Automatic Selection and Sequencing of Traps for Vibratory Feeders

Simon Mathiesen and Lars-Peter Ellekilde

The Maersk McKinney Moller Institute, University of Southern Denmark, Campusvej 55, 5230 Odense M, Denmark

Keywords:

Automatic Configuration, Dynamic Simulation, Design from Simulation, Parts Feeding, Vibratory Bowl

Feeders.

Abstract:

Vibratory parts feeders with mechanical orienting devices are used extensively in the assembly automation

industry. Even so, the design process is based on trial-and-error approaches and is largely manual. In this

paper, a methodology is presented for automatic design of this type of feeder. The approach uses dynamic

simulation for generating the necessary data for configuring a feeder with a sequence of mechanical orienting

devices called traps, with the goal of reorienting all parts from a random to fixed orientation. Then, a fast

algorithm for facilitating this configuration task automatically is developed from domain specific knowledge.

Finally, the algorithm is validated on three industrial cases and its drawbacks and strengths are discussed in

detail.

1 INTRODUCTION

Parts feeders using vibrations as means of conveying

have been a widely used concept in industrial automa-

tion for decades. This type of feeder comes in two

forms being the linear feeder and the bowl feeder (il-

lustrated in Figure 1).

The working principle for the feeders is fairly sim-

ple, using combined vertical and horizontal vibration

to shake parts forward along the either straight or spi-

ral track. On this track the parts encounter mecha-

nisms, so-called traps, that can cause the parts to re-

orient or force wrongly oriented parts off the track.

When used correctly, the effect of these traps are that

all parts reaching the end of the track will have the

same orientation, thereby being ready to be picked or

fed into an automated assembly system.

Although the technology has been readily avail-

able for decades, little has changed in the approach to

designing this feeder type. This task still relies heav-

ily on trial-and-error and is done by skilled techni-

cians, or engineers, combining experiences with sig-

nificant amounts of parameter tuning on the physical

system. Although some part families can be associ-

ated with some standard solution of combining spe-

cific trap mechanisms (such as caps or bolts) a high

degree of customisation is often needed. This fre-

quently result in excessively high prices even for basic

feeding solution due to the cost of the manual labour

put into designing and testing the feeder.

Figure 1: CAD-model of a vibratory bowl feeder.

Researchers have investigated the topic of feeder de-

sign before, but to our knowledge a holistic solution

for automatic design of vibratory feeders is still lack-

ing. The overall aim of this work is to produce such an

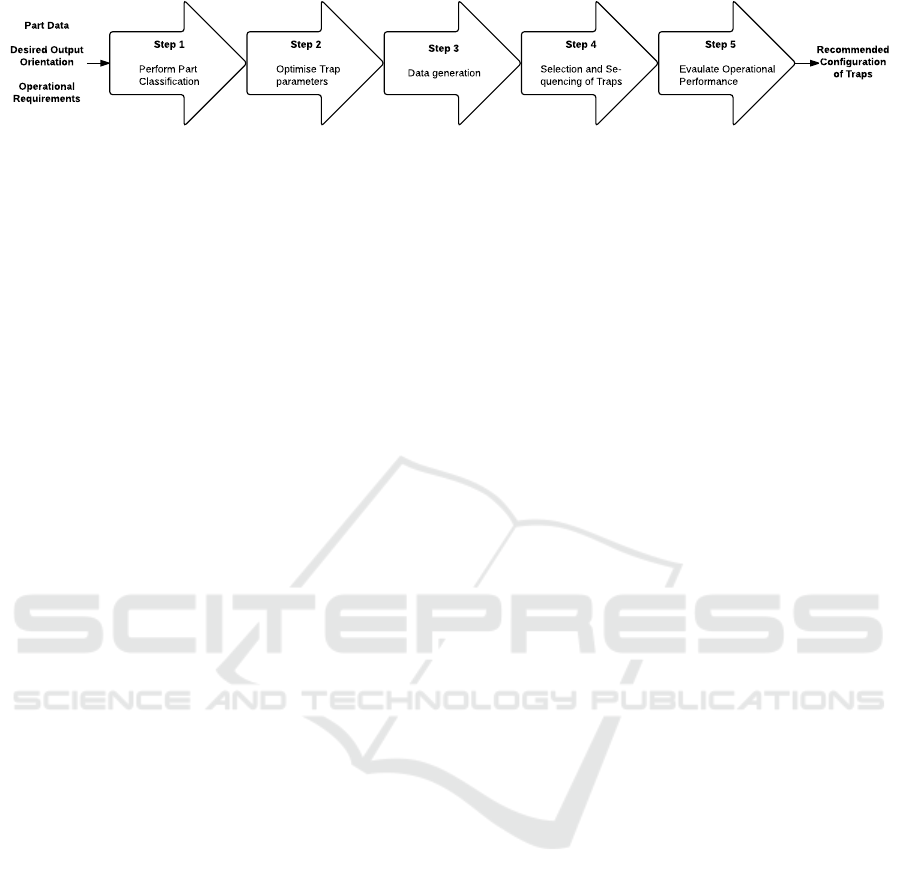

automatic solution, for which a general methodology

is presented in Figure 2.

The proposed method is inspired from (Mathiesen

and Ellekilde, 2016) and (Hansson et al., 2016), but

will not rely on precomputed data for generic object

categories. The four steps in the proposed method are

therefore:

1. Classifying the part to be fed to a family of parts

with the purpose of determining suited trap prin-

ciples.

2. Setting the trap parameters for the specific part

and potentially optimising these using simulation.

Mathiesen, S. and Ellekilde, L-P.

Automatic Selection and Sequencing of Traps for Vibratory Feeders.

