Design, Ion Beam Fabrication and Test of Integrated Optical

Elements

I. Bányász

1

, S. Pelli

2,3

, G. Nunzi-Conti

2

, G. C. Righini

3

, S. Berneschi

2

, E. Szilágyi

1

, A. Németh

1

,

M. Fried

4,5

, P. Petrik

4

, E. Agócs

4

, B. Kalas

4

, Z. Zolnai

4

, N. Q. Khanh

4

, I. Rajta

6

, G. U. L. Nagy

6

,

V. Havranek

7

, V. Vosecek

7

, M. Veres

8

, L. Himics

8

1

Department of Nuclear Materials Science, Wigner Research Centre for Physics, Hungarian Academy of Sciences,

P.O.B. 49, H-1525, Budapest, Hungary

2

MDF-Lab, “Nello Carrara” Institute of Applied Physics, IFAC-CNR, Via Madonna del Piano 10,

50019 Sesto Fiorentino (FI), Italy

3

“Enrico Fermi” Center for Study and Research, Piazza del Viminale 2, 00184 Roma, Italy

4

Research Institute for Technical Physics and Materials Science, Centre for Energy Research,

Hungarian Academy of Sciences, Budapest, P.O.B. 49, H-1525, Hungary

5

Institute of Microelectronics and Technology, Óbuda University, Tavaszmező u. 17, H-1084 Budapest, Hungary

6

MTA Atomki, Institute for Nuclear Research, Hungarian Academy of Sciences, H-4001 Debrecen, P.O. Box 51, Hungary

7

Nuclear Physics Institute AV CR, Řež near Prague, 250 68, Czech Republic

8

Department of Applied and Nonlinear Optics, Wigner Research Centre for Physics, Hungarian Academy of Sciences,

P.O.B. 49, H-1525, Budapest, Hungary

Keywords: Ion Implantation, Integrated Optics, Optical Planar Waveguide, Optical Channel Waveguide, Optical Grating,

M-Line Spectroscopy, Spectroscopic Ellipsometry, Micro Raman Spectroscopy, Rutherford Backscattering.

Abstract: Various methods, based on the use of ion beams, were used for the fabrication of planar and channel optical

waveguides and Bragg gratings in optical crystals and glasses. Some examples of the results of these

researches are presented in this review. Researches were initiated on ion beam fabrication of planar and

channel optical waveguides in tellurite glasses. The ions used in the experiments were mainly helium, carbon,

nitrogen and oxygen. In case of the two dimensional elements, like channel waveguides, both masked ion

implantation and direct writing with ion microbeam were used. Optical microscopy (phase contrast,

interference and interference contrast (INTERPHAKO), spectroscopic ellipsometry, m-line spectroscopy,

Rutherford Backscattering and micro Raman spectroscopy were used to test the integrated optical elements.

1 INTRODUCTION

Realization of light confinement in optical guiding

structures, both longitudinally and transversally,

represented the milestone for the development of

Integrated Optics (IO) devices of various

functionalities, like optical amplification and light

coupling or splitting, coexisting in a same chip

(Miller, 1969 and Jaouen, 1999). Currently, the main

effort in this field, coming from the research is that of

discovering and developing the best materials –

fabrication processes combination in order to reduce

the cost and increase the performance of the

previously mentioned devices. Glasses and crystals,

because of their physical and optical properties,

continue to find an even more increasing interest in

different technology fields. Generally, glasses with

their amorphous structure and relatively low

refractive better interface with the optical fiber, thus

resulting in lower values of coupling losses in the

optical devices (Li, 2011 and Zou, 2001).

Glasses doped with Rare Earth (RE) ions are still

the best choice for the development of integrated

optical amplifiers where the request of a flat gain in a

broader bandwidth is well satisfied by the disordered

structure of these materials (Ogoshi, 2000 and Ohishi,

1998). Crystalline materials with their nonlinear

properties and possibility of refractive index

modulation by different effects, such as electro-

optical and/or thermo – optical, are strongly used in

different fields of the optoelectronics (Wooten, 2000

and Xu, 2015). Due to their ordered structure, these

materials represent a suitable RE host for the

Bányász, I., Pelli, S., Nunzi-Conti, G., Righini, G., Berneschi, S., Szilágyi, E., Németh, A., Fried, M., Petrik, P., Agócs, E., Kalas, B., Zolnai, Z., Khanh, N., Rajta, I., Nagy, G., Havranek, V.,

Vosecek, V., Veres, M. and Himics, L.

Design, Ion Beam Fabrication and Test of Integrated Optical Elements .

DOI: 10.5220/0006679002790285

In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), pages 279-285

ISBN: 978-989-758-286-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

279

realization of high gain and low threshold lasing

devices (Sohler, 2005).

