Accuracy Analysis and Improvement for Cooperative Industrial Robots

M. Wagner

1

, A. Buschhaus

2

, S. Reitelsh

¨

ofer

2

, P. Heß

3

and J. Franke

2

1

Nuremberg Campus of Technology (NCT), Nuremberg Institute of Technology, 90429 Nuremberg, Germany

2

Institute for Factory Automation and Production Systems (FAPS), Friedrich-Alexander-Universit

¨

at

Erlangen-N

¨

urnberg (FAU), 91058 Erlangen, Germany

3

Faculty of Mechanical Engineering and Building Services Engineering, Nuremberg Institute of Technology,

90489 Nuremberg, Germany

Keywords:

Accuracy, Calibration, Industrial Robots, Multi-robot Systems.

Abstract:

The cooperative working of multiple robots on a common task often requires a high geometric accuracy. If

such a system is modeled, many sources of error are present, which can quickly lead to inadequate process

results. In order to avoid this, it is important to carry out a calibration in which deviations are determined.

Subsequently, the model can be adapted to the actual conditions. In the scope of this work a kinematic

calibration method for multi-robot systems is developed and realized with a robot setup consisting of two

industrial robot arms. The accuracy of the robot system is significantly improved by the developed approach,

which has been proven by experimental investigations.

1 INTRODUCTION

The accuracy of industrial robots has been under in-

vestigation for many years. Due to the current devel-

opment of new industrial robot applications the ac-

curacy gets more and more important. For example,

high precision processes, like robot-based medical in-

terventions (Boctor et al., 2004; Baron et al., 2010),

are implemented using industrial robots. In addition,

the number of processes programmed by offline pro-

gramming rises and it is important to ensure a suf-

ficient accuracy for these applications by matching

the virtual model of the robot with the corresponding

real robot. Therefore, many approaches for the im-

provement of the robot accuracy are developed. Since

the changing of the mechanical structure is connected

with a large expenditure, most commonly a calibra-

tion is done. Thus, the robot positioning accuracy is

improved by detecting and compensating the error be-

tween the robot model and the real robot.

Another trend in industrial robotics is the use

of multi-robot systems. Hence, applications can

be improved or developed by a cooperation be-

tween multiple robots. The coordination between

the involved robots may have four different levels

(Wagner et al., 2014). In the first level, no coordi-

nation is done between the robots. Thus, the coor-

dination must be considered in advance by the pro-

grammer. If the robots move independently, but re-

ceive individual signals from each other, this is called

asynchronous coordination. As a result, for exam-

ple, the transfer of workpieces can be coordinated. If

the motions of the robots are linked by simple state-

ments, this is called semi-synchronous coordination.

The common lifting of heavy loads, as presented in

(M

¨

uller et al., 2011) and in (Knepper et al., 2013),

is an example for this kind of coordination. A more

complex coordination of the movements is called syn-

chronous coordination. In this case, for example, a

common base movement is carried out while a robot

is performing a superimposed processing movement,

as shown in (Smits et al., 2008). Another example

presented in (Wagner et al., 2014) is the cooperative

processing by dividing the process movement in a tool

and a workpiece movement.

More complex cooperative processes are often

programmed offline, since the effort would otherwise

be disproportionate. Also for cooperative processes

a maximum match between the model and the real

robot is very important in order to ensure a suffi-

cient relative accuracy between the robots. An ex-

ample for a cooperative process with a requirement

of a high accuracy is the incremental sheet metal

forming by two cooperating industrial robot arms

(Meier et al., 2009). Also for the cooperative process-

ing, presented in (Wagner et al., 2014), a high accu-

racy is necessary. Thus, a new approach for the im-

provement of the accuracy of multi-robot systems is

Wagner, M., Buschhaus, A., Reitelshöfer, S., Heß, P. and Franke, J.

Accuracy Analysis and Improvement for Cooperative Industrial Robots.

DOI: 10.5220/0006396805390546

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 539-546

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

539

presented in the scope of this paper.

This paper is structured as follows: Section 2

gives an overview about the current state of the art in

kinematic calibration. Subsequently, the researched

method for the accuracy improvement for cooperative

industrial robots is presented in Section 3. The im-

plementation of the approach with a setup consisting

of two industrial robot arms is explained in Section 4.

The last section concludes the paper.

