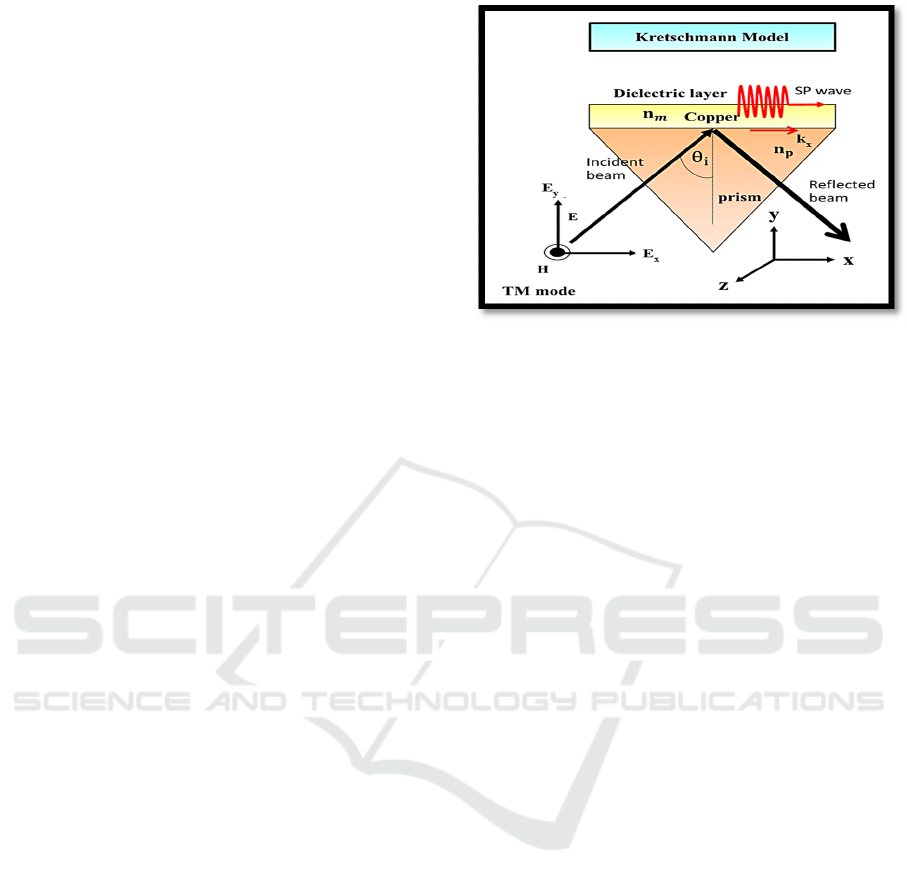

The Kretschmann method employs a detecting

microscope which moves to different positions to

give different angles as shown in Figure 1. When

the incoming light travels from the medium which

has higher refractive index to the medium which has

lesser refractive index, and the light impacts the

interface between the two medium with the angle

greater than the critical angle, the light will be

totally reflected. This phenomenon is called Total

Internal Reflection (TIR). The TIR creates a kind of

electromagnetic wave between the contact surfaces

of the two media called the evanescent

electromagnetic field. The minimum amount of the

total internal reflection is observed when the

incoming energy of the incident light is coupled onto

the flat metal. This is referred to as “attenuated total

reflection” (ATR).

Figure 1: Surface Plasmon excitation at the surface when

activated by light impact to the prism using the

Kretschmann’s configuration.

As shown in Figure 1, the TM-polarized incident

light impacts the prism and activates the excitation

of the surface plasmon waves at the interface

between the metal thin film and dielectric layer (air

layer). The wave vector of the light can be adjusted

to be equal to the wave vector of the surface

plasmon by launching it from the prism through the

metal thin film. The prism is a medium with a higher

refractive index than the metal film. Light moving in

the prism is reflected at the prism-metal layer

interface by means of total internal reflection. The

evanescent field of the reflected light at the prism-

metal interface penetrates into the metal. With the

appropriate thickness of the metal layer, the

evanescent wave reaches the metal-dielectric

interface (or metal-air interface). In the case that the

phase of the incoming light propagating in the prism

matches the phase of the surface plasmon waves, the

surface plasmon resonance is generated and surface

plasmon waves propagate along this metal-dielectric

interface. They are generated according to a certain

condition which depends on the incident angle and

the incident wavelength:

k

k

k

n

sin

θ

(1)

k

sp

is the wave vector of surface plasmon waves

k

x

is the wave vector of the incoming light

n

p

is the refractive index of the prism

θ is the resonance angle ( ATR angle)

