SystemC Test Case Generation with the Gazebo Simulator

Thomas W. Pieber, Thomas Ulz and Christian Steger

Institute for Technical Informatics, Graz University of Technology, Inffeldgasse 16/I, Graz, Austria

Keywords:

SystemC, Gazebo, Plugin, Cosimulation, Simulation, XML, Test Case Generation.

Abstract:

The current approach of hardware simulators are testbeds that supply the Device under Test (DUT) with inputs.

These sequences of inputs are the result of engineers reverse engineering the use cases extracting the inputs

from them and adding some extreme cases. This paper describes an approach where the input sequences are

generated directly from the use case itself. The use case is therefore simulated in an environmental simulator

such as Gazebo. This generates the stimuli for the DUT. To facilitate the compatibility between the different

simulation environments we present an easy-to-use and easy-to-implement communication strategy.

1 INTRODUCTION

A system design needs to be simulated in order to

test it extensively. Such a simulation should be stimu-

lated with real world events and unusual events to test

the functionality under normal working situations and

extreme cases. Such tests are normally designed by

thinking of scenarios, defining how the device should

react, and testing these input sequences. Furthermore,

random input sequences can be applied to the sys-

tem to test the design more extensively. These ran-

dom tests are unlikely to produce valid inputs and pri-

marily test the error handling. As these tests are un-

likely to perform useful tasks, it is necessary to have

a system that can generate useful input and the ac-

cording expected data. We have therefore designed a

system that uses an environment simulation to gener-

ate the inputs for testing a sensor system. This de-

sign can also reduce the effort needed to design test

cases, as only scenarios in which the DUT normally

operates need to be constructed. From these scenar-

ios valid input data is automatically generated. As an

environmental simulator, a robotics simulator, such as

Gazebo, can be used.

A robotics simulator is designed to handle com-

plex systems and generate sensory information of any

kind. A widely used robotics simulator is the Gazebo

simulator (Open Source Robotics Foundation, 2004;

Koenig and Howard, 2004). This open source product

can be modified (in a, for us, useful way) by writing

plugins for the entire world, the models, the sensors,

and an entire system. Further modifications can be

made to the visuals and the GUI. The Gazebo simu-

lator operates in discrete time steps of 1 ms . This is

enough for simulating the movement of a robot and

scarce enough that the robot’s operating system can

handle most commands in this time step.

For simulating a sensory device (hereafter Device

under Test or DUT) a tool like SystemC (Accelera,

2000) can be used. With this simulator, a complex mi-

crosystem can be designed and tested. Also the com-

ponent parts of this system can be modelled in varying

detail, allowing for later synthetization. SystemC can

simulate the DUT in discrete time intervals as small

as 1 fs.

This difference in simulation speed is a major

problem to be solved to combine the two simulation

environments. As the SystemC simulation is operates

in such fine time intervals, it generates huge amounts

of data during the execution of a test scenario, as such

a test scenario can last for many minutes. The prob-

lem of generating and handling these amounts of data

must be considered when designing the status output

of the DUT. Also the connection of the DUT on the

SystemC side of the simulation needs to be modified

in order to allow the storage of communication data

between it and the simulator and the correct input of

the data to the DUT.

Another issue that comes with connecting the

simulators comes from the communication between

them. The simulators have to communicate in order

to exchange status information like the actual simu-

lation time, commands, and generated messages. As

the SystemC simulation works with finer time steps it

requires much more fine granular input data and pro-

duces huge amounts of output data. This data needs

Pieber, T., Ulz, T. and Steger, C.

SystemC Test Case Generation with the Gazebo Simulator.

DOI: 10.5220/0006404800650072

In Proceedings of the 7th Inter national Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 65-72

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

65

to be extrapolated from the data Gazebo provides and

afterwards filtered to allow Gazebo to work with the

return data.

The remainder of this paper is structured as fol-

lows: In Section 2 other works that combine SystemC

or Gazebo with other simulators are described. Sec-

tion 3 explains the motivation for our design, the re-

quirements that need to be implemented, and details

of the solution for the requirements. An evaluation

of the usability and functionality of the design is de-

scribed in Section 4. Following that, Section 5 men-

tions ideas on how to further improve the proposed

design. This paper concludes with Section 6.

2 RELATED WORK

Gazebo is an open source robotics simulator. It is

primarily combined with the Robot Operating Sys-

tem (ROS). There are some approaches for combining

Gazebo with other software for robotics and compu-

tational intelligence (Zamora et al., 2016).

There are approaches that connect other tools that can

be used to simulate hardware, to Gazebo (Mathworks,

2016). In these approaches, the main interface to the

simulation environment is the interface to ROS.

SystemC is a modelling language based on C++.

The extension consists of a class library and a simu-

lation kernel. In (Panda, 2001) a short summary of

design processes for SystemC is given.

