Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled

Etching for Label-Free Glucose Concentration Monitoring

Biomedical Optics

Sergio Mena, Maria Morant, Juan Hurtado and Roberto Llorente

Nanophotonics Technology Center, Universitat Politècnica de València, Camino de Vera s/n, Valencia, Spain

Keywords: TFOBS, Glucose Sensing, Label-Free, Optical Sensor, Chemical Etching, Biconical Taper, Refractive Index,

Optically Controlled Etching.

Abstract: This paper proposes, designs and demonstrates experimentally a tapered fibre optic biosensor (TFOBS)

fabricated by an optically controlled HF chemical etching. The fabricated device is demonstrated to operate

properly as a label-free sensor for glucose concentration detection. This work presents a novel fabrication

method of a single-mode TFOBS controlling the reaction rate by changing the HF concentration and

monitoring the optical power variation at the fibre output. Two TFOBS fabricated with different cladding

diameters are evaluated experimentally to sense different glucose concentrations observing the changes in the

refractive index of the medium in various solvents. The sensing capabilities are evaluated by modal

interferometry measurement of both intensity and phase variations of the received optical signal.

1 INTRODUCTION

Glucose (C

6

H

12

O

6

) is one of the most abundant

organic compound in the human body, being part of a

large number of macromolecules with structural

importance. The singularity of this molecule comes

from its capability of providing cellular energy. The

presence of glucose in blood enables the energetic

cell’s sustenance, but it is also present in other

biofluids such as urine, tears and sweat. The

concentration control of glucose is of vital importance

in patients with diabetes mellitus, whose amount

increases every year (World Health Organization,

2016), for the maintenance of homeostasis and the

regulation of insulin application. At present, most

common commercial methods to measure glucose

concentration are based on amperometric sensing

measuring the reaction of glucose oxidase (GOx) with

the glucose (Ferri et al., 2011). The amperometric

sensing method is specific only for glucose detection

and enables low-levels detection but has some

disadvantages, such as:

▪ Complicated adaptation to continuous

measurement.

▪ Electrical interference in biological fluids.

▪ Specificity affected by other oxidizing

substances.

Due to the limitations of electrochemical sensors,

optical biosensing has been appointed as a good

solution to measure different biological elements

such as Botulinum Neurotoxin (Guo et al., 2011) or

Ammonia (Ruan et al., 2008). In fibre optic

biosensors, the optical fibre is employed as a

transduction media in order to produce or detect a

signal proportional to the concentration of the

biological element to sense (Bosch et al., 2007).

Among other optical sensor types, tapered optical

fibre sensors enables the exposure of evanescent field

(EF) beyond the surface of the sensing region

(Fielding and Davis, 2002). These systems are known

as tapered fibre optic biosensors (TFOBS) and enable

label-free detection (Leung et al., 2008a), reduced

sample size and real-time response at a reduced size

and low price (Qiu et al., 2015). In the last years,

several TFOBS studies have been performed

comparing single-mode and multimode fibre sensors,

pointing out that multimode fibre sensor are less

efficient due to a lower average electric field at the

surface of the fibre compared with single-mode fibres

(Fielding and Davis, 2002).

More complex sensors have been developed in the

last years, such as graphene-based sensors (Qiu et al.,

2015) and antibody-immobilized protein sensors

(Leung et al., 2008b). The simplicity of TFOBS

resides on the suitability of optical fibre media to

166

Mena, S., Morant, M., Hurtado, J. and Llorente, R.

Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled Etching for Label-Free Glucose Concentration Monitoring - Biomedical Optics.

DOI: 10.5220/0006556301660173

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 166-173

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

radiate the evanescent waves travelling through the

fibre to the outside to interact with the sample to be

detected (Qiang et al., 2014). A tapered fibre is

produced by reducing gradually the diameter of a

common optical fibre, which enables the interaction

of the evanescent field guided in the fibre with the

external environment (Baude and Branco, 2013).

There are two main techniques for the fabrication of

tapered fibre: (i) by chemical or mechanical corrosion

of the fibre cladding (Ruan et al., 2008; Bal et al.,

2012) or (ii) by simultaneous heating and stretching

of the fibre (Kenny et al., 1991). The main differences

between both techniques resides in the resulting core

diameter. In the first case, implementing corrosion of

the cladding, the fibre core remains the same (i.e.

8.2 μm in single-mode fibre SMF-28). While, in the

second case, by heating and stretching, the diameter

of both the cladding and the core is reduced in the

same proportion (Kenny et al., 1991). In this work, a

simple method to produce the EF on a single-mode

fibre by cladding corrosion is described, producing a

tapered fibre with hydrofluoric acid etching

(Haddock et al., 2003). This approach provides better

light transmission due to the no degradation of the

fibre core (Bal et al., 2012). The resulting tapered

fibre can be used as an optical biosensor and is an

affordable solution for glucose monitoring.

This paper is structured as follows: in section 2 the

laboratory steps for the fabrication of the tapered

optical fibre are described in detail. A novel

fabrication method of TFOBS is proposed controlling

the reaction rate by changing the HF concentration

and monitoring the optical power variation at the fibre

output. Next, in section 3 of this work, we evaluate

experimentally the sensing method based on modal

interferometry for different concentrations. Finally,

in section 4, the main conclusions of this work and

the consideration of future implementations are

reported.

2 OPTICALLY CONTROLLED

CHEMICAL ETCHING

TAPERED FIBRE

FABRICATION

The novelty of the proposed fabrication method

resides in performing the chemical etching at a

controlled rate. There are two different approaches

for monitoring the chemical etching process. The first

one employs an optical system (e.g a microscope or

magnifying glass) to measure in real-time the waist

diameter while the chemical etching is performed.

