Autonomous Navigation with ROS for a Mobile Robot in Agricultural

Fields

Mark A. Post, Alessandro Bianco and Xiu T. Yan

University of Strathclyde, 75 Montrose St., Glasgow, U.K.

Keywords:

Field Robotics, Navigation, Agriculture, ROS.

Abstract:

Autonomous monitoring of agricultural farms and fields has recently become feasible due to continuing ad-

vances in robotics technology, but many notable challenges remain. In this paper, we describe the state of

ongoing work to create a fully autonomous ground rover platform for monitoring and intervention tasks on

modern farms that is built using inexpensive and off the shelf hardware and Robot Operating System (ROS)

software so as to be affordable to farmers. The hardware and software architectures used in this rover are

described along with challenges and solutions in odometry and localization, object recognition and mapping,

and path planning algorithms under the constraints of the current hardware. Results obtained from laboratory

and field testing show both the key challenges to be overcome, and the current successes in applying a low-cost

rover platform to the task of autonomously navigating the outdoor farming environment.

1 INTRODUCTION

Interest in the application of robotic automation to

agriculture has grown quickly in recent years, due to

robotic technologies having reached a degree of matu-

rity that allows autonomous experimentation in agri-

cultural fields. Mobile robotic platforms have tradi-

tionally been very expensive in term of production

costs with only the ability to perform simple tasks

such as moving and recording images, and have been

focused on data gathering and repetitive work in ap-

plications such as space exploration or factory mass

production. Agricultural tasks are more challenging:

in a non-structured environment, gathering informa-

tion from the environment, harvesting randomly dis-

tributed crops, and simply navigating continuously

for a long time away from a power source require a

higher level of autonomous intelligence. It is only re-

cently that improvements in sensor and actuator tech-

nologies and progress in data processing speed and

energy have enabled robots to process enough infor-

mation to reliably and affordably perform basic nav-

igational tasks autonomously in an agricultural envi-

ronment. The development and testing of navigation

methods suitable for an autonomous agricultural data

gathering robot is the focus of this paper.

In (Roßmann et al., 2009), (Krahwinkler et al.,

2011) and (Roßmann et al., 2010), the authors pro-

pose a robotic platform which is able to move through

a large forested area and produce a map of the

trees. Their robot senses the environment by mean of

GPS, stereo camera, and range scanner information.

Since the GPS could not be always reliable under the

canopy of trees, it is used as a first position estimation

for a Kalman Filter. Aerial and satellite information

are integrated in order to extract a better representa-

tion of the environment. Finally a virtual forest is ex-

tracted as a map of the area, and trees are classified

according to their image.

In (Katupitiya et al., 2007), the authors propose a

robotic platform for precision seeding. Their robotic

architecture uses two high precision differential GPS

units and an IMU to determine the exact location for

the placement of the seeds. The path tracking algo-

rithm monitors the movement with high precision in

order to reduce the error of seed placement.

In (Henten et al., 2003b), (Henten et al., 2003a),

(van Henten et al., 2002) the authors propose a robotic

cucumber harvester. The platform is a robotic arm

that moves along rails mounted in a greenhouse. The

robot uses stereo vision information to detect the cu-

cumbers hanging from the vines, determine whether

they are ready for harvest and create a 3D represen-

tation of the environment. The 3D representation is

used to allow the arm to plan a harvesting task. An-

other strawberry harvesting system have been devel-

oped in (Hayashi et al., 2010) and (Hayashi et al.,

2012). These harvesting systems require that the arm

Post, M., Bianco, A. and Yan, X.

Autonomous Navigation with ROS for a Mobile Robot in Agricultural Fields.

DOI: 10.5220/0006434400790087

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 79-87

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

79

Figure 1: Rover Platform.

moves along predefined rails and resulting in a long

harvesting time and still exhibit a high failure rate.

The purpose of our project is to combine several

approaches to navigation and control into one au-

tonomous rover, which shall be able to navigate au-

tonomously in a farm field while constructing a map

of the environment. The rover’s main use is auto-

mated visual inspection and soil nitrogen level data

gathering, but as an autonomously navigating plat-

form it is designed with the capacity for other tasks

such as harvesting and crop treatment. A soil testing

payload and a controllable arm payload are currently

being developed for use on this rover.

Our ongoing aim to create a low-cost, fully au-

tonomous mobile robotic platform, which can provide

useful services to farmers and make full use of mod-

ern robotic technology. In this paper, we describe the

current state in development and technology of this

practical rover that has the ability to localize itself

through odometry and the ability to navigate reliably

to locations in a farm field while using off the shelf

parts in its construction without the need for high-

priced inertial measurement, processing, and sensing

hardware.

2 SYSTEM ARCHITECTURE

An image of the rover used in this work is shown

in 1. The chassis is articulated to allow the front

and back halves of the rover to rotate and compen-

sate for balance in the advent of uneven rough ter-

rain. Two wheels are attached to the front and back

of the chassis, each with an integrated DC brush gear-

head motor and controller within the wheel hub and

with angular steering by means of small linear steer-

ing actuators. The space within the front half of the

rover stores a 22 amp-hour lithium-polymer battery

pack for power, and the space within the back half

contains an NVidia Jetson TK1 single-board com-

puter (SBC), an SPI-connected Arduino board that

handles fast kinematic control of the drive and steer-

ing motors, and a SparkFun Razor attitude and head-

ing reference system (AHRS) board. Four sensors

allow the perception of the environment: the Razor

AHRS board containing a three degree of freedom ac-

celerometer, angular rate sensor, and magnetometer, a

Hokuyo UTM-30LX-EW scanning laser rangefinder

mounted on the front of the chassis, a Stereolabs ZED

stereo vision camera mounted on top of the laser and

a global navigation satellite system (GNSS) receiver

mounted on top of the camera.