There exist some interfaces to SystemC in the lit-

erature such as (Martin et al., 2002; Possadas et al.,

2005; Bouchhima et al., 2006; Huang et al., 2008;

Mueller-Gritschneder et al., 2013). These papers use

SystemC as a primary basis and extend the function-

ality of it. (Huang et al., 2008) describe a possibility

of running a SystemC simulation on a distributed net-

work, improving the time performance significantly.

An interface to SystemC was designed in (Bouch-

hima et al., 2006). This work uses Matlab/Simulink

as a continuous simulation for the environment, which

communicates with the SystemC model.

In the work found in (Martin et al., 2002),

SystemC was connected with an analog circuit simu-

lator like SPICE (Simulation Program with Integrated

Circuit Emphasis) and VHDL (Very High Speed Inte-

grated Circuit Hardware Description Language (VH-

SIC Hardware Description Language)).

In (Mueller-Gritschneder et al., 2013) a platform

for simulating an entire robot is modelled in SystemC.

In this approach the SystemC simulation was used

to simulate the behaviour of a robotic system on the

transaction layer. With their simulation results the au-

thors update the model of a robot in a virtual world,

simulated in a Java environment. After that measure-

ments are taken in the Java environment and sent to

the SystemC robot model for further processing. They

use network sockets to communicate between the two

simulations. In this paper SystemC was used to sim-

ulate the robot’s movement as accurate as possible,

while in our proposal the robot’s behaviour gives the

input to the simulation of other hardware.

In summary, SystemC was connected with many

simulators for cycle accurate measurements, other

hardware description languages, or circuit simulators.

In (Mueller-Gritschneder et al., 2013) SystemC was

used to simulate physical effects on robots.

Comparing this previous work with our proposal,

our contributions are a completely new aspect of

connecting simulators for generating test cases for

systems automatically, as well as connecting the

SystemC simulation with an open source robotics

simulation. That means that SystemC was previously

used to simulate effects in the larger simulation, in

this approach the larger simulation is used to stimu-

late the whole system simulated in SystemC.

In our use-case a sensor is read using a wireless

channel. For such a use-case the NFC technology is

well well-suited. This is due to the fact that energy

can be transmitted through the RF (radio frequency)

field. With that energy the sensor and the supporting

microcontroller(s) can be operated. The same energy

can also be used to charge a small battery or capacity.

In (Wireless Power Consortium et al., 2010; Strom-

mer et al., 2012; Lee et al., 2013) the mechanism for

transmitting energy alongside data and for storing that

energy are described.

There are different approaches to communicate

between simulation environments; commonly used

are XML (Extensible Markup Language) and JSON

(JavaScript Object Notation). Of these two, JSON

is more efficient as (Nurseitov et al., 2009) show.

(Sumaray and Makki, 2012) furthermore compares

Google’s Protocol Buffer (protobuf), which is used by

the Gazebo simulator, alongside JSON and XML.

As the SystemC simulation works in many cycles

for every internal time step, the efficient generation of

JSON objects, as well as the generation of protobuf-

messages, would require major changes in the exist-

ing simulations. Following this, the approach to com-

municate from SystemC to Gazebo is to embed the

values of interest in XML-tags.

3 DESIGN

The goal of the presented design is to connect a

SystemC simulation to a high-level simulator in order

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

66

to generate stimuli for the simulation. Using this ap-

proach, the testbed for the SystemC simulation is the

simulation of the use-case. This method allows the

generation of stimuli for the SystemC simulation from

the specification of an interaction of the designed sys-

tem with the environment. This is not only more effi-

cient than a system engineer could be, but also small

variations of the environment can generate a wide va-

riety of tests.

To support a SystemC simulation with input from

an environment simulator like Gazebo, a plugin for

that simulator needs to be developed. This plugin

must be able to send commands and data to the

SystemC environment and receive the results and sta-

tus of the SystemC simulation.

A huge hurdle for connecting the two simula-

tion environments is the different simulation speeds.

Gazebo works with time steps of 1 ms whilst SystemC

can handle steps as small as 1 fs. This is a twelve or-

ders of magnitude higher time resolution of SystemC.

Even a “slow” computer which only works at 50 MHz

performs 5·10

4

steps in one time step of Gazebo. This

results in amounts of data that are hard to evaluate in

a high-level simulation environment. Therefore, mea-

sures have to be made to limit the amount of data that

needs to be transmitted. In order to do this a connec-

tion between the simulators needs to be defined.