2 KINEMATIC CALIBRATION

The aim of the kinematic calibration is the minimiza-

tion of the deviation between the current path and the

target path of the robot movement. The kinematic

calibration can be carried out according to two ba-

sic principles (Day, 1996). On the one hand it can be

done by an inline calibration using closed-loop cor-

rection (Buschhaus et al., 2016). Here, the error is

detected and compensated during the processing. On

the other hand the calibration can be performed by an

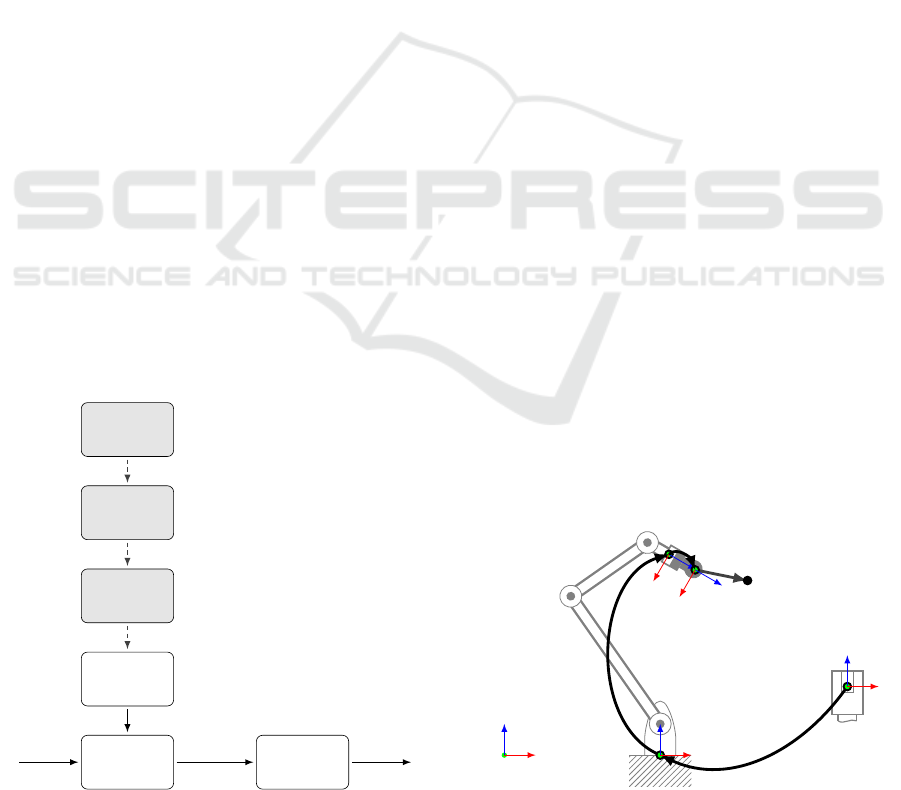

open-loop correction (see Figure 1). In doing so, the

error in the system is recorded once in a measuring

process and the kinematic model is adapted accord-

ingly.

According to (Elatta et al., 2004), the kinematic

calibration consists of four sequential steps. First, the

robot kinematics is modeled. Second, the necessary

measurements are performed. Third, the calibration

parameters are estimated based on the measured data.

Finally, the calculated calibration parameters are used

to adjust the kinematic model and thus to compensate

the error. These four steps are explained in the fol-

lowing subsections.

Inverse

Kinematics

Robot

Model of

Kinematics

Compen-

sation

Identifi-

cation

Measure-

ments

Desired

Pose

Axis

Values

Robot

Pose

Figure 1: Open-loop correction method for industrial

robots.

2.1 Modeling

The considered robot has a base coordinate system

{B} (see Figure 2) which is usually located inside of

the robot base. Thus, the exact position of the base

coordinate system is unknown. The pose of the flange

{F} results from the kinematics of the robot and is de-

scribed by the transformation

B

T

F

. For common ap-

plications the tool center point (TCP) {T } is located

in front of the flange. The equivalent transformation

is denoted by

F

T

T

.

Furthermore, two calibrations have to be per-

formed in advance in order to achieve a sufficient

accuracy. First, the exact base coordinate system

{B} must be determined. Thus, the base transforma-

tion

S

T

B

has to be measured indirectly and calculated

based on geometric relations. Second, the transforma-

tion between the robot flange and the TCP

F

T

T

needs

to be determined. Even if the tool is produced with

high accuracy, there is still a relevant inaccuracy in

its installation to the robot flange. If the base of the

tool is not reachable by a mechanical measuring in-

strument, it has to be determined by a calibration pro-

cedure as well.

2.2 Measurements

During the measurements, the position of the TCP in

the workspace of the robot is recorded. Various mea-

surement methods, e.g. acoustic or visual sensors as

well as coordinate measuring machines, can be used

for this purpose. Most of the approaches use auto-

matic theodolites, also known as laser tracker, due

to their high precision (Alicia and Shirinzadeh, 2005;

Nguyena et al., 2015).

The definition of the measurement positions de-

pends on the respective applications. Thus, in (Alicia

and Shirinzadeh, 2005) 80 positions are used to cover

the range of motions for example. In order to reduce

the number of positions, the optimal measuring posi-

{F}

e

i

{T }

p

S

T

B

{S}

B

T

F

F

T

T

{B}

y

z

x

Figure 2: Coordinate systems at the accuracy analysis for

industrial robots.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

540

tions can be selected by using a genetic algorithm in

(Aoyagi et al., 2010).