As the Jetson TK1 and ZED stereo camera are rel-

atively inexpensive, the sensor and processing hard-

ware has a total price of a few hundred Euros, only the

laser can be considered as a fairly high-priced com-

ponent in this system, and with the current interest in

development of low-cost LIDAR technology it is ex-

pected that the cost of this component will decrease

in the near future. Differential GNSS is not yet used

due to the lack of internet access to reference stations

in most farming environments. Two ultrasonic range

sensors on the front of the rover provide additional ca-

pability to detect potential collisions. The sensors are

small and leave the entire back half area on top of the

rover for payloads, and the total weight of the rover

platform is 15.5kg. Payloads currently being built

for the rover include a laser-induced breakdown spec-

trometer (LIBS) system for measuring chemical com-

ponents of soil such as Nitrogen, and a lightweight

mechanical arm with three degrees of freedom for

camera-based crop inspection and sample cutting.

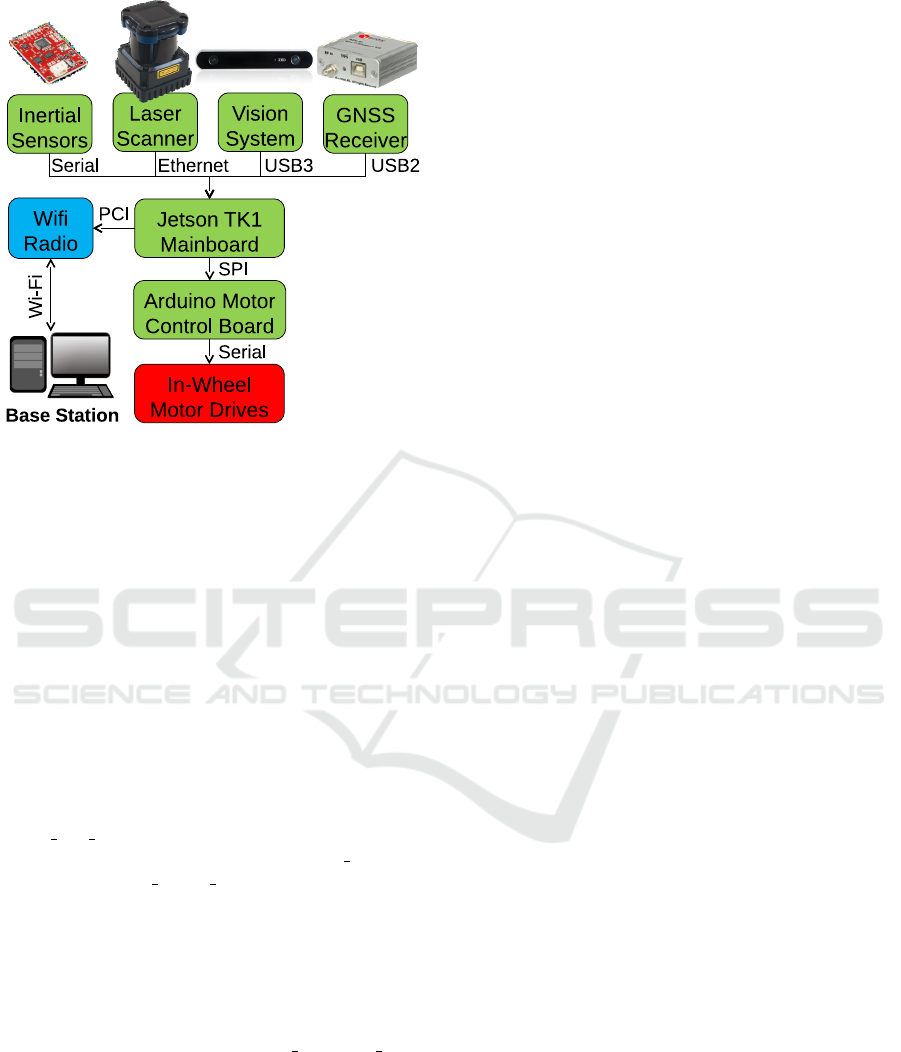

Figure 2 contains a representation of the hardware

components and their connections. Inertial sensors

are connected directly via TTL serial to the Jetson

TK1 SBC. The Hokuyo scanning laser rangefinder

is connected via Ethernet, the ZED stereo camera by

USB3, and the GNSS unit by USB2. All sensor pro-

cessing is done on the Jetson TK1 SBC. Directional

movement commands (speed and steering rate) are

generated using an on-board planner and sent at a rate

of 100Hz to the Arduino board for kinematic trans-

formation. The Arduino board in turn calculates the

required steering angles and motor speeds to execute

the desired movement and transmits them via TTL se-

rial and PWM to the motor controllers and steering

actuators. Communications and telemetry from the

rover is provided using an Intel Mini-PCI Wi-Fi card.

A software system allows the rover to au-

tonomously navigate and perform tasks in the envi-

ronment. The NVidia Jetson TK1 board runs Robot

Operating System middleware (ROS Indigo) on an

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

80

Figure 2: Hardware Architecture.