The connection between the two simulation envi-

ronments must be supported by both environments. In

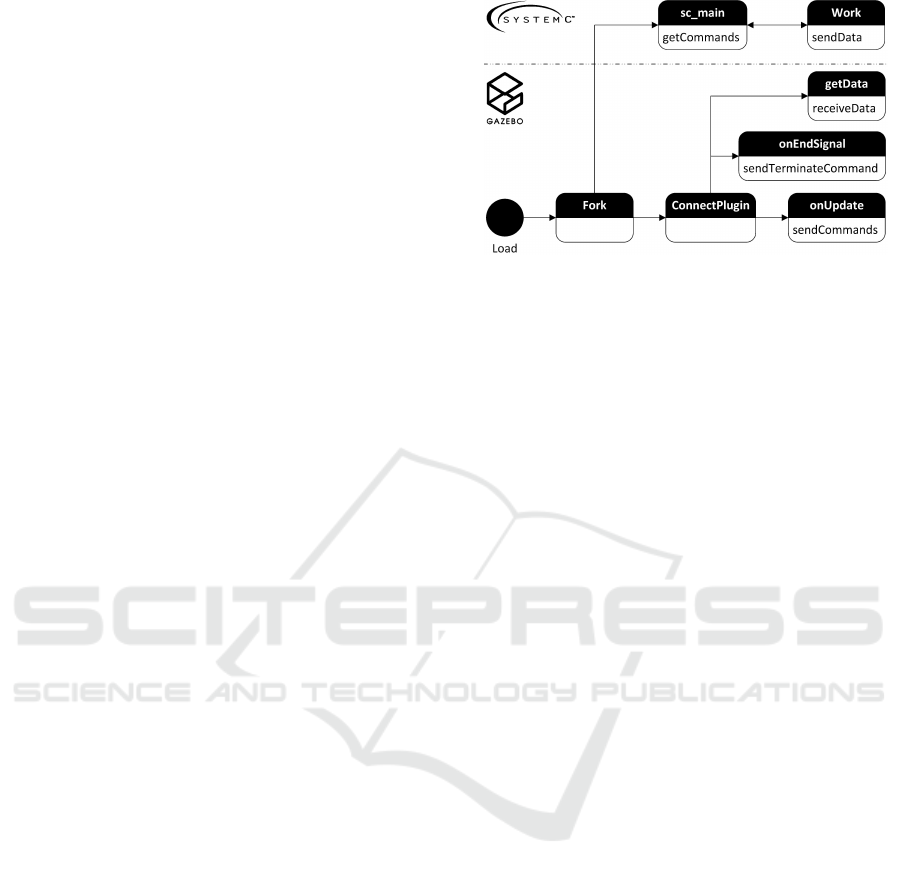

the Gazebo simulator a plugin can be written. Figure

1 shows a subset of the states the plugin needs to per-

form during the execution. This model-plugin needs

to open communication channels and fork a new pro-

cess that will become the SystemC simulation. The

plugin then proceeds to the normal execution. For

that it connects to the required Gazebo internal sig-

nals. One of the required connections is to the onUp-

date signal. This signal is set on every time step in

the simulation. On activation of this signal the plugin

retrieves the status information and other messages

from the DUT in the SystemC simulation. When this

is done and the data is processed, the plugin can send

new commands and messages to the DUT.

To send different messages between the communi-

cating parties an easy-to-implement approach is used.

In the SystemC simulation the interesting parameters

can be sent to the communication channel. The quick-

est way to implement such a communication would

be to redirect the standard output to the communi-

cation pipe before forking the SystemC simulation,

and send the interesting values encased by XML-style

tags. With these tags it is easy to find the interest-

ing values in the input stream and separate it from

the rest. With this approach the produced data can

Figure 1: States of the execution of the implemented plugin.

be collected by Gazebo in the order it was produced.

Another approach is the collection of the interesting

data in a global data structure, generate a JSON mes-

sage, and send it at the end of the time step. This

approach however would require more changes in the

simulation, while the improvement of the efficiency is

negligible in contrast to the whole execution.

The Gazebo plugin needs to parse the incoming

stream of data. With the XML-tags it can detect the

values, perform some preprocessing and store it in a

fitting datastructure. When the simulation halts at the

specified time, a sync tag needs to be sent to Gazebo.

When this signal is received, the plugin can operate

again and send the received data to the processing

nodes. As (Sumaray and Makki, 2012) show, this

communication is done most efficiently with Google’s

protobuf approach. To use this method, custom mes-

sages are defined. These messages can then be sent

to a simulation of the channel. This separation is

done in order to provide the possibility of changing

the channel and the parameters independently of the

rest. In our design a NFC communication is chosen.

The channel simulation is implemented as a World-

plugin of Gazebo. This plugin takes the environmen-

tal states and calculates the transmitted power and can

induce errors or attacks on the communication. The

calculations of the transmission statistics are based on

(Wireless Power Consortium et al., 2010; Lee et al.,

2013) The channel plugin can then relay the (modi-

fied) messages with additional information about the

channel to the receiving party. In our scenario, the

ROS system can then access the received data.

The communication in the other direction follows

the same rules. The robot’s OS sends data to the chan-

nel, the channel modifies and appends the message

and retransmits it to the sensor plugin (if the sensor

is within communication range). The sensor plugin

gathers the data and commands from the robot and

from the channel, and generates a message that can

be sent to the SystemC simulation.

Another useful extension is another World-plugin

SystemC Test Case Generation with the Gazebo Simulator

67

that gatheres sensory information for the sensor to

process. Also this information can be collected by the

sensor plugin and relayed to the SystemC simulation.