2.3 Identification

Each of the N measured positions p

a

= (x

a

y

a

z

a

)

T

can be compared with the corresponding desired

position p

d

= (x

d

y

d

z

d

)

T

. Thus, an error vector

e = (x

e

y

e

z

e

)

T

can be calculated according to:

e

i

= p

a

i

− p

d

i

, i ∈ {1, 2, . . . , N} (1)

Furthermore, the error ε of a position can be indi-

cated by the distance between the two points by:

ε

i

= ||e

i

|| =

=

q

(x

a

i

− x

d

i

)

2

+ (y

a

i

− y

d

i

)

2

+ (z

a

i

− z

d

i

)

2

,

i ∈ {1, 2, . . . , N}

(2)

2.4 Compensation

In the final step of the kinematic calibration, the kine-

matic model of the robot is adapted according to

the identified errors. The error consists of geomet-

rical and non-geometrical errors (Elatta et al., 2004;

Nguyena et al., 2015). Geometrical errors result from

deviations in the link length or twist errors and can be

determined relatively easy. Thus, e.g. the joint an-

gle error can be estimated by a calibration, as shown

in (Chen et al., 2008) by tracking a laser line in the

robot workspace. Most of the approaches calculate

the geometrical error based on the measurement of

multiple robot positions with an external high preci-

sion measurement unit and a calculation of the devi-

ation based on alorithms like extended Kalman filter-

ing (Nguyena et al., 2015), root mean square (Alicia

and Shirinzadeh, 2005) or non-linear least squares op-

timization (Lightcap et al., 2008; Aoyagi et al., 2010).

Non-geometrical errors, such as gear backlash or join

and link flexibility, are more difficult to determine.

Some approaches use an artificial neural network to

compensate this errors (Nguyena et al., 2015; Aoy-

agi et al., 2010). Other approaches try to model the

non-geometrical errors, e.g. with a class of polynom-

inals (Alicia and Shirinzadeh, 2005) or a Monte Carlo

simulation (Lightcap et al., 2008).

3 APPROACH

For the cooperative processing, the relative accuracy

between the robots is of importance. Thus, it is an-

alyzed by measuring the absolute accuracy for both

robots and by calculating the deviation between both

measurements. Subsequently, the systematic error is

compensated by an adaption of the kinematic model.

According to the previous section, this section is di-

vided into the same four subsections.

3.1 Modeling

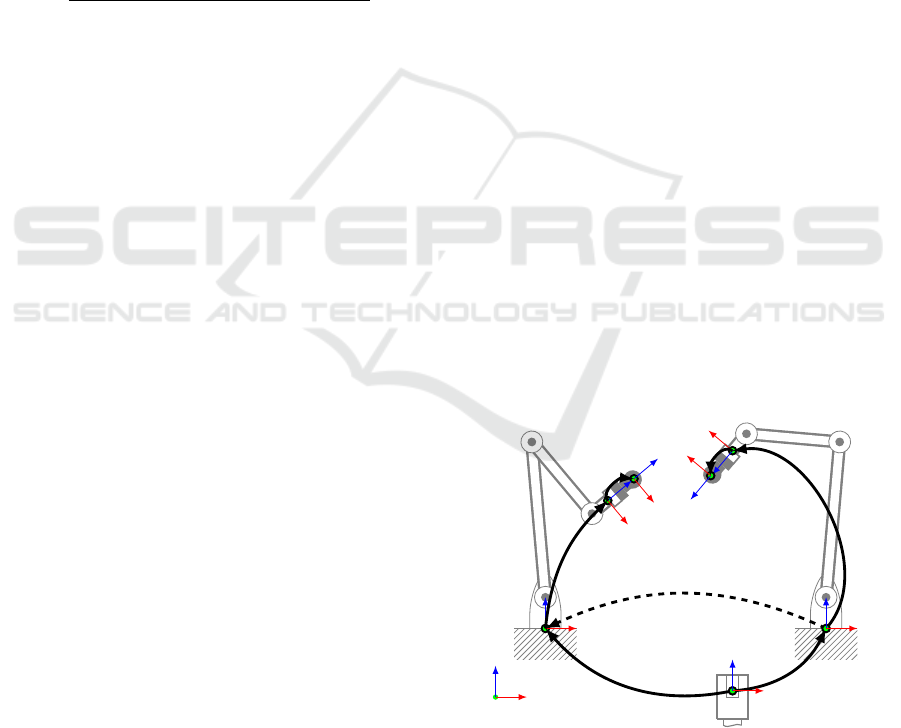

At least two robots are required for cooperative pro-

cessing (see Figure 3). In the following, the terms

workpiece guiding robot and tool guiding robot are

used for the involved robots. However, several robots

can also guide the workpiece or the tool. Each robot

has a transformation from its base to its flange, de-

noted by

B

T

T

F

T

and

B

W

T

F

W

. Furthermore, each robot

has a transformation from its flange to its TCP. This

also applies to the reflector {R} used for examining

the accuracy by a laser tracker. The transformations to

the center of the reflectors are

F

T

T

R

T

and

F

W

T

R

W

. The

transformation between the two robot base frames is

denoted by

B

T

T

B

W

. In addition, the transformations

between the sensor base frame {S} and the two robot

base frames, denoted by

S

T

B

T

and

S

T

B

W

, are relevant.

