Fuzzy Logic Control for Varied Inspection for Manufacturing Lead

Time Reduction

A Fuzzy Control Implementation of a Dynamic Inspection Technique to Reduce

Manufacturing Lead Time

Trishen Naidoo

1

, Anthony Walker

1

, Glen Bright

1

and Shaniel Davrajh

2

1

Mechanical Engineering, University of KwaZulu-Natal, Durban, South Africa

2

Mining Engineering and Mine Surveying, University of Johannesburg, Johannesburg, South Africa

Keywords: Fuzzy Logic Control, Manufacturing Lead Time, Quality Control.

Abstract: Varied inspection is an online dynamic inspection method where the amount of parts inspected can be changed

based on the quality of the part stream and characteristics of the production system. The research outlines the

development of a supervisory and distributed Fuzzy Logic Controller (FLC) to perform varied inspection.

The supervisory fuzzy controller was used to tune the weights of the rules used in the distributed fuzzy

controller that initiates the varied inspection in quality control systems. Simulation of a single-station

manufacturing cell showed that varied inspection had significantly reduced Manufacturing Lead Time (MLT)

through reduced inspection, which could help manufacturers handle fluctuating demands. The contribution of

the study was to illustrate the benefit of varied inspection through MLT reduction and to add flexibility to

control architectures for quality control systems to aid manufacturers meet demands.

1 INTRODUCTION

Recent trends towards Mass Customization (MC) had

led to the research and development of flexible

technologies to mass produce different products

within a product family (Fogliatto et al., 2012).

Global market trends have fuelled companies to adapt

to customers’ demands (Tsourveloudis, 2000).

Research had been focused on flexible fixtures,

flexible machining, supply chain coordination, MC

economics and scheduling however, there has been

minimal emphasis on Quality Control (QC) for high

variety manufacturing environments (Fogliatto et al.,

2012). QC was traditionally defined by Juran (1998)

as methods to produce products that were “free from

deficiencies”. Traditional QC techniques include

control charts, check sheets and sampling (Davrajh et

al., 2012). QC needed to be developed to handle

product variations while still ensuring that customers

receive products of acceptable functionality.

Traditional QC hinged upon statistical inference as

part variation was minimal, therefore only samples

were inspected to deduce the quality of the entire

product population (Davrajh and Bright, 2010).

Increased part variation poses challenges to QC as

new strategies require flexible inspection methods

(Brabazon and MacCarthy, 2007).

Varied inspection was investigated as a flexible

form of inspection for MC. Varied inspection was

defined by the authors as a QC strategy where the

frequency of inspection could be increased or

decreased based on the needs of the manufacturer.

Naidoo et al. (2016) illustrated that varied inspection

could be used in reducing Work-In-Process (WIP).

WIP reduction remains a goal in lean, agile and Just-

In-Time (JIT) manufacturing (Tsourveloudis, 2000),

(Tsourveloudis et al., 2007). A Fuzzy Logic

Controller (FLC) was used to perform the varied

inspection because it could handle imprecise inputs

while performing adequate control. The aim of the

research was to test the performance of varied

inspection on reducing Manufacturing Lead Time

(MLT) with a supervisory and distributed fuzzy

controller. MLT reduction warrants that parts spend

less time in processing thus ensuring robust response

to demands, which is a requirement for the successful

operation of MC. The motivation for this research

was to illustrate the advantages of varied inspection

by aiding a common performance metric such as

MLT reduction. The novelty lies in using QC to

regulate production for better responsiveness and

Naidoo, T., Walker, A., Bright, G. and Davrajh, S.

Fuzzy Logic Control for Varied Inspection for Manufacturing Lead Time Reduction - A Fuzzy Control Implementation of a Dynamic Inspection Technique to Reduce Manufacturing Lead Time.

DOI: 10.5220/0006395902070214

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 207-214

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

207

robustness to demands. Existing approaches to MLT

reduction rely on flow control techniques that

required mathematical models to predict MLT.

Varied inspection can be viewed as a flow control

technique however, it does not require mathematical

modelling because of the fuzzy implementation–

which is useful in complex manufacturing situations

where the models are difficult to acquire.

2 LITERATURE REVIEW

2.1 Varied Inspection for Quality

Control in Mass Customization

Varied inspection is an aperiodic inspection method

compared to traditional methods. The inspection

system may choose to inspect or not inspect parts as

they pass through production based on factors such as

part quality, supply/demand, WIP, MLT,

bottlenecking, starving or other needs of the

manufacturer (Naidoo et al., 2016). The research was

focused on part quality and MLT reduction, whereas

previous research done by Naidoo et al., (2016)

focused on WIP reduction. MLT reduction was

desired as parts provide no profit while they remain

unfinished and in production. Through reducing the

amount of time on inspection, parts spend less time in

production thus reducing lead time. Shorter lead time

ensures better robustness to manufacturers in

supplying demands. Table 1 shows common

characteristics of varied inspection in terms of

advantages and disadvantages (Naidoo et al., 2016).