Ion beam irradiation, thanks to its high

controllability and reproducibility, represents a

suitable technique for the fabrication of integrated

optical elements, such as active and passive

waveguides and optical gratings, in most optical

materials. (Townsend, 1994, Chen, 2007, Chen,

2012, Peña-Rodríguez, 2012).

Buried planar and channel waveguides were

usually obtained using light ions (i.e.: protons,

helium) via increasing the index of refraction of the

target in a zone around the stopping range, which is

relatively long for these kind of ions (Ren, 2010, Yao.

2011a, Yao, 2011b and Dong, 2011).

Medium-mass ions, especially carbon and oxygen,

were also used for fabrication of optical waveguides in

amorphous and crystalline materials (Tan, 2007, Zhao,

2010, Montanari, 2012, He, 2013, Liu, 2014).

Formation of adequate refractive index changes

for waveguide fabrication with light and medium-

mass ions requires relatively high fluences, in the

10

15

-10

17

ions/cm

2

region, especially when the mass

and energy of the implanting ion are low.

The use of swift heavy ion irradiation for the

modification of the optical properties of materials was

first reported in the1990’s.

Aithal and his co-workers

irradiated organic nonlinear optical crystals with 100

MeV Ag

14+

ions, and studied optical properties of the

irradiated samples (Aithal, 1997).

Those results

opened a new possible method of fabricating optical

waveguides in the organic nonlinear optical crystals.

Opferman et al. detected formation of amorphous

tracks and layers in KTiOPO

4

crystals during

implantation with swift heavy ions at low fluences

(150 MeV Kr and 250 MeV Xe, 3·10

12

ions/cm

2

- 4·

10

13

ions/cm2) (Opfermann, 2000).

Track and

amorphous layer formation were due to electronic

interaction, and could be explained using the Gibbons

model (Gibbons, 1972). Olivares et al. reported on

implantation of LiNbO

3

crystals using 5-MeV Si

2+

,

7.5-MeV Si

2+

and 30-MeV Si

5+

ions with fluences

from 5·10

13

ions/cm

2

–1·10

15

ions/cm

2

(Olivares,

2005a). They succeeded in producing optically

isotropic amorphous layers of thicknesses increasing

with the fluence. The same group succeeded in

fabricating planar optical waveguides in LiNbO

3

crystals via implantation with 20 and 22 MeV

fluorine ions and fluences from 1·10

14

ions/cm

2

- 3·

10

15

ions/cm

2

(Olivares 2005b).

An amorphised layer

situated around the maximum of electronic stopping

power served as optical barriers while the layer left

below the crystal surface remained crystalline and

constituted the well of the optical waveguide.

2 EXPERIMENTAL

2.1 Planar Waveguides

Based on the results of our previous results of the

fabrication of low grating-constant optical gratings in

Pyrex glass with helium and nitrogen implantation in

the 500 keV – 2 MeV energy range (Bányász, 2001),

we opted for the use of nitrogen ions for the

fabrication of planar optical waveguides. We

succeeded in fabricating planar optical waveguides in

an Er-doped tungsten-tellurite oxide glass with 1.5

MeV N

+

ion implantation at fluences up to 8 ·10

16

ion/cm

2

(Berneschi, 2011).

The waveguides proved to

operative up to the wavelength of 980 nm. This was

due to the limitations caused by the small thickness of

the guiding well, 1.6 µm, calculated by the SRIM

code (Ziegler, 2004). Propagation losses in the

waveguides were reduced by thermal annealing of the

implanted samples.

Further experiments using

implantation with N

+

ions of an increased energy of

3.5 MeV resulted in planar optical waveguides in the

same glass operating up the 1550 nm

telecommunication wavelength (Bányász, 2012).