According to Section 2.1, a base and a tool cal-

ibration must also be carried out in advance for the

cooperative approach. Thus, for each robot a base

transformation, denoted by

S

T

B

T

and

S

T

B

W

, as well

as a reflector transformation, denoted by

F

T

T

R

T

and

F

W

T

R

W

, are determined.

{F

T

}

{R

T

}

{R

W

}

{B

W

}

{F

W

}

S

T

B

T

S

T

B

W

B

T

T

B

W

{S}

B

T

T

F

T

F

T

T

R

T

B

W

T

F

W

F

W

T

R

W

{B

T

}

y

z

x

Figure 3: Coordinate systems at the accuracy analysis for

cooperative processing.

Accuracy Analysis and Improvement for Cooperative Industrial Robots

541

3.2 Measurements

The investigation focuses on the part of the

workspace which is relevant for the coopera-

tive processing—the common workspace. In order to

limit the amount of measurements, measuring points

are equally distributed within the common workspace

by an algorithm (see Figure 4). The algorithm runs

with a constant step size from the bottom to the top of

a box containing the workspace. In order to keep the

robot paths to a minimum, the x-direction is toggled.

Each iterated position is checked for reachability by

inverse kinematics and the position will be added to

the measurement positions, if it is reachable.

The algorithm generates programs for both robots

that enables them to move the reflector to the absolute

set poses of the accuracy analysis path. Due to the

inaccuracies in the system, each robot movement has

a deviation compared to the pre-defined path.

3.3 Identification

Based on the measurement results, the relative de-

viations between the measured positions and the de-

sired positions is calculated via Equation 1 and Equa-

tion 2. However, the relative position between the two

robots is essential for the cooperative process. Thus,

the equations are adapted to the relative deviation be-

tween the two robot poses. The error vector e results

from the difference between the measured tool posi-

1: procedure GENERATE PATHS(S

k

)

2: for z ← z

min

, z

max

do

3: for y ← y

min

, y

max

do

4: if toggle then

5: for x ← x

min

, x

max

do

6: if REACHABLE(x, y, z) then

7: commands → programs

8: end if

9: end for

10: else

11: for x ← x

max

, x

min

do

12: if REACHABLE(x, y, z) then

13: commands → programs

14: end if

15: end for

16: end if

17: toggle ←!toggle

18: end for

19: end for

20: end procedure

Figure 4: Procedure for creating the robot paths with

equally distributed measurement points for the accuracy

analysis for cooperative processing.

tion p

T

and the measured workpiece position p

W

by:

e

i

= p

T

i

− p

W

i

, i ∈ {1, 2, . . . , N} (3)

The absolute error ε at the position results from

the distance between the two measured positions by:

ε

i

= ||e

i

|| =

=

q

(x

T

i

− x

W

i

)

2

+ (y

T

i

− y

W

i

)

2

+ (z

T

i

− z

W

i

)

2

,

i ∈ {1, 2, . . . , N}

(4)

Furthermore, a compensation transformation T

C

can be calculated from all of the deviations by the It-

erative Closest Point (ICP) algorithm (Zhang, 1992).

In the course of this, the transformation is determined

by an interative minimization of the distances be-

tween the point clouds.

3.4 Compensation

The open-loop correction method presented in Sec-

tion 2 is modified in order to adapt the desired pose of

the workpiece guiding robot (see Figure 5). For this

purpose, the base transformation

B

T

T

B

W

is adapted

using the compensation transformation T

C

. The

compensation transformation consists of a translation

t

C

= (x

C

y

C

z

C

)

T

and a rotation r

C

= (α

C

β

C

γ

C

)

T

.

Based on these parameters, the base transformation

between the two robots can be modified by:

B

T

T

0

B

W

=

B

T

T

B

W

· T

C

(5)

Accordingly, a target pose for the workpiece guid-

ing robot

B

W

T

P

can be determined by the target pose

of the tool guiding robot

B

T

T

P

according to the equa-

tion:

B

W

T

P

= (T

C

)

−1

·

B

T

T

B

W

−1

·

B

T

T

P

=

=

B

T

T

0

B

W

−1

·

B

T

T

P

(6)

Compen-

sation

Inverse

Kinematics

Robot

Model of

Kinematics

Identifi-

cation

Measure-

ments

Desired

Pose

Axis

Values

Robot

Pose

Comp.

Pose

Figure 5: Open-loop correction method for the desired pose

of cooperative industrial robots.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

542

4 IMPLEMENTATION &

RESULTS

The previously described approach is implemented

with a robot setup consisting of two industrial robot

arms. The setup is presented in the next subsection.