In the SystemC simulation the testbed needs to be

changed to accommodate the interface to the high-

level Gazebo simulation. The requirements that the

altered testbed has to fulfil, in order to work properly,

are:

R.1 The simulation parameters, commands to the

DUT, and other information regarding the hard-

ware simulation must be configurable.

R.2 The commands that come from the Gazebo sim-

ulator must be parsed and distributed.

R.3 The testbed must be able to be activated contin-

uously.

R.4 The simulation time for each iteration should be

variable to allow a variety of scenarios.

R.5 A direct communication to the parts that can be

affected by the commands must be possible.

R.6 The incoming commands must be stored and ex-

ecuted in the correct order.

R.7 A proper time synchronization between the two

environments needs to be established.

R.8 The traces from the simulation should be de-

activated, or at least reduced, as a execution

over a prolonged simulation time produces huge

amounts of data.

Furthermore, some minor changes have to be made in

the rest of the simulation. Most notably is the inser-

tion of messages back to the Gazebo simulator. These

changes are similar to the changes needed for require-

ment R.7.

Requirement R.1 is fulfilled by providing a

POSIX (Portable Operating System Interface) pipe

that connects the standard input of the SystemC

testbed with the Gazebo plugin. This allows the

transfer of information (like configuration parame-

ters) through the standard input from the Gazebo sim-

ulator to the SystemC simulation.

To satisfy requrement R.2 a parser for the received

messages is implemented and called at the start of ev-

ery execution cycle.

To fulfil requirement R.3 the testbed is written in

an endless loop. The condition to terminate the pro-

cess is taken from the standard input. As the input

is connected via a POSIX pipe to the Gazebo simula-

tor, the SystemC simulation can be ended if Gazebo

is closed.

Special commands to change timing parameters

are included in the command structure to implement

requirement R.4. In SystemC two commands are

needed; one for the time unit and one for the value.

As we want to simulate a sensor system, it is use-

ful to feed the simulated sensory information to the

sensor-input of the SystemC simulation. This cor-

responds to specification R.5. With special tags this

data can be extracted from the received message. This

data is then sent to a FIFO (first in, first out) memory

“sensor”. This sensor can then set the required values

on its data lines.

The same approach can be used for requirement

R.6. In this requirement the input is stored in a FIFO

at the control unit of the sensor. This control unit can

then execute the commands in order. For a proper

execution of the commands an additional data field is

required. This data field stores the exact time values at

which the command should have arrived to simulate a

serialized channel.

To fulfil requirement R.7, a channel to communi-

cate back to the Gazebo simulation needs to be de-

clared. This is most easily done by redirecting the

standard output to another pipe before executing the

simulation. The synchronization between the simu-

lation environments is done by creating a sync-signal

at the end of a simulation step. The sync-signal is de-

fined by a specialized XML-tag that is sent to the stan-

dard output. After this signal is received, the Gazebo

simulator is allowed to excite another step. This step

in turn triggers the advance of the SystemC simulation

by one time step. The same method for communicat-

ing to the Gazebo environment can be used for other

data as well. These data-fragments are then encased

in XML-tags that can be found in the output stream

of the SystemC simulation. For each interesting event

in the SystemC environment a separate XML-tag is

defined. In our test-design, interesting events are: (I)

the sending of data packets from different execution

stages and (II) the status of the battery of the sensor.

When simulating an environment it is necessary

that longer amounts of time are simulated, in order

to also simulate the edge conditions. This results in

huge amounts of data that come from the SystemC

environment. Normally, this data comes in form of

VCD-files (Value Change Dump files). If the clock of

the simulation is dumped as well, this results in vast

amounts of data referring to clock changes while the

actual simulation process has not even begun.

Requirement R.8 refers to that problem. There-

fore it is necessary to wait for input before initializing

the simulation. This input determines if traces will

be made, and if yes, which traces should be activated.