Appearance of the leaky modes in ion beam

implanted planar optical waveguides is due to the low

thickness of the barrier layer produced around the

stopping range of the implanted ions. To overcome

that problem, double-energy ion beam implantation

was used (Bányász, 2013). Design of such planar

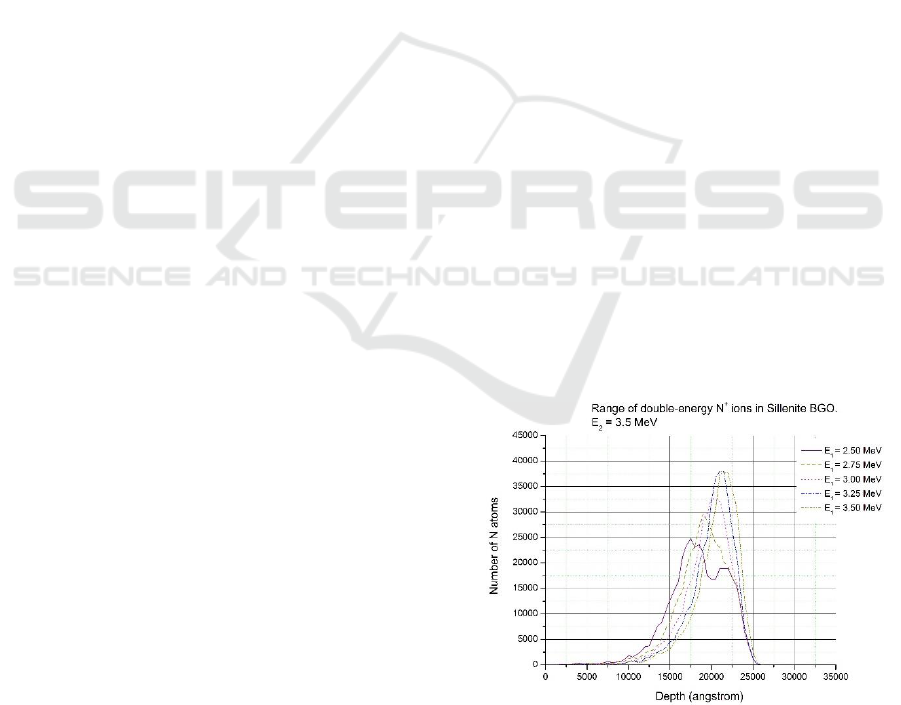

waveguides is presented in Figures 1 and 2. The target

material was sillenite type BGO crystal (Bi

12

GeO

20

).

Double energy N

+

ion implantations were simulated

using the SRIM code. The higher energy in each case

was 3.5 MeV, the highest available energy at the one-

Figure 1:

Depth-distributions of the implanted N

+

ions in

sillenite type BGO crystal, calculated by the SRIM code.

Higher energy was 3.5 MeV in each case. Lower energy is

indicated in the inset.

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

280

Figure 2: Width of the well and barrier layers vs. the lower

energy of irradiation in the sillenite type BGO crystal.

Figure 3: M-line spectra of the planar waveguide in sillenite

type BGO crystal, irradiated with double energy N

+

ions at

3.5 MeV and 3.1 MeV, with a fluence of 2.0· 101

6

ions/cm

2

,

taken at 1310 nm.

stage accelerator used for those experiments, while

the lower energies ranged from 2.5 to 3.25 MeV.

It can be seen in both Figures 1 and 2 that higher

implantation energy differences resulted in thicker

barrier layers and slightly reduced well thickness.

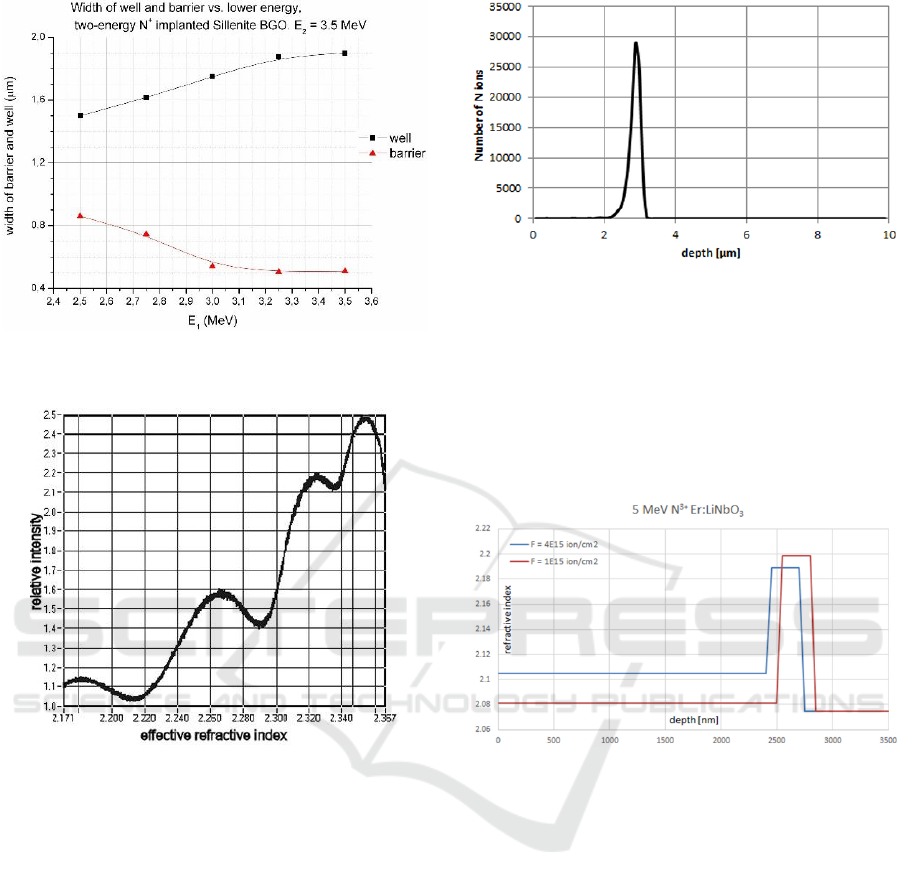

Waveguide operation at the 1310 and 1550 nm

telecommunication wavelength was demonstrated in

the planar waveguides fabricated in the Er-doped

tungsten-tellurite oxide glass and the sillenite type

BGO, see Figure 3.