However, this method is not appropriate for chemical

etching employing hydrofluoric (HF) acid for

security reasons. The second approach is based on

monitoring the pass-through optical power, using an

optical light source and a potentiometer, and

correlating the power loss with the diameter of the

optical fibre in the reaction length. This approach is

implemented following the experimental setup

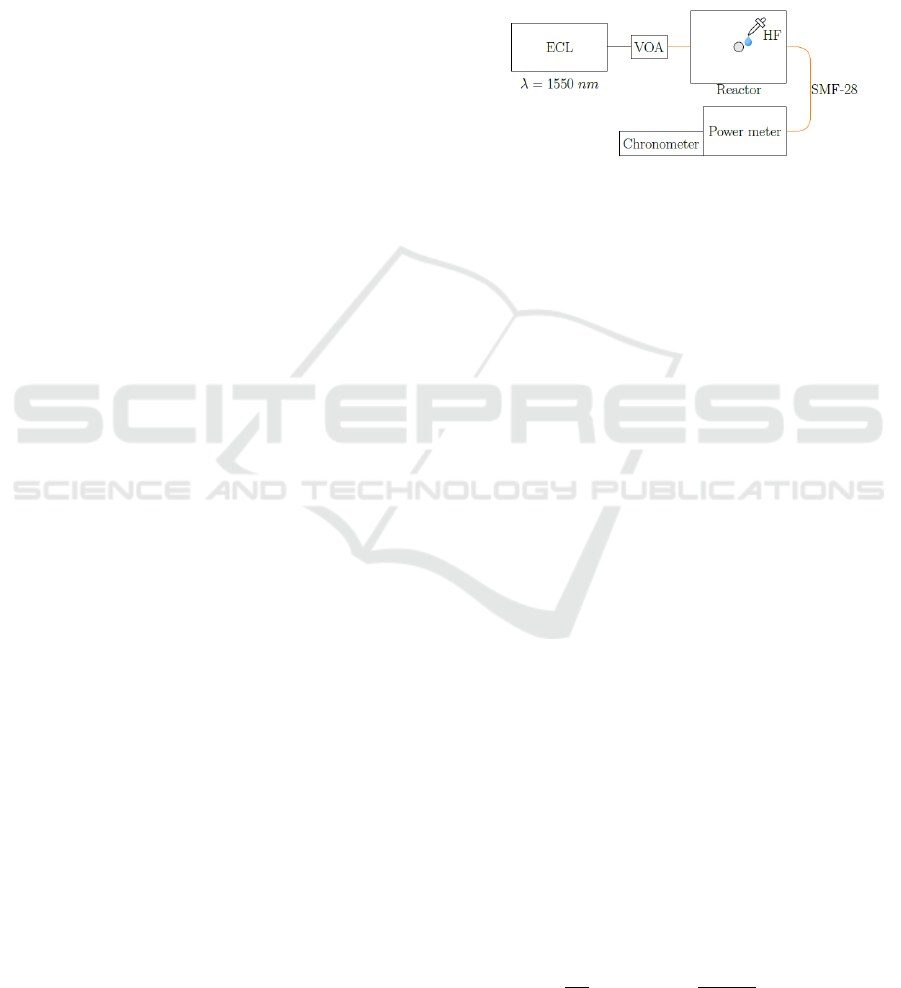

depicted in Figure 1.

Figure 1: Laboratory setup for optically controlled HF acid

chemical etching.

In this experimental demonstration an external

cavity laser (ECL) operating at λ = 1549.65 nm (Ando

AQ8201-13B) is employed. A variable optical

attenuator (VOA) is used to reduce the optical power

level at the input of the SMF-28 reactor to avoid a

possible fibre break. The chemical etching is

performed using a HF solution of 49.5 wt% to be

neutralized with NaOH solutions of 0.1 M and 5 M.

An optical power meter and a chronometer are used

to measure the evolution of optical power level

passing through the tapered fibre with time.

When the HF come into contact with the SiO

2

of

the optical fibre, the resulting chemical reactions are

defined in Equation 1 and Equation 2. When the HF

acid has a high concentration, the second reaction is

prevailing (Abbadie et al., 2007), which makes it

easier to obtain a mathematical model of the reaction

process:

2 4 2

42SiO HF SiF H O

(1)

2 2 6 2

62SiO HF H SiF H O

(2)

The mathematical expressions for the chemical

reaction are included in Equation 3 and Equation 4

(Haddock et al., 2003), where D

i

and D

f

are the initial

and final diameters of the fibre, respectively, C and Z

are constant values, t is the reaction time, [HF] is the

acid concentration, k is the reaction constant, r is the

density of the silica, P is the received optical power

level and L is the length of the fibre in contact with

the acid.

2 [ ]

,

f

ii

D

k HF

C Kt K

DD

(3)

22

P D L P ZD L

(4)

Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled Etching for Label-Free Glucose Concentration Monitoring - Biomedical

Optics

167

The K parameter groups the constant parameters

of the Equation 3. As a result of Equation 3 and

Equation 4, we obtain the linear relation expressed in

Equation 5:

f

i

P

C Kt

P

(5)

With these equations it is possible to have a first

calculation of the necessary reaction time in order to

reach the desired diameter of the fibre for the TFOBS.

Next, using a simple experimental setup as depicted

in Figure 1, the optical power level can be monitored

to confirm if the chemical reaction is done properly

and to determine when to neutralize and stop the

reaction. However, some aspects should be taken into

account:

▪ The reaction variable K of the mathematical

model is constant as long as the environmental

conditions are stable (i.e. room temperature,

lighting...)