Ubuntu Linux 14.04 operating system environment,

allowing convenient and free access to a large array

of open-source software modules developed by the

ROS community (with names noted when appropri-

ate here), including many that implement results from

other research projects. ROS nodes may be connected

to sensors or actuators, or they may be intermedi-

ate nodes that process data. Sensor-connected nodes

broadcast sensor information via topics in the ROS

system, so that other nodes may use them as inputs for

computation, actuator-connected nodes read informa-

tion from ROS topics and output commands to their

controllers, and other nodes simply process informa-

tion from topics while broadcasting new topics. Our

system contains four ROS sensor nodes: an IMU node

(razor imu 9dof), a ZED stereo camera node (zed-

ros-wrapper), a laser scanner node (hokuyo node) and

a GPS node (nmea navsat driver).

Several intermediate nodes that are available as

part of the ROS community perform various naviga-

tion processing tasks as follows:

• A transform broadcaster publishes information re-

garding the relative movement of the rover parts.

• A GPS transform node (navsat transform node)

converts the GPS coordinates to approximate 2-D

orthogonal coordinates in a fixed Cartesian Coor-

dinate System parallel to the rover plane of oper-

ation.

• A Hector-SLAM node (Kohlbrecher et al., 2011)

converts laser readings into odometry estimation

according to the displacement of laser-detected

objects.

• A visual odometry node converts information

from the stereo camera into estimation of robot

movements. and extended Kalman Filter node

(Moore and Stouch, 2014) fuses all the odometry

information and the velocity and orientation infor-

mation from the IMU to produce one final global

odometry estimate.

• An RTAB-MAP node (Labb

´

e and Michaud, 2014)

uses the final odometry estimate and the camera

data to reconstruct a 3-D and 2-D representation

of the environment

• A map-server node manages complex maps by de-

composing them into multiple smaller parts and

determines when to use the various map parts.

Several new ROS nodes were written specifically

for the agricultural rover platform to facilitate outdoor

agricultural navigation tasks in the context of farm

monitoring as follows:

• A custom-designed controller node sets wheel

speed for all four wheels, controls the wheel an-

gles through the linear actuators for steering, and

feeds back wheel and steering odometry via the

SPI interface to the Arduino board.

• As most existing path planners are precise in

nature and do not perform well in uncertain or

changing environments, a path planner node was

created with a simplified algorithm for choos-

ing uncomplicated paths efficiently through open

spaces such as farm fields.

• A global planner node takes goal information and

produces a plan though the 2-D map that allows

the rover to reach its destination, a local planner

takes a global plan and sends command to the

wheel controller, moreover it stops the rover in the

advent of unmapped obstacles such as passing an-

imals, a navigator node store the set of goals that

a user may input into the rover and oversees the

execution of the plan.

• Finally a connector node connects ROS to an ex-

ternal user interface, such interface is the point of

access of a farmer and it offers the ability to look

at the re-constructed map and input high level

goals to the rover, such as sampling at multiple

destinations.

These new ROS nodes perform the key functions

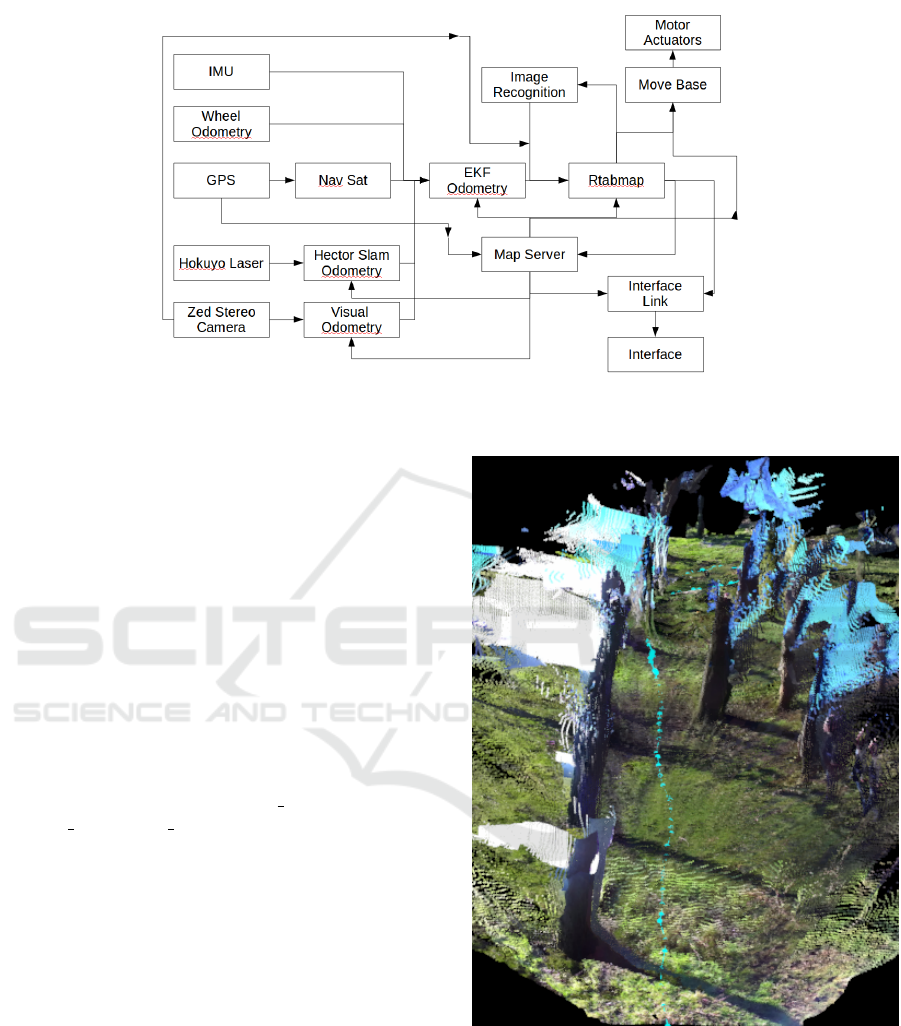

that are the focus of the remainder of the paper. Figure

3 shows an overview of the architecture of the soft-

ware system.