With access to a modern Tandetron accelerator,

implantation with higher-mass ions at higher energies

became possible. In one of those experiments, planar

optical waveguides were formed in an Er: LiNbO

3

crystal by implantation with 5 MeV N

3+

ions.

Calculated depth distribution of the ions in the target

is shown in Figure 4.

Figure 4: Depth distribution of 5 MeV N

3+

ions in Er:

LiNbO

3

, calculated with SRIM.

The planar waveguides were studied by spectroscopic

ellipsometry using a Woollam M-2000DI spectro-

scopic ellipsometer (wavelength range of 193-1690

nm). Reconstructed refractive index profiles of two of

the waveguides are presented in Figure 5. Note

difference in barrier position, width and height.

Figure 5: Fitted refractive index profiles of two ion-

implanted planar waveguides. Er: LiNbO3 with 5 MeV N

3+

ion at fluences of 1 and 4·10

15

ion/cm

2

.

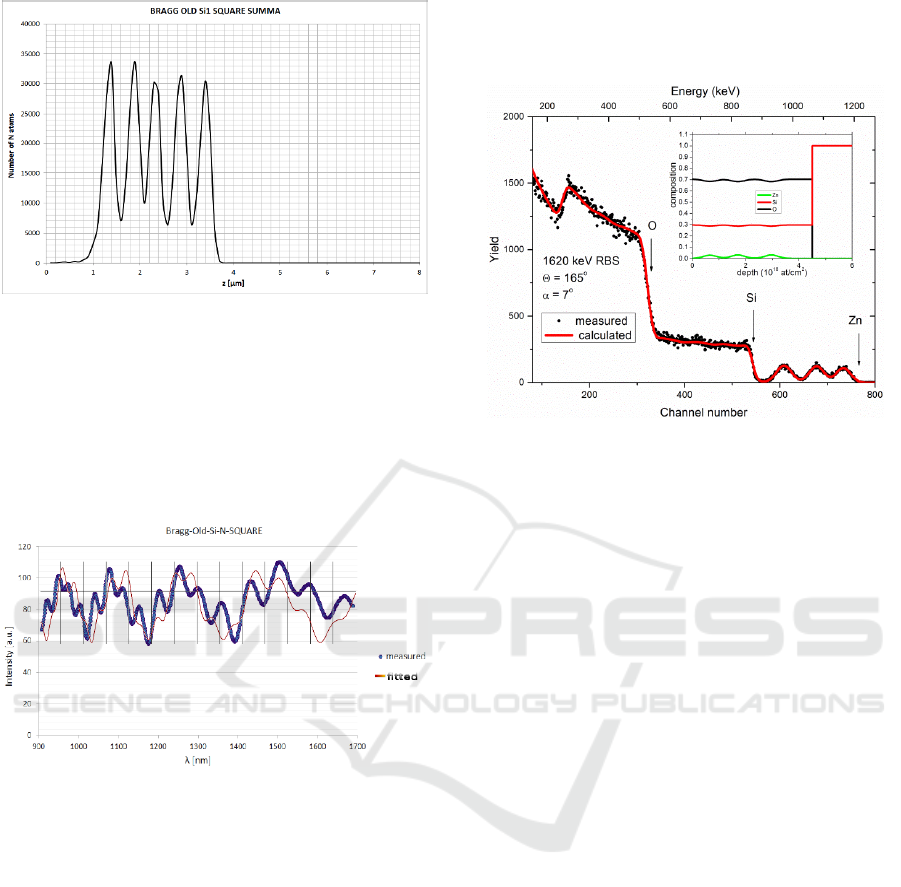

2.2 Bragg Gratings

Multi-energy ion implantation makes it possible to

fabricated optical elements structured in depth. Such

elements can be stacked planar waveguides or Bragg

gratings. Depth distribution of the implanted ions is

of flat-topped skewed Gaussian, and the position of

the peak of those curves changes monotonically with

ion energy. Design of such a Bragg grating, made by

the SRIM code, is shown in Figure 6. Total thickness

of the Bragg grating was about 3 µm, grating constant

Λ = 0.5 µm.