Table 1: Characteristics of Varied Inspection.

Advantages Disadvantages

Appraisal costs are reduced

through reduced inspection.

Could allow defective parts to

move throughout the system.

Can be used to prevent

bottlenecking by

increasing/decreasing the

number of inspected

products.

May result in external failure

costs when products fail at the

site of the customer.

Over-inspection is reduced.

High average consequence

costs.

Reduced average MLT as

reduced inspection reduces

overall production time.

Reduced WIP as some parts

are sent through the

production without

inspection.

The significant advantage of varied inspection (as

compared to 100% inspection and acceptance

sampling) was that the inspection frequency was not

fixed – it could be adjusted to suit the production

requirements. Varied inspection could be

implemented as a solution to slow inspection that

affects production rates (Davrajh and Bright, 2010).

However, Groover (2014) stated that this type of

inspection yielded high average consequence costs.

2.2 Fuzzy Logic Control for Production

Systems and Varied Inspection

FLCs had been used in production systems to

improve control since the 1990s (Homayouni et al.,

2009). However, Azadegan et al., (2011) stated that

there was minimal FL applications in the field of QC.

Complex manufacturing environments are difficult to

analytically model and probability theory cannot be

used to solve all manufacturing issues, which was

why fuzzy set theory was supported for control over

production (Tsourveloudis, 2000), (Gien, 1999). A

FLC was used in this research as it could handle

imprecise inputs and does not require a model of the

system to control it (Naidoo et al., 2016). Classical

control methods require accurate mathematical

models for effective control- fuzzy control is a

heuristic control approach thus the complex task of

obtaining mathematical models are not required. A

great advantage of FLCs is that it represents an

extension of human logic and can be based on human

evaluations, therefore it can replicate how a human

expert would control a system (Tsourveloudis, 2000).

FLCs have learning capabilities and can be improved

with other computational tools such as neural

networks and Evolutionary Algorithms (EA)

(Homayouni et al., 2009). Research done by Naidoo

et al. (2016) showed that a FLC could be used to

perform varied inspection for the purpose of WIP

reduction. This research was to investigate the effects

of varied inspection on MLT, where fuzzy controllers

are “Mamdani-type” with rules in the form of (1).

IF X is A AND Y is B THEN Z is C

(RuleWeight)

(1)

X and Y are the inputs with A and B linguistic values

respectively, and Z is the output with C linguistic

values. Linguistic values are the fuzzy sets that

consist of membership functions (Ioannidis et al.,

2004). The “RuleWeight” determines the strength of

the rule with ‘1’ having the strongest weight. The

fuzzy controllers designed used minimum for “AND”

and the centroid method for defuzzification. The

controllers were designed with the Fuzzy Logic

Toolbox

®

in Simulink

®

.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

208

2.3 Supervisory and Distributed Fuzzy

Control in Production Systems

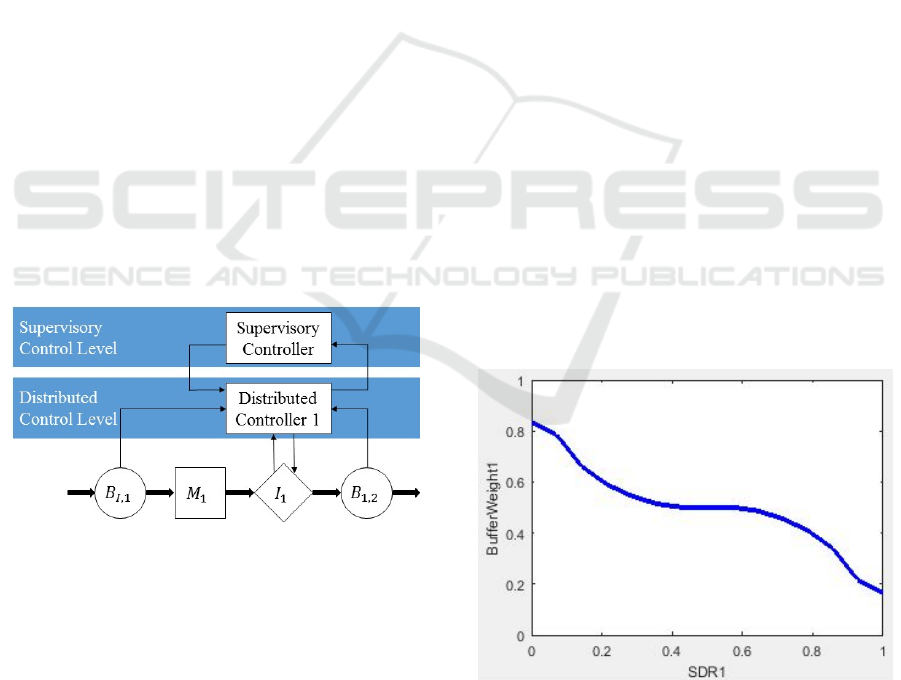

Ioannidis, Tsourveloudis and Valavanis (2004) stated

that production systems could be viewed as a

“network of machines/work-stations and buffers”.