DOI: 10.5220/0006440801450154

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 145-154

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

Step 1

Perform Part

Classification

Step 2

Optimise Trap

parameters

Step 4

Selection and Se-

quencing of Traps

Step 5

Evaulate Operational

Performance

Part Data

Desired Output

Orientation

Operational

Requirements

Recommended

Configuration

of Traps

Step 3

Data generation

Figure 2: Design methodology for automatic configuration of vibratory feeders.

3. Producing the behavioural data for traps through

simulation of the part interacting with these traps.

4. Using this data to automatically select the best se-

quence of traps that orients the part.

5. Evaluate the performance of the solution against

requirements (orienting capability, feed rate, etc.).

In this paper we specifically address steps 3 and 4

of automatically finding feeder configurations. Steps

1 and 2 are done according to (Boothroyd, 2005).

The remainder of the paper is structured as fol-

lows: Relevant literature on previous work are re-

viewed in Section 2. Section 3 presents the proposed

approach for generating behavioural data and the al-

gorithm for automatic selection and sequencing of

traps. This is followed by test results in Section 4

and general discussion, conclusion and future work in

Sections 5 and 6.

2 RELATED WORK

The work of (Boothroyd, 2005) is an extensive collec-

tion of work with guidelines for aiding in the design

of vibratory bowl feeders. The work covers the me-

chanics of the vibratory bowl feeder in detail, but also

provides an extensive appendix on part classification

for mapping specific part features (e.g. protrusions,

holes. etc.) to mechanisms potentially utilising those

features to orient the part.

Other researches have also investigated the use of

guidelines to help designers. An expert advisory sys-

tem is presented by (Tan et al., 1995) for the selection

of traps to orient parts. This expert advisor uses data

from a part classification system to provide an user

with suggestions on feasible traps. A similar rule-

based system capable of suggesting traps is presented

by (La Brooy et al., 1995), where relevant part fea-

tures are extracted directly from the CAD-model of

the part, thus eliminating the need for designers to

manually be able to classify the part.

The works described above are based on knowl-

edge obtained from formalised prior experiences and

extensive testing on physical hardware and are useful

to guide the conceptual design of the vibratory feed-

ers. Specifically, the work of (Boothroyd, 2005) also

delivers approximations of how to set the internal

parameters of a number of trap mechanisms to obtain

the desired orienting capabilities. Even so, the only

way to fully validate the performance of a feeder de-

sign is to construct it. Doing this physically is time-

consuming and costly and therefore greatly merits the

use of simulation for prototyping and data acquisition

as discussed in (Mathiesen and Ellekilde, 2016) and

(Hansson et al., 2016).

Using simulation to model and validate designs of

vibratory feeders is not a new concept. (Berkowitz

and Canny, 1996) and (Berkowitz and Canny, 1997)

investigated the interaction between one trap mecha-

nism and two types of parts being cuboids and cylin-

drical. Their work presented an overall consistency

between their prediction in simulation and experi-

ments on a physical test platform, although with some

differences. (Jiang et al., 2003) developed a custom

simulation software for vibratory bowl feeders and

validates the performance of a trap with varying op-

erational parameters for rejecting wrongly oriented

cuboids. In recent work (Stocker and Reinhart, 2016)

the Bullet Physics Engine (Coumans, 2010) is used

to model part behaviour in a vibratory feeder. Here

they investigate the efficiency of a step mechanisms

and the correlation between this efficiency, the height

of the step and the length of the part.

In the literature, simulation has primarily been

used to validate a trap design, with some parameters

manually set by a designer, but in the work by (Hof-

mann et al., 2013) an algorithm is presented for au-

tomatic parameter optimisation of trap mechanisms.

This work also uses dynamic simulation for evalua-

tion of trap performance and, in addition to the geo-

metric shape of the trap, also incorporates the vibra-

tional amplitude into the optimisation. Their optimi-

sation algorithm have been tested with a single step

trap, feeding a cuboid and a cylindrical-like object.

Another approach to optimisation of trap parame-

ters is presented in (Berretty et al., 2001). They de-

veloped an algorithm based on computational geom-

etry for finding good parameter values for four dif-

ferent trap mechanisms. Common for all four traps

is that they work by letting wrongly oriented parts

fall through a gap in the feeding track, but using only

this type of trap, the authors show that their algorithm

can find traps correctly filtering out wrong orientation

of a complex industrial part. A similar approach to

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

146

trap design is found in (Goemans et al., 2006) which

presents an algorithm for finding the parameters for a

trap family of blades.

Automatic optimisation of the parameters of in-

dividual traps has been explored to some degree, but

little work has been done in the automatic selection

and sequencing of these mechanisms beyond the rule-

based suggestion systems listed in the beginning of

this section. This is with the exception of (Chris-

tiansen et al., 1996) who tackles the problem using a

Genetic Algorithm (GA) approach. Their algorithm

finds good feeder designs, but due to the GA ap-

proach optimality is not guaranteed. The input data

for the algorithm is based on results from (Murch and

Boothroyd, 1971) and (Boothroyd, 1992) (earlier ver-

sion of (Boothroyd, 2005)), in the form of several ma-

trices mapping the input orientations to output orien-

tations of a part. In their work (Christiansen et al.,

1996) express plans to augment their approach with

automatic generation of the required input data for the

algorithm, but to our knowledge these plans where ei-

ther not pursued or successful.

3 AUTOMATIC

CONFIGURATION OF

VIBRATORY FEEDERS

Assuming a finite number of possible orientations of a

part on the track, the work of (Murch and Boothroyd,

1971) and (Boothroyd, 2005), presents how the be-

haviour of a trap can be encoded into a stochastic tran-

sition matrix mapping an observed input orientation

distribution to an output distribution. An example of

such a transition matrix is given in (1)

T =

O

1

O

2

... O

N

O

1

P(O

1

|O

1

) P(O

2

|O

1

) . . . P(O

N

|O

1

)

O

2

P(O

1

|O

2

) P(O

2

|O

2

) . . . P(O

N

|O

2

)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

O

N

P(O

1

|O

N

) P(O

2

|O

N

) . . . P(O

N

|O

N

)

(1)

where O

i

represents the different orientations and

P(O

j

|O

k

) is the probability of ending in orientation

O

j

given it starts in O

k

.