Autonomous Navigation with ROS for a Mobile Robot in Agricultural Fields

81

Figure 3: Software Architecture.

3 SENSOR FUSION FOR

ODOMETRY

Due to the focus on reducing costs of the rover plat-

form and sensors, rover perception is short in range

and low in precision, and due to the focus on outdoor

mobility, wheel odometry by itself is too unreliable

for mapping purposes and GNSS localization alone

is considered to be too inaccurate for short (less than

3m) distances. To obtain accurate movement odom-

etry, a combination of visual odometry using RTAB-

Map, laser-based odometry using Hector-SLAM, and

wheel odometry is used. This information is fused us-

ing the Extended Kalman Filter and robot localization

model available in the ROS robot localization pack-

age (ekf localization node).

The greatest challenge for robotic navigation in

farming fields is the uniformity of terrain and exter-

nal features. Each part of a field or orchard looks

very much the same visually or in terms of solid ob-

stacles, and even when navigating down crop rows,

visual measurement of distances is a challenge. The

most precise sensor on the rover is a Hokuyo UTM-

30LX-EW laser scanner, which performs very well

in an indoor environment with walls and well-defined

obstacles, but cannot provide consistent tracking in a

sparse, unchanging or empty environment. Initially,

visual odometry and mapping using the ZED stereo

camera and RTAB-Map was evaluated as a single sen-

sory method, producing a good-quality 3D represen-

tation of our lab and some outdoor areas in which fea-

tures are rich in complex, recognizable objects such as

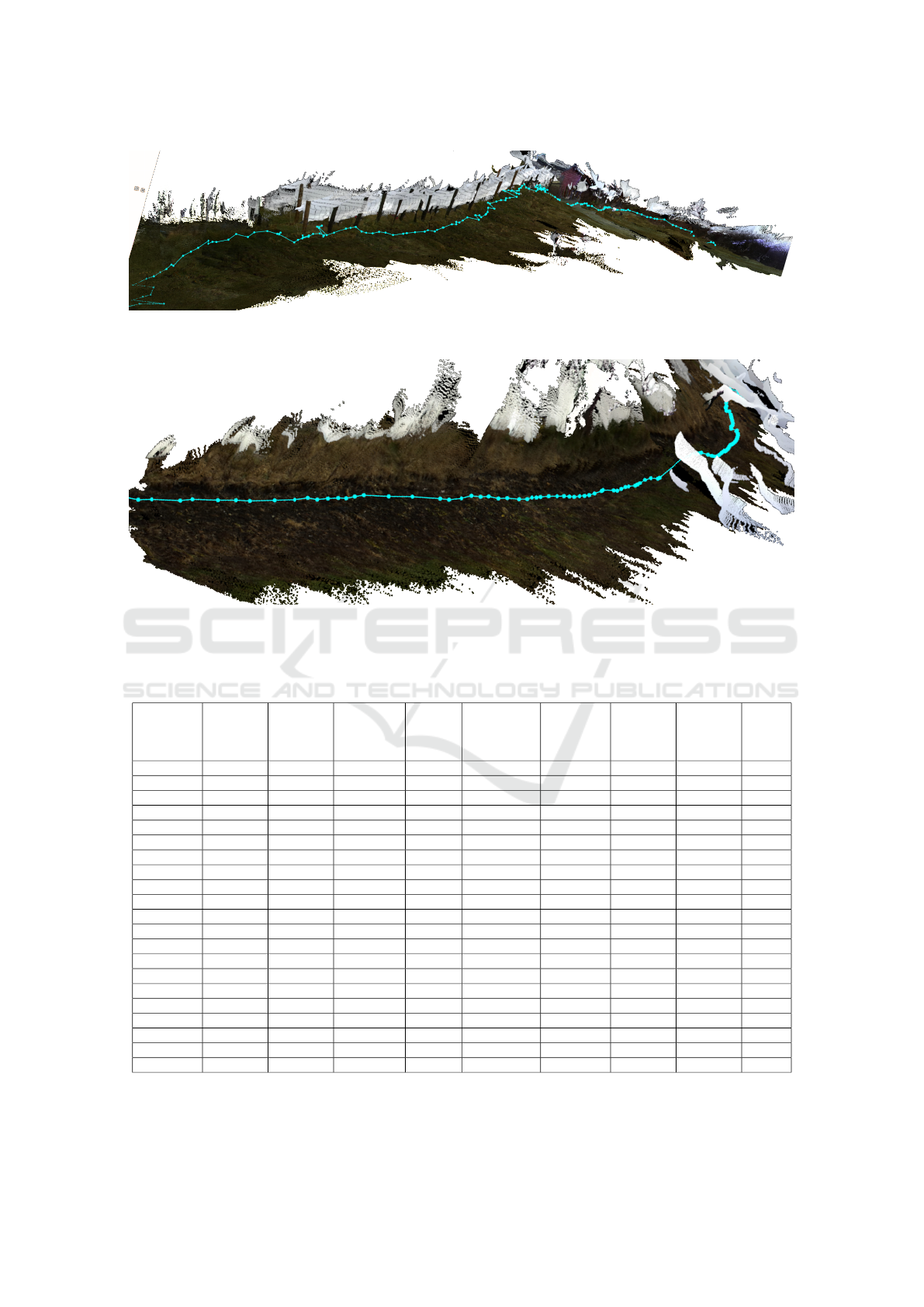

the grove of trees shown in Figure 4. However, exper-

imenting with RTAB-MAP software under different

system configurations made it became clear that small

Figure 4: High-quality 3-D reconstruction of a grove of

trees on a farm from RTAB-Map. Visual odometry is con-

sistent only while differences between locations in the scene

are obvious and discernible.

errors in the odometry estimation caused the 3-D ob-

jects to shift in space and produce very bad recon-

structions, and in outdoor environments it is generally

not possible to reproduce good quality 3-D maps like

these in real time.