According to the equation, the energy and

momentum of the incoming light which impact the

prism are transfered to the electrons group of the

metal thus excites surface plasmon wave. Dispersion

relation of surface plasmon wave is shown in the

following equation:

Simulation of Copper Thin Film Thickness Optimization for Surface Plasmon using the Finite Element Method

189

k

k

ω

c

ε

ε

ε

ε

(2)

When the dispersion relation is combined with

the excited condition, it is found that the minimum

incident angle of the incoming light is:

θ

sin

1

n

ε

ε

ε

ε

(3)

If the wavelength of the incident light and the

relative permittivity of the metal layer are known,

the suitable incident angle which activates the

surface plasmon wave can be calculated.

3 THE SIMULATED

EXPERIMENTS

The excitation of the surface plasmon resonance

phenomenon needs to have the k-vector of the

activating light which impacts the prism equals to

the k-vector of the surface plasmon wave (SP wave)

at the interface between the metal thin film layer and

the air layer. We therefore simulate the light

activation using the Kretsckmann’s configuration

which is a relatively easy to implement activation

method. A prism with high refractive index and

coated with copper thin film is implemented as

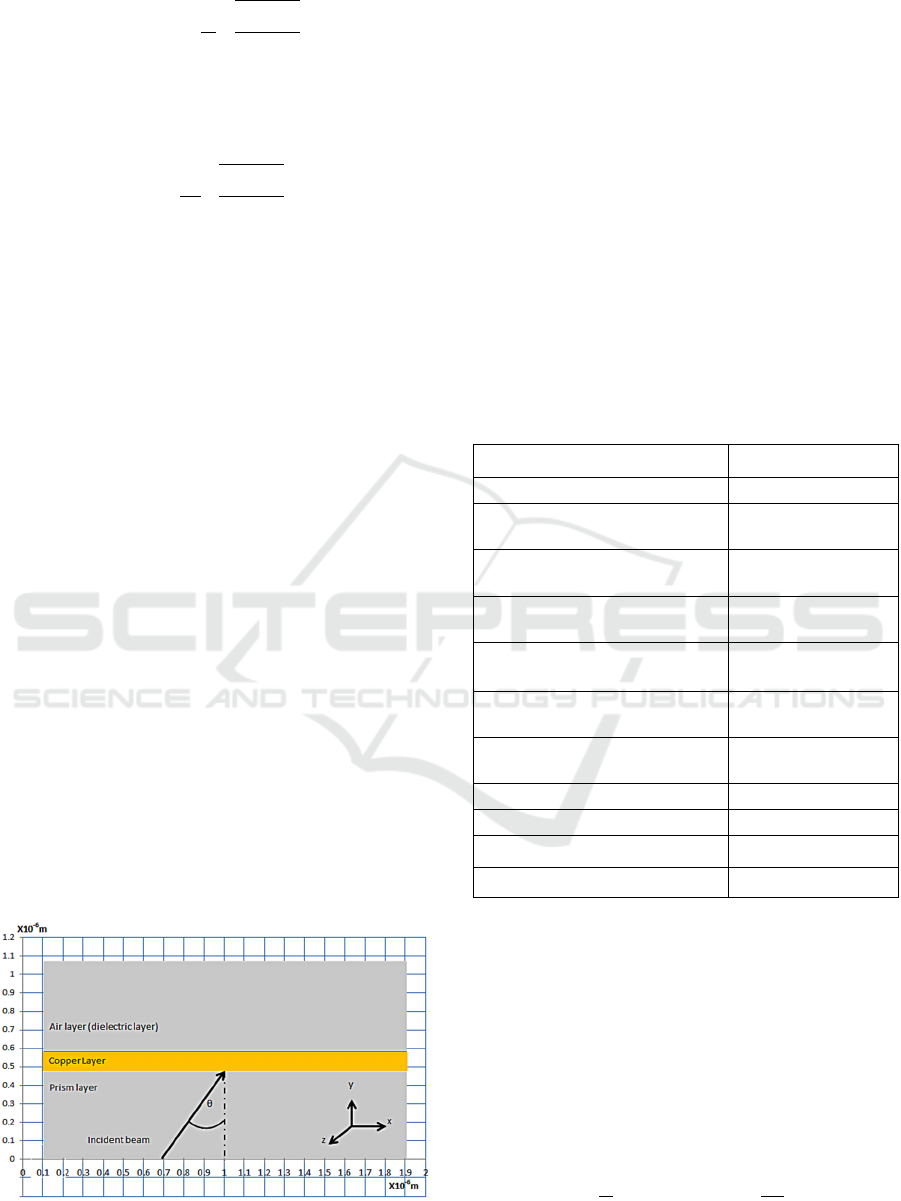

shown in Figure 2. Electric fields of the surface

plasmon wave at the copper-air interface (metal-air

interface) are analyzed using the finite element

method (FEM). The COMSOL Multiphysics

software is deployed.

Parameters as shown in the Table 1 are set

according to the dispersion relation. This is to make

the k-vector of the p-polarized (TM mode) light

which impacts the prism equals to the k-vector of the

Figure 2: The optical excitation of the Kretschmann’s

configuration.

SP wave. When the light penetrates into the metal

thin film, free electrons groups in the metal are

coupling with the activating light and vibrate

resonantly with the frequency of light. This

phenomenon is called the surface plasmon resonance.

When the incident angle of the light is equal to

the resonance angle (also called the Attenuated Total

Reflection angle θ

ATR

), the parallel component of k-

vector of the incoming light is matched to the

parallel k-vector of the surface plasmon. At this

stage, the light transfers its energy to electrons

groups in the metal and becomes surface plasmon