However, depth distribution of the

damage shows only about one third of the modulation

seen in Figure 6.

Design, Ion Beam Fabrication and Test of Integrated Optical Elements

281

Figure 6: Calculated depth distribution of the implanted

ions across a Bragg grating in silicon. The energies were

800 keV, 1.4, 2.0, 2.75 and 3.5 MeV.

The Bragg grating was studied using NIR

reflectometry.

The results of the measurement are

presented in Figure 7. The high modulation in the

reflectivity suggests a strong refractive index

modulation in the grating.

Figure 7: Measured (points) and fitted (red line) NIR

reflectance of an ion-implanted Bragg grating. N

+

, 800 keV

< E < 3.5 MeV, Si sample, Fluence per energy: 2·10

16

ion/cm

2

.

Instead of varying the energy of the implanted

ions in a bulk target, one can fabricate ion implanted

Bragg grating in another way. One can combine the

use of relatively low-energy ions and thin film

deposition. Once a thin film of thickness

corresponding to the designed grating constant of the

Bragg grating is deposited on a substrate, it is

implanted with low-energy ions of a suitable energy

to obtain an ion distribution centered at the middle of

the layer. Then the whole procedure is repeated until

the desired total thickness of the Bragg grating is

reached.

Similarly, to the previous method, stacking

of the ion-implanted thin layers can result in a quasi-

sinusoidal depth profile of the refractive index.

Such Bragg gratings were prepared in SiO

2

thin

films, both on silicon and glass substrates. The Bragg

gratings were studied by Rutherford Backscattering

Spectrometry (RBS). The results of the RBS study

can be seen in Figure 8.

Figure 8: RBS measurement of an ion implanted Bragg

grating.

The sample was prepared by repeating Chemical

Vapor Deposition (CVD) of SiO

2

thin layers (first

300 nm and then twice 200 nm) and low-energy ion

implantation of each layer by 130 keV Zn

+

ions on a

silicon substrate. Both the measured and simulated

RBS spectrum spectra and the calculated depth

distribution (inset) of Zn in the sample show regular

quasi-sinusoidal distributions. The high implanted

fluences (2·10

16

ions/cm

2

each) resulted in about 3 %

peak Zn concentration (see inset).

That concentration

implies high modulation of the refractive index, so

that even a low number of implanted grating layers

could result in high diffraction efficiency.

Diffraction efficiency measurements of the

various ion implanted Bragg gratings are under way.

2.3 Channel Waveguides

Two basic methods were used for the fabrication of

channel waveguides in Er-Te glass, eulytine and

sillenite type BGO crystals, CaF

2

, LiNbO

3

and other

optical crystals. The first one was implantation

through masks. Various masks were used, such as a

special silicon membrane mask that contained 24 μm

wide slits and a patterned thick AZ4562 photoresist

layer on the surface of the sample. The thickness of

the channel waveguides was between 5 μm and 24

μm.

Experiments using both methods were also

carried out at the van de Graaff accelerator of the

Wigner Research Centre for Physics, using N

+

ions at

energies of 1.5 MeV and 3.5 MeV.

The second method was direct the writing of 15-

µm channel waveguides in Er-Te glass with carbon,

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

282

oxygen and nitrogen microbeams of low (around 5

MeV) and high (around 10 MeV) using a 3-MV

Tandetron 4130 MC (High Voltage Engineering

Europa B.V.) accelerator with a quadrupole triplet

OM150 Oxford Microbeams Ltd. at the Řež Nuclear

Physics Institute, Czech Republic.

Design of channel waveguides was similar to that

of the planar ones. However, lateral confinement in

the ion-implanted channel waveguides was not

always automatically ensured in the experiments.

The first working channel waveguides were

obtained in an Er: tungsten-tellurite glass, using a

thick silicon membrane with 24 µm wide slits and

implantation with 1.5 MeV energy N

+

ions

(Berneschi, 2007). Guiding up to λ = 980 nm was

demonstrated.

Green upconversion at the same

wavelength was also observed.