RTAB-Map has not been extensively tested in out-

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

82

door environments, and the use of appearance-based

mapping requires large numbers of distinct features

for accurate odometry and loop closure. RTAB-Map

does not provide any correction on the odometry es-

timation between two successive frames, only large

loop closures are subject to optimization once a map

has been created. In the agricultural context the great-

est challenge is traversal across farmers’ fields, where

very few nearby visual references are available for

odometry and loop closure. Figure 5 shows a naviga-

tional map obtained from a farm field with a fenced

boundary, in which good visual odometry is main-

tained as long as distinct objects around the bound-

ary are present. This represents a relatively easy map

to obtain at a speed of approximately 0.5 m/s due to

the diversity of features available and navigation is

straightforward as long as the boundary is in view of

the rover. A more difficult situation is shown in 6,

where the farm field boundary is grassy and lacking in

distinct features. A slower forward speed of 0.2 m/s or

lower is necessary to perform mapping while travel-

ling along the boundary of this field, and visual odom-

etry is less consistent. It is still possible to maintain

good odometry when travelling along the perimeter

of this field as long as some features are tracked well.

However, as soon as the boundary is out of the rover’s

view when entering the centre of the field, odometry

is easily lost and the quality of the map is compro-

mised.

To evaluate the quality of odometry in an outdoor

environment, a test was run outdoors in which five

points were chosen in a 100 squared meter area and

their relative position from a starting point was mea-

sured. The rover was manually driven through the five

points, and the odometry estimation was recorded.

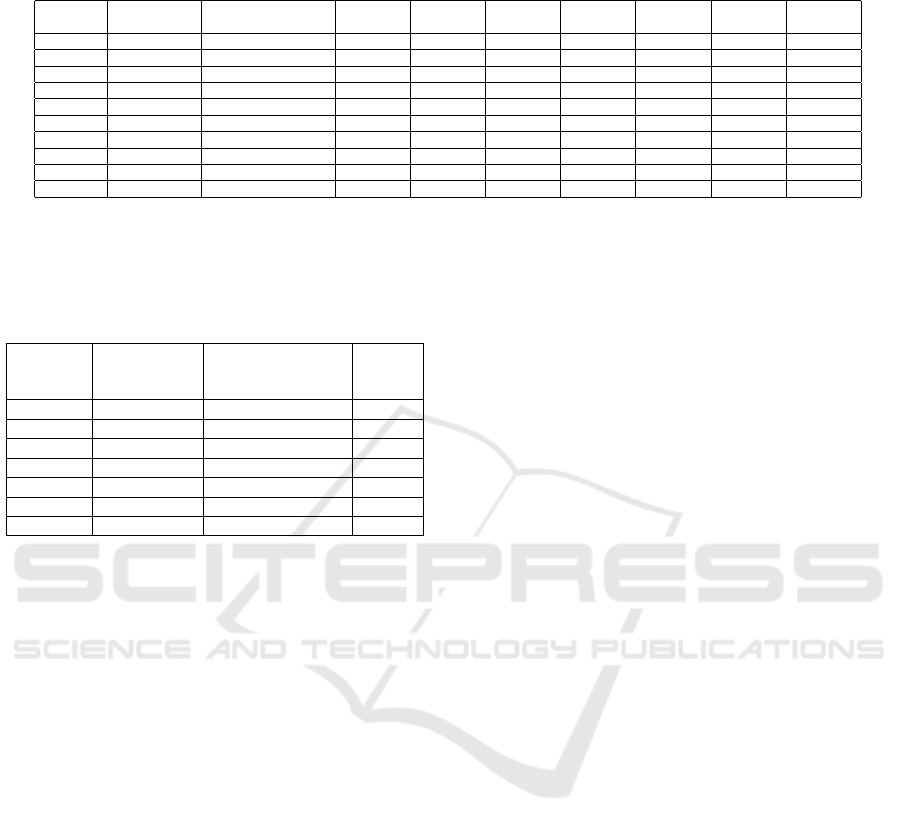

Table 1 reports the average error between real position

and recorded odometry under different configurations

of the extended Kalman Filter node. The left column

highlights the sensor information that has been fused

in the EKF node, and the right column contains the

average error in meters. The smallest error recorded

in this test was 1.77 meters.