The authors introduced another module to the

network which was the “inspection system”.

Inspection systems are strategically placed in the

production system based on quality checks after

processing, assembly and/or disassembly. Figure 1

shows the control architecture for the research that

implemented a two-level control system. This

research was restricted to a single-station

manufacturing cell, where a single machine performs

machining on raw material to produce a finished

product. From Figure 1, B

I,1

represents a buffer, M

1

represents machining cell and I

1

represents the

inspection system.

The supervisory fuzzy control was previously

used by Ioannidis, Tsourveloudis and Valavanis

(2004) for a production network where it tuned

parameters in multiple distributed fuzzy controllers

(that control the processing rates of individual

machines) for the purpose of WIP reduction. This

research was similar to the work performed by

(Ioannidis et al., 2004), however the amount of

inspection was varied instead of the machining

processing rate, and the inputs to the supervisory

fuzzy controller was supplied from the distributed

controller and not from the overall production rate.

Figure 1: Supervisory Control Architecture for Varied

Inspection.

3 SUPERVISORY AND

DISTRIBUTED FUZZY

CONTROLLER DESIGN

The supervisory controller was used to tune the

distributed controller. The supervisory controller

used the Defect Rates (DRs) of the part stream to

calculate the weights of the rules (within the

distributed controller) that are affected by the buffer

level input. The supervisory fuzzy controller used the

DR as an input to determine the rule weights of the

distributed fuzzy controller only when the buffer

levels were high, as high buffer levels slow down

production thus leading to high MLT. The purpose of

the supervisory fuzzy controller was to ensure that

MLT reduction would not become a higher priority

such that part quality would be significantly

compromised. An FLC approach to supervisory

control was used as it could effectively tune lower-

level controllers. The supervisory FLC could also be

easily extended for more objectives other than MLT

reduction.

3.1 Supervisory Fuzzy Controller

The supervisory controller used the DR inputs from

the distributed controller to determine the rule

weights that concern the buffer levels reaching

maximum capacity of the distributed controller. The

supervisory control contained the rules of the form:

IF SDR1 is DR

(k)

THEN BufferWeight1 is

BW

(k)

(2)

Where k was the rule number (1,2,3) , DR was the

fuzzy set of the “Sampled Defect Rate” (SDR1) input

with linguistic values DR = {High, Average, Low}

using three Gaussian membership functions and BW

was the fuzzy set of the BufferWeight1 output with

linguistic values BW = {Low, Medium, High}. All

rules have the same weight of 1 with a generated

curve relating the BufferWeight1 output to the SDR1

input shown in Figure 2.

Figure 2: Relationship between BufferWeight1 and

Sampled Defect Rate (SDR).

3.2 Distributed Fuzzy Controller

Three inputs were described for the distributed fuzzy

Fuzzy Logic Control for Varied Inspection for Manufacturing Lead Time Reduction - A Fuzzy Control Implementation of a Dynamic

Inspection Technique to Reduce Manufacturing Lead Time

209

controller i.e. DR, buffer level and batch size. The DR

was used as an input to ensure that the inspection

intensity was dictated by the quality of the parts.

Trapezoidal membership functions were used for the

DR input with the linguistic values DR =

{ExtremeHigh, ModerateHigh, Average,

ModerateLow, ExtremeLow}. Buffer level was used

as in input to prevent buffers from reaching maximum

capacity or becoming too low that starving occurs,

described by two Gaussian membership functions for

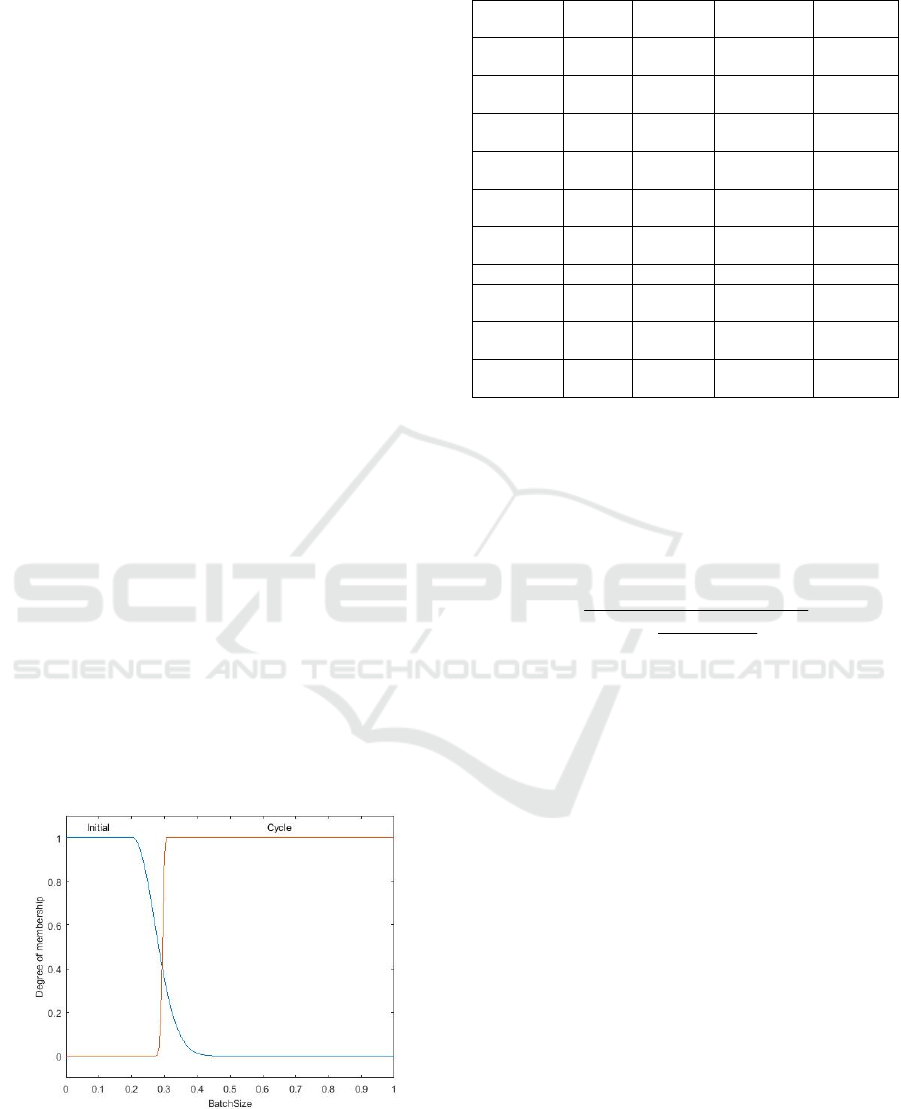

“Low” and “High”. The batch size input was used to

ensure that 100% inspection (screening) always

occurred at the beginning of the production as a

means of establishing the most accurate DR. The

amount of 100% inspection performed at the start was

determined by the Gaussian membership function

shown in Figure 3, where screening was performed

for the ‘Initial’ membership function and varied

inspection for the ‘Cycle’ membership function. The

“Initial” membership function ensures that the first

30% (pre-determined value) parts of the part stream

would be fully inspected. Ten rules were outlined for

the distributed controller, shown in Table 2. The

control actions were to perform 100% inspection at

the start of production, and to reduce the inspection

intensity where buffer levels were high – thus

reducing MLT. The prescribed rules ensured that

inspection intensity was always high at the start of

production, and that intensity should only be reduced

significantly when the DR input was also lowered to

reduce the occurrences of defective parts not being

inspected. The four rules associated with high buffer

levels (rules 4, 6, 8 and 10) have rule weights that

were set by the supervisory fuzzy controller. Only the

major rules were outlined as each input covered its

respective solution space.

Figure 3: Batch Size Membership Function.

Table 2: Distributed Fuzzy Controller Rule Set.

Defect

Rate

Buffer

Level

Batch

Size

Inspection

Intensity

Weight

0 0 Initial

Extreme

High

1

Extreme

High

0 Cycle

Extreme

High

1

Extreme

High

Low Cycle

Extreme

High

1

Moderate

High

High Cycle

Moderate

High

Buffer

Weight1

Moderate

High

Low Cycle

Moderate

High

1

Average High Cycle High

Buffer

Weight1

Average Low Cycle Medium 1

Moderate

Low

High Cycle Low

Buffer

Weight1

Moderate

Low

Low Cycle Medium 1

Extreme

Low

High Cycle Low

Buffer

Weight1

The output was the inspection intensity, which

was how much of the part stream to inspect. For

example, for an inspection intensity of 0.70 and 100

parts, 70 parts would be inspected and would be

Independent and Identically Distributed (IID)

throughout the 100 parts. IID implementation of the

inspection intensity was perform through (3):

]

]

)1(

1

log[

)]1(*)1,1(log[

[

Intensity

Intensityrand

floorp

(3)

Where p = 1 for “inspect” and p = 2 for “do not

inspect”. The “floor” function in Matlab

®

rounds

down towards negative infinity to the nearest integer,

“rand” was used for uniformly distributed random

number generation and “Intensity” was the inspection

intensity calculated from the distributed FLC.

Equation (3) was tested to determine how effective

the IID inspection could be performed. Multiple runs

showed that (3) was acceptable as a good realisation

of the inspection intensity when averaged out. An

averaging approach was used for the best realisation

of the inspection intensity with a sample size of 100

parts. Results between the actual intensity and the

averaged intensity were discussed in Section 5. From

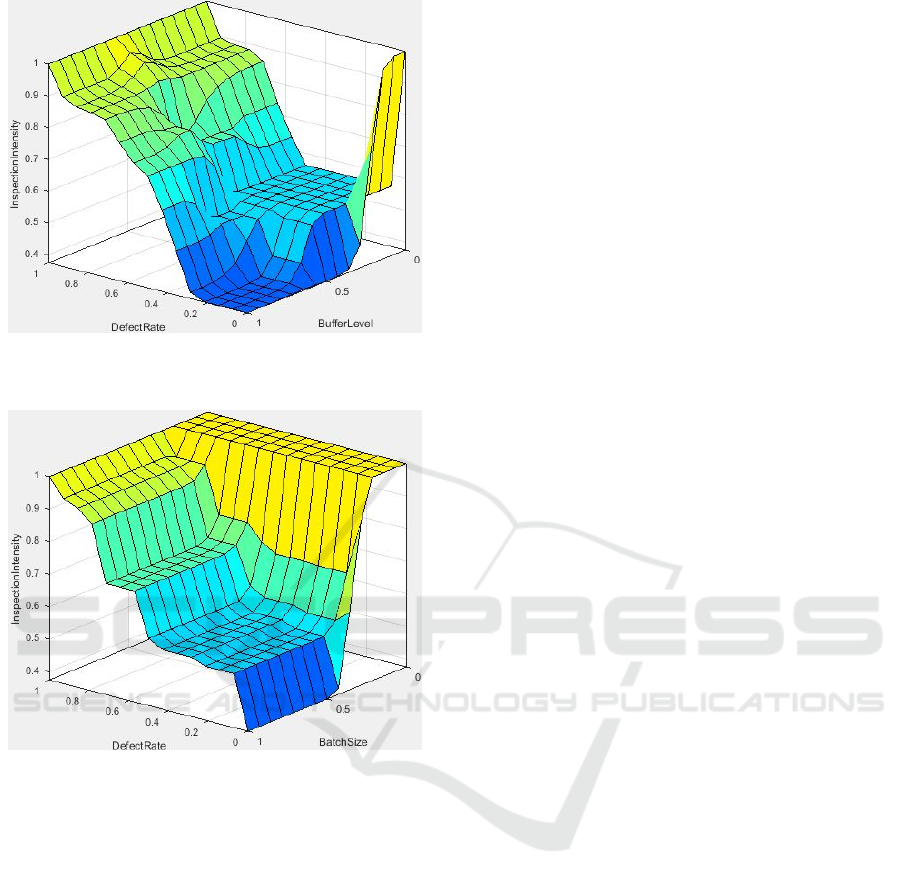

the rules in Table 2 and membership functions,

surfaces can be used to view the relationships

between the inputs and outputs. Figure 4 shows the

relationships between the DR and buffer levels on

inspection intensity. Figure 5 shows the relationship

between the DR and batch size on the inspection

intensity output. Yellow areas (lightly shaded)

indicate when inspection intensity was high and blue

areas (dark shaded) indicate low inspection intensity.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

210

Figure 4: Surface View of Distributed Fuzzy Controller for

Defect Rate and Buffer Level Inputs.

Figure 5: Surface View of Distributed Fuzzy Controller for

Defect Rate and Batch Size Inputs.

4 SIMULATION OF FUZZY

LOGIC CONTROLLERS IN

MANUFACTURING CELL

The supervisory and distributed fuzzy controllers

were implemented into a single-station

manufacturing cell, shown in Figure 1, to determine

the effects of varied inspection on MLT. From Figure

1, raw material arrived in buffer B

I,1

with an arrival

rate of 1 piece per time-unit (note the time-unit may

represent seconds, minutes, hours, days etc. as long

as consistency was kept). Buffers have a maximum

capacity of 10 storage spaces. Machine M

1

was

modelled to produce at capacity with a machining

time of 2 time-units per part. Inspection I

1

, if

performed, was 5 time-units. The “Poisson” random

distribution was used to simulate the quality of the

incoming parts, with a threshold range of 10% to

determine the parts that were conforming and non-

conforming. Nonconforming parts were removed

from the part stream. The distributed fuzzy controller

(that was tuned by the supervisory fuzzy controller)

used the prescribed inputs to calculate the inspection

intensity that was averaged out for IID realisation.

SimEvents

®

in Simulink

®

was used for discrete-event

simulation and the Fuzzy Logic Toolbox

®

was used

to design and tune the FLCs.

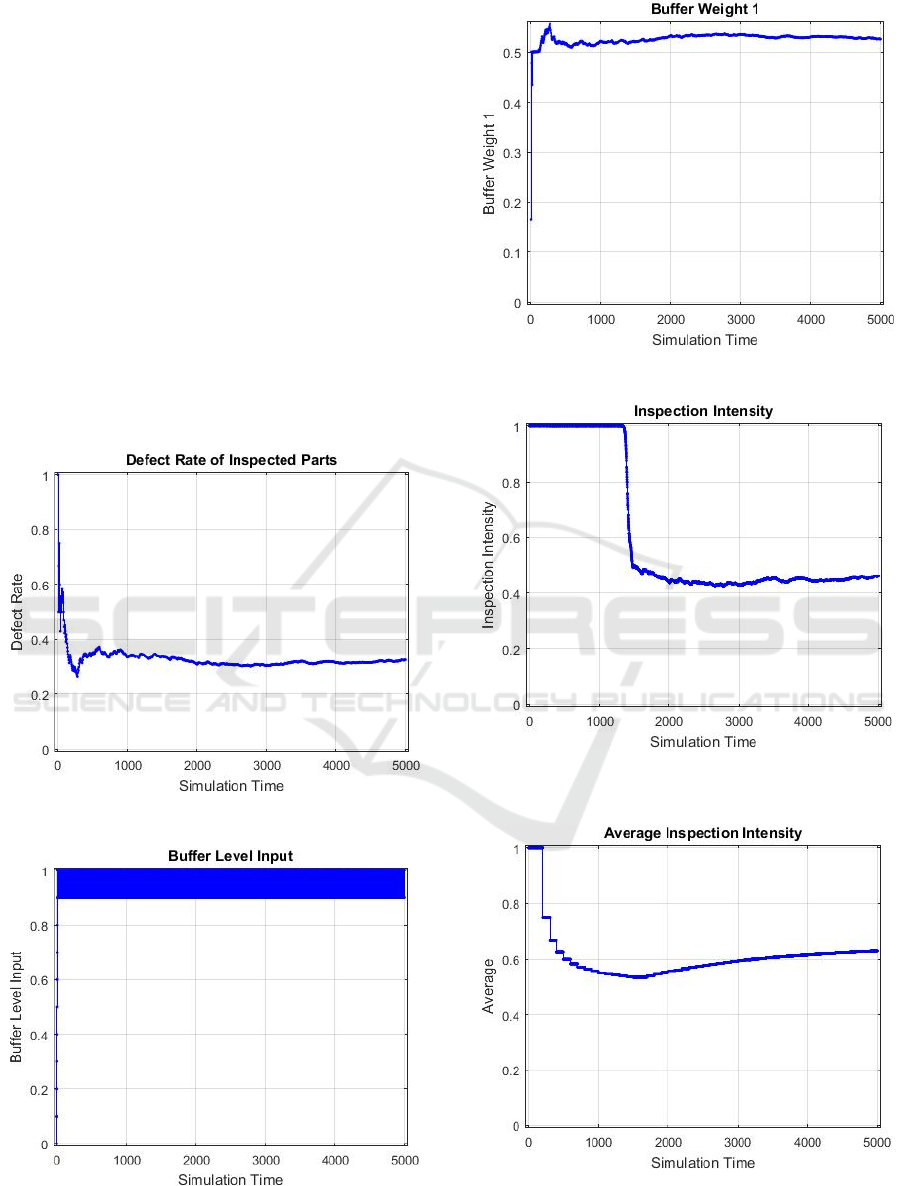

5 RESULTS AND DISCUSSION

Important parameters from the simulation were

recorded to determine the effects of the two-level

fuzzy controllers on MLT. Figure 6 and Figure 7

show the DR input and buffer level input respectively.

The buffer level input was scaled to a maximum of 1.

Figure 8 shows the buffer weight that was determined

by the supervisory fuzzy controller (based on the DR

input shown in Figure 6) for use in the distributed

fuzzy controller. It was noted the buffer weight had

an average of 0.53, indicating that MLT reduction -

by lowering the buffer levels - was less important than

the actual part stream quality. Figure 9 shows the real-

time inspection intensity. The intensity started at 1

(100%) due to the batch size input membership

function shown in Figure 3. By performing 100%

inspection at the beginning of the cycle, the best form

of the DR can be obtained. After 1400 time-units, the

intensity significantly reduced to ensure parts spend

less time in production by reducing the amount of

inspected parts. Figure 10 shows the averaged

inspection intensity, where 100 parts were used as a

sample size. A size of 100 was chosen intuitively as a

large sample size would incur large discrepancies

between the real-time and the averaged inspection

intensity, while a small sample size would not

accurately realise the inspection intensity as a mean.