energy. There is no reflect back of the light from the

prism. The evanescent wave at the metal-dielectric

layer couples to the surface plasmon which results in

the propagation of the surface plasmon wave along

to the metal-air interface as previously mentioned.

Table 1: Important parameters of each medium.

Parameter name Value

Refractive index of Air 1

Refractive index of Prism

(BK7)

1.5151

Relative permittivity of Prism

(Real part)

2.2955

Relative permittivity of Prism

(Imaginary part)

3.6715e-8

Refractive index of Copper

Thin film

0.30730

Relative permittivity of Copper

(Real part)

-11.681

Relative permittivity of Copper

(Imaginary part)

2.1090

Incident wavelength of Light 632.5 nm

Power of Light 1 W

kx

k0*n

prism

*sin(θ)

ky

k0*n

prism

*cos(θ)

In this simulation project, the incident angles are

changed gradually 1 degree at a time from 30 to 80

degrees. Corresponding surface resonance waves

which are activated by the light are observed. The

light source is the TM mode laser which has the

wavelength of 632.5 nm with a power of 1 W. The

simulated thickness of the copper layer varies from

20 nm, 40 nm, 60 nm, 80 nm to 100 nm.

Electromagnetic wave propagation as described

by the Maxwell’s wave equation (in frequency

domain) is as follows:

E

k

ε

E0

(4)

where

is the

relative permittivity of material

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

190

E is the

electric field equation

is the

wave vector in free space

It is a differential form equation. We use this

equation in the RF module of the Comsol

Multiphysics for analyzing the amount of the

electromagnetic field at the interface between the

thin metal film and the air.

Moreover, we specify Floquet boundary

condition both at the left surface and the right

surface of every layer in this model to ensure the

symmetry of the electric field along and parallel to

the interface in the x-y plane.

We also determine the Port boundary condition

of this model by using the

bottom boundary as

Active Port for light impact. The

input power of the

laser source is set to

1 Watt. The top boundary is

used as the Passive Port

which allow light to be

transmitted through without reflections.

For the meshing of the 2D geometry in this

research work, We partition

the subdomain into

triangular mesh elements. The resolution of the

mesh is set to be extra fine.