Our experiment confirmed that while the laser

scanner was the most reliable sensor indoors, provides

little reliable information in a large outdoor area. The

irregular shapes of the plants does not only offer a

challenge to Hector-Slam node in the reconstruction

of a 2-D laser map, but the uneven terrain adds noisy

shifts in the laser readings. As 3D reconstruction at-

tempts proved that the error was too large to produce

a full 3-D map of the area under test, emphasis in the

mapping process is now being shifted to producing a

reliable 2-D obstacle map that can be overlaid on a

topographic elevation map.

4 LOCAL PLANNER

In our original design we planned to use the

global planners and local planners available for the

move base node of ROS, which provides a general

infrastructure to integrate different pairs of global and

local planners. The node requires a 2-D occupancy

map and a set of goal locations to compute a global

plan and output velocity commands in real time to

the drive motors until the destination is reached. Ini-

tially, the basic Navfn global planner in ROS was

tested on the rover since it provides valid planning

around mapped obstacles. However, it was found that

nearly all ROS-based planners made critical assump-

tions about the underlying mobility hardware, in par-

ticular that commands and odometry feedback would

be executed immediately with negligible time lag and

that small incremental movements would be possible.

As the rover platform uses four-wheel steering and

takes time to accelerate and turn, the planning algo-

rithms would repeatedly issue commands for small,

incremental angular adjustments (or in the case of

the ROS teb local planner, back-and-forth steering

movements) and when this failed due to either actua-

tor lag or lack of precise movement, execute recovery

behaviours. To remedy this problem, we developed

a new and simplified planner that relaxed the con-

straints on timing and precision in favour of a best-

effort approach.

For trial testing, we created a very simple al-

gorithm: at the start the rover rotates on the spot

and aligns itself along the direction of the global

path, then it tries to follow the path by steering

when needed either when the direction of the curves

changes too much or the rover moves too far away

from the plan. Once the destination is reached a sig-

nal is sent to the navigator nodes which may provide

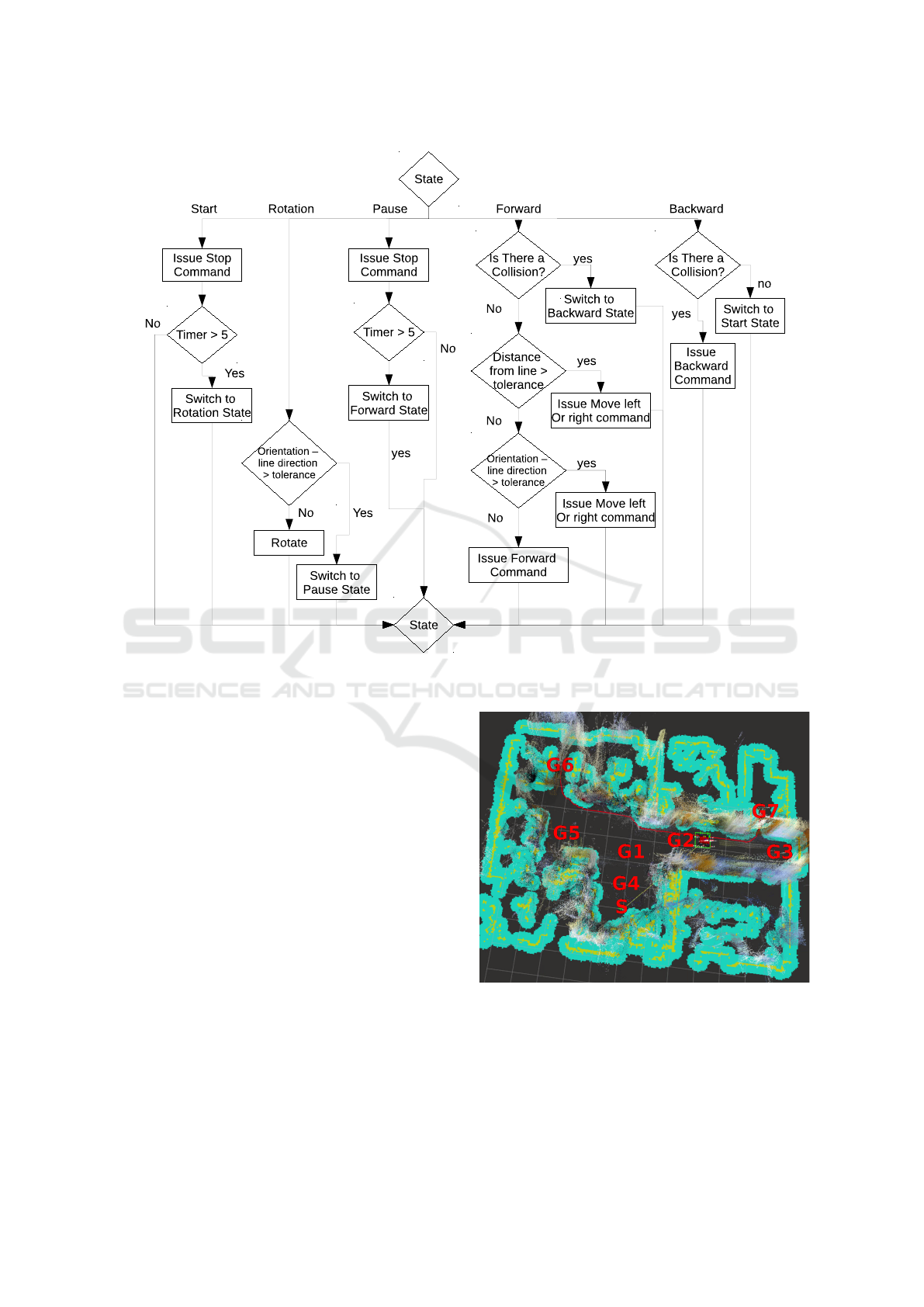

another goal or halt the rover. The planner uses five

states of operation with appropriate commands sent

to the drive motors for the duration of each state:

Start, Forward, Backward, Pause, and Rotation. A

flowchart of the process the planner uses when mov-

ing from the current movement state to the next move-

ment state is given in Figure 7.