When multiple traps are placed in sequence the

combined behaviour can be obtained by simple ma-

trix multiplication of the transition matrices. Given

an initial distribution, p

init

, as a row vector, of orien-

tations of the parts on the track and a sequence of M

traps with transition matrices T

i

the output distribution

p

out

can be computed as:

p

out

= p

init

M

∏

i=1

T

i

(2)

Figure 3: To obtain data mapping input orientations to

output orientations parts are simulated conveying from the

Starting area (blue), across the Trap area (grey) to the Tar-

get area (red).

The method is straight forward, but has a problem

with availability of data. Constructing the transition

matrices requires observations on how a part interacts

with a trap. First, for the method to be reliable, a sig-

nificant amount of observations are needed and manu-

ally acquiring the necessary magnitude of data is im-

practical. Secondly, these matrices are highly dedi-

cated to a specific part-trap pair as well as the specific

parameter settings for that trap. Physically building

the traps for orienting a specific part and next observ-

ing the performance of each is hence an infeasible

strategy, thus we suggest the use of dynamic simu-

lation of the vibratory feeder to produce the data effi-

ciently as discussed below.

3.1 Generating the Transition Matrices

In our earlier work (Mathiesen and Ellekilde, 2016),

dynamic simulation of vibratory feeders were anal-

ysed when using the physics engine ODE v0.13

(Smith, 2006) together with the simulation environ-

ment RobWorkSim (Joergensen et al., 2010). Using

the same simulation environment and physics engine,

and knowing the possible orientations of the part, the

transition matrices for a part-trap combination can be

generated automatically.

Figure 3 illustrates a piece of the feeder track with

three marked areas: 1) Starting area (blue), 2) Trap

area (grey), 3) Target area (red). As the name indi-

cates, traps are inserted into the Trap area with the

purpose of interacting with the parts and potentially

reorient or reject them. Any non-rejected part will

reach the target area where its resulting orientation

can be saved. This final orientation of the part is

paired with its initial orientation prior to interacting

with the trap.

The transition matrix is then constructed by

matching the two orientations to the defined set of ori-

entations of the part as follows:

1. If the part is rejected by the trap, increment the re-

jection counter for that starting orientation index.

Automatic Selection and Sequencing of Traps for Vibratory Feeders

147

2. If not rejected, find in the defined set of orienta-

tions the best matching for the the pre- and post-

trap orientations and update the corresponding el-

ement in the transition matrix.

3. Normalise each row together with its correspond-

ing rejection counter (unless all elements in equal

0).

When finding the best matching orientations it is

important to compensate for the rotation of the track,

such that the part orientation is found relative to the

direction of the track.

It is important to note, that not all traps consists of

a transition between two pieces of the original track

type (e.g. a flat track, the a trap and then the same flat

track). An example is the trap consisting of a groove,

which can be used to catch a part by its protrusion.

For this trap to function, the track is tilted at an an-

gle towards the centre of the bowl effectively making

parts, not caught in the groove as intended, slide off

the track. In this case, the tilt angle of the track must

be accounted for in the matching, which should there-

fore not only consider the direction of the track but

also the normal.

In this work a total of nine trap principles are used.

These are illustrated in Figure 4. The set of nine traps

are chosen to be sufficient for describing the algo-

rithm. The sloped track with groove and the slotted

track are treated as final traps as none of the other

traps can succeed them due to the before mentioned

angling of the track. For convenience, abbreviations

for the traps are listed in the captions.

3.1.1 Dealing with Rotational Symmetry of

Parts

Some parts, like discs and cylinders, are symmetric

around an axis of rotation, which needs to be ac-

counted for in the method for automatically matching

observed orientations. For this a so-called orientation

group is defined to represent a set of orientations only

differing in a rotation around the symmetry axis. A

practical implementation of such a group is as a list

of orientations representing the set, then a match to

the orientation can be found to the best sample within

this set.

3.2 Selecting and Sequencing Traps

The transition matrices allows combining the func-

tionality of the traps into a feeder configuration (se-

quence of traps), thus estimating the functionality of a

specific sequence of traps. The proposed search strat-

egy consists of dynamically constructing a tree, where

each node represents a feeder configuration and has

(a) Edgeriser (Er) (b) Narrowed

track (NT)

(c) Hole (Hl)

(d) Scallop (Sc) (e) Sloped track

with groove (Sp,

Final)

(f) Slotted track

(Sl, Final)

(g) Step (St) (h) Wiper blade

(WB)

(i) Wall projection

w. NT (WP)

Figure 4: All nine trap principles used in this work. Listed

with abbreviations for further reference and marking of ”Fi-

nal” to indicate a final trap.

an associated output distribution of orientations en-

coded as a row-vector p

out

and a rejection rate p

r

. For

the root the distribution will be the expected initial

distribution of parts on the track and the rejection rate

will be 0. Edges in the tree now represents different

traps and when branching to a new node, the transi-

tion matrix of the trap is post-multiplied on the distri-

bution vector of the parent, given the expected output

distribution for the child.

p

out,child

= p

out,parent

T

trap

(3)

The probability of rejection can be obtained from

p

out

by (4).

p

r

= 1 −

∑

p

out

(4)

(5)

A quality score, Q, of the configuration can now be

calculated using (7):

ˆp

out

=

p

out

|p

out

|

(6)

Q = (1 − p

r

)p

CO

(7)

where p

CO

corresponds to the correctly oriented parts

within ˆp

out

. The best quality which can be achieved

is Q = 1 and is when all parts are oriented correctly

and no parts are rejected in the process.