For the impact angle from 30 to 80 degrees, we

use the Parametric Sweep to be

range(alpha_min,alpha_step,alpha_max)

where

alpha_min

is equal to

30

degrees, alpha_max is

equal to

80 degrees, and alpha_step is 0.01 degrees.

After specifying physical quantities such as

material properties, constraints, parameter,

COMSOL Multiphysics is then

internally compiles

all related

PDE equations automatically using the

finite element analysis. Multiple solvers are used

together with adaptive meshing and error control

which has been previously specified. Results can be

observed from the graphical user interface.

4 RESULTS

In the first analysis using the finite element method

on the COMSOL Multiphysics software, the TM-

polarized incident light with the 632.5 nm

wavelength impacts the prism with different impact

angles. We found that when the surface plasmon

resonance phenomenon takes place at the interface

between the air layer and the copper layer with the

thickness of 20 nm, 40 nm, 60 nm, 80 nm, and 100

nm, there are surface plasmon waves when the

incident angle of the incoming light is 44.8 degrees.

The incident angle and the light’s wavelength

correspond with the dispersion relation equation.

However, the characteristics of the electric field of

surface plasmon wave are different when the

thickness of the thin copper film layer is changed.

When the surface plasmon resonance

phenomenon is taking place at the contact point

between the metal thin film and the air, if the

thickness of the metal film is suitable, and the

impact angle of the TM mode light is suitable, the

simulated electric field at the interface will be

clearly seen with high amplitude. This demonstrates

that the light reflectance

approaches the minimum or

even zero. Such an angle is called the

resonance

angle.

The resonance angel can be shifted if the

dielectric layer is changed to other materials such as

biomolegular sustances. The resonance angle is

therefore can be applied to checked the existence of

bio-molecular DNA.