Making use of the high-quality odometry informa-

tion available by using Hector SLAM and the scan-

ning laser rangefinder in the lab environment, this

planner showed much better reliability on the rover

platform. In the trial for the planner, seven different

points were set spaced far apart on the lab floor and

the rover was directed to visit them autonomously in

order. Table 2 reports the distance between the set

goals and the point the rover stopped at, and an aver-

age error of 15cm was recorded at the points the rover

stopped. Figure 8 shows the 2-D Hector SLAM and

Autonomous Navigation with ROS for a Mobile Robot in Agricultural Fields

83

Figure 5: High-quality 3-D reconstruction of a farm field with fenced border from RTAB-Map. As long as the border is in

view, visual odometry can be maintained.

Figure 6: High-quality 3-D reconstruction of a farm field with grassy border from RTAB-Map. The border of the field provides

barely enough discernible references to maintain visual odometry.

Table 1: The average fused odometry error in localizing at five points in a 100 squared meter outdoor area with respect to the

different sensors fused by the EKF node.

Laser

Odometry

Visual

Odometry

Linear

Velocity

Visual

Odometry

Angular

Velocity

IMU

Orientation

IMU

Angular

Velocity

IMU

Linear

Acceleration

GPS Wheel

Odometry

Linear

Velocity

Wheel

Odometry

Angular

Velocity

Error

in

Meters

absolute 6.81

absolute absolute 2.22

absolute absolute 4.01

absolute absolute 4.31

absolute absolute absolute 2.74

absolute absolute 5.13

absolute absolute 2.95

absolute differential 7.14

absolute differential absolute absolute 6.03

absolute absolute 7.92

absolute absolute 5.25

absolute absolute absolute 5.96

absolute absolute 4.61

absolute differential 7.99

absolute differential differential 4.26

absolute absolute absolute absolute 8.10

absolute absolute absolute differential absolute absolute differential 4.47

absolute absolute absolute differential absolute absolute differential absolute absolute 4.99

differential absolute absolute absolute absolute absolute absolute 1.77

differential absolute absolute absolute absolute 1.23

differential absolute absolute absolute absolute absolute absolute absolute absolute 3.87

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

84

Figure 7: Flowchart of the navigational planner process. The planner sends commands to the drive motors while in each of

five states, and state transitions are performed where indicated.

reconstructed 3-D RTAB-Map maps of our lab and the

testing path: S marks the starting point and each num-

bered goal point is marked G. The goals are structured

in order of the difficulty of reachability:

1. from S to G1 there is a straight path

2. from G1 to G2 a turn on the spot is involved

3. from G3 to G4 there is a sharp corner

4. from G5 to G6 there is a narrow path

5. from G6 to G7 the path includes a narrow door

The same experiment was executed in an outdoor

area. Unfortunately, due to the low mapping quality

and the higher position uncertainty of the rover in out-

door environment, the rover could reach only the first

goal with an error of 1-2 meters and was not able to

reach the following ones. Table 3 reports the distance

between the set goal and the point the rover stopped

at. During these test the GPS system was not used,

since it was missing at the time and the experiment

was not repeated.

Figure 8: Reconstructed map of our lab and testing paths.

The picture was taken when the rover was attempting the

navigation from G6 to G7, but G7 was never reached as the

rover could not cross the door.

5 CONCLUSION

In this paper we introduced a practical and cost-

Autonomous Navigation with ROS for a Mobile Robot in Agricultural Fields

85

Table 2: The navigation error in the lab environment for each one of the six goals, depending on the enabled sensors (NR

stands for Not Reached).

Laser

Odometry

Other

Sensors

Measure Goal 1

Error (cm)

Goal 2

Error (cm)

Goal 3

Error (cm)

Goal 4

Error (cm)

Goal 5

Error (cm)

Goal 6

Error (cm)

Goal 7

Error (cm)

absolute 0 20 20 NR NR NR NR

absolute IMU Angular Velocity 0 5 15 0 0 0 NR

absolute IMU Linear Acceleration 25 10 35 NR NR NR NR

absolute IMU Both above measures 0 20 35 0 20 NR NR

absolute Visual Odom. Linear Velocity 20 30 5 5 NR NR NR

absolute Visual Odom. Angular Velocity 0 10 25 0 0 20 NR

absolute Visual Odom. All Velocities 0 50 20 5 40 20 NR

absolute Wheel Odom. Linear Velocity 70 30 30 0 NR NR NR

absolute Wheel Odom. Angular Velocity 10 60 25 150 25 0 NR

absolute Wheel Odom. All velocities 5 NR NR NR NR NR NR

Table 3: The navigation error in garden environment for

one goal located 15 meters ahead of the starting position,

depending on the enabled sensors. NR stands for Not

Reached.