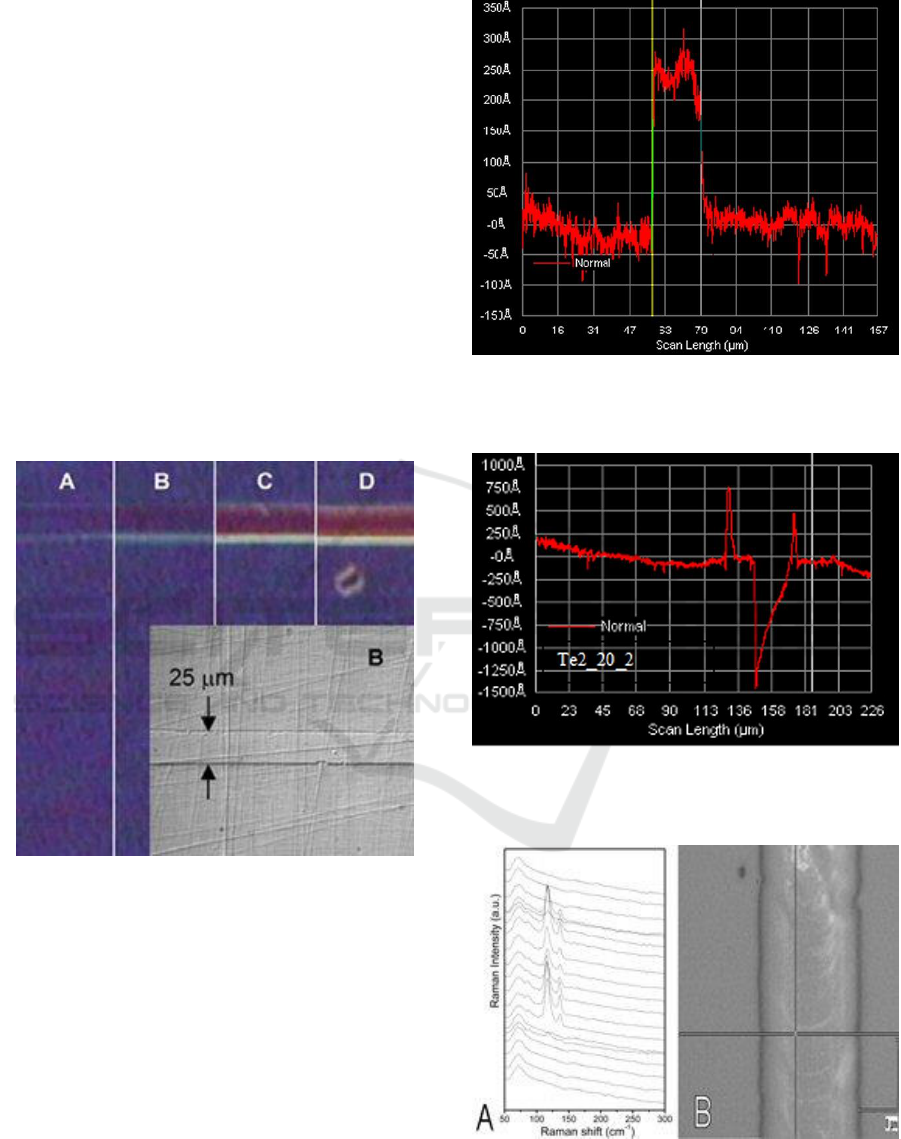

Interference phase

contrast (INTERPHAKO) microphotos of the

channel waveguides are shown in Figure 9.

Figure 9: Interference phase contrast microscopic image of

1.5 MeV N

+

irradiated channel waveguides. Fluence was

0.5, 1, 2 and 4∙10

16

/cm

2

for waveguides A, B, C and D.

Inset: Conventional microscopic image of waveguide B.

In Figure 9, higher difference in hue corresponds

to a higher difference in optical path, and hence

refractive index modulation in the ion-implanted

channel waveguides.

Profilometric scans (performed by a Talysurf

device) of the ion implanted channel waveguides

revealed that, depending on the implanted fluence, a

swelling or depression of the implanted surface can

occur. The results are shown in Figures 10 and 11.

Just a two-fold increase in fluence drastically

changed the sign and profile of the surface change

across the ion-implanted channel waveguide.

Figure 10: Profilometric scan across an ion implanted

channel waveguide. Implantation: 1.5 MeV energy N

+

ions,

fluence = 1∙10

16

ions/cm

2

.

Rectangular ridge, h = 25 nm.

Figure 11: Profilometric scan across an ion implanted

channel waveguide. Implantation: 1.5 MeV energy N

+

ions,

fluence = 2∙10

16

ions/cm

2

. Triangular groove, h = 125 nm.

Figure 12: Micro Raman spectra (A) taken across a channel

waveguide (B) fabricated in an Er-Te glass with 3.5 MeV

N

3+

ion irradiation through a silicon mask. Parameter of the

curves is laser microbeam position along the horizontal line

in the microphotograph.

Design, Ion Beam Fabrication and Test of Integrated Optical Elements

283

More recently, the same method was used to

fabricate channel waveguides in the same Er:

tungsten-tellurite glass, but with N

+

ions of 3.5 MeV

energy. Functionality tests of those channel

waveguides are under way. The channel waveguides

were also studied using micro Raman spectroscopy.

Result of such a measurement is shown in Figure 12.

Note the appearance of new Raman lines in the

implanted region, as very prominent manifestation of

the structural changes caused in the target by the ion

implantation.