Furthermore, it is possible to pause the execution of

the SystemC simulation if all relevant operations for

this time step are handeled which results in shorter

simulation times. This approach does however reduce

the quality of the simulation results and should there-

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

68

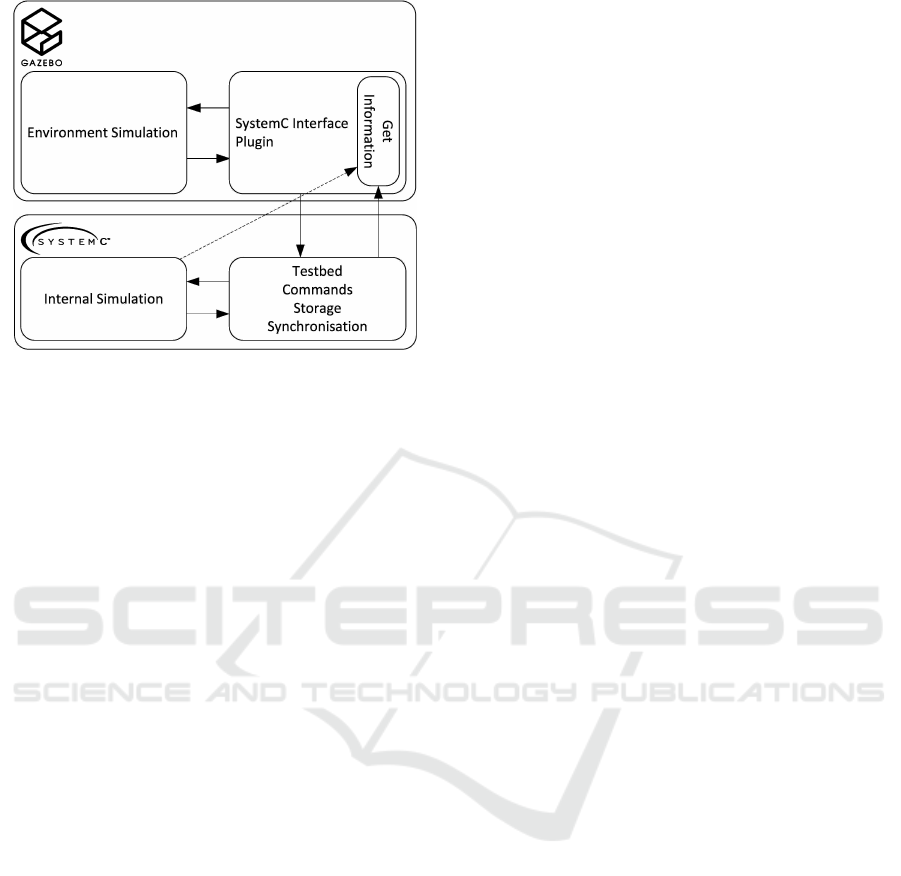

Figure 2: Overall communication process between Gazebo

and SystemC.

fore only be used if the DUT is in a low power mode.

If the simulation is paused prematurely two addi-

tional challenges emerge. The first is the disconnec-

tion of the simulation time of Gazebo and SystemC.

In order to prevent that from happening in the trace,

an additional value can be generated. This value is

toggled if the simulation pauses prematurely.

The second challenge is the simulation of values

that change even if basically no useful operation is

performed. An example for such a value is the energy

level of a battery that is drained a little even in low-

power mode. A fashionable solution to this problem

is the estimation of this value at the supposed end of

the simulation.

With these calculations at the premature pausing

of the simulation and the knowledge that every sim-

ulation step takes 1 ms the timings of the operations

can be restored and the sharp edges on estimated val-

ues can be reduced by interpolating between the data

points.

Figure 2 shows the global communication paths

between the two simulation systems and the changed

interfaces. The robot from the Gazebo simulator, as

well as the environment in which the robot operates,

compute the input for the SystemC simulation. These

input parameters are sent to the interface (testbed) of

the SystemC simulation, which in turn distributes this

data to the required parts of the internal simulation.

This simulation produces outputs which are sent over

the standard output to the Gazebo simulator (dashed

line). Furthermore, data is sent to the testbed, as some

traces still need to be captured. In the Gazebo simu-

lator, the environment can affect the communication

channel between the sensor and the robot again. Fi-

nally, the robot can access the gathered data. This data

can then be compared to the data generated by the sen-

sor in order to optimize the communication process.

All parts of the simulation in the Gazebo simulator

are implemented using plugins. This allows the easy

reconfiguration of the simulation to feature other or

more actors, inputs, obstacles, parameters, and even

allows the change of the whole communication chan-

nel.

4 EVALUATION

To evaluate the developed system, a SystemC simula-

tion of a smart sensor that communicates and charges

the internal battery with NFC (Near Field Commu-

nication) technology was constructed. This is the

sensory device denoted DUT beforehand. This sim-

ulation is then started by a Gazebo plugin. The

Gazebo simulator provides the context for the sim-

ulation and gives useful sensory values as input to

the system. The Gazebo simulator can communicate

with the SystemC simulation over the standard input

and output of the SystemC simulation. In our design

the wireless NFC communication channel is modelled

in a Gazebo World-plugin. A World-plugin is a plu-

gin, that is loaded at the beginning, connected to all

parts of the simulation, and is active until the simu-

lation ends. With this approach, the channel simula-

tion can get different parameters that affect the com-

munication. Such parameters are the distance and

orientation between the antennas, obstacles between

the antennas, and other noise on the communication

band. Because the channel is modelled separately, it

can be easily changed to accommodate other commu-

nication techniques like WiFi, Bluetooth, Zigbee, or

wired connections.

The communication between the simulators is per-

formed with strings encased in XML-tags. On each

side of the communication an XML parser is written

that searches for the declared tags. The strings found

by this parser are then stored in a suiting data struc-

ture. For our use case, this data structure consists of

a list of objects, referring to the XML-tags, each con-

taining a list of the received data values.

The data contained in this structure can then be

read sorted by topic in the order it was received. For

data that needs to be transmitted via the NFC chan-

nel, a preprocessing step is executed that generates

protobuf-messages.