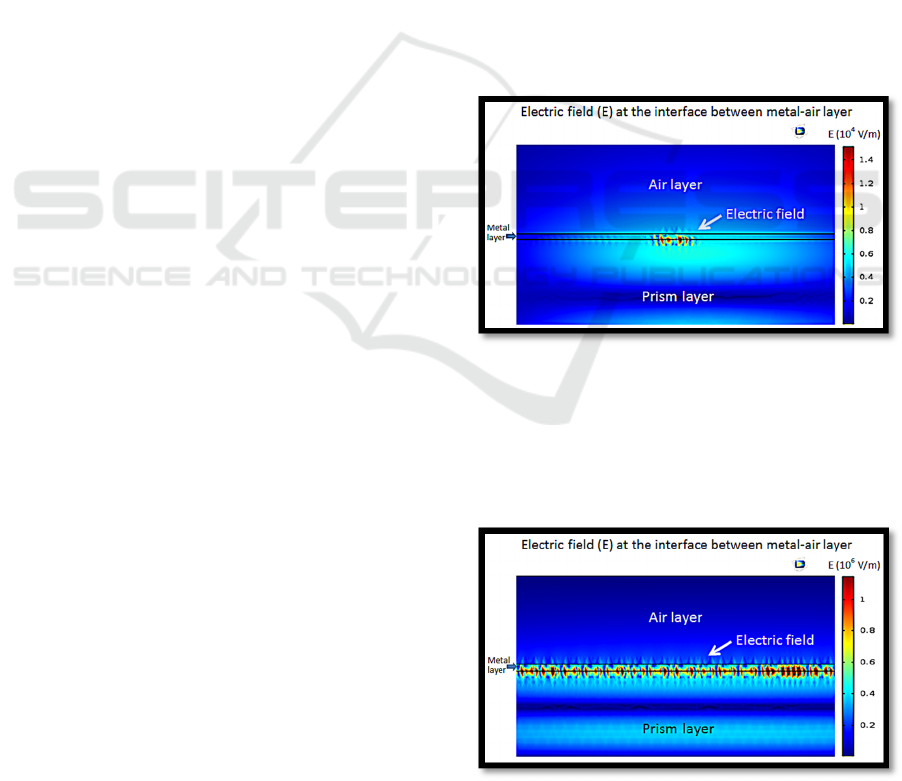

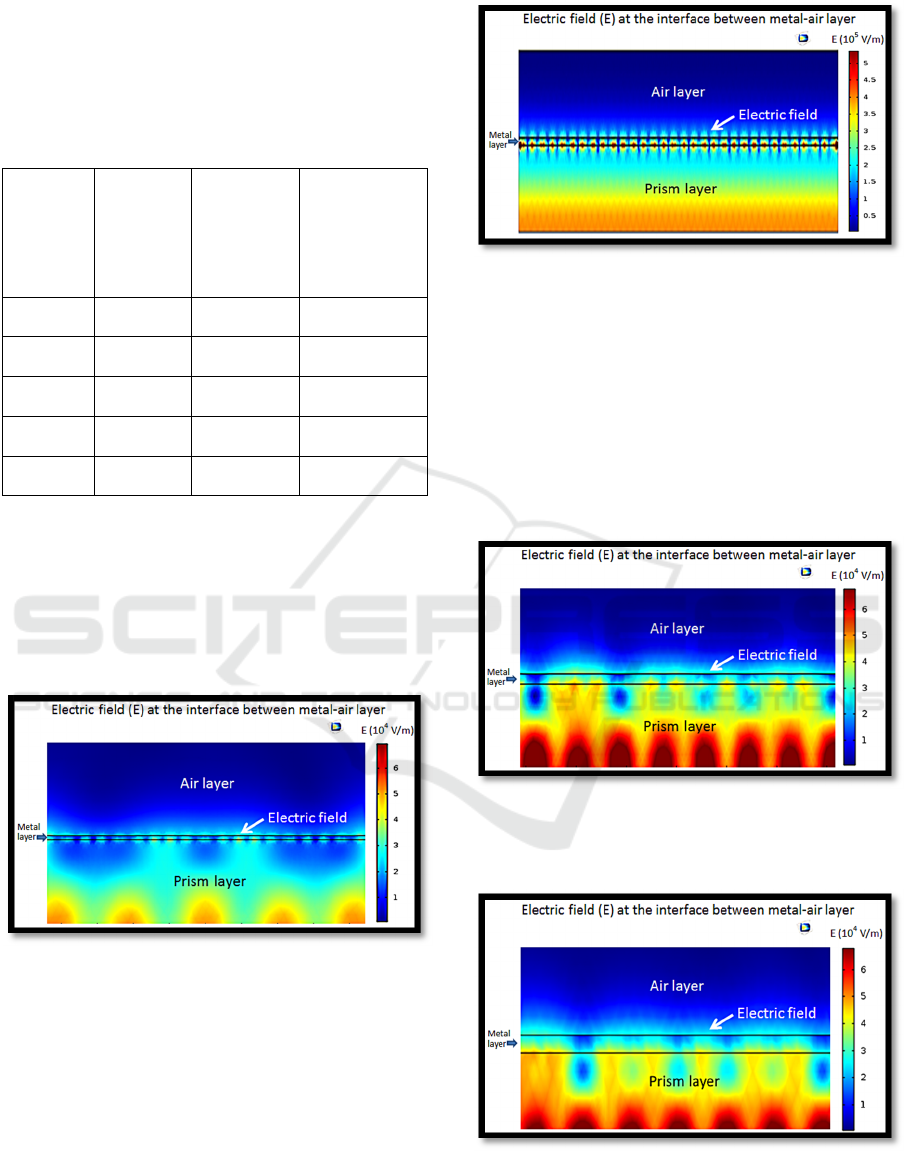

When the copper thin film thickness is 20 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The average amplitude is 5.1x10

4

V/m as shown in

Figure 3. The electric field that occurs does not

show clear patterns and does not seem to be

consistent along the copper-air interface.

Figure 3: Electric fields of surface plasmon wave at the

interface between the 20 nm copper film and the air.

When the copper thin film thickness is 40 nm, it

is found that the electric field between the copper-air

interface has high amplitudes. The average

amplitude is 2.7x10

5

V/m as shown in Figure 4. The

Figure 4: Electric fields of surface plasmon wave at the

interface between the 40 nm copper film and the air.

Simulation of Copper Thin Film Thickness Optimization for Surface Plasmon using the Finite Element Method

191

electric field that occurs show clearer patterns and

consistent along the copper-air interface.