Laser

Odometry

Other

Sensors

Measure Goal

Error in

meters

absolute 1.5

absolute IMU Angular Velocity 2

absolute IMU Linear Acceleration 3

absolute Visual Odom. Linear Velocity 0.5

absolute Visual Odom. Angular Velocity NR

absolute Wheel Odom. Linear Velocity 1

absolute Wheel Odom. Angular Velocity 1.5

-effective robotic rover platform for autonomous envi-

ronment monitoring in agriculture, and discussed sev-

eral key technologies implemented in ROS for odom-

etry and localization, identification of objects, and,

path planning under limited kinematic precision. Our

results to date regarding navigation indicate that the

rover can successfully reach set navigational points

with high precision so long as accurate and real-

time localization is available such as that provided

by Hector SLAM against fixed obstacles. We have

also established that the methods used for indoor and

feature-rich localization and odometry are not suit-

able for use outdoors in uniformly-visual farm fields.

We are nonetheless able using a low-cost rover plat-

form with a minimal sensor set to traverse naviga-

tional goals efficiently and quickly using a simple, ef-

ficient, and kinematically-tolerant planning algorithm

for our rover platform.

The next steps in our ongoing work to develop

this platform include the integration of differential

GNSS localization between a local base station and

the rover using the recently-released u-blox C94M8P

devices as a supplement for odometry in feature-poor

field environments, and the integration of soil sam-

pling and visual measurement technologies to allow

autonomous monitoring activities to be tested in the

field.

ACKNOWLEDGEMENTS

This work was made possible and supported by grants

from the Science and Technology Facilities Council

Newton Fund. The authors gratefully acknowledge

the work of the Rutherford Appleton Laboratories

(RAL) Autonomous Systems Group for the design

and construction of the mechanical platform for the

rover, the James Hutton Institute for providing field

test facilities in support of this research, and the work

of Jonathan Watson, Giacomo Corvi, Kyle Burnett,

Jennifer Miller, and Finlay Harris on setting up and

testing RTAB-Map algorithms in ROS.

REFERENCES

Hayashi, S., Shigematsu, K., Yamamoto, S., Kobayashi, K.,

Kohno, Y., Kamata, J., and Kurita, M. (2010). Eval-

uation of a strawberry-harvesting robot in a field test.

Biosyst. Eng., 105:160–171.

Hayashi, S., Yamamoto, S., Saito, S., Ochiai, Y., Kohno, Y.,

Yamamoto, K., Kamata, J., and Kurita, M. (2012). De-

velopment of a movable strawberry-harvesting robot

using a travelling platform. In Proc. Int. Conf. Agric.

Eng. CIGR-AgEng 2012, Valencia, Spain.

Henten, E. V., Tuijl, B. V., Hemming, J., Kornet, J., and

Bontsema, J. (2003a). Collision-free motion planning

for a cucumber picking robot. Biosyst. Eng., 86:135–

144.

Henten, E. V., Tuijl, B. V., Hemming, J., Kornet, J.,

Bontsema, J., and van Os, E. A. (2003b). Field test

of an autonomous cucumber picking robot. Biosyst.

Eng., 86:305–313.

Katupitiya, J., Eaton, R., and Yaqub, T. (2007). Systems

engineering approach to agricultural automation: New

developments. In 1st Annual IEEE Syst. Conf., pages

298–304.

Kohlbrecher, S., Meyer, J., von Stryk, O., and Klingauf, U.

(2011). A flexible and scalable slam system with full

3d motion estimation. In Proc. IEEE International

Symposium on Safety, Security and Rescue Robotics

(SSRR). IEEE.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

86

Krahwinkler, P., Roßmann, J., and Sondermann, B. (2011).

Support vector machine based decision tree for very

high resolution multispectral forest mapping. In 2011

IEEE International Geoscience and Remote Sensing

Symposium, IGARSS 2011, Vancouver, BC, Canada,

July 24-29, 2011, pages 43–46.

Labb

´

e, M. and Michaud, F. (2014). Online global loop

closure detection for large-scale multi-session graph-

based SLAM. In 2014 IEEE/RSJ International Con-

ference on Intelligent Robots and Systems, Chicago,

IL, USA, September 14-18, 2014, pages 2661–2666.

Moore, T. and Stouch, D. (2014). A generalized extended

kalman filter implementation for the robot operating

system. In Proceedings of the 13th International Con-

ference on Intelligent Autonomous Systems (IAS-13).

Springer.

Roßmann, J., Jung, T. J., and Rast, M. (2010). Developing

virtual testbeds for mobile robotic applications in the

woods and on the moon. In 2010 IEEE/RSJ Interna-

tional Conference on Intelligent Robots and Systems,

October 18-22, 2010, Taipei, Taiwan, pages 4952–

4957.

Roßmann, J., Schluse, M., Schlette, C., B

¨

ucken, A., Krah-

winkler, P., and Emde, M. (2009). Realization of a

highly accurate mobile robot system for multi purpose

precision forestry applications. In The 14th Int. Conf.

Adv. Robotics, pages 133–138.

van Henten, E. J., Hemming, J., van Tuijl, B. A. J., Kornet,

J. G., Meuleman, J., Bontsema, J., and van Os, E. A.

(2002). An autonomous robot for harvesting cucum-

bers in greenhouses. Auton. Robots, 13(3):241–258.

Autonomous Navigation with ROS for a Mobile Robot in Agricultural Fields

87