In many cases it can be an advantage to not look

for a specific orientation, but see which orientation

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

148

gives the most efficient output. In this case p

CO

in (7)

can be replaced by max( ˆp

out

).

The algorithm described above is essentially a

non-informed exhaustive search strategy and com-

plexity scales exponentially with the length of the se-

quence of traps. In general, a feeder configuration

is not limited to contain just a single instance of a

trap. This is because of some traps having probabilis-

tic behaviour. This means, that a trap can map one

input orientation to multiple output orientations with

different probabilities, e.g. a Step where parts can

end in multiple orientations, but with a potential bias

based on their shape and distribution of mass. In these

cases, repeating the same trap multiple times could be

needed for reducing the probability of an undesired

orientation. Therefore, the maximum allowed search

depth, M, must be bounded to some finite value for the

algorithm to terminate. Furthermore, the amount of

different traps, N, which can be applied to orient the

part also impact search time for the algorithm. The ac-

tual size of the tree, T , to explore for finding a feeder

configuration is therefore given by (8):

|T | =

M

∑

j=1

N

j

(8)

Searching through all possibilities will have an ex-

ponential and infeasible running time. However, by

realising that a solution can never achieve a higher

quality score than its probability of rejecting the part,

branches of the tree can efficiently be pruned away.

This is done by comparing the (1 − p

r

) value for a

node with the quality of the currently known best so-

lution. In the pseudocode of Algorithm 1 this is im-

plemented by not adding the non-promising node to

the queue where non-evaluated nodes are held. Fur-

thermore, the same check is made after a node is

taken from that queue as it could potentially have been

added before the current best solution was found. The

queue is implemented as a priority queue always hav-

ing the element with highest Q as the first element.

In addition to this branch closing strategy, an upper

bound for p

r

can be given to the algorithm to disre-

gard solutions rejecting too many parts to be feasible.

All sub-branches to a trap designated as final traps

are also closed as no trap can follow. The purpose

of a feeder configuration is to fully orient a part by

forcing the probability of an orientation to 1. Since

the data used for testing the algorithm in Section 4 is

made from traps with hand-tuned parameter-sets they

may not work optimally, hence feeder configurations

that nearly does full orientation can well be applica-

ble in a real world scenario. Therefore a margin for

treating a feeder configuration as a correct solution is

introduced.

Algorithm 1 Algorithm for finding suitable feeder

configurations for orienting parts.

// Initial state: Empty queue, q, for containing

nodes and empty list, c, for feeder configurations

add(root) to q // dummy node with Q = 0

while q 6=

/

0 do

node

cur

= best(q) // max(Q)

if depth(node

cur

) < M then

for each child node k do

Using (2) compute p

out

p

r

= 1 − sum(p

out

)

ˆp

out

=

p

out

|p

out

|

// normalise p

out

p

CO

= ˆp

out,desired

or max( ˆp

out

)

Q = (1 − p

r

) p

CO

if p

CO

≥ m

c

then

add(k) to c

end if

if (1 − p

r

) > Q

best

then

if p

r

< p

r,max

then

add(k) to q

end if

end if

end for

end if

end while

Return c

The final algorithm has three parameters that ef-

fects the result:

1. Margin for correct solution, m

c

.

2. Maximum allowed probability of rejection, p

r,max

.

3. Maximum search depth, M.

The maximum allowed p

r

should be set accord-

ing to specification from the surrounding system on

required feed rate based on possible conveying speed

for parts in the feeder. The max search depth must

also be set according to limitations on the physical

dimensions of the feeder, i.e. larger bowl diameter

makes room for more traps.

The final algorithm is presented in Algorithm 1,

where ˆp

out,desired

refers to the desired index of ˆq

out

when searching for a specific solution.

4 RESULTS

The algorithm described in the previous section has

been used to plan sequences of traps for the parts

shown in Figure 5.

Some trap principles are only applicable to certain

geometric features or dimension ratios, e.g a sloped

Automatic Selection and Sequencing of Traps for Vibratory Feeders

149

Table 1: List of the nine traps marking, with ”x”, which

were used for each part.

Trap name Cap Cone Brick

Edge riser - - x

Narrowed track - x x

Hole - - x

Scallop x - -

Sloped track w. groove x x x

Slotted track - x x

Step x x x

Wall projection w. NT x x x

Wiper blade - - x

track with a groove will not work if the part has no

protrusion that can be caught in that groove. There-

fore, data for interaction between the three parts and

the traps has only been made for a subset of the nine

traps, as listed in Table 1.

4.1 Stability Analysis of the Transition

Matrices

The proposed approach relies on accurate estimation

of the probabilities that make up the transition matri-

ces, recall (1). To investigate how many samples are

needed for this estimation to become stable, 10,000

simulations have been run for the three parts and all

of their associated traps. The effect of the trap is then

determined using (2), effectively resulting in the out-

put probability distribution vectors, p

out,i

, computed

from T

i

, where i refers to the number of samples used

to create that transition matrix. We then calculate the

difference between the current estimate and the previ-

ous using (9),

∆

i

= p

out,i

− p

out,i−100

(9)

Figure 5: The three parts used as cases for this work. From

left to right: Cap, Cone and Brick. Parts are shown in pro-

portion. For reference the coordinate system is oriented as

shown with origin in the centre of gravity of each part.

2000 4000 6000 8000 10 000

Samples

-0.015

-0.010

-0.005

0.005

0.010

0.015

Difference

Cap

Cone

Brick

Figure 6: Convergence of the transition matrices for the

three parts. The horizontal axis shows the number of sam-

ples used and the vertical the change in the output distribu-

tion, given in probability from 0 − 1.

where ∆

i

is computed for i = 100, 200, . . . , 10, 000

in steps of 100. For the three parts, we then

take the mean (∆

i

) across all traps and plotted as

{i, mean(∆

i

)} in Figure 6.