When the copper thin film thickness is 60 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The average amplitude is 2.2x10

4

V/m as shown in

Figure 5. The electric field that occurs show unclear

patterns and not consistent along the copper-air

interface.

Figure 5: Electric fields of surface plasmon wave at the

interface between the 60 nm copper film and the air.

When the copper thin film thickness is 80 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The average amplitude is 2.9x10

4

V/m as shown in

Figure 6. The electric field that occurs show unclear

patterns and not consistent along the copper-air

interface.

Figure 6: Electric fields of surface plasmon wave at the

interface between the 80 nm copper film and the air.

When the copper thin film thickness is 100 nm, it

is found that the electric field between the interface

of the copper film and the air still has very low

amplitudes. The average amplitude is 1.1x10

4

V/m

as shown in Figure 7. However, the electric field that

occurs does not show clear patterns and is not

consistent along the copper-air interface. The

patterns can not be used to identify if they are

surface plasmon wave at the interface.

Figure 7: Electric fields of surface plasmon wave at the

interface between the 100 nm copper film and the air.

A graph is plotted to show the relationship

between the maximum amplitude of the electric field

at the copper-air interface and the thickness of the

copper film. The graph shows a concave downward

pattern. The highest point of the graph is when the

thickness of the copper film is 40 nm. This is the

best point when activated by the 632.5 nm light

source.

Figure 8: The graph which shows relationships between

the maximum amplitude of the electric field at the copper-

air interface and the thickness of the copper thin film.

The next step is to find the most suitable impact

angle for the given light source. We then change the

impact angle parameter to other values around the

44.80 degrees (this is the degree according to the

dispersion relation equation) and keep the impact

light TM mode to have the wavelength of 632.5 nm

to find a suitable impact angle for best surface

plasmon resonance phenomenon. The simulated

observable surface plasmon wave with highest

amplitude at the interface between the copper thin

film and the air are considered. Table 2 shows the

observation results.

After having the first results, the second analysis

is conducted. The finite element method on the

COMSOL Multiphysics software is still employed.

The wavelength of the TM-polarized incident light is

changed to be 785 nm with a power of 1 W and the

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

192

incident angle is now changed to be 44 degrees. The

thickness of the thin copper film are 20 nm, 40 nm,

60 nm, and 80 nm. The simulated electric field

patterns and amplitudes are observed.

Table 2: The incident angles (ϴ

ATR

) which are suitable for

different copper thin film thickness.

Copper

thin film

thickness

(nm)

Optimized

incident

angle

(ϴ

ATR

,

degrees)

Δϴ

(degrees)

E

avg

(V/m)