▪ The relation between the diameter and the

received power is accurate when D

f

approaches

the core diameter, as the optical signal is

mainly transmitted through the core. Thus, the

linear relation depicted in Equation 5 is valid

when the received optical power starts

decreasing.

In this work, the objective is to obtain, from a

SMF-28 fibre with 125 μm diameter cladding, a

biconical structure with a reduced cladding of 15 μm

for TFOBS implementation. Table 1 includes the

monitoring parameters obtained using the

mathematical model. The K value is obtained from 20

essays under standard conditions according to

(Haddock et al., 2003). The volume of HF acid used

is 75 μL, of which only about 0.8% will react, making

the etching process rate approximately constant.

Table 1: Monitoring parameters of the chemical etching.

1

()Ks

a

i

P

P

()ts

34

2.3 10 1.9 10

2

1.4 10

428.5 40

2.1 Design and Assembly of the

Reactor

In order to be able to control the chemical etching of

the single-mode fibre, we designed and fabricated a

reactor that enables the immobilization of the fibre in

an HF-resistant structure, exposing only a given fibre

length L to the acid.

Figure 2: Scheme of the reactor designed for HF chemical

etching of single-mode fibre. Heights represented in

millimetres. The well depth is, approximately, 4.5 mm.

Figure 2 describes the size and shape of the

fabricated reactor. In the assembly, 6 mm of the fibre

is positioned in the place of the acid, while the rest of

the fibre is isolated. The process followed for the

fabrication comprises:

1. Drilling a 100×75×3 mm polymethylmethacrylate

(PMMA) plate (Plexiglass®) with 6 mm

diameter.

2. Locate another PMMA plate with the same

dimensions below with an indent under the same

6 mm diameter hole as the top plate.

3. Placement of the optical fibre between both plates,

having peeled the plastic coating of the fibre in the

length to be etched. A small slot is marked in the

PMMA to locate the SMF-28 fibre.

4. Both plates are sealed with Ethylene-vinyl acetate

(EVA) plastic glue (Rapid®).

5. Measurement of the received power after

transmission through the installed fibre (using the

experimental setup depicted in Figure 1) before

starting the chemical etching in order to verify that

the fibre has not been damaged.

With the SMF-28 fibre located in the reactor we

can start the chemical etching following the

procedure described in the next section.

2.2 Chemical Etching of the Fibre

In this paper, we report the results obtained with two

different methods for tapered fibre fabrication. In first

place, we evaluate a chemical etching procedure

performed at a single reaction rate (Bal et al., 2012).

This procedure is very sensitive and difficult to

control, so we present a novel method that controls

the produced reaction in order to obtain a stable

diameter reduction. This second fabrication method is

presented with the intention of increasing the

repeatability and automation of the process.

The main steps followed for the chemical etching

and fabrication of the tapered fibre are:

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

168

1. Connection of the ECL laser to the input of the

SMF-28 reactor and monitoring the optical power

level at the fibre output using the experimental

setup depicted before in Figure 1. In this

experiment, the input power is set to -15 dBm

(31.6 μW).

2. Addition of 75 μL HF 49.5 wt % in the reactor.

3. Power monitoring and extraction of the HF when

the desired power level is reached.

4. Addition and extraction of 75 μL of deionized

water for removing of HF residue.

5. Neutralization of the acid in the reactor with

75 μL of 5M NaOH. It should be noted that the

chemical reaction between HF and NaOH is

aggressive and forms NaF crystals that could

damage the microfibre. For this reason, the HF

residue should be minimum and the concentration

is reduced in the previous step with deionized

water.

6. Stabilization of the reactor with 75 μL of 0.1M

NaOH over 30 minutes. While the stabilization

takes place, the power is also monitored as if the

power continues decreasing means that the

diameter is also decreasing.

7. Evaluation of the resulting fibre diameter by

microscopy observation.

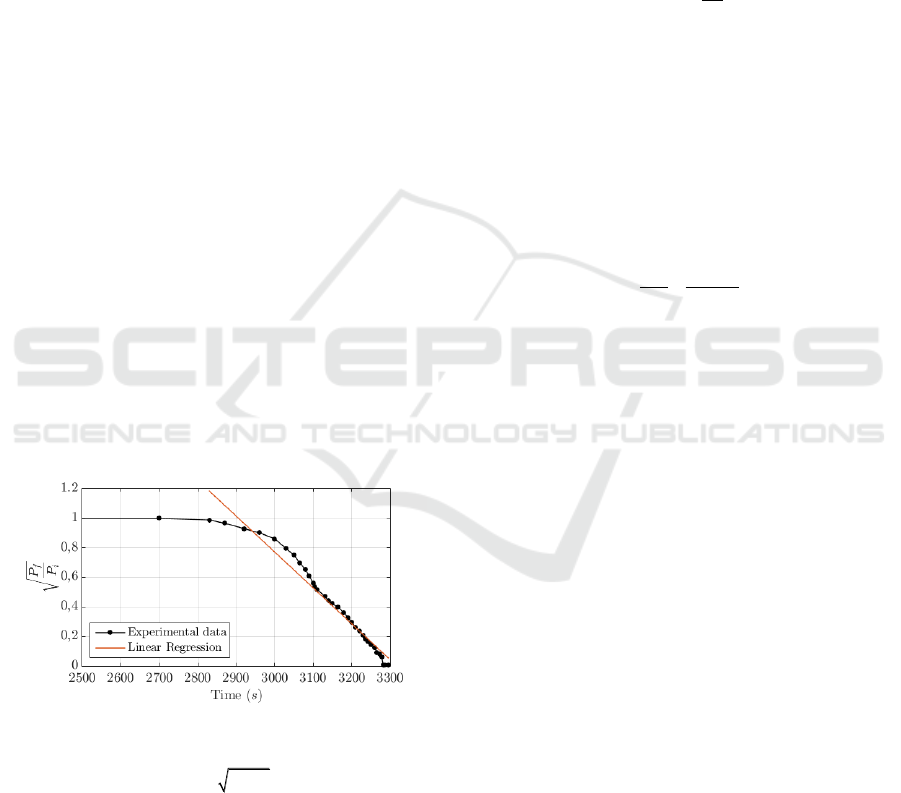

The power relation from Equation 5 is represented in

Figure 3 from the experimental data obtained with the

conventional chemical etching procedure. The

received optical power level at the output of the fibre

does not vary before 2800 s following the linear

relation reported in (Haddock et al., 2003).

Figure 3: Experimental optical power levels measured

using conventional chemical etching and linear regression

with analytical expression

/ 8.06 0.0024

fi

P P t

and a

coefficient of determination

2

0.9602R

.

As it can be observed in Figure 3, the power fall

is considerably fast and abrupt, making the procedure

of acid extraction and neutralization complicated

considering the security measures when dealing with

HF acid. In this first experiment, due to the inability

to extract the acid at the exact moment, the fibre was

completely degraded. For this reason, we propose to

include an additional step between 2 a 3 adding some

extra drops of water during the chemical reaction.

This reduces the HF concentration in the reactor and

therefore reduces the reaction rate (Ko et al., 2016)

and the K parameter of Equation 5. This enables a

more controllable and reproducible chemical etching.

In this work, a water volume input control system

depending on the rate of change of output power

(dP

f

/dt) was implemented as:

2

0

1

( 1)

H O i HF

C

VV

C

(6)

The direct relationship between P

f

and [HF] is not

known, but we know that dP

f

/dt decrease in absolute

value when [HF] is reduced. Thus, the control system

decreases the concentration of acid proportionally to

the increase of dP

f

/dt over a desired value by adding

a certain volume of water and extracting the same

volume from the resulting solution. This reaction is

represented mathematically in Equation 6 and

Equation 7:

1 0 0

()

f

desired

dP

dP

C C C

dt dt

(7)

where

2

HO

V

is the volume of water to be added,

HF

is

the density of the HF acid and C

0

and C

1

are the initial

and final concentrations of the solution, respectively.

Following this approach, a reasonable value of

variation rate of P

f

is 1 μW/s.

2.3 TFOBS Fabrication Results with

Optically Controlled Etching

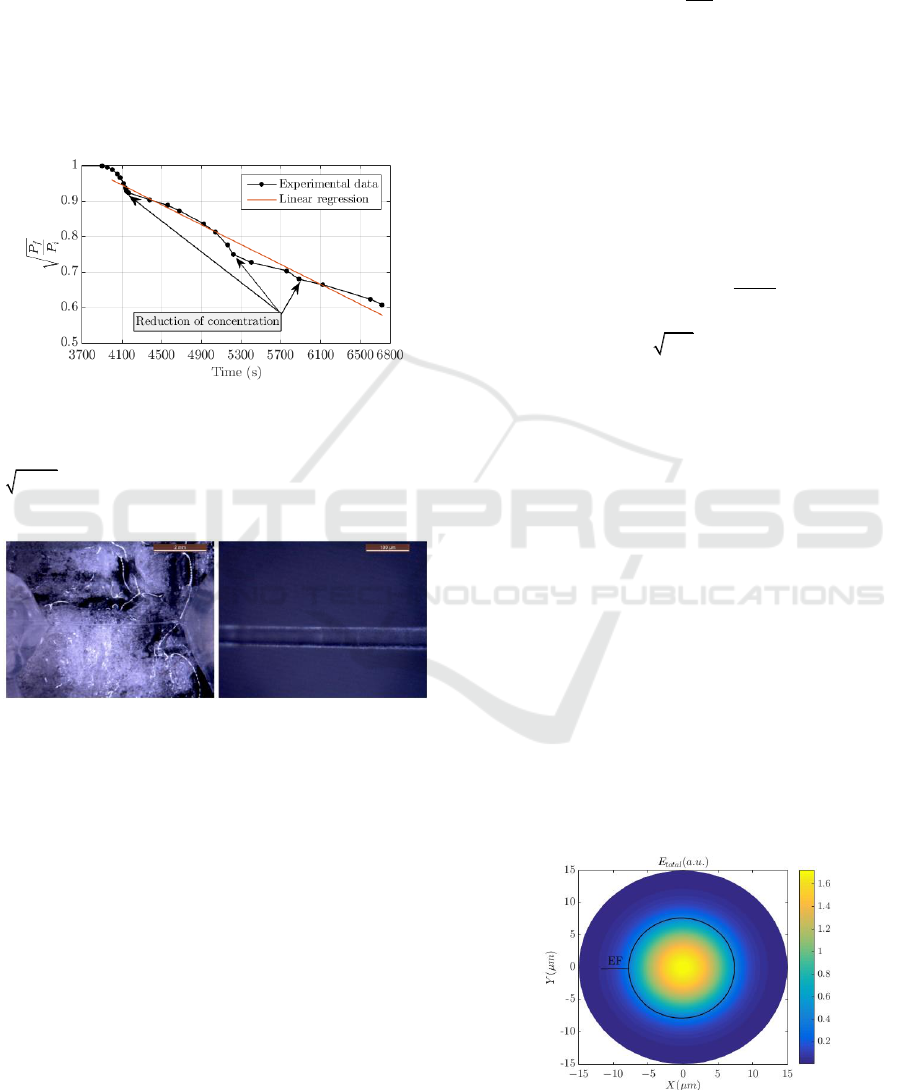

Figure 4 shows the experimental power variation

measured with the optically controlled etching

method as a function of the reaction time. In this

research, eight tapered fibres samples were

manufactured using manual control of [HF] as a

function of the P

f

variation, to ensure the reliability

and repeatability of the method. The results depicted

in Figure 4 correspond to TFOBS sample 7. We

represented the three extra steps of

2

HO

V

addition to

control the etching rate. In this case, the added

volume was

2

HO

V

= 75 μL. If we consider an

automated control system for mass production, the

added volume would depend on the increase of

| / |

f

dP dt

.

Taking into account the K obtained from the linear

regression and the duration of the etching, the

procedure using the optically controlled etching is

less abrupt as it can be observed in Figure 4. This

Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled Etching for Label-Free Glucose Concentration Monitoring - Biomedical

Optics

169

means that more time is available to perform the acid

neutralization, but at the expense of longer etching

time for the fabrication of the tapered fibre.

Figure 5 shows the images of the resulting tapered

fibre taken with a digital microscope camera (Leica

DFC420) of the 7

th

sample. The results with the eight

samples obtained a final cladding diameter ranging

from 10 μm to 40 μm, depending on the power ratio

considered to stop the etching. Due to fibre contact

with EVA, the resulting tapers were more likely non-

adiabatic.

Figure 4: Experimental optical power levels measured

using optically controlled chemical etching and linear

regression with analytical expression

4

/ 1.52 1.40 10

fi

P P t

and a coefficient of

determination

2

0.9754R

.

Figure 5: Microscope images of the 7

th

sample fabricated

with the optically controlled etching: (a) the 5 mm length of

the microfibre taper and (b) zoom of the microfibre.

3 TFOBS PERFORMANCE FOR

LABEL-FREE GLUCOSE

CONCENTRATION SENSING

Fibre optic tapers and microfibres generate a strong

EF, making the optical transmission dependent on the

refractive index of the medium (Polynkin et al.,

2005). Especially in non-adiabatic optical fibres, but

also in adiabatic depending on its characteristics, the

fundamental mode (LP

01

) propagated by a standard

SMF-28 fibre is coupled to higher order modes,

mainly LP

02

and LP

11

, whose power distribution in

the fibre core is displaced to the cladding (Zibaii et

al., 2010). The velocity of propagation (β) of each

mode depends on the effective refractive index of the

medium (n

eff

):

0

2

eff

n

(8)

According to Equation 8, the β of the modes

transmitted on the cladding depends on the n

eff

of the

external medium more than the modes transmitted in

the core. This generates an offset, dependent to the

medium, between the modes defined in Equation 9,

that can be registered as a phase shift in the received

signal (Yadav et al., 2014). The change of the

medium also generates a intensity variation in the

received signal according to Equation 10.

0

2

eff

L

Ln

(9)

1 2 1 2

2 ( )I I I I I cos

(10)

In addition to this, due to the taper’s behaviour as

a resonance cavity, the output signal exhibits quasi-

periodic oscillations in the transmittance spectrum

(Salceda-Delgado et al., 2012), whose spatial

frequency also depends on the refractive index of the

medium. This enables measuring experimentally

three main optical parameters: intensity, phase shift

and spatial period of the oscillatory signal, all of them

correlated with the refractive index of the medium

(Shi et al., 2012).

3.1 Glucose Sensing Simulation Study

In order to completely characterize the physical

behaviour for the detection of glucose concentration,

a simulation study was performed using COMSOL

Multiphysics and MATLAB Optical Fibre Toolbox

(Karapetyan, 2012). Figure 6 shows the simulated

electric field generated in the microfibre considering

a 15 μm cladding diameter and the transmission of

first and second order modes at λ = 1550 nm.

Figure 6: Simulated total electric field transverse plane

propagated in a fibre with D

f

= 15 μm cladding diameter.

(a) (b)

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

170

Figure 7: Transmittance between simulated results of the

2D biconical structure designed in COMSOL. Input signal

implementing with LP

01

and LP

02

modes.

The simulation results indicate that the electric

field intensity at 4 μm away from the cladding is

approximately 10% of the mean intensity transmitted

through the microfibre. Additionally, a 2D model of

the TFOBS structure was programmed, where the

index of refraction of the external medium was

defined as a function of a glucose concentration in

distilled water. A complete simulation study is

performed considering 50 wavelength values

between 1536 nm and 1555 nm with a parametric

sweep of 50 glucose concentrations between

0 mg/mL and 50 mg/mL (Zibaii et al., 2010). Figure 7

shows the transmittance values obtained for different

glucose concentrations. Considering a fixed

wavelength, we can observe the power decrease with

the glucose concentration. The phase shift when the

concentration of glucose in the medium changes can

also be observed in Figure 7.

3.2 TFOBS Experimental Results for

Glucose Concentration Sensing

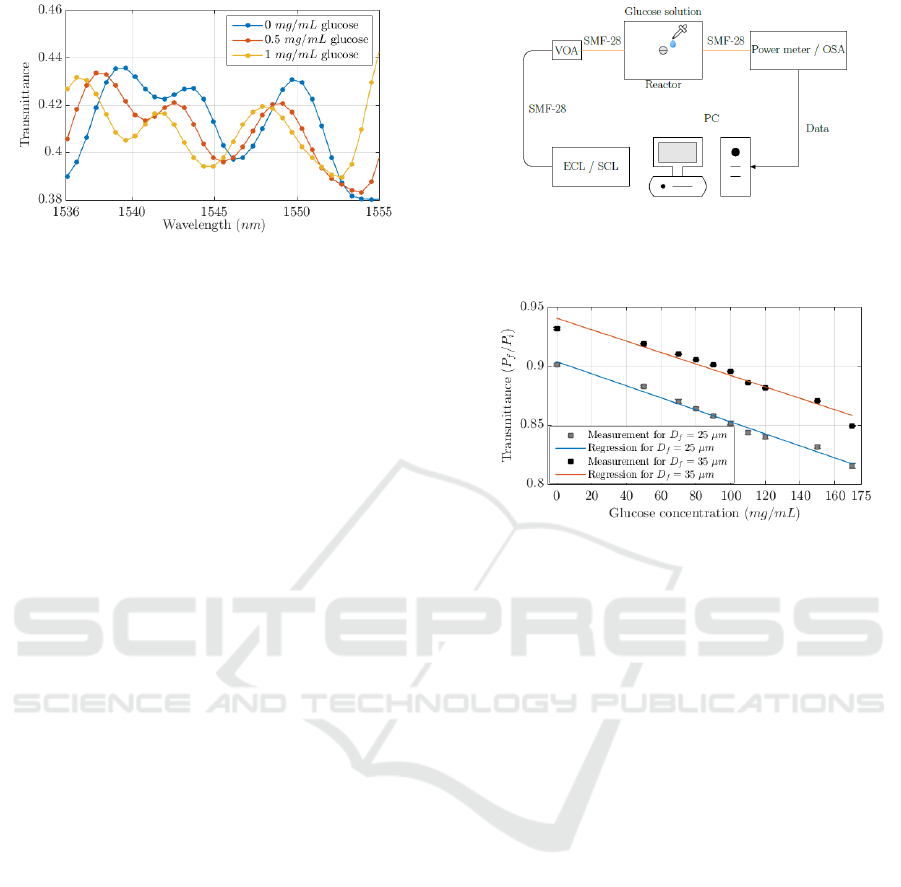

Figure 8 shows the experimental setup implemented

in the laboratory to evaluate the performance of the

developed TFOBS for glucose concentration sensing.

Ten glucose solutions between 0 mg/mL and

170 mg/mL in sterile saline, and 5 sodium chloride

solutions between 0 mg/mL and 20 mg/mL in glucose

50 mg/mL solution were prepared with anhydrous

glucose (99.7% pure), sterile saline solution (0.9%)

and sodium chloride (99.6% pure). An external cavity

laser (ECL) or a super-continuum laser (SCL) are

used to measure the intensity or phase behaviour with

different glucose concentrations. The received signal

after the transmission through the TFOBS is

measured with a power meter and an optical spectrum

analyser (OSA, Advantest Q8384). Once the light

source is stabilized, the optical signal is fed to the

TFOBS using a VOA to set the input level

to -21 dBm.

Figure 8: Experimental setup developed at the laboratory

for the evaluation of the TFOBS intensity and phase

variations for glucose concentration sensing.

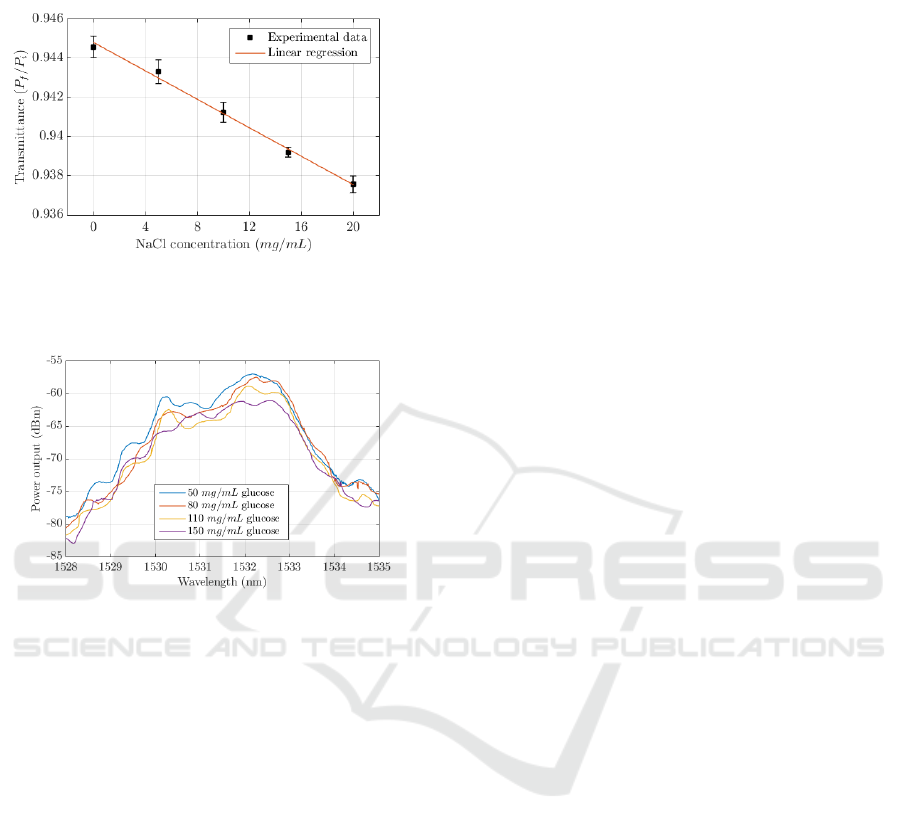

Figure 9: Measured transmittance and linear regression for

different glucose concentrations in sterile saline solution.

Then, the target solutions with different glucose

concentrations are applied to the TFOBS. After each

measurement, the TFOBS is cleaned with deionized

water 5 times before applying a new solution.

Figure 9 shows the measured transmittance and

calculated linear regression obtained with TFOBS

samples 5 and 7 fabricated with the proposed

optically controlled etching method. The

transmittance is defined as the ratio between the

output power measured with an air sample and with a

glucose solution. The difference between the

measurements obtained with the different TFOBS

samples correspond to a different final cladding

diameter: 25 μm for 5

th

sample and 35 μm for 7

th

sample. It can be observed that the behaviour of the

linear regression is similar despite the differences in

diameter: the D

f

= 35 μm TFOBS (corresponding to

the 7

th

sample) has an analytical regression defined by

T = 0.9413–4.89·10

–4

[G] with a coefficient of

determination R

2

= 0.9608, while the TFOBS with

D

f

= 25 μm (5

th

fabricated sample) corresponds to

T = 0.9039–5.10·10

–4

[G] with R

2

= 0.9865.

The sensitivity begins to increase considerably

when approaching to the core diameter, but at the

expenses of increasing also its fragility and the noise

level in the measure. The sensitivity of the TFOBS

with 35 μm cladding (7

th

sample) is calculated to be

Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled Etching for Label-Free Glucose Concentration Monitoring - Biomedical

Optics

171

4.89·10

–4

in absolute value, with a limit of detection

(LOD) by noise at 0.481 mg/mL.

Figure 10: Mean, standard deviation and linear regression

for NaCl concentrations in glucose 50 mg/mL measured

with TFOBS with 25 μm cladding (5

th

sample).

Figure 11: Received SCL spectrum measured with different

glucose concentrations obtained with a TFOBS with 35 μm

cladding (7

th

sample). (0:01 nm resolution).

Figure 10 shows the mean, standard deviation and

linear regression of the transmittance variation of the

TFOBS with 25 μm cladding (5

th

sample) for

different NaCl concentrations in 50 mg/mL glucose.

Due to the non-specific measurement of the refractive

index, a variation in NaCl concentration also impacts

on the resulting TFOBS transmittance.

To increase the TFOBS specificity, it would be

necessary to immobilize a bioreceptor such as

antibodies (Ruan et al., 2008) with a glucose

conjugation (Liébana et al., 2016) or glucose oxidase

enzyme (Khan et al., 2014), which could also be used

as a labelled sensor because of GOx fluorescent

performance (Klonoff, 2012). Figure 11 shows the

experimental data obtained with TFOBS with 35 μm

cladding (7th sample) for different glucose

concentrations in sterile saline solution. In this case,

as depicted in Figure 8, a SCL generating a full width

half maximum (FWHM) optical spectrum of 5 nm

centred at 1532 nm wavelength is used as the light

source to obtain the frequency response of the

TFOBS. Figure 11 shows the variation of the

spectrum measured with the OSA when different

glucose concentrations are applied to the TFOBS.

4 CONCLUSIONS

This paper proposes and evaluates experimentally an

optically controlled etching method for the

fabrication of single-mode TFOBS. Comparing the

performance of the proposed method with single rate

chemical etching, a more accurate design of the

resulting tapered fibre is obtained with a controlled-

rate etching, which improves the accuracy and

repeatability of the fabrication. A reactor was

designed to perform a secure chemical etching with

HF acid. Also, the reliability of the output power

monitoring and its correlation with the resulting

diameter of the microfibre has been evaluated

experimentally, confirming that it is a safe method for

the chemical etching monitoring fulfilling the safety

guidelines for HF handling.

Eight TFOBS samples with different final

cladding diameters of the tapered fibre have been

produced with the proposed optically controlled

etching fabrication method and evaluated

experimentally for the detection of glucose

concentration. The TFOBS sensor comprising a

tapered fibre with 35 μm final cladding diameter

obtained a sensibility of glucose concentration

sensing of 4.89·10

–4

(mg/mL)

–1

in absolute value,

with a LOD of 0.481 mg/mL. This is an acceptable

sensing range for glucose concentration monitoring

with a simple and low-cost implementation.

In this work, label-free glucose detection is

evaluated. Specific glucose bioreceptors could be

used to further improve the TFOBS specificity, and

consequently, its sensitivity and LOD. The materials

employed for the single-mode TFOBS fabrication are

low-cost, which makes the process affordable and

optimized for the fabrication of glucose concentration

sensors. The proposed fabrication method could be

implemented as an automated control system for mass

production.

ACKNOWLEDGEMENTS

This research was supported in part by Spain National

Plan MINECO/FEDER UE TEC2015-70858-C2-1-R

XCORE and RTC-2014-2232-3 HIDRASENSE

projects. M. Morant work was partly supported by

UPV postdoc PAID-10-16 program. BIOFRACTIVE

project with IIS La Fe is also acknowledged.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

172

REFERENCES

Abbadie, a., Hartmann, J. M., and Brunier, F. (2007). A

review of different and promising defect etching

techniques: from Si to Ge. The Electrochemical Society

A, 10(1):3–19.

Bal, H. K., Brodzeli, Z., Dragomir, N. M., Collins, S. F.,

and Sidiroglou, F. (2012). Uniformly thinned optical

fibers produced via HF etching with spectral and

microscopic verification. Applied optics, 51(13):2282–

2287.

Baude, E. and Branco, P. (2013). Numerical study of

tapered fiber optics as evanescent field sensors.

SBMO/IEEE MTT-S International Microwave &

Optoelectronics Conference (IMOC), 1–5.

Bosch, M. E., Jes´us, A., S´anchez, R., Rojas, F. S., and

Ojeda, C. B. (2007). Recent development in optical

fiber biosensors. Sensors, 7:797–859.

Ferri, S., Kojima, K., and Sode, K. (2011). Review of

glucose oxidases and glucose dehydrogenases: a bird’s

eye view of glucose sensing enzymes. Diabetes Science

and Technology, 5(5):1068–1076.

Fielding, A. J. and Davis, C. C. (2002). Tapered single-

mode optical fiber evanescent coupling. IEEE

Photonics Technology Letters, 14(1):53–55. G.

Guo, Z. J., Boyter, C., Cohoon, G., Salik, E., and Lin, W.-

J. (2011). Detection of botulinum neurotoxin by tapered

fiber optic biosensor. GSTF Journal of BioSciences

1(1):36–42.

Haddock, H. S., Shankar, P. M., and Mutharasan, R. (2003).

Fabrication of biconical tapered optical fibers using

hydrofluoric acid. Materials Science and Engineering

B: Solid-State Materials for Advanced Technology.

Karapetyan, K. (2012). Single optical modal

interferometer. PhD thesis.

Khan, A. Y., Noronha, S. B., and Bandyopadhyaya, R.

(2014). Glucose oxidase enzyme immobilized porous

silica for improved performance of a glucose biosensor.

Biochemical Engineering Journal, 91:78–85.

Klonoff, D. C. (2012). Overview of fluorescence glucose

sensing: f Technology with a bright future. Journal of

Diabetes Science and Technology, 6(6):1242–1250.

Ko, S., Lee, J., Koo, J., Joo, B. S., Gu, M., and Lee, J. H.

(2016). Chemical wet etching of an optical fiber using

a hydrogen fluoride-free solution for a saturable

absorber based on the evanescent field interaction.

Journal of Lightwave Technology, 34(16):3776–3784.

Leung, A., Shankar, P. M., and Mutharasan, R. (2008a).

Label-free detection of DNA hybridization using gold-

coated tapered fiber optic biosensors (TFOBS) in a flow

cell at 1310 nm and 1550 nm. Elsevier, 131:640–645.

Leung, A., Shankar, P. M., and Mutharasan, R. (2008b).

Model protein detection using antibody-immobilized

tapered fiber optic biosensors (TFOBS) in a flow cell at

1310 nm and 1550 nm. Sensors and Actuators, B:

Chemical, 129(2):716–725.

Liébana S, and Drago G.A. (2016). Bioconjugation and

stabilisation of biomolecules in biosensors. Essays in

Biochemistry, 60(1):59–68.

Kenny, R. P., Birks, T. A, and Oakley, K. P. (1991). Control

of optical fibre taper shape. Electronics Letters, 27.

Polynkin, P., Polynkin, A., Peyghambarian, N., and

Mansuripur, M. (2005). Evanescent field-based optical

fiber sensing device for measuring the refractive index

of liquids in microfluidic channels. Optics Letters,

30(11):1273–1275.

Qiang, Z., Junyang, L., Yanling, Y., Libo, G., and

Chenyang, X. (2014). Micro double tapered optical

fiber sensors based on the evanescent field-effect and

surface modification. Optik, 125(17):4614–4617.

Qiu, H. W., Xu, S. C., Jiang, S. Z., Li, Z., Chen, P. X., Gao,

S. S., Zhang, C., and Feng, D. J. (2015). Applied surface

science a novel graphene-based tapered optical fiber

sensor for glucose detection. Elsevier, 329:390–395.

Ruan, Y., Foo, T. C., Warren-Smith, S., Hoffmann, P.,

Moore, R. C., Ebendorff-Heidepriem, H., and Monro,

T. M. (2008). Antibody immobilization within glass

microstructured fibers: a route to sensitive and selective

biosensors. Optics Express, 16(22):18514–18523.

Salceda-Delgado, G., Monzon-Hernandez, D., Martinez-

Rios, a., Cardenas-Sevilla, G. a., and Villatoro, J.

(2012). Optical microfiber mode interferometer for

temperature-independent refractometric sensing.

Optics Letters, 37(11):1974.

Shi, J., Xiao, S., Yi, L., and Bi, M. (2012). A sensitivity-

enhanced refractive index sensor using a single-mode

thin-core fiber incorporating an abrupt taper. Sensors,

12(4), 4697–4705.

World Health Organization (2016). Diabetes Global

Report. Technical report.

Yadav, T. K., Narayanaswamy, R., Abu Bakar, M. H.,

Kamil, Y. M., and Mahdi, M. A. (2014). Single mode

tapered fiber-optic interferometer based refractive

index sensor and its application to protein sensing.

Optics Express, 22(19):22802.

Zibaii, M. I., Latifi, H., Karami, M., Gholami, M., Hosseini,

S. M., and Ghezelayagh, M. H. (2010). Non-adiabatic

tapered optical fiber sensor for measuring the

interaction between a-amino acids in aqueous

carbohydrate solution. Measurement Science and

Technology, 21(10):105801.

Tapered Fibre Optic Biosensor (TFOBS) by Optically Controlled Etching for Label-Free Glucose Concentration Monitoring - Biomedical

Optics

173