For low values of i, ∆

i

is large, thus the view in

Figure 6 is zoomed to the appropriate level of detail.

From the graph it can be seen that ∆

i

for all three parts

converges to near zero values fast, but with the Cap

and Cone both showing oscillating behaviour. This

is also the case for the Brick, but with less ampli-

tude. The result gradually becomes more stable, and

at 4000 samples ∆

i

< 0.001 for all parts, indicating

that less than 1h of the samples will change their out-

put orientation.

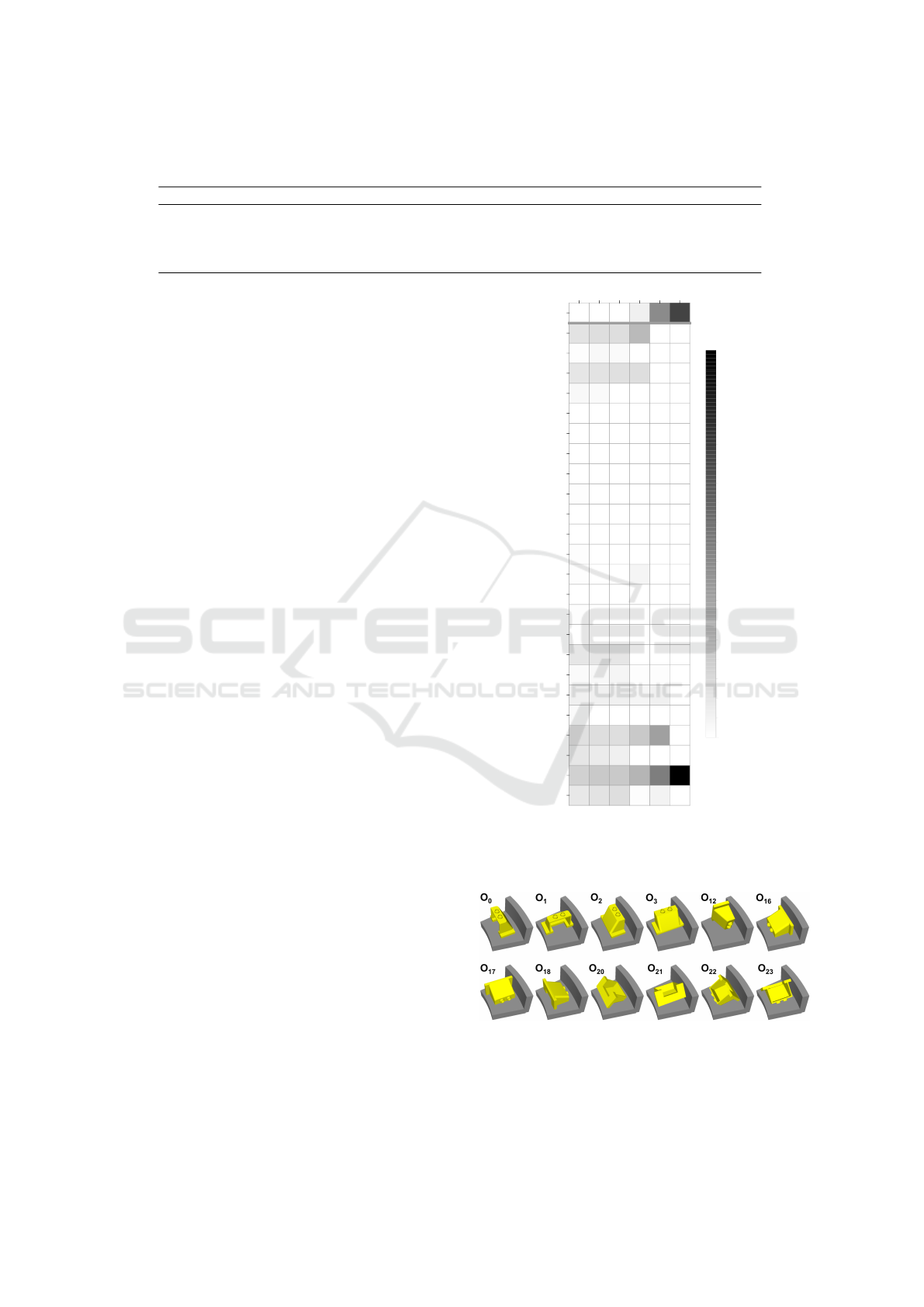

4.2 Orienting the Parts

The algorithm finds the feeder configurations listed in

Table 2 for the three cases. For all results shown in

the table the parameters of the algorithm were set as

follows: m

c

= 0.95, p

r,max

= 0.9, M = 5.

Recall p

CO

, was the estimated probability of correctly

orienting the part, p

r

the probability of rejection and

Q the quality score computed by (7). The results

show, that the Cap can be oriented using a Scallop

trap after a Step trap, which changes the probability

towards an orientation that can pass the scallop (the

orientation shown in Figure 5). For the Cone part, the

found configuration consists of four steps and finally

a narrowed track with a wall projection rejecting all

Cone parts not in the upright orientation labelled O

0

in Figure 11, showing the most occurring orientations

of the Cone. Using the algorithm, feeder configura-

tions are also found for the Brick. The best solution

uses a fairly involved sequence of traps to orient the

part. The probability distribution after each trap is

shown in Figure 7 and the dominant orientations of

the Brick illustrated in Figure 8. It should be noted

that a total of 24 distinct, and stable, orientations of

the Brick has been observed in simulation.

First the steps pushes the distribution of prob-

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

150

Table 2: The four feeder configurations found by the algorithm. ”Evals.” denotes the number evaluations made by the

algorithm and ”Found i.” the evaluation step that configuration was found in.

Part Feeder config. p

CO

p

r

Q Evals. Found i. Time[s]

1 Cap St → Sc 0.99 0.29 0.70 28 4 0.002

2 Cone St → St → St → St → W P 0.99 0.55 0.45 95 24 0.008

3 Brick St → St → Er → W B → NT 0.99 0.73 0.26 4671 1235 0.379

4 Brick St → Er → St → Er → W P 1.00 0.88 0.12 7731 817 0.631

ability towards the most stable orientations. The

Edgeriser trap attempts to raise the Brick resulting in

an increase in O

0

and O

12

. The Edgeriser is not suc-

cessful in raising all parts and some are reoriented to

O

22

. All parts resting in the upright orientation (O

0

,

O

1

, etc.) are then rejected by the Wiper blade. This

leaves Bricks lying down as O

18

, O

20

− O

23

, but due

to the centre of gravity of the Brick, the Narrowed

track can then reject all other orientations than O

22

.

Forcing the algorithm to search for specific ori-

entations, an alternative feeder configuration is found

for the Brick that orients it to O

0

. This configuration

scores a lower quality due to higher probability of re-

jection. Feeder configuration 1,2 and 3 only achieve a

score for correct orientation of the part of 0.99. This

is due to the hand-tuning of the trap parameters men-

tioned in Section 3.

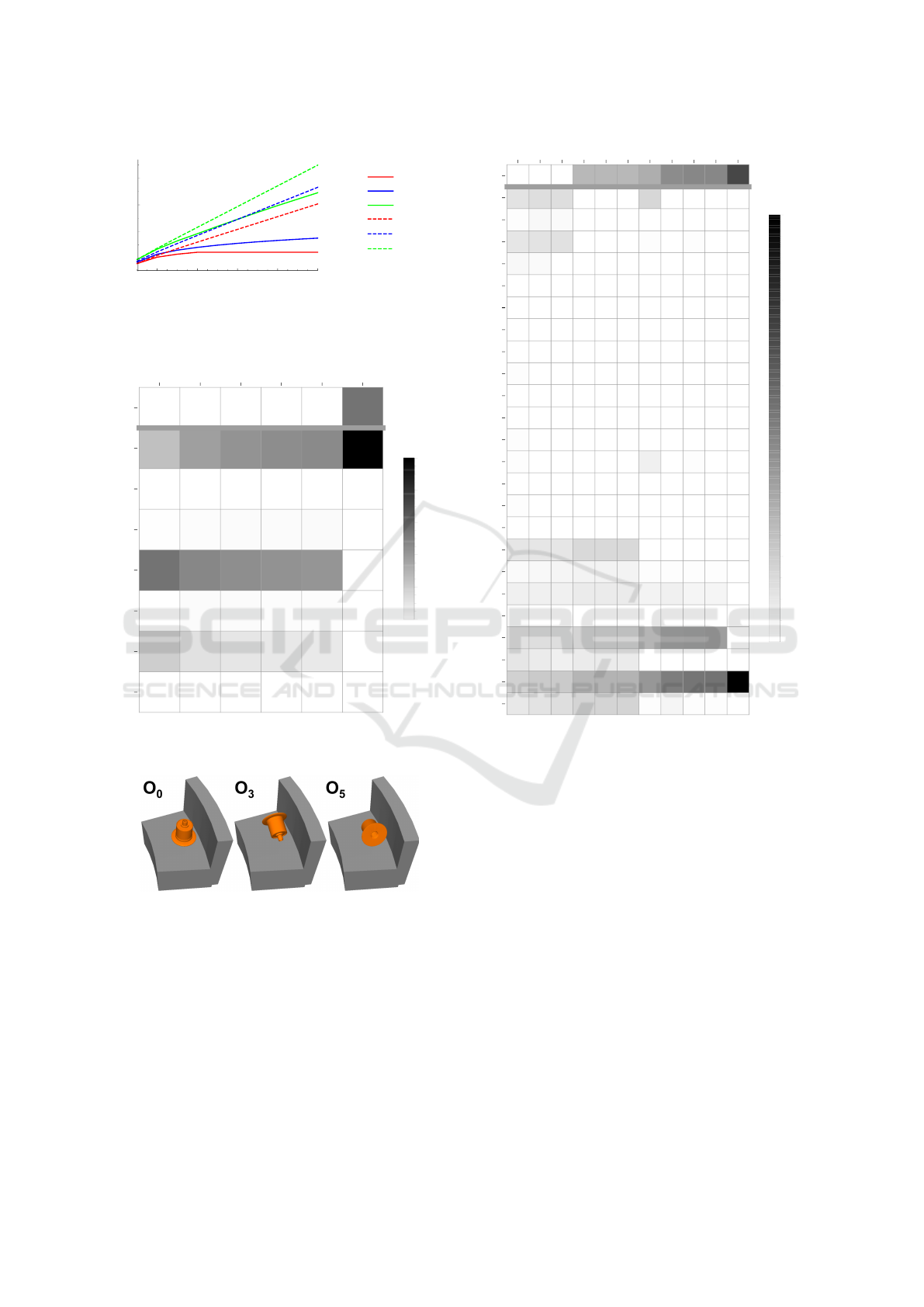

4.3 Informed vs. Non-informed Search

To show the difference between using the presented

informed search compared to an exhaustive strategy

the number of required evaluations needs to be con-

sidered. Figure 9 shows a logarithmic plot of the

number of evaluations for the three cases, when using

the informed strategy (denoted I and shown with solid

lines) reducing the search space compared to the ex-

haustive strategy (denoted NI and shown with dashed

lines). Both the informed and exhaustive strategy in-

cluding the concept of final traps.

It can be seen in Figure 9, that the informed search

strategy improves the number of evaluations required

by several orders of magnitude. For both the Cap and

Cone part, the savings with the informed method is

around a factor of 10

4

. For the Brick part, the relative

difference is lower, but still around a factor of 10

2

. Al-

though the graphs indicate a sub-exponential runtime

for the informed search, we have no formal proof and

in worst-case it may still require exponential run time.

4.4 Repeating Traps

In the work of (Christiansen et al., 1996) they report a

feeder configuration consisting of eight repetitions of

a Pressure break trap (not used in this work), a Wiper

blade and a Slotted track. Our algorithm finds a simi-

lar repetitive sequence for the Cone part with multiple

p

r

O

0

O

1

O

2

O

3

O

4

O

5

O

6

O

7

O

8

O

9

O

10

O

11

O

12

O

13

O

14

O

15

O

16

O

17

O

18

O

19

O

20

O

21

O

22

O

23

ID St St Er WB NT

0

0.2

0.4

0.6

0.8

Figure 7: Step wise probability of orientations for feeder

configuration 3. All O

x

are the orientations and p

r

the prob-

ability of rejection. ”ID” denotes the initial probability dis-

tribution of orientations before any traps.

Figure 8: Illustration showing the dominant orientations

and when these are effected by the traps of feeder config-

uration 3.

Step traps in succession. The result of applying each

trap is illustrated in Figure 10, where the seven dis-

Automatic Selection and Sequencing of Traps for Vibratory Feeders

151

●

●

●

● ● ● ● ● ●

●

■

■

■

■

■

■

■

■

■

■

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

○

○

○

○

○

○

○

○

○

○

2 4 6 8 10

SearchDepth

10

1000

10

5

10

7

Evaluations

●

Cap, I

■

Cone, I

◆

Brick, I

▲

Cap, NI

▼

Cone, NI

○

Brick, NI

Figure 9: Run data for the search algorithm with varying

max search depth, comparing the amount of evaluations

made by the informed search vs the a non-informed, shown

on a logarithmic scale.

p

r

O

0

O

1

O

2

O

3

O

4

O

5

O

6

ID St St St St WP

0

0.2

0.4

0.6

0.8

1.0

Figure 10: Step wise probability of orientations for feeder

configuration 2.

Figure 11: The three most frequent orientations of the Cone

part.

tinct orientations of the Cone is visualized with the

probability of occurrence shown as a grey-scale from

white P(0

i

) = 0 to black P(O

i

) = 1. The three most

frequent orientations are shown in Figure 11.

The figure show that the repetition of the Step trap

moves the probability for orientation O

3

and O

5

to-

wards O

0

in steps of ≈ {0.13, 0.05, 0.02, 0.01}. In-

creasing M for the algorithm allows it to add more

Step traps with, for each, a diminishing effect. For

comparison, the improvement between configuration

p

r

O

0

O

1

O

2

O

3

O

4

O

5

O

6

O

7

O

8

O

9

O

10

O

11

O

12

O

13

O

14

O

15

O

16

O

17

O

18

O

19

O

20

O

21

O

22

O

23

ID St St WB WB WB Er WB Er WB NT

0

0.2

0.4

0.6

0.8

1.0

Figure 12: Step wise probability of orientations for best

feeder configuration found for the Brick part when sequence

length M = 10.

2 in Table 2 (where M = 5) to the configuration found

for M = 10 is just 0.02 for the quality Q due to a sim-

ilar decrease of p

r

. The effect of this is even clearer

for the result shown in Figure 12. This figure show

the step-wise results for the best feeder configuration

the algorithm finds for the Brick part, allowing a max

search depth of M = 10.

The result is similar to the feeder configuration

for M = 5, but includes an extra Step trap, another

Er → W B sequence and three extra Wiper blades. Al-

though the solution is valid from the perspective of

the algorithm there is actually very little improvement

over configuration 3 previously listed in Table 2. This

new configuration scores a Q = 0.28 (0.02 higher)

due to a 0.01 decrease in p

r

. Looking at Figure 12

and the consecutive three Wiper blades, only the first

makes real changes to the probability distribution of

the 24 orientations. This is also the case for the first

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

152

Er → W B sequence, where the impact of the second

sequence is insignificant. Running this test with the

dataset used in (Christiansen et al., 1996), confirms

the validity of their result, but also shows that the

before mentioned sequence of consecutive Pressure

break traps have close to zero impact on the result af-

ter the fourth repetition of the trap.

5 DISCUSSION AND FUTURE

WORK

The results presented in Section 4 show that the al-

gorithm automatically finds feeder configurations that

orients the three parts used as cases. The solutions

found are optimal for the given input data, but the

quality of these feeder configuration also relies com-

pletely on behavioural data. Finding better solutions

for orienting the three parts would therefore require

either the traps being tuned to optimal performance or

more trap principles capable of reorienting the parts to

other orientations. Regarding the latter, this could es-

pecially be an advantage for the Brick, which is well

suited for orientation using the Slotted track trap, but

has very little probability of entering that trap in the

required input orientation for it to work.

The margin for considering a part fully oriented,

m

c

, should ideally be set to 1 (as discussed), but for

the test it was set m

c

= 0.95. This could potentially

have resulted in the algorithm returning solutions with

worse orienting capabilities (p

CO

score), than the ones

presented in Table 2, but scoring a higher quality due

to lower p

r

. Setting this parameter for the algorithm

should therefore be governed by some knowledge on

the optimality of the traps used in the search and the

closer the traps are to being optimal the smaller the

need will be for decreasing m

c

.

In Section 4.4 it was shown that the algorithm uses

time exploring branches of the solution tree that offers

improvement of insignificant magnitude. This is to be

expected and dealing with this appropriately would

lead to further reduction in search times. A simple

way of doing this could be to impose a lower bound

for changes in quality, but that raises the question of

where the threshold for significant improvement lies.

In the future we intend to explore this problem fur-

ther and pursue improving the algorithm by looking

for heuristics guiding the search towards good feeder

configurations faster, as well other, more aggressive,

branch termination strategies.

In the current state our method for generating data

is unable to identify stacking parts. This is a prob-

lem occurring frequently in this type of feeding sys-

tem and should be taken into account when designing

the feeder. This becomes and issue as our method as-

sumes that parts are singulated when generating data

and therefore only simulated one part interacting with

the trap at a given time. Simulating just a single part

in the feeder also does not model the effects of parts

pushing on each other, potentially introducing parts

being conveyed in other orientations than expected.

Future work should be directed at efficiently simulat-

ing multiple parts interacting with each other as well

as the feeder.

Finally we are in the process of validating the de-

signs found using the algorithm with real world tests.

6 CONCLUSION

In this paper we have outlined a framework for auto-

matic design of vibratory feeders and presented con-

crete methods for automatically encoding behavioural

data and the subsequently selection and sequenc-

ing of traps for orienting parts in a vibratory parts

feeder. The behavioural data are generated using dy-

namic simulation and encoded into transition matri-

ces known from prior literature. The selection and se-

quencing method is an informed search strategy that

efficiently reduces the computation time making the

otherwise hard combinatorial problem manageable.

To test the presented methods nine different trap types

have been implemented and behavioural data gener-

ated for three different parts together with an analysis

on how many samples are required for a stable esti-

mate of the transition matrices. The resulting designs

has been further analysed and properties of the solu-

tions are discussed.

ACKNOWLEDGEMENTS

This work was supported by The Danish Innovation

Foundation through the strategic platform MADE-

Platform for Future Production.

REFERENCES

Berkowitz, D. R. and Canny, J. (1996). Designing parts

feeders using dynamic simulation. In Robotics and

Automation, 1996. Proceedings., 1996 IEEE Interna-

tional Conference on, volume 2, pages 1127–1132

vol.2.

Berkowitz, D. R. and Canny, J. (1997). A comparison of

real and simulated designs for vibratory parts feed-

ing. In Robotics and Automation, 1997. Proceedings.,

1997 IEEE International Conference on, volume 3,

pages 2377–2382. IEEE.

Automatic Selection and Sequencing of Traps for Vibratory Feeders

153

Berretty, R.-P., Goldberg, K. e., Overmars, M. H., and

van der Stappen, A. F. (2001). Trap design for vi-

bratory bowl feeders. The International Journal of

Robotics Research, 20(11):891–908.

Boothroyd, G. (1992). Assembly Automation and Product

Design. Marcel Dekker Inc., NY.

Boothroyd, G. (2005). Assembly Automation and Product

Design. CRC Press, 2nd ed. edition.

Christiansen, A. D., Edwards, A. D., and Coello, C. A. C.

(1996). Automated design of part feeders using a ge-

netic algorithm. In Robotics and Automation, 1996.

Proceedings., 1996 IEEE International Conference

on, volume 1, pages 846–851. IEEE.

Coumans, E. (2010). Bullet physics engine. Open Source

Software: http://bulletphysics.org, 1.

Goemans, O. C., Goldberg, K., and van der Stappen, A. F.

(2006). Blades: a new class of geometric primi-

tives for feeding 3d parts on vibratory tracks. In

Proceedings 2006 IEEE International Conference on

Robotics and Automation, 2006. ICRA 2006., pages

1730–1736. IEEE.

Hansson, M. N., Mathiesen, S., Ellekilde, L.-P., and Mad-

sen, O. (2016). Configuration system for simulation

based design of vibratory bowl feeders. In Simulation,

Modeling, and Programming for Autonomous Robots

(SIMPAR), IEEE International Conference on, pages

147–154. IEEE.

Hofmann, D., Huang, H., and Reinhart, G. (2013). Auto-

mated shape optimization of orienting devices for vi-

bratory bowl feeders. Journal of Manufacturing Sci-

ence and Engineering, 135(5).

Jiang, M. H., Chua, P. S. K., and Tan, F. L. (2003). Sim-

ulation software for parts feeding in a vibratory bowl

feeder. International Journal of Production Research,

41(9):2037–2055.

Joergensen, J. A., Ellekilde, L.-P., and Petersen, H. G.

(2010). Robworksim - an open simulator for sensor

based grasping. In Robotics (ISR), 2010 41st Interna-

tional Symposium on and 2010 6th German Confer-

ence on Robotics (ROBOTIK), pages 1–8. VDE.

La Brooy, R., Jiang, C., Chan, P., et al. (1995). Design of an

expert system for automatic high-speed parts feeding.

In Sixth International Conference on Manufacturing

Engineering: Manufacturing; a Global Perspective;

Proceedings, The, page 359. Institution of Engineers,

Australia.

Mathiesen, S. and Ellekilde, L.-P. (2016). Configuration

and validation of dynamic simulation for design of vi-

bratory bowl feeders. In 2016 12th IEEE International

Conference on Control and Automation (ICCA), pages

485–492. IEEE.

Murch, L. and Boothroyd, G. (1971). Predicting efficiency

of parts orienting systems. Autom, 18:55–57.

Smith, R. (2006). Open dynamics engine. Accessed: 10-

05-2017, http://ode.org/ode-latest-userguide.pdf.

Stocker, C. and Reinhart, G. (2016). Sensitivity analysis of

the dynamic behavior of transported material in vibra-

tory bowl feeders using physics simulation. Applied

Mechanics & Materials, 840.

Tan, P., Ngoi, B., Lee, S., and Lim, L. (1995). A knowledge-

based advisor for the automatic selection and sequenc-

ing of orienting devices for vibratory feeding. Engi-

neering Applications of Artificial Intelligence, 8(1):1

– 13.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

154