20 44.14 0.66 4.4x10

4

40 44.80 0 2.7x10

5

60 44.84 0.04 2.1x10

4

80 44.86 0.06 1.4x10

4

100 45.88 1.08 1.2x10

5

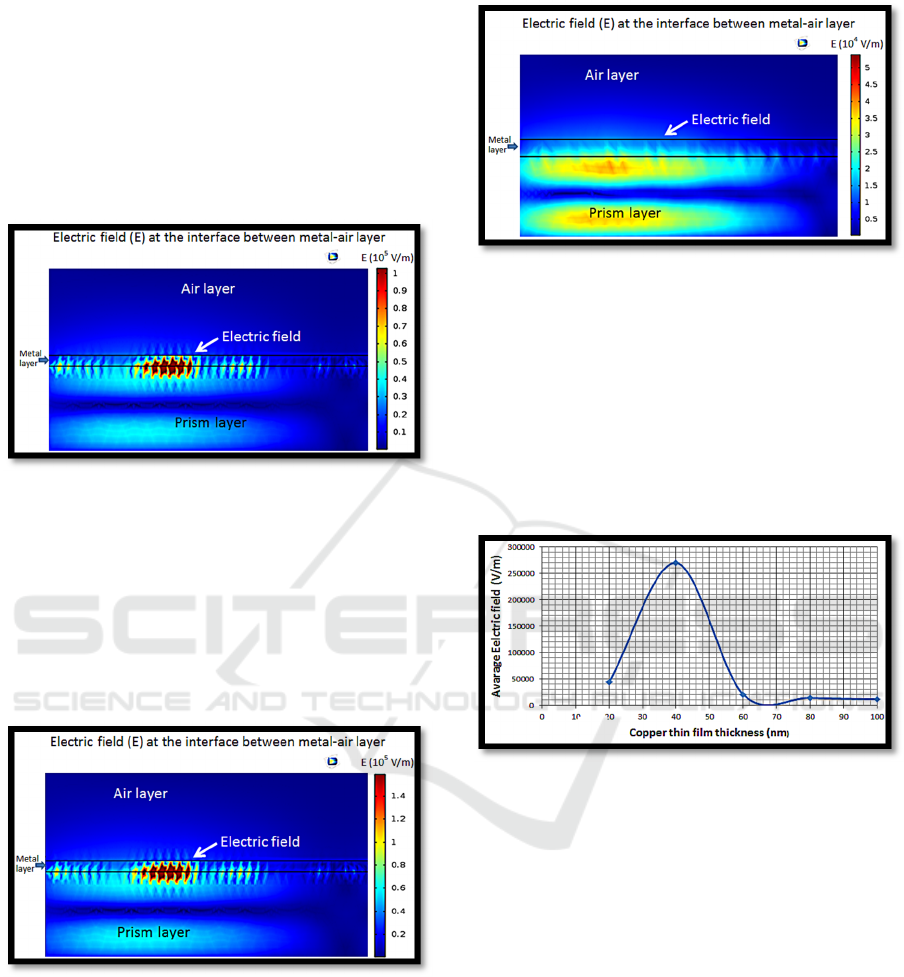

When the copper thin film thickness is 20 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The average amplitude is 2.8.x10

4

V/m as shown in

Figure 9. The electric field that occurs show clear

patterns and consistent along the copper-air

interface.

Figure 9: Electric fields at the interface between the 20 nm

copper film and the air when the light has 785 nm

wavelength.

When the copper thin film thickness is 40 nm, it

is found that the electric field between the interface

of the copper film and the air has high amplitudes.

The average amplitude is 2.5x10

5

V/m as shown in

Figure 10. The electric field that occurs show clear

patterns and consistent along the copper-air

interface.

Figure 10: Electric fields at the interface between the 40

nm copper film and the air when the light has 785 nm

wavelength.

When the copper thin film thickness is 60 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The average amplitude is 2.5x10

4

V/m as shown in

Figure 11. The electric field that occurs show

unclear patterns and not consistent along the copper-

air interface.

Figure 11: Electric fields at the interface between the 60

nm copper film and the air when the light has 785 nm

wavelength.

Figure 12: Electric fields at the interface between the 80

nm copper film and the air when the light has 785 nm

wavelength.

Simulation of Copper Thin Film Thickness Optimization for Surface Plasmon using the Finite Element Method

193

When the copper thin film thickness is 80 nm, it

is found that the electric field between the interface

of the copper film and the air has low amplitudes.

The maximum amplitude is 2.7x10

4

V/m as shown

in Figure 12. The electric field that occurs show

unclear patterns and not consistent along the copper-

air interface.

From the simulation results, it is found that the

thickness of the thin copper film has direct effect to

the occurrence of the surface plasmon waves. The

thickness of 40 nm is considered the best thickness

for the activation with the 632.5 nm wavelength. It

yields very clear and consistent surface plasmon

waves pattern. It also has the highest electric field

amplitude at the copper-air interface.

Our analysis results which are obtained by using

the finite element method, give similar results to (F.

Atida Said et al., 2016) which uses the finite

difference method when the incident light source has

785 nm wavelength. That is, when the light source

with the 785 nm wavelength is used, the best copper

thin film thickness is 40 nm. It gives high and

consistent surface plasmon wave amplitudes at the

copper-air interface.

5 CONCLUSIONS

Recently, researches in the area of plasmonics have

been highly active. There are applications in various

areas such as biomedical engineering where SPR

devices are used as sensors to detect the presence of

DNA molecules which are adhered to metal

surfaces. Such adhesion layer change the local

refractive index which results in the shift of the

resonance angle of the incoming light. Moreover, the

electric field of the plasmon wave with high

applitudes can be used to generate second ( or third)

harmonics due to surface plasmon coupling

(E.M.