Figure 13: INTERPHAKO microphotographs of channel

waveguides written in Er-Te glass with 6 MeV C

3+

microbeam without charge compensation (A) and with an

electron source (B).

As for the direct writing of channel waveguides, a

number of samples have been completed so far, and

functionality tests are under way. Just to illustrate the

practical difficulties arising in such experiments,

microscopic photographs of two sets of focused ion

beam written channel waveguides are presented in

Figure 13.

It can be seen that in the absence of charge

compensation the electric field of the charge

accumulating on the surface of the sample

periodically deviates the ion microbeam, resulting in

broken channel waveguides (Figure 13 A). After

installing an electron source in the vacuum chamber

charge accumulation was eliminated, and contiguous

channel waveguides could be written (Figure 13 B).

3 CONCLUSION

It was proved that various integrated optical elements

could be fabricated with ion implantation, using

medium-mass ions, such as carbon, nitrogen and

oxygen of energies in the 1–10 MeV range. Planar

and channel optical waveguides and Bragg gratings

were fabricated by the ion beam techniques. The

optical elements were prepared in a number of optical

crystals and glasses, e.g. sillenite and eulytine type

BGO, doped and undoped LiNbO

3

, SiO

2

, Si and Er: -

tungsten-tellurite glass.

As for the results with ion

implanted planar waveguides, it was found that

nitrogen ion implantation resulted in higher refractive

index contrasts and hence better confinement than the

previously widely used proton and helium ion

implantation. It proved to give even better results in

several materials than carbon and oxygen

implantation. Double-energy implantation was

successfully adapted in those experiments to produce

wider barriers and suppress leaky modes.

Thermal

annealing was used to eliminate or reduce lattice

damages caused by the implantation and reduce

propagation losses. Operation at telecommunication

wavelengths of 1310 and 1550 nm was demonstrated

in the waveguides written in the majority of the glass

and crystalline materials studied. It was demonstrated

that Bragg gratings of quasi-sinusoidal profile could

be fabricated in glasses and crystals either by multi-

energy implantation with MeV energy ions or by the

combination of the growth of a stack of thin films and

successive implantation of low-energy (50–100 keV)

ions in each layer. In principle, high diffraction

efficiency could be achieved with such gratings

consisting of a relatively low number of grating

periods, and having a moderate refractive index

modulation. Ion beam implantation through special

masks and direct writing with medium- to high-

energy focused beams of medium-mass ions was

proposed and used for the fabrication of channel

waveguides. The first channel waveguides fabricated

in an Er: -tungsten-tellurite glass by implantation

through mask operated up to the wavelength of 980

nm. Although evaluation of a large part of the ion

beam implanted optical elements is still under way,

the results so far confirmed show that ion beam

fabrication is an adequate method for fabrication of

various types of optical elements. The use of swift

heavy ions is an especially promising method, since

it requires very low fluences (down to 10

11

ions/cm

2

),

corresponding to short processing times.

ACKNOWLEDGEMENTS

This work was supported by the following funds:

Hungarian National Research Fund, Project Number

OTKA 115852. Part of this work has been carried out

at the CANAM (Centre of Accelerators and

Nuclear

Analytical Methods) infrastructure LM 2015056.

This publication was supported by the OP RDE,

PHOTOPTICS 2018 - 6th International Conference on Photonics, Optics and Laser Technology

284

MEYS, and Czech Republic under the project

CANAM OP, CZ.02.1.01/0.0/0.0/16_013/0001812.

REFERENCES

Aithal, P. Sreeramana, Nagaraja, H. S., Mohan Rao, P,

Avasthi, D. K., and Sarma, Asati, Journal of Applied

Physics 81, 7526 (1997); doi: 10.1063/1.365294

Bányász, I., Fried, M., Dücső, Cs., and Vértesy, Z., Appl.

Phys. Lett., 79, 3755 (2001)

Bányász, I., S. Berneschi, M. Bettinelli, M. Brenci, et al.,

“MeV energy N

+

- implanted planar optical waveguides

in Er-doped tungsten-tellurite glass operating at 1.55

µm”, IEEE Photonics Journal, Volume 4, Issue 3, pp.

721-7, DOI: 10.1109/JPHOT.2012.2194997 (2012)

Bányász, I., Z. Zolnai, M. Fried, T. Lohner, et al., “Single -

and double energy N

+

ion irradiated planar optical

waveguides in Er: Tungsten-Tellurite Oxide glass and

sillenite type Bismuth Germanate crystals for telecom

applications”, Nuclear Instruments and Methods in

Physics Research Section B, 307, 299-304 (2013)

Berneschi, S., G. Nunzi Conti, I. Bányász, et al., “Ion beam

irradiated channel waveguides in Er

3+

-doped tellurite

glass", Applied Physics Letters, 90, 121136, (2007)

Berneschi, S, Brenci, M., Nunzi Conti, G., Pelli, S., et al.,

Slab optical waveguides in Er

3+

-doped tellurite glass by

N

+

ion implantation at 1.5 MeV, Optical Engineering,

50, 071110 (2011).

Chen, F.,

Wang, Xue-Lin and Wang, Ke-Ming, Opt. Mat.,

29, 1523-1542, DOI: 10.1016/j.optmat.2006.08.001

(2007).

Dong, N., Jaque, D., Chen, F. and Lu, Q., “Second

harmonic and Raman imaging of He

+

implanted

KTiOPO4 waveguides”, Optics Express, 19, 13934-

13939 (2011).

Gibbons, J.F., Proceedings of the IEEE, 60, 1062 – 1096,

(1972), DOI: 10.1109/PROC.1972.8854

He, Ruiyun, Shuqian Sun, Miaomiao Xu, Feng Chen,

Shavkat Akhmadaliev, Shengqiang Zhou, Nucl. Instr.

and Meth. in Phys. Res. B, 308, 6-8 (2013)

Li, S.- L. Han, P., Shi, M., Yao, Y., et al., “Low-loss

channel optical waveguide fabrication in Nd

3+

-doped

silicate glasses by femtosecond laser direct writing”,

Optics Express, 19, 23958-23964 (2011).

Liu Chun-Xiao; Xu Jun; Xu Xiao-Li; Wu Shu; Wei Wei;

Guo Hai-Tao; Li Wei-Nan; and Peng Bo, Optical

Engineering, 53(3), 037101 (2014)

Jaouen, Y., du Mouza, L., Barbier, D. Delavaux, J., Bruno,

P., “Eight-wavelength Er-Yb doped amplifier:

combiner/splitter planar integrated module”, IEEE

Photonics Technology Letters, 11, 1105 – 1107 (1999).

Miller, S. E. “Integrated Optics: An introduction”, Bell

System Technical Journal, 48, 2059 – 2069 (1969).

Ogoshi, H., Ichino, S. and Kurotori, K., “Broadband Optical

Amplifiers for DWDM Systems”, Furukawa Review,

No. 19, 17-21 (2000).

Ohishi, Y., Mori, A., Yamada, M., Ono, H., et al., “Gain

characteristics of tellurite-based erbium-doped fiber

amplifiers for 1.5 μm broadband amplification”, Optics

Letters, 23, 274-276 (1998).

Olivares, J., García, G., Agulló-López, F., Agulló-Rueda,

F., Kling, A., Soares, J.C., Appl. Phys. A, 81, 1465–

1469 (2005) DOI: 10.1007/s00339-005-3237-x

Olivares, J., García, García-Navarro, Agulló-López, F., A.,

Caballero, O., García-Cabañes, A, Appl. Phys. Lett., 86,

183501 (2005)

Opfermann, Th., Höche, Klaumünzer, S., Wesch, W, Nucl.

Instr. and Meth. in Phys. Res. B, 166-167, 954-958

(2000)

Peña-Rodríguez, O., Olivares, J., Carrascosa, M., García-

Cabañes, A., Rivera A. and Agulló-López, F., “Optical

Waveguides Fabricated by Ion Implantations/Ir-

radiation: A Review”, in: Ion Implantation, Prof. Mark

Goorsky (Ed.), ISBN: 978-953-51-0634-0, InTech,

Available from: http://www.intechopen.com/books/

ion-implantations/optical-waveguides-fabricated-by-

ion-implantation-irradiation-a-review (2012)

Ren, Y., Tan, Y., Chen, F., Jaque, D., et al, “Optical channel

waveguides in Nd: LGS laser crystals produced by

proton implantation”, Optics Express, 18, 16258-16263

(2010).

Sohler, W., Das, B., Dey, D., Reza, S., et al., “Erbium-

Doped Lithium Niobate Waveguide Lasers”, IEICE

Trans. Electron., E88-C, 990-997 (2005).

Tan Y, Chen F, Physica Status Solidi-Rapid Research

Letters 1 (6), 277-279 (2007)

Townsend, P. D., Chandler, P. J.

and Zhang, L., Optical

Effects of Ion Implantation, Cambridge University

Press, Cambridge, U.K. (1994)

Xu, Kaikai, Liu, Haitao and Zhang, Zhengyuan, “Gate-

controlled diode structure based electro-optical

interfaces in standard silicon-CMOS integrated

circuitry”, Applied Optics, 54, 6420-6424 (2015)

Yao, Y., Tan, Y., Dong, N., Chen, F. and Bettiol, A. A.,

“Continuous wave Nd: YAG channel waveguide laser

produced by focused proton beam writing”, