Eco-Gresilient: Coalescing Ingredient of Economic, Green and

Resilience in Supply Chain Network Design

Ahmed Mohammed

1,2

, Irina Harris

1

and Reda Nujoom

2

1

Cardiff Business School, Cardiff University, Aberconway Building, Colum Dr, CF10 3EU, Cardiff, U.K.

2

School of Engineering, University of Portsmouth, PO1 3DJ, Portsmouth, U.K.

Keywords: Supply Chain Resilience, Go Green, RALF, Fuzzy AHP, Multi-criteria Decision Making, Multi-objective

Optimization.

Abstract: This research presents a new approach that considers green and resilience dimensions in addition to economic

(eco-gresilient, henceforth) aspects to design an eco-gresilient supply chain network. Thus, fuzzy AHP

(analytical hierarchy process) is used to determine the relative weight of evaluation criteria for each resilience

pillars (robustness, agility, leanness and flexibility (RALF)), and then it is used for assigning the importance

weight for each potential facility with respect to RALF. The determined weights revealed via fuzzy AHP are

then integrated into a multi-objective optimization model to identify the number of facilities that should be

established in the meat supply chain. Three objective functions were formulated and include minimization of

total cost and environmental impact and maximization of value of resilience (V-RALF). The ε-constraint

approach is used to obtain a set of Pareto solutions. The effectiveness of the developed eco-gresilient multi-

objective model is presented on a case study in the meat sector.

1 INTRODUCTION

The economic aspect represents the traditional

concerns in the supply chain design. Nevertheless,

environmental concerns have been increasingly

discussed in the supply chain management literature

where decision makers are required to address

increasing regulations related to green development.

Recently, there has been an increasing interest in

private and public sector and academia in improving

supply chain resilience to act against disruptions that

occur due unexpected events such as natural disasters,

earthquake, floods, and potential catastrophic failures

(Levalle and Nof, 2015). Despite various definitions

presented in the literature, the required resilience

pillars are not well identified from practical or

theoretical perspectives. Recently, Purvis et al.,

(2016) proposed a supply chain framework

highlighting the necessary ‘ingredients’ to achieve

resilience and it includes specific management

paradigms: robustness, agility, leanness and

flexibility (RALF).

In the context of supply chain network design, it

should consider economic, environmental and

resilience (Perrings, 2006). Thus, there is a need for a

survival plan through an integrated approach that

simultaneously considers resilience to efficiently

cope with unexpected disruptions and green

dimension to manage increasing global requirements

to reduce the environmental impact (Govindan et al.,

2017).

Multi-objective optimization in the supply chain

design has been widely applied in academia

(Mohammed et al., 2017a, b, c; Mohammed and

Wang, 2017 and 2015). Most recently, Govindan et

al., (2017) reviewed researches in the field of green

supply chains network design under uncertainty.

Mohammed and Wang (2017b) developed a

mathematical programming model for optimizing

location-allocation problem towards a green meat

supply chain using LP-metrics, ε-constraint and goal

programming.

Research of resilient supply chain design has been

increasing steadily in recent times. Nooraie et al.,

(2015) formulated a multi-objective model includes

minimization of investment costs, minimization of

the variance of the total cost and minimization of the

financial risk aiming to obtain a trade-off among them

using a relaxation heuristic method. Dixit et al.,

(2016) proposed a multi-objective model to maximize

supply chain resilience in minimizing unfulfilled

demand and transportation cost post-disaster. NSGA-

Mohammed, A., Harris, I. and Nujoom, R.

Eco-Gresilient: Coalescing Ingredient of Economic, Green and Resilience in Supply Chain Network Design.

DOI: 10.5220/0006614702010208

In Proceedings of the 7th International Conference on Operations Research and Enterprise Systems (ICORES 2018), pages 201-208

ISBN: 978-989-758-285-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

201

II and Co-Kriging approaches were adopted to solve

the model. However, the literature review revealed

that there is no research that integrates supply chain

resilience (for example with respect to RALF) and the

environmental impact.

This research paper presents a new multi-

objective optimization model for an eco-gresilient

meat supply chain network design in identifying the

optimal number of facilities that should be

established. The model considers the optimization of

three objectives: minimizing the total costs and CO

2

emissions throughout the supply chain and

maximizing the value of resilience (V-RALF) as a

third objective. Initially, the weight for each

resilience pillar and corresponding weight for each

potential facility are determined using fuzzy AHP

based on decision makers’ experts. Then, the weights

obtained by the fuzzy AHP are integrated in the

objective function that considers the four resilience

pillars. Based on the developed model, the ε-

constraint method is used to solve multi-objective

optimisation model.

2 DEVELOPING THE

ECO-GRESILIENT APPROACH

We Figure 1 illustrates the meat supply chain that is

used in the study which encompasses of multi-tier

network: farms, abattoirs and retailers. This research

aims to obtain an eco-gresilient meat supply chain

network design in identifying the optimal number of

farms and abattoirs that should be established

according to emerging economic, green and resilience

responsibilities.

The eco-gresilient approach is developed as

follows:

1. The fuzzy AHP technique is utilized to determine

relative weights for resilience pillars (i.e.,

robustness, agility, leanness and flexibility).

2. A fuzzy technique is used to determine the weight

for each potential farm and abattoir according to

their resilience performance.

3. A multi-objective optimization model is

developed towards the optimization of minimum

total cost and environmental impact and

maximum V-RALF. The latter is developed by

integrating the weights obtained from the fuzzy

techniques.

4. ε-constraint is used to generate Pareto solutions

for multi-objective optimization model.

Figure 1: Structure of the meat supply chain network under

study.

2.1 Weighting RALF and Facilities

In this research, fuzzy AHP is used to determine the

importance weight for each resilience pillar. Fuzzy

AHP is a decision-making algorithm presented by

incorporating the crisp AHP with the fuzzy set theory

(Saaty, 2000). In this algorithm, fuzzy numbers are

presented by a membership function that is a real

number between 0 and 1. Table 1 presents the

linguistic variables used for evaluating the four

resilience pillars. Decision makers need to evaluate

the importance of each pillar using the given

linguistic variables. The Fuzzy AHP is applied as

described in Srichetta and Thurachon, 2012.

Afterward, the steps were subsequently used to

determine the weight of each potential facility with

respect to resilience pillar. Table 1 presents the

linguistic variables used for evaluating farms and

abattoirs with respect to each resilience pillar based

on decision makers ’experts.

Table 1: Linguistic variables used for weighting resilience

pillars and potential facilities.

Evaluating pillars Fuzzy number (a,n,m)

Equally important (EI) (0.1, 0.1, 0.3)

Weakly important (WI) (0.1, 0.3, 0.5)

Strongly more important (SMI) (0.3, 0.5, 0.7)

Very strongly important (VSI) (0.5, 0.7, 0.9)

Extremely important (EI) (0.7, 0.9, 0.10)

Evaluating facilities Fuzzy number (a,n,m)

Very Low (VL) (1, 1, 3)

Low (L) (1, 3, 5)

Medium (M) (3, 5, 7)

High (H) (5, 7, 9)

Very High (VH) (7, 9, 9)

2.2 Model Formulation

The multi-objective optimization model supports

strategic decision in determining the optimal number

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

202

of farms and abattoirs that should be established with

respect to eco-gresilient performance. Three

objective functions are formulated which include

minimization of the total cost (TC), environmental

impacts (EI), and maximization of value of

robustness, agility, leanness and flexibility (V-

RALF).

Sets

E

set of farms

(1... ... )eE

F

set of abattoirs

(1... f ... F)

G

set of retailers

(1... g... G)

Input parameters

p

e

C

purchasing cost per unit of livestock ordered

from farm e

p

f

C

purchasing cost per unit of meat packets (units)

ordered from abattoir f

t

ef

C

unit transportation cost per mile from farm e to

abattoir f

t

f

g

C

unit transportation cost per mile from abattoir

f to retailer g

o

e

C

operating cost per hour required at farms e

o

f

C

operating cost per hour required at abattoir f

a

e

C

administration cost per order from fame e

a

f

C

administration cost per order from abattoir f

e

R

working rate per labourer at farm e

f

R

working rate per labourer at abattoir f

e

N

minimum required number of working hours

for labourer at farm e

f

N

minimum required number of working hours

for labourer at abattoir f

d

ef

transportation distance (mile) of livestock from

farm e t abattoir f

d

fg

transportation distance (mile) of processed meats

from abattoir f to retailer g

l

C

transportation capacity (units) per lorry

e

C

maximum supply capacity (units) of farm e

f

C

maximum supply capacity (units) of abattoir f

D

f

minimum demand (in units) of abattoir f

D

g

minimum demand (units) of retailer g

CO

2e

CO

2

emission in grams for opening farm e

CO

2f

CO

2

emission in grams for opening abattoir f

CO

2ef

CO

2

emission in grams per mile for each lorry

travelling from farm e to abattoir f

CO

2fg

CO

2

emission in grams per mile for lorry

travelling from abattoir f to retailer g

R

e

W

Weight of robustness obtained from fuzzy AHP

from the perspective of decision makers at abattoirs

R

f

W

Weight of robustness obtained from fuzzy AHP

from the perspective of decision makers at retailers

A

e

W

Weight of agility obtained from fuzzy AHP from

the perspective of decision makers at abattoirs

A

f

W

Weight of agility obtained from fuzzy AHP from

the perspective of decision makers at retailers

L

e

W

Weight of leanness obtained from fuzzy AHP

from the perspective of decision makers at abattoirs

L

f

W

Weight of leanness obtained from fuzzy AHP

from the perspective of decision makers at retailers

F

e

W

Weight of flexibility obtained from fuzzy AHP

from the perspective of decision makers at abattoirs

F

f

W

Weight of flexibility obtained from fuzzy AHP

from the perspective of decision makers at retailers

R

e

w

weight of farm e with respect to redundancy

obtained from fuzzy AHP

R

f

w

weight of abattoir f with respect to redundancy

obtained from fuzzy AHP

A

e

w

weight of farm e with respect to agility obtained

from fuzzy AHP

A

f

w

weight of abattoir f with respect to agility obtained

from fuzzy AHP

L

e

w

weight of farm e with respect to leanness obtained

from fuzzy AHP

L

f

w

weight of abattoir f with respect to leanness

obtained from fuzzy AHP

F

e

w

weight of farm e with respect to flexibility

obtained from fuzzy AHP

F

f

w

weight of abattoir f with respect to flexibility

obtained from fuzzy AHP

Output Decision variables

ef

m

quantity of livestock transported from farm e to

abattoir f

Eco-Gresilient: Coalescing Ingredient of Economic, Green and Resilience in Supply Chain Network Design

203

f

g

m

quantity of meat packets (units) transported from

abattoir f to retailer g

e

x

number of required labourers at farm e

f

x

number of required labourers at abattoir f

Binary decision variables:

e

y

1: if farm e is open

0: otherwise

f

y

1: if abattoir f is open

0: otherwise

2.2.1 Model Formulation

(1)

22

22

ee f f

eE f F

ef fg

ef ef fg fg

eEfF fFgG

Min EI CO y CO y

mm

CO CO

W

dd

W

(2)

RR R R

eeef ff

eE f F

AA A A

eeef ff

eE f F

LL L L

eeef ff

eE f F

FF FF

eeeeee

eE eE

M

ax V RALF W w y W w y

WwyWwy

WwyWwy

WwyWwy

(3)

Subject to:

ef

e

e

E

e

ymC

f

F

(4)

g

f

fg

F

ff

ymC G

(5)

D

e

E

f

f

e

m

f

F

(6)

D

f

F

gg

f

m

g G

(7)

D

gG

f

fg

m

f

F

(8)

R

ef e e

fF

mx

e E

(9)

f R

fg f f

gG

mx F

(10)

,0,,

ef fg

mm efg

(11)

,{1,0},,

ef

yy ef

(12)

Eq. 1 refers to objective function to minimize the total

transportation costs, which includes purchasing cost,

operating cost, administration cost and transportation

cost. Eq. 2 refers to the second objective function that

minimises the environmental impact, in particular

CO

2

emissions from opening network facilities and

transportation. Eq. 3 refers to the third objective

function that aims to maximize the value of supply

chain resilience in term of maximizing resilience

pillars i.e. RALF. The weights for each pillar and

each farm and abattoirs (with respect to RALF)

revealed from the fuzzy AHP are used to formalize

the maximization of V-RALF. Eq. 4 restricts the

quantity of livestock transported from farms to

abattoirs so that it cannot exceed the capacity of

farms. Eq. 5 ensures the quantity flow of meat packets

from abattoirs to retailer does not overcome the

capacity of abattoirs. Eqs. 6-8 ensure that the

demands of abattoir

f and retailer g are fulfilled from

farms e and abattoirs f, respectively. Eqs. 9 and 10

indicate the required number of labourers at farms

and abattoirs. Eqs. 11 and 12 limit the non-binary and

non-negativity restrictions on decision variables.

2.3 Revealing Pareto Solutions

In this research, the ε-constraint method is employed

towards the optimization of the three objectives. This

method transforms the multi-objective model to a

mono-objective model by keeping one of the function

as an objective function, and treating other functions

as constraints limited to ε values (Ehrgott, 2005). In

this work, minimization of total cost is used as an

objective function while minimization of

environmental impact and maximization of V-RALF

are moved to be ε-based constraints. The equivalent

solution formula (S) is given by:

TCMin S Min

(13)

Subject to:

1

EI

(14)

eEf F f FgG

eEfF fFgG

eEfF fFg

pp

eef ffg

aa

ef ef fg fg

oo

ef e e fg f f

ef fg

tt

ef ef

G

eEf F gG

fg fg

fF

Min TC m m

mCm

xN C xN

mm

C

CC

C

C

ddC

WW

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

204

1

min max

EI EI

(15)

2

VRALF

(16)

2

min max

V RALF V RALF

(17)

In addition to Eqs. 4-12.

3 APPLICATION AND

EVALUATION OF THE

ECO-GRESILIENT APPROACH

In this section, a case study is utilized to validate the

effectiveness of the developed eco-gresilient

approach to determine (1) the optimal number of

farms and abattoirs that should be established with

respect to economic, green and resilient

responsibilities, and (2) trade-off solutions among

three objectives: minimising total cost, environmental

impact and maximising the value of supply chain

resilience. The example includes 3 farms, 4 abattoirs

to supply 7 retailers. Table 2 presents values for input

parameters used in the model formulation discussed

in Section 3. The supply capacity of farm

e (

e

C

) is

generated in a range 1,500 – 1,800 livestock. The data

is collected from the meat committee in the UK

(HMC, 2010). The travel distances between farms

and abattoirs and between abattoirs and retailers are

estimated using the Google map. Also, the demand

values presented in Table 2, is the total demand over

a one year period. LINGO

11

software was used to

solve presented problem on a personal computer with

a Corei5 3.2GHz processor, 8GB RAM.

Table 2: Input parameters.

E = 3

t

e

C

= 1-1.5

f

g

d

= 110-205

F = 4

t

f

g

C

= 1-1.5

l

C

= 50

G = 7

a

e

C

= 3-4.5

e

C

= 1500-1800

p

e

C

= 130– 150

a

f

C

= 3-4.5

f

C

= 1600-2000

p

f

C

= 160– 190

ef

d

= 43-250

N

e

= 9

o

e

C

= 8-9.5

o

f

C

= 10-11

N

f

= 9

D

f

= 1250-1450 D

g

= 1100-1300 CO

2ef

= 271-294

CO

2fg

= 271-294

CO

2e

= 82000-

85000

CO

2f

= 220000-

250000

R

e

= 60 R

f

= 15

A decision maker (ADM) from an abattoir was

asked to evaluate the importance of resilience pillars

and the potential three farms (f1, f2 and f3) with

respect to each pillar, and two decision makers

(RDM

1

and RDM

2

) from two retailers in the UK were

asked to evaluate the importance of resilience pillars

and the potential four abattoirs (a1, a2, a3 and a4)

with respect to each resilience pillar.

Next, fuzzy AHP is applied for allocating the

importance weight for each resilience pillar

(robustness, agility, leanness and flexibility) based on

decision makers’ experts obtained in the previous

step. Table 3 shows the obtained weight for each

pillar. As can be seen in Table 3, the importance

weight order is

Agility>Robustness>flexibility>Leanness based on

ADM’s experts, and Agility> flexibility>

Robustness>Leanness based on RDMs’ experts.

Fuzzy AHP steps is then applied to determine the

importance weights of the potential three farms and

four abattoirs using the input parameters obtained

from the previous step. Table 4 shows the results

corresponding to the relevant facilities. Based on the

obtained results, farm 2 and abattoir 3 revealed the

highest resilience performance with respect to RALF

compared to farm 3 and abattoir 2 which revealed the

worst resilience performance.

The developed multi-objective optimization

model that integrates the obtained weights is

optimized using the ε-constraint method as follows:

1. Table 5 lists the minimum and maximum values

for each objective. These values are determined

by applying Eqs. 18-23, respectively. For

instance, the minimum and maximum values of

the total cost are 344,703 and 501,868,

respectively. These values are used for assigning

ε values.

Table 3: Weights of RALF.

Pilla

r

RA L F

DM ADM

Weigh

t

0.196 0.585 0.042 0.175

DM RDM1/RDM2

Weigh

t

0.123 0.438 0.036 0.400

Table 4: Weights of facilities with respect to RALF.

R A L F Global

f1 0.654 0.210 0.141 0.053 0.343

f2 0.841 0.211 0.198 0.068 0.383

f3 0.467 0.164 0.084 0.053 0.272

a1 0.397 0.131 0.101 0.087 0.269

a2 0.221 0.073 0.061 0.112 0.214

a3 0.397 0.131 0.142 0.112 0.298

a4 0.221 0.102 0.061 0.087 0.218

Eco-Gresilient: Coalescing Ingredient of Economic, Green and Resilience in Supply Chain Network Design

205

eEfF fFgG

eEfF fFgG

eEfF fFg

pp

eef ffg

aa

ef ef fg fg

oo

ef e e fg f f

ef fg

tt

ef ef

G

eEf F gG

fg fg

fF

Min TC m m

mCm

xN C xN

mm

C

CC

C

C

ddC

WW

(18)

22

22

ee f f

eE f F

ef fg

ef ef fg fg

eEfF fFgG

Mi n EI CO y CO y

mm

CO CO

W

dd

W

(19)

RR R R

eeef ff

eE f F

AA A A

eeef ff

eE f F

LL L L

eeef ff

eE f F

FF FF

eeeeee

eE eE

M

in V RALF W w y W w y

WwyWwy

WwyWwy

WwyWwy

(20)

eEfF fFgG

eEfF fFgG

eEfF fFg

pp

eef ffg

aa

ef ef fg fg

oo

ef e e fg f f

ef fg

tt

ef ef

G

eEf F gG

f

gfg

fF

Max TC m m

mCm

xN C xN

mm

C

CC

C

C

ddC

WW

(21)

22

22

ee f f

eE f F

ef fg

ef ef fg fg

eEfF fFgG

Max EI CO y CO y

mm

CO CO

W

dd

W

(22)

RR R R

eeef ff

eE f F

AA A A

eeef ff

eE f F

LL L L

eeef ff

eE f F

FF FF

eeeeee

eE eE

M

ax V RALF W w y W w y

WwyWwy

WwyWwy

WwyWwy

(23)

2. Minimizing the total cost is used as an objective

function where the environmental impact and V-

RALF aspects are considered as constraints as

previously presented in Eqs. 20-24. The range

between the maximum and minimum values for

objective functions two (environmental impact)

and three (V-RALF) are segmented into ten

segments, the points in between are assigned as ε

values in Eq. (21 and 23). However, it can be

segmented in more or less number of segments to

get more or less number of Pareto solutions.

3. Table 6 lists Pareto solutions obtained by solving

the problem formulation using ε-constraint (Eqs.

13-17). These solutions represent trade-offs

among minimizing the total cost and

environmental impact and maximization of V-

RALF. As shown in Table 6, these solutions are

also associated with the correspondence number

of farms and abattoirs that should be established.

For instance, solution#1 leads to a total cost of

361,348, a CO

2

emission of 211,000 and a value

of resilient (V-RALF) of 2. This solution requires

an establishment of farm two (0 1 0) to supply

livestock to abattoirs two and four (0 1 0 1). This

solution is obtained via an allocation of

ε1=211,075 and ε2 = 2. Pareto fronts among the

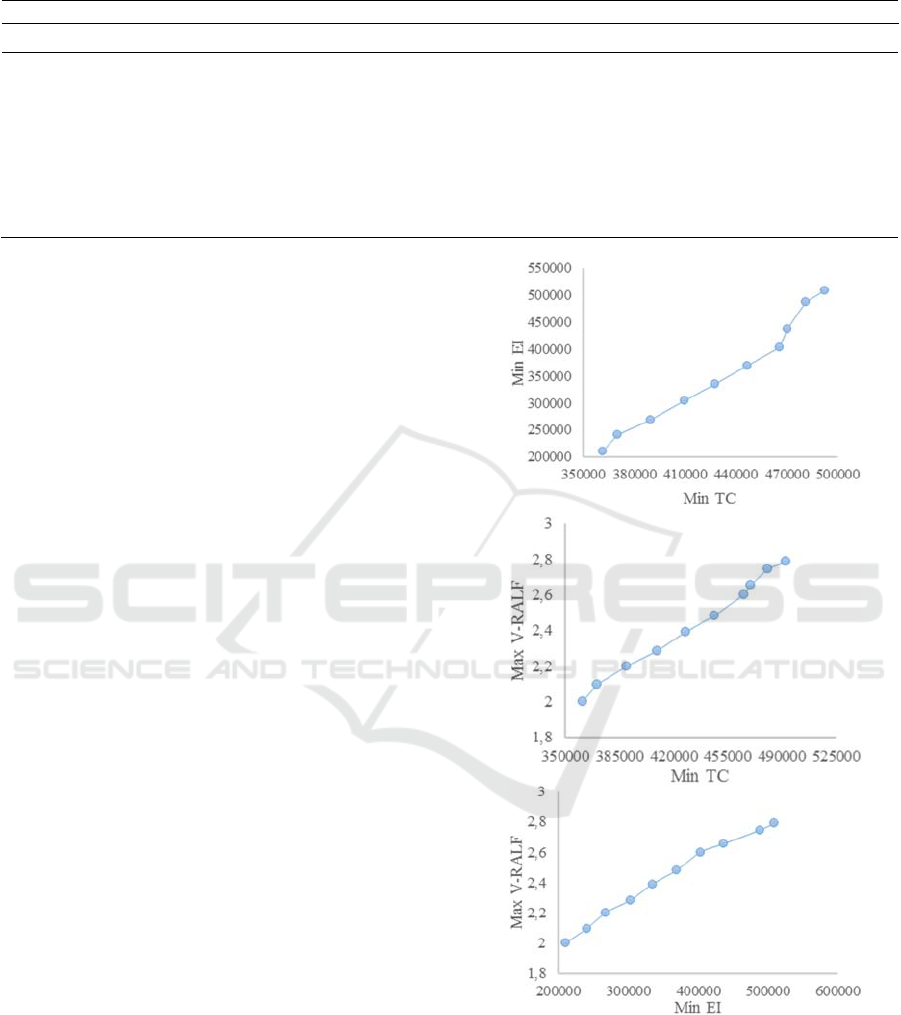

TC, EI and V-RALF are illustrated in Figure 2.

Finally, decision makers need to select the final

Pareto solution to design their supply chain

network based on their preferences. In this

research, solution#5 is selected as a final trade-off

solution among the values of the three objectives

to design the eco-gresilient meat supply chain

network.

Table 5: Maximum and minimum values related to TC, EI

and V-RALF.

Objective functions Max

Min

TC 501868 344703

EI 517847.785 180075.077

V-RALF 2.7901 1.93109

This solution leads to a minimum total cost of

427,626, a minimum CO2 emission of 335,262 and a

maximum value of resilience pillars (V-RALF) of

2.390. With respect to the allocation of facilities, this

solution requires an establishment of two farms to

supply livestock to three abattoirs. This solution is

obtained via an allocation of ε1= 337,075 and ε2 =

2.38.

4 CONCLUSIONS

Economic, green and resilient supply chain network

design has become a new challenge for supply chain

managers aiming to design a robust supply chain

network that not merely consider economic and green

objectives, but also be resilient to sustain its

operations under any disruption.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

206

Table 6: Pareto solutions.

values

Objective function solutions Opened Facilities

#

1

2

Min TC Min EI Max V-RALF Farms Abattoirs

1 211075 2 361348 211000 2 0 1 0 1 0 1 0

2 241075 2.095 370350 241075 2.095 0 1 0 1 0 1 0

3 271075 2.190 389550 268223 2.200 1 1 0 1 0 1 0

4 304075 2.285 409515 304000 2.285 1 1 0 1 0 1 1

5 337075 2.380 427626 335262 2.390 0 1 1 1 0 1 1

6 370075 2.475 446631 369998 2.482 1 1 0 1 0 1 1

7 404075 2.570 465843 404000 2.600 1 1 1 1 1 1 0

8 437075 2.655 470052 437005 2.655 1 1 0 1 1 1 1

9 490075 2.732 481118 488200 2.744 1 1 1 1 1 1 1

10 517847 2.790 492512 509121 2.790 1 1 1 1 1 1 1

This study has motivated by this challenge in

emerging economic, green and resilience

responsibilities in the design and optimization of a

supply chain network. A hybrid MCDM-multi-

objective optimization model is developed to design

an eco-gresilient supply chain network. Fuzzy AHP

is used to determine the weight for resilience pillars

which include robustness, agility, leanness and

flexibility (RALF) based on decision makers ‘experts.

Next, fuzzy AHP is also used to determine the

importance weight for the potential facilities with

respect to their resilience performance. The obtained

weights are then integrated into a developed multi-

objective optimization model used for allocating the

optimal number of facilities that should be

established.

The model includes a formulation of three

objectives including minimization of the total cost

and environmental impact in particular the CO

2

emissions and maximization the value of supply chain

resilience in terms of maximizing resilience pillars

(Maximization of V-RALF) as a third objective.

Finally, the ε-constraint method is used to obtain

trade-offs among the three objectives via optimizing

the developed multi-objective model. The

applicability of the developed model is validated

through a case study. The results demonstrate that the

model can be used as an aid for enterprises to design

an eco-gresilient supply chain network. Furthermore,

it can be used by supply chain managers of related

facilities to improve their resilience performance.

The current work avenue includes the re-

development of the current model incorporating the

social aspect and uncertainties in the input data such

as demands, supply capacities of related facilities and

CO

2

emissions. Finally, the rank reversal approach

can be applied to help the decision makers in selecting

the final Pareto solution.

Figure 2: Pareto fronts among TC, EI and V-RALF.

REFERENCES

Bing Bing, X., Bloemhof-Ruwaard, J., Chaabane, A., van

der Vorst, J., 2015. Global reverse supply chain

Eco-Gresilient: Coalescing Ingredient of Economic, Green and Resilience in Supply Chain Network Design

207

redesign for household plastic waste under the emission

trading scheme. J. Clean. Prod. 103, 28-39.

Dixit, V., Seshadrinath, N., Tiwari, M.K. 2016.

Performance measures based optimization of supply

chain network resilience: A NSGA-II + Co-Kriging

approach. Computers & Industrial Engineering 93,

205–214.

Ehrgott, M., 2005. Multicriteria Optimization. 2

nd

ed.,

Springer, New York.

Govindan, K., Fattahi, M., Keyvanshokooh, E. 2017.

Supply chain network design under uncertainty: A

comprehensive review and future research directions,

European Journal of Operational Research, doi:

10.1016/j.ejor.2017.04.009.

Harris, I., Mumford, C.L. and Naim, M.M. 2014. A hybrid

multi-objective approach to capacitated facility location

with flexible store allocation for green logistics

modeling. Transportation Research Part E: Logistics

and Transportation Review 66, 1-22.

HMC, UK. 2010. http://www.halalhmc.org/, Available:

http://www.halalhmc.org/test-demo.htm. (Accessed

Jan 19, 2017).

IBM, 2008. Supply Chain Risk Management: A Delicate

Balancing Act. IBM Global Business Services, New

York, NY.

Levalle, R.R., Nof, S.Y. 2015. A resilience by teaming

framework for collaborative supply networks.

Computers & Industrial Engineering, 90, 67–85.

Miranda-Ackerman, M.A., Azzaro-Pantel, C., Aguilar-

Lasserre, A.A. 2017. A green supply chain network

design framework for the processed food. Computers &

Industrial Engineering, 109, 369–389.

Mohammed A. and Wang Q. 2015. Integrity of an RFID-

enabled HMSC Network. Proceedings of the Third

International Conference on Digital Enterprise and

Information Systems, Shenzhen, China, 2015a, 79-86.

Mohammed A. and Wang Q. 2017. Multi-criteria

optimization for a cost-effective design of an RFID-

based meat supply chain. British Food Journal, 119, 3,

676-689.

Mohammed A. and Wang Q. and Li X. 2017a. Developing

a meat supply chain network design using a multi-

objective possibilistic programming approach. British

Food Journal, 119, 3, 690-706.

Mohammed, A. and Wang, Q., 2017b. The fuzzy multi-

objective distribution planner for a green meat supply

chain. International J. Pro Eco., 184, 47–58.

Mohammed, A., Wang, Q., Alyahya, S. and Binnette, N.

2017c. Design and optimization of an RFID-enabled

automated warehousing system under uncertainties: A

multi-criterion fuzzy programming approach. The

International Journal of Advanced Manufacturing

Technology. 91 (5), 1661-1670.

Nooraie, S.V., Parast, M.M. 2015. A multi-objective

approach to supply chain risk management: Integrating

visibility with supply and demand risk. Int. J.

Production Economics 161 (2015) 192–200.

Srichetta, P. and Thurachon, W. 2012. Applying Fuzzy

Analytic Hierarchy Process to Evaluate and Select

Product of Notebook Computers. International Journal

of Modeling and Optimization, 2 (2), 168-173.

Pereira, C.R., Silva, A.L., 2015. Key Organisational Factors

For Building Supply Chain Resilience: A Multiple Case

Study Of Buyers And Suppliers. J. Oper. Supply Chain

Manag. 8, 77–95.

Perrings, C. Resilience and sustainable development.

Environ. Dev. Econ. 2006, 11, 417–427.

Purvis, L., Spall, S., Naim, M. and Spiegler, V. 2016.

Developing a resilient supply chain strategy during

‘boom’ and ‘bust’,

Production Planning & Control,

27:7-8, 579-590, DOI: 10.1080/09537287.2016.

1165306.

Saaty, T.L., 2000. Fundamentals of decision making and

priority theory with the analytic hierarchy process, vol.

6. Rws Publications.

Soni, U., Jain, V., Kumar, S. 2014. Measuring supply chain

resilience using a deterministic modeling approach.

Computers & Industrial Engineering. 74, 11–25.

Tiwari, A., Chang, P.C., Tiwari, M.K., Kandhway, R. 2016.

A Hybrid Territory Defined evolutionary algorithm

approach for closed. Computers & Industrial

Engineering, 99, 432–447.

ICORES 2018 - 7th International Conference on Operations Research and Enterprise Systems

208