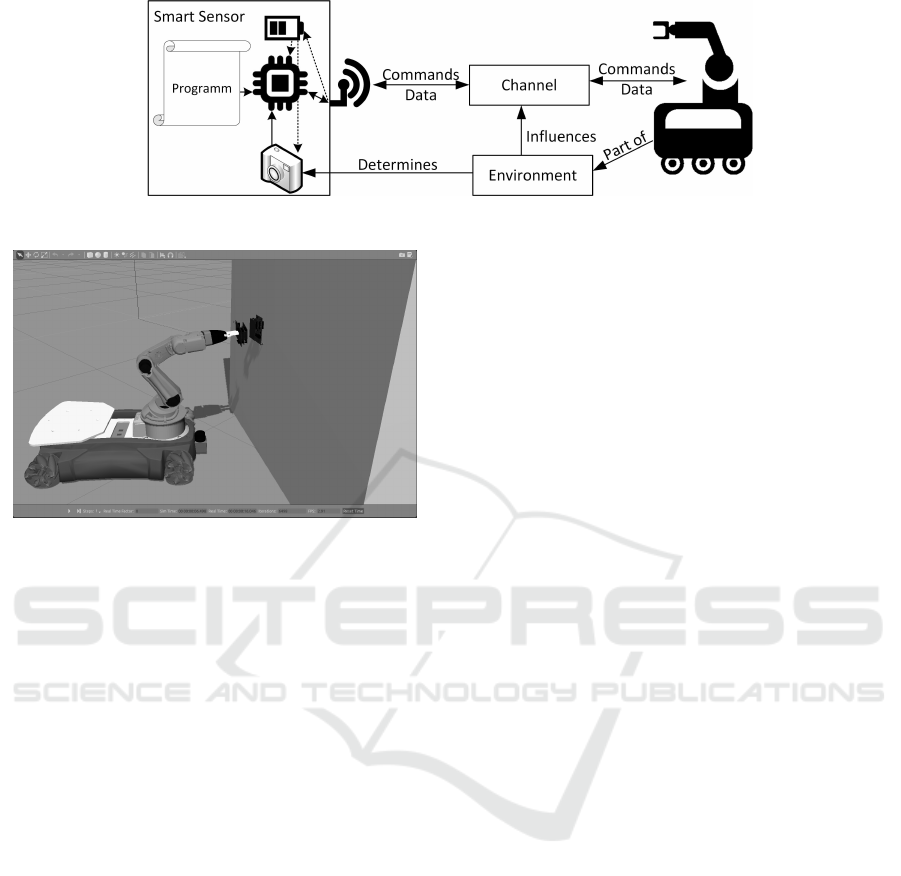

The SystemC simulation can get the required

stimuli from the environment of the Gazebo simula-

tor. In Figure 3 a concept for the simulation is shown.

The robot, as part of the environment, interacts with

the DUT. In this simulation the DUT is attached to a

crate as an environmental feature. The robot moves

SystemC Test Case Generation with the Gazebo Simulator

69

Figure 3: Concept of the Evaluation Design.

Figure 4: Interaction of a robot with the sensor.

towards the DUT and tries to communicate with it.

As the robot gets closer, the NFC connection between

the robot and the DUT gets better. When the channel

is good enough such that enough energy gets trans-

mitted the DUT switches on and the communication

can happen.

This simulation performs every operational phase

of such a DUT when some entity tries to communi-

cate with it. Because the global simulation is done

in a robotics simulator, a new test case can be imple-

mented by repositioning the DUT and robot and giv-

ing the robot some new instructions. The local sim-

ulation of the DUT is still done with SystemC. This

allows very accurate measurements on the DUT. In

this scenario we want to monitor the power usage and

ability to store excess energy during such a read cy-

cle. With these measurements we hope to develop a

more efficient power manage system on our DUT. Ad-

ditionally more information about the NFC communi-

cation can be gathered from this simulation.

Figure 4 shows the environment with the robotic

arm and the DUT. To communicate with the DUT an-

other sensor was mounted on the end of the robotic

arm.

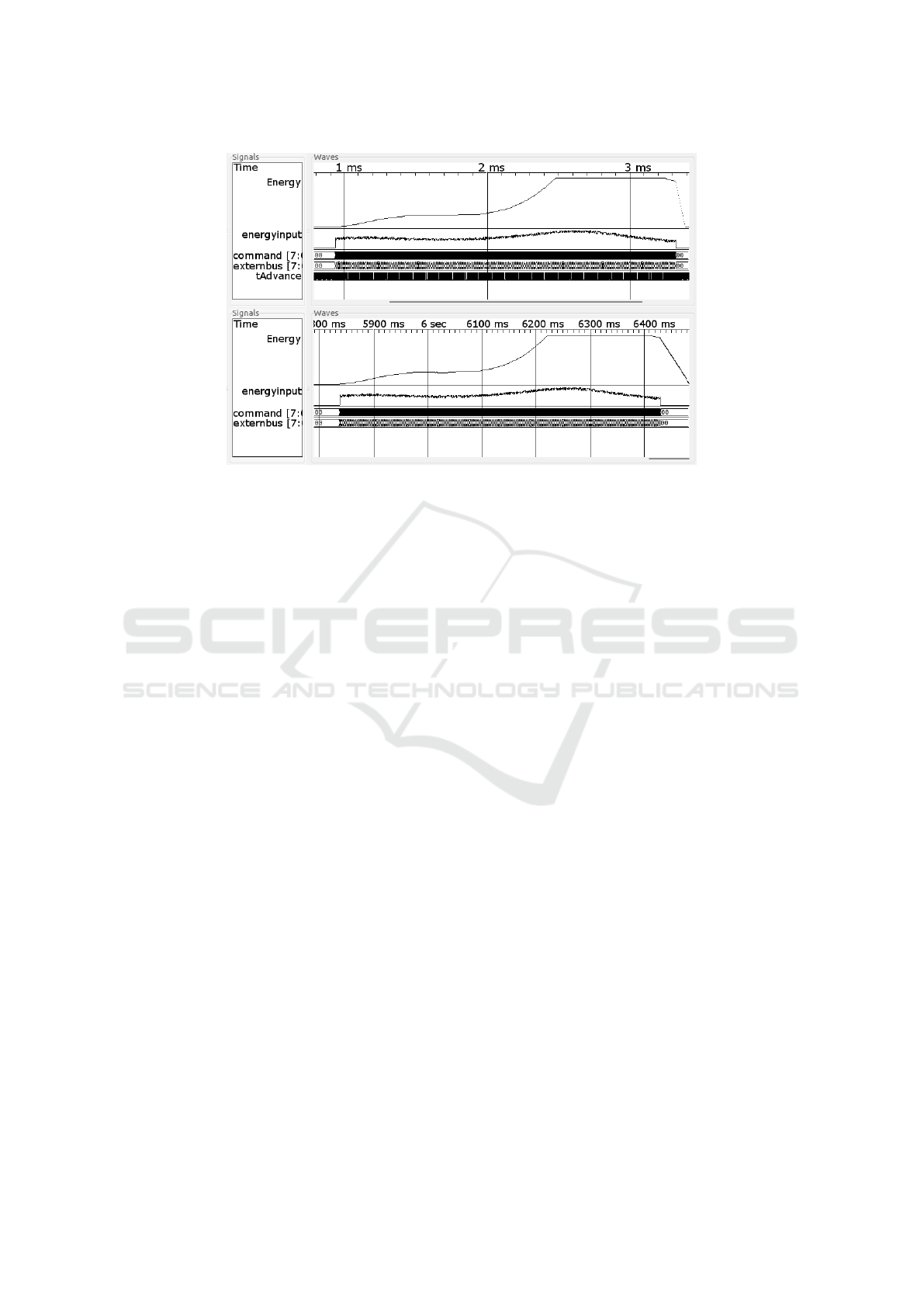

While the robot is approaching the sensor the NFC

antenna on the robot’s arm is activated. The trans-

mitted energy and commands are received at the sen-

sor. The sensor’s energy intake can be seen in Figure

5. This figure furthermore shows the compression of

simulation time as a result of requirement R.8. The

upper graph starts at approximately 0.9 ms and runs

to about 3.5 ms. The lower graph is time-expanded to

correlate with the Gazebo simulation time. This graph

starts at 5840 ms and runs to 6480 ms. This results in

a compression of the 5.8 s idle time to 0.9 ms.

5 FUTURE WORK

As many hardware elements are simulated in lan-

guages other than SystemC, plugin-structures need to

be developed to also include such simulations with a

high-level simulator. From our point of view a simi-

lar approach to include languages such as Verilog or

VHDL seems promising.

For bigger simulations it may also be useful to

connect to the SystemC simulation using network

sockets to allow the parallel computation of multiple

sensors.

Furthermore, simulations of the planned system as a

whole, of multiple sensors, senders and receivers, and

different channels need to be performed.

6 CONCLUSIONS

We presented a new approach for connecting a

SystemC hardware simulation to a robotic simula-

tor. This is done in order to automatically generate

the stimuli for the SystemC testbed. The huge dif-

ference in time resolution between these simulators

pose a barrier to connect them. To solve this hur-

dle, a mechanism to synchronize the simulations and

transport data between them is shown. In addition to

that, we have mentioned that extrapolating data for the

SystemC simulation, as well as filtering the produced

data for the Gazebo simulator, is necessary. Further-

more, the SystemC simulation needs some changes in

order to be able to connect to such a high-level simu-

lator. These changes include:

• Reduction of output if possible - without greatly

decreasing the degree of detail where it is needed.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

70

Figure 5: Energy trace of the sensor while a robot is approaching. The shorter simulation time at the top is a result of the

reduction of execution time due to requirement R.8

• Rewriting the testbed to allow the external simu-

lation to control the simulation

• Inclusion of special outputs for synchronization,

passing status information, and transmitting the

generated data to the Gazebo simulator.

Additional changes have been made to the Gazebo

simulator.

• A plugin to control SystemC has been developed.

This plugin handles all communication from and

to SystemC, keeps the simulations synchronized,

and controls the start and end conditions for the

SystemC simulation.

• Different channels, wireless and wired, have been

modelled in Gazebo that can be used to simulate

the connection between arbitrary devices.

ACKNOWLEDGEMENTS

This project has received funding from the Electronic

Component Systems for European Leadership Joint

Undertaking under grant agreement No 692480. This

Joint Undertaking receives support from the European

Unions Horizon 2020 research and innovation pro-

gramme and Germany, Netherlands, Spain, Austria,

Belgium, Slovakia.

REFERENCES

Accelera (2000). SystemC. http://accellera.org/downloads/

standards/systemc. Last accessed on Jan 17, 2017.

Bouchhima, F., Briere, M., Nicolescu, G., Abid, M., and

Aboulhamid, E. (2006). A SystemC/simulink co-

simulation framework for continuous/discrete-events

simulation. In 2006 IEEE International Behavioral

Modeling and Simulation Workshop. Institute of Elec-

trical and Electronics Engineers (IEEE).

Huang, K., Bacivarov, I., Hugelshofer, F., and Thiele, L.

(2008). Scalably distributed SystemC simulation for

embedded applications. In 2008 International Sym-

posium on Industrial Embedded Systems. Institute of

Electrical and Electronics Engineers (IEEE).

Koenig, N. and Howard, A. (2004). Design and use

paradigms for gazebo, an open-source multi-robot

simulator. In 2004 IEEE/RSJ International Confer-

ence on Intelligent Robots and Systems (IROS) (IEEE

Cat. No.04CH37566). Institute of Electrical and Elec-

tronics Engineers (IEEE).

Lee, W.-S., Son, W.-I., Oh, K.-S., and Yu, J.-W. (2013).

Contactless energy transfer systems using antiparallel

resonant loops. IEEE Transactions on Industrial Elec-

tronics, 60(1):350–359.

Martin, D., Wilsey, P., Hoekstra, R., Keiter, E., Hutchinson,

S., Russo, T., and Waters, L. (2002). Integrating mul-

tiple parallel simulation engines for mixed-technology

parallel simulation. In Proceedings 35th Annual Simu-

lation Symposium. SS 2002. Institute of Electrical and

Electronics Engineers (IEEE).

Mathworks (2016). Get Started with Gazebo and a Sim-

ulated TurtleBot. https://de.mathworks.com/help/

robotics/examples/get-started-with-gazebo-and-a-

simulated-turtlebot.html. Last accessed on Jan 03,

2017.

Mueller-Gritschneder, D., Lu, K., Wallander, E., Greim, M.,

and Schlichtmann, U. (2013). A virtual prototyping

platform for real-time systems with a case study for

a two-wheeled robot. In Design, Automation & Test

SystemC Test Case Generation with the Gazebo Simulator

71

in Europe Conference & Exhibition (DATE), 2013.

EDAA.

Nurseitov, N., Paulson, M., Reynolds, R., and Izurieta, C.

(2009). Comparison of json and xml data interchange

formats: A case study. Caine, 2009:157–162.

Open Source Robotics Foundation (2004). Gazebo simula-

tor. http://www.gazebosim.org. Last accessed on Jan

03, 2017.

Panda, P. R. (2001). SystemC - Amodelling platform sup-

porting multiple design abstractions. In Proceedings

of the 14th international symposium on Systems syn-

thesis - ISSS. Association for Computing Machinery

(ACM).

Possadas, H., Adamez, J. A., Villar, E., Blasco, F., and Es-

cuder, F. (2005). RTOS modeling in SystemC for real-

time embedded SW simulation: A POSIX model. De-

sign Automation for Embedded Systems.

Strommer, E., Jurvansuu, M., Tuikka, T., Ylisaukko-oja, A.,

Rapakko, H., and Vesterinen, J. (2012). NFC-enabled

wireless charging. In 2012 4th International Work-

shop on Near Field Communication. Institute of Elec-

trical and Electronics Engineers (IEEE).

Sumaray, A. and Makki, S. K. (2012). A comparison of data

serialization formats for optimal efficiency on a mo-

bile platform. In Proceedings of the 6th International

Conference on Ubiquitous Information Management

and Communication, ICUIMC ’12, pages 48:1–48:6,

New York, NY, USA. ACM.

Wireless Power Consortium et al. (2010). System descrip-

tion wireless power transfer. Volume I: Low Power,

Part, 1.

Zamora, I., Lopez, N. G., Vilches, V. M., and Cordero, A. H.

(2016). Extending the OpenAI Gym for robotics:

a toolkit for reinforcement learning using ROS and

Gazebo. arXiv preprint arXiv:1608.05742.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

72