Kim et al., 2005) (H.J. Simon et al., 1974). This

could identify the

structural information of bio-

molecular substances

. Plasmons also have been

considered as a means of transmitting information

on computer chips. This is another potential

application in technology. Plasmons support

frequencies in the THz range. This would solve the

data loss problem of conventional wires which have

the GHz transmissions loss problem. In this project,

we try to find the suitable thickness of the copper

film which creates the surface plasmon resonance at

the copper-air interface when the light source is the

632.5 nm TM mode. This light source is an

economical red laser which can be easily found

commercially. It is cheaper and easier to find than

the green laser and blue laser lights. Based on the

finite element method, the results suggest that the

copper thin film with the thickness of 40 nm is the

most suitable one for the surface plasmon resonance

using the Kretschmann configuration. The simulated

electric field amplitude at the copper-air interface is

high and consistent along the interface when the

632.5 light is applied which also means that the best

surface plasmon resonance is generated at this

metal-air interface.

It is very likely that if a

Graphene film is applied over the copper thin film

with the thickness of 40

nm, the plasmonic

characteristics will be positively improved; thus

improves the copper based

surface plasmon sensors

which are to be developed.

REFERENCES

Anker, J. N., Hall, W. P., Lyandres, O., Shah, N. C., Zhao,

J. and Van Duyne, R. P., 2008. Biosensing with

plasmonic nanosensors. In Nature Materials 7, 442-

453.

G. Boisde, A. Harmer, 1996. Chemical and biochemical

Sensing with Optical Fibers and Waveguides. In

Artech House: Boston, USA.

G. V. Naik, V. M. Shalaev, A. Boltasseva, 2013.

Alternative Plasmonic Materials: Beyond Gold and

Silver. In Advance Materials, 25, 3264-3294.

P. Robusto, R. Braunstein, 1981. Optical measurements of

the surface plasmon of copper. In Phys. Stat. sol. (b)

107, 443-449.

V. G. Kravets, et al., 2014. Graphene-protected copper and

silver plasmonics. In Scientific Reports 4, 5517, 1-7.

H. Sakai, S. Okahisa, Y. Nakayama, K. Nakayama, M.

Fukuhara, Y. Kimura, Y. Ishii, M. Fukuda, 2016.

Plasmonic and electronic device-based integrated

circuits and their characteristics. In Solid-State

Electronics(125), 240-246.

COMSOL Inc., 2017. COMSOL Multiphysics® The

Platform for Physics-Based Modeling and Simulation.

In Website: https://www.comsol.com/comsol-

multiphysics.

Y. Suzuki, S. Shimada, A. Hatta, W. Suëtaka, 1989.

Enhancement of the IR absorption of a thin film on

gold in the otto ATR configuration. In Surface Science

Letters( 219), L595-L600.

T. A. Leskova, M. Leyva-Lucero, E. R. Méndez, A. A.

Maradudin, I.V. Novikov, 2000. The surface enhanced

second harmonic generation of light from a randomly

rough metal surface in the Kretschmann geometry. In

Optics Communications(183), 529-545.

A. Iadicicco, A. Cusano, S. Campopiano., A. Cutolo and

M. Giordano, 2005. Thinned fiber Bragg grating as

refractive index sensors. In IEEE Sensors Journal

5(6), 1288-1295.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

194

Wei Du, Feng Zhao, 2014. Surface plasmon resonance

based silicon carbide optical waveguide sensor. In

Materials Letters(115), 92–95.

F. Atida Said, P. Susthitha Menon, M. Nuriman Nawi, A.

Md Zain , A. Jalar , B. Yeop Majlis, 2016. Copper-

graphene SPR-based biosensor for urea detection. In

IEEE International Conference on Semiconductor

Electronics (ICSE) , 264-267.

E. M. Kim et al., 2005, Surface –enhanced optical third-

harmonic generation in Ag island films. In Phys. Rev.

Lett. 95, 227402.

H. J. Simon, D. E. Mitchell, J. G. Watson, 1974 , Optical

second-harmonic generation with surface plasmons in

silver films. Phys.Rev. Lett. 33, 1531-1534.

Simulation of Copper Thin Film Thickness Optimization for Surface Plasmon using the Finite Element Method

195