Real-time inspection intensity could not be used as it

would be unrealisable with unacceptable errors. The

error between the averaged and real-time inspection

is shown in Figure 11. The error was calculated using

(4):

e_I = (Intensity-Mean Intensity)/(Mean

Intensity)

(4)

Where “Intensity” is the real-time inspection

intensity, the “Mean Intensity” was averaged over

100 parts and “e_I” was the intensity error. A positive

error indicated that less inspection was performed

than what was desired, while a negative error

Fuzzy Logic Control for Varied Inspection for Manufacturing Lead Time Reduction - A Fuzzy Control Implementation of a Dynamic

Inspection Technique to Reduce Manufacturing Lead Time

211

indicated that more inspection was perform than the

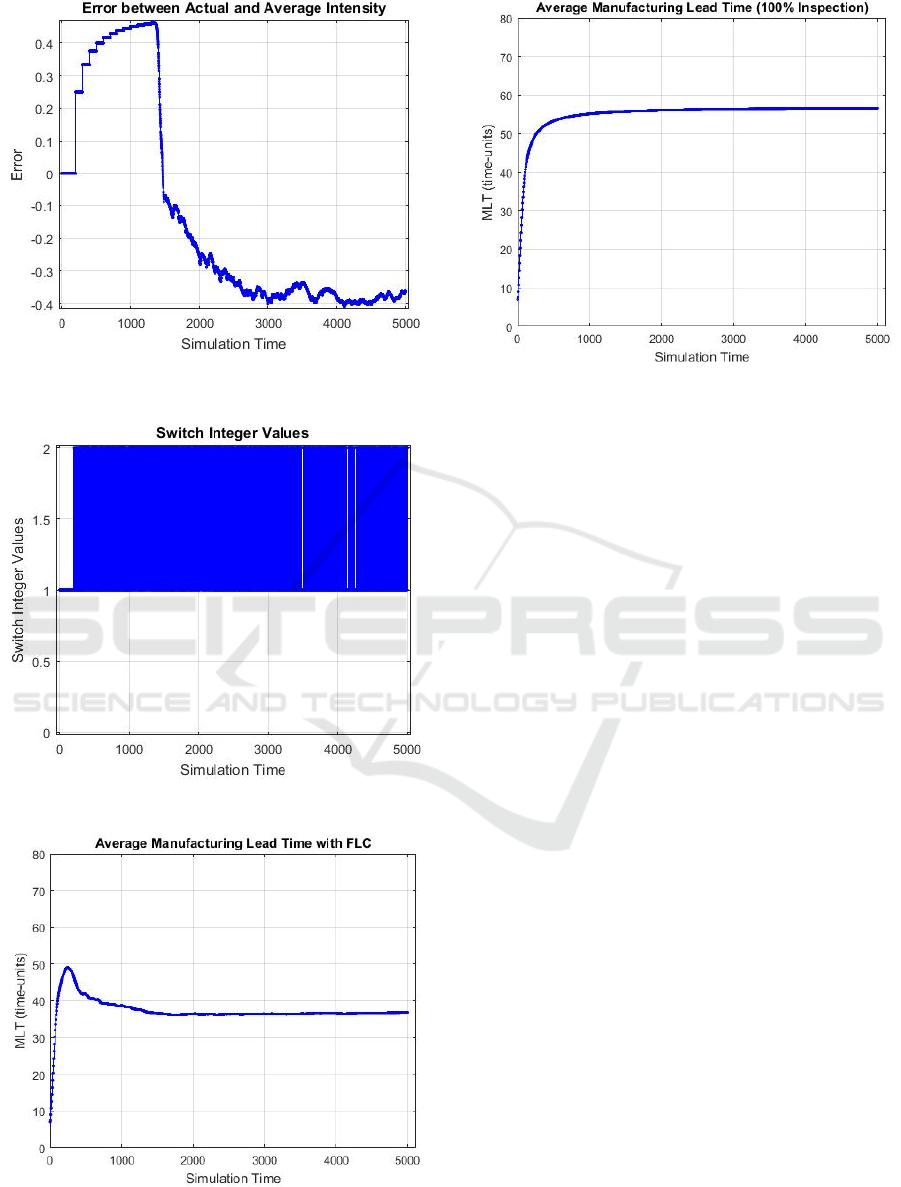

desired amount. The maximum error of 46% occurred

at 1375 time-units.

The amount of switching between “inspection”

and “no inspection” is shown in Figure 12. Although

not clear, the distributed fuzzy controller performs the

switching independently based on the average

inspection intensity shown in Figure 10. Where the

switch integer value (“p” value from (3)) was 1,

inspection was performed and no inspection was

performed when the integer value was 2.

Two simulations were performed to determine the

effects of the fuzzy controllers on MLT. Figure 13

shows the MLT when the controllers implemented

varied inspection. Figure 14 shows the average MLT

where 100% inspection was performed. By

comparison, varied inspection reduced MLT by 37

time-units over 1500 cycles, which represented a 35%

reduction in MLT.

Figure 6: Defect Rate Input of Inspected Parts.

Figure 7: Buffer Level Input.

Figure 8: Buffer Weight from Supervisory Controller.

Figure 9: Inspection Intensity (Percentage of Inspection

Performed on Incoming Parts).

Figure 10: Average Inspection Intensity Based on 100 Part

Batches.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

212

Figure 11: Error between Actual and Average Inspection

Intensity.

Figure 12: Switch Values (1 – Inspect; 2 – Do Not Inspect).

Figure 13: Average MLT with the Distributed and

Supervisory Fuzzy Controller.

Figure 14: Average MLT with 100% Inspection.

6 CONCLUSION AND FURTHER

RESEARCH

The results showed that varied inspection could be

used to reduce MLT and that a fuzzy solution could

facilitate the dynamic inspection method. The results

showed a 35% reduction in MLT. However,

Tsourveloudis (2000) outlined two major problems

with FL control for complex systems:

It is impractical to constantly monitor buffer

levels.

FLCs require a large amount of rules which adds

complexity to control.

Other limitations of this type of inspection was that

overall quality cannot be quantified, as parts were

allowed to pass through without inspection. Lastly,

there existed an error between the real-time

inspection intensity and the IID implementation,

shown in Figure 11, as the inspection was done in

sample batch sizes of 100 which resulted in a

maximum error of 46%. Real-time varied inspection

may result in larger errors as the inspection intensity

averages would not be executed accurately. Future

research will seek to reduce the errors and to

investigate the cost effectiveness of implementing

varied inspection. The FLC approach to varied

inspection will be extended for complex

manufacturing layouts. Lastly, a fuzzy solution will

be employed into the supervisory fuzzy controller to

address product-mix-prioritization.

Fuzzy Logic Control for Varied Inspection for Manufacturing Lead Time Reduction - A Fuzzy Control Implementation of a Dynamic

Inspection Technique to Reduce Manufacturing Lead Time

213

ACKNOWLEDGMENTS

The authors wish to thank the “Blue Sky Research

Grant” under the grant number 91339. The financial

assistance of the National Research Foundation

(NRF) towards this research is hereby acknowledged.

Opinions expressed and conclusions arrived at, are

those of the authors and are not necessarily to be

attributed to the NRF.

REFERENCES

Azadegan, A. et al., 2011. Fuzzy logic in manufacturing: A

review of literature and a specialized application.

International Journal of Production Economics,

132(2), pp.258–270.

Brabazon, P.G. & MacCarthy, B., 2007. Consideration of

the relevance of standard quality techniques in mass

customisation. International Journal of Mass

Customisation, 2(1/2), pp.76–94.

Davrajh, S. & Bright, G., 2010. An automated apparatus for

dynamic inspection of mass-produced custom parts.

Assembly Automation, 30(1), pp.47–55.

Davrajh, S., Bright, G. & Stopforth, R., 2012. Modular

Research Equipment for On-line Inspection in

Advanced Manufacturing Systems. The South African

Journal of Industrial Engineering, 23(May), pp.136–

150.

Fogliatto, F.S., Da Silveira, G.J.C. & Borenstein, D., 2012.

The mass customization decade: An updated review of

the literature. International Journal of Production

Economics, 138(1), pp.14–25.

Gien, D., 1999. Towards a unified representation of quality

in manufacturing systems. International Journal of

Computer Integrated Manufacturing, 12(2), pp.141–

155.

Groover, M.P., 2014. Inspection Principles and Practices.

In Automation, Production Systems, and Computer-

Integrated Manufacturing. Edinburgh: Pearson

Education Limited, pp. 643–672.

Homayouni, S.M., Sai Hong, T. & Ismail, N., 2009.

Development of genetic fuzzy logic controllers for

complex production systems. Computers & Industrial

Engineering, 57(4), pp.1247–1257.

Ioannidis, S., Tsourveloudis, N. & Valavanis, K., 2004.

Fuzzy Supervisory Control of Manufacturing Systems.

IEEE Transactions on Robotics and Automation, 20(3),

pp.379–389.

Juran, J.M. & Godfrey, A.B., 1998. Juran’s Quality Control

Handbook 5th ed. R. E. Hoogstoel & E. G. Schilling,

eds., New York: McGraw-Hill, Inc.

Naidoo, T. et al., 2016. Fuzzy Logic Control for Varied

Inspection Applications in Advanced Manufacturing

Cells. in 2016 Pattern Recognition Association of South

Africa and Robotics and Mechatronics International

Conference (PRASA-RobMech). Stellenbosch: IEEE,

pp. 257–262.

Tsourveloudis, N., 2000. Fuzzy work-in-process inventory

control of unreliable manufacturing systems.

Information Sciences, 127(1–2), pp.69–83.

Tsourveloudis, N., Doitsidis, L. & Ioannidis, S., 2007.

Work-in-process scheduling by evolutionary tuned

fuzzy controllers. International Journal of Advanced

Manufacturing Technology, 34(7–8), pp.748–761.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

214