Subsequently, the realization of the preliminary cali-

brations is explained. In the last subsection the real-

ization of the measurements and the resulting data is

presented.

4.1 Setup

The robotic system used for the investigation con-

sists of two KUKA KR 6 R900 sixx industrial robot

arms (see Figure 6). They are mounted next to each

other with a distance of approximately 1325 mm in

y-direction. Each robot arm consists of six axis and a

position repeatability of ±0.03 mm according to man-

ufacturer specifications.

The laser tracker API R-20 Radian is used as an

external measuring device. It is placed in front of the

robots to be able to measure within the entire common

workspace. Each robot has a reflector mounted to its

flange via an adapter plate.

4.2 Calibrations

According to Section 3.1, two calibrations have to

be performed before the measurements. First, the

base coordinate systems of the robots have to be

determined. They are measured by mounting a re-

flector on the rotating part of the robot next to the

first and the second rotational axis. For both axes a

measurement is performed by rotating the axes. This

results in a circular path whose center point lies in the

rotational axis. The actual robot base can be deter-

mined via the intersection of the resulting rotational

axes.

Figure 6: Setup for the accuracy analysis for cooperative

industrial robots.

Furthermore, the transformation between the two

robots base coordinate systems can be determined by:

B

T

T

B

W

=

S

T

B

T

−1

·

S

T

B

W

(7)

The resulting base transformation for the

examined setup consists of a translation of

t

B

= (3.18 − 1319.28 0.17)

T

in mm and a ro-

tation of r

B

= (0.00 0.01 0.26)

T

in degree.

Second, the translation between the flange and

the mounted reflector needs to be determined. Since

the fixing adapter is produced with a very high accu-

racy in radial direction, a low eccentricity is assumed.

Therefore, only the offset in z-direction is estimated

by the calibration. For this purpose, the robot per-

forms a pitch rotation around its flange axis. Thereby,

a circular path of the reflector can be recorded. The

z-offset is equivalent to the radius of the fitting cir-

cle. The resulting values for the considered setup

are z

R

T

= 36.79 mm for the tool guiding robot and

z

R

W

= 36.71 mm for the workpiece guiding robot.

4.3 Measurements & Data

The measurement paths for both robots are gener-

ated according to Section 3.2. The resulting programs

contain movements inside the common workspace of

both robots, which are aligned on a uniformly dis-

tributed grid (see Figure 7). After each movement

command the program contains a wait-command to

ensure a measurement at the desired position. The

generated path consist of a total of 472 measurement

positions.

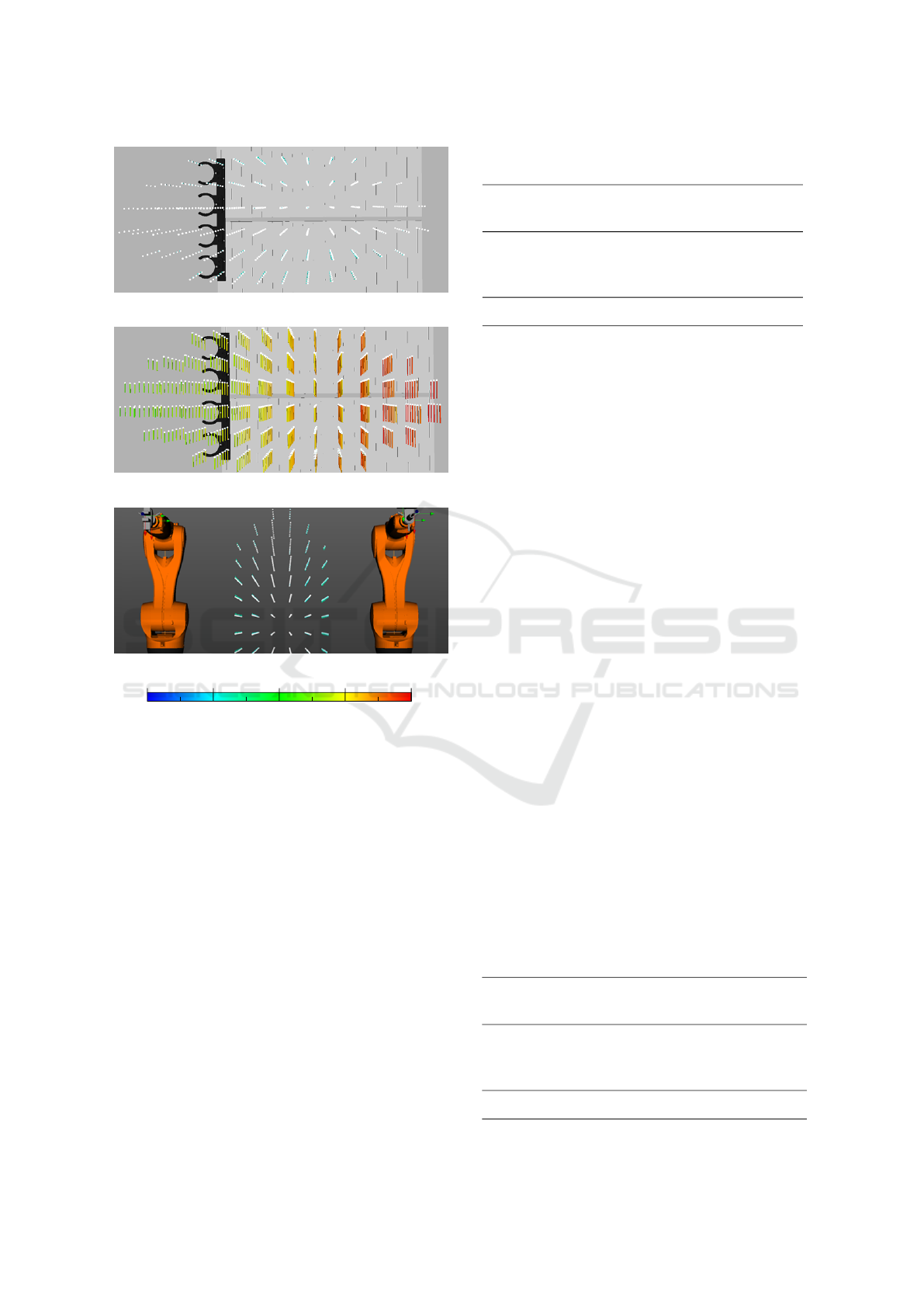

Based on the measurement results, the relative de-

viations between the matching positions can be calcu-

lated by Equation 3 and Equation 4. Figure 8(a)-8(c)

show the resulting deviations divided in x-, y- and

z-direction. The magnitude of the deviation is directly

proportional to the length of the line and the lines are

colored according to a heatmap, which is shown in

Figure 8(d).

Figure 7: Generated robot path for the tool guiding robot

for the accuracy analysis.

Accuracy Analysis and Improvement for Cooperative Industrial Robots

543

(a) Deviation in x-direction.

(b) Deviation in y-direction.

(c) Deviation in z-direction.

0 2 4

6

8

x

e

, y

e

, z

e

in mm

(d) Heatmap.

Figure 8: Accuracy maps with scaled deviations colored by

a heat map depending on the absolute value.

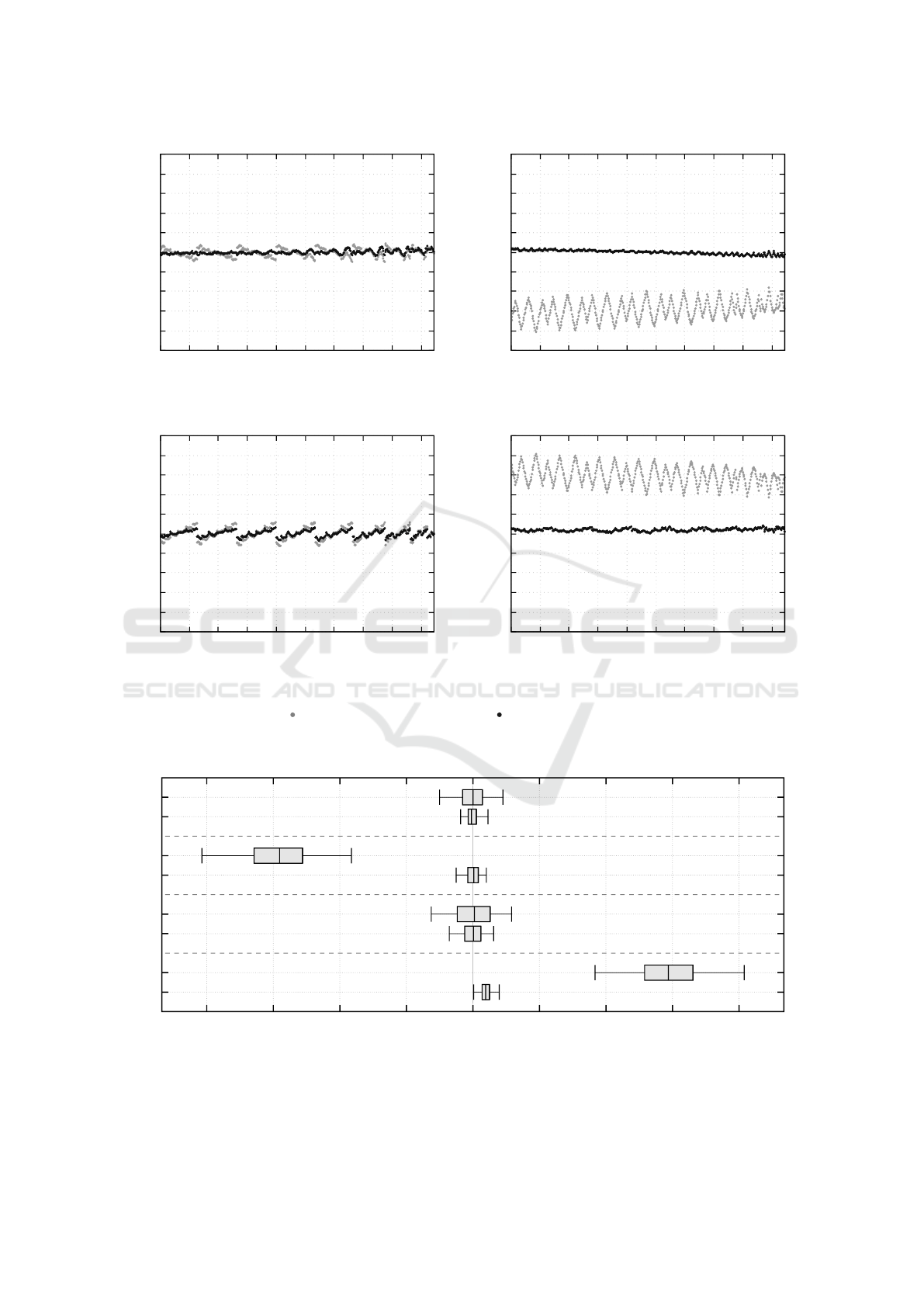

Furthermore, the deviation values are summarized

in diagrams (see Figure 9) in order to get a better

overview. Here, all measurement points are listed in

sequence. Each axial direction (x

e

, y

e

, z

e

) is presented

in a separate diagram as well as the absolute error ε.

The distribution of the deviations before the com-

pensation is presented in Table 1.

The deviation in x- and z-direction varies in

the range between about -1.0 mm and 1.0 mm.

A comparatively large negative deviation in the

y-direction is obvious, which presumably is due to

the oppositeness of the two robots in this direction.

This deviation is decisive for the absolute error with

a maximum of more than 8.0 mm. The standard

deviations before the compensation are in the range

of 0.40 mm to 0.96 mm.

Table 1: Distribution of relative positional deviations for the

cooperative robot system.

¯

e min(e) max(e) σ(e)

(mm) (mm) (mm) (mm)

x

e

-0.0262 -1.0007 0.9037 0.4044

y

e

-5.8465 -8.1463 -3.6525 0.9559

z

e

0.0087 -1.2508 1.1629 0.6119

ε 5.8925 3.6713 8.1544 0.9547

According to Section 3.4, a compensation is per-

formed. The resulting compensation transformation

for the considered setup consists of a translation of

t

C

= (−1.81 6.96 1.41)

T

in mm and a rotation of

r

C

= (0.16 0.00 0.12)

T

in degree. The deviations

after the compensation are also shown in the diagrams

(see Figure 9). Table 2 shows the distribution of the

deviations after the compensation. The mean error

vector tends to zero and all deviations are less than

0.8 mm. The standard deviations after the compensa-

tion are between 0.14 mm and 0.31 mm. In order to

provide better comparability, the data is displayed in

a box-and-whisker diagram (see Figure 10).

5 CONCLUSIONS

In the scope of this paper an approach for the im-

provement of the accuracy for cooperative industrial

robots is developed. Thus, the robots are examined by

means of a high-precision external measuring device.

On the one hand, the approach includes the creation

of robot programs for the measurement. On the other

hand, the estimation of an error compensation is pre-

sented. The approach is implemented with a robot

system with two industrial robot arms for validation.

The comparison of the deviations before and after the

compensation shows a significant reduction of about

90 %. In addition, the variation is significantly re-

duced in comparison to the deviations without com-

pensation.

Table 2: Distribution of relative positional deviations for the

cooperative robot system after the compensation.

¯

e

0

min(e

0

) max(e

0

) σ(e

0

)

(mm) (mm) (mm) (mm)

x

0

e

-0.0001 -0.3687 0.6136 0.1889

y

0

e

0.0001 -0.5031 0.4041 0.2088

z

0

e

0.0000 -0.7086 0.6213 0.3077

ε

0

0.3905 0.0223 0.7938 0.1456

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

544

-10

-8

-6

-4

-2

0

2

4

6

8

10

0 50 100 150 200 250 300 350 400 450

x

e

in mm

Point number

(a) Error in x-direction.

-10

-8

-6

-4

-2

0

2

4

6

8

10

0 50 100 150 200 250 300 350 400 450

y

e

in mm

Point number

(b) Error in y-direction.

-10

-8

-6

-4

-2

0

2

4

6

8

10

0 50 100 150 200 250 300 350 400 450

z

e

in mm

Point number

(c) Error in z-direction.

-10

-8

-6

-4

-2

0

2

4

6

8

10

0 50 100 150 200 250 300 350 400 450

ε in mm

Point number

(d) Absolute error.

Before compensation After compensation

Figure 9: Deviations at the different measurement positions.

−8

−6

−4 −2 0 2 4

6

8

ε

ε

0

z

e

z

0

e

y

e

y

0

e

x

e

x

0

e

Deviation in mm

Figure 10: Box-and-whisker diagram of relative positional deviations for the cooperative robot system.

Accuracy Analysis and Improvement for Cooperative Industrial Robots

545

REFERENCES

Alicia, G. and Shirinzadeh, B. (2005). A systematic tech-

nique to estimate positioning errors for robot accuracy

improvement using laser interferometry based sens-

ing. In Mechanism and Machine Theory, volume 40,

pages 879–906. Elsevier.

Aoyagi, S., Kohama, A., Nakata, Y., Hayano, Y., and

Suzuki, M. (2010). Improvement of robot accuracy

by calibrating kinematic model using a laser track-

ing system-compensation of non-geometric errors us-

ing neural networks and selection of optimal measur-

ing points using genetic algorithm. In Proceedings of

the IEEE/RSJ International Conference on Intelligent

Robots and Systems (IROS 2010), pages 5660–5665.

IEEE.

Baron, S., Eilers, H., Munske, B., Toennies, J. L., Balachan-

dran, R., Labadie, R. F., Ortmaier, T., and III, R. J. W.

(2010). Percutaneous inner-ear access via an image-

guided industrial robot system. In Proceedings of the

Institution of Mechanical Engineers, Part H: Journal

of Engineering in Medicine, volume 224, pages 633–

649. SAGE.

Boctor, E. M., Fischer, G., Choti, M. A., Fichtinger, G., and

Taylor, R. H. (2004). A dual-armed robotic system for

intraoperative ultrasound guided hepatic ablative ther-

apy: a prospective study. In Proceedings of the IEEE

International Conference on Robotics and Automation

(ICRA 2004), volume 3, pages 2517–2522. IEEE.

Buschhaus, A., Gr

¨

unsteudel, H., and Franke, J. (2016).

Geometry-based 6d-pose visual servoing system en-

abling accuracy improvements of industrial robots.

In Proceedings of the International Conference on

Advanced Mechatronic Systems (ICAMechS 2016),

pages 195–200. IEEE.

Chen, H., Fuhlbrigge, T., Choi, S., Wang, J., and Li, X.

(2008). Practical industrial robot zero offset cali-

bration. In Proceedings of the IEEE International

Conference on Automation Science and Engineering

(CASE 2008), pages 516–521. IEEE.

Day, C. P. (1996). Robot accuracy issues and methods of

improvement. In Progress in Robotics and Intelligent

Systems, volume 2, pages 90–108. Intellect Books.

Elatta, A., Gen, L., Zhi, F., Daoyuan, Y., and Fei, L. (2004).

An overview of robot calibration. In Information

Technology Journal, volume 3, pages 74–78. Asian

Network for Scientific Information.

Knepper, R. A., Layton, T., Romanishin, J., and Rus, D.

(2013). Ikeabot: An autonomous multi-robot coordi-

nated furniture assembly system. In Proceedings of

the IEEE International Conference on Robotics and

Automation (ICRA 2013), pages 855–862. IEEE.

Lightcap, C., Hamner, S., Schmitz, T., and Banks, S.

(2008). Improved positioning accuracy of the pa10-

6ce robot with geometric and flexibility calibration.

In IEEE Transactions on Robotics, volume 24, pages

452–456. IEEE.

Meier, H., Buff, B., Laurischkat, R., and Smukala, V.

(2009). Increasing the part accuracy in dieless robot-

based incremental sheet metal forming. In CIRP An-

nals - Manufacturing Technology, pages 233–238. El-

sevier.

M

¨

uller, R., Esser, M., and Janssen, M. (2011). Integrative

path planning and motion control for handling large

components. In Proceedings of the 4th International

Conference on Intelligent Robotics and Applications

(ICIRA 2011), pages 93–101. Springer-Verlag, Berlin,

Germany.

Nguyena, H.-N., Zhoua, J., and Kang, H.-J. (2015). A cali-

bration method for enhancing robot accuracy through

integration of an extended kalman filter algorithm and

an artificial neural network. In Neurocomputing, vol-

ume 151, pages 996–1005. Elsevier.

Smits, R., Laet, T. D., Claes, K., Bruyninckx, H., and Schut-

ter, J. (2008). itasc: a tool for multi-sensor integration

in robot manipulation. In Proceedings of the IEEE

International Conference on Multisensor Fusion and

Integration for Intelligent Systems, pages 426–433.

IEEE.

Wagner, M., Heß, P., and Reitelsh

¨

ofer, S. (2014). Auto-

mated programming of cooperating industrial robots.

In Proceedings for the joint conference of 45st Inter-

national Symposium on Robotics (ISR 2014) und 8th

German Conference on Robotics (ROBOTIK 2014),

pages 129–136. VDE-Verlag, Berlin, Germany.

Zhang, Z. (1992). Iterative point matching for registration

of free-form curves. In Technical Report RR-1658.

INRIA Sophia Antipolis, Valbonne Cedex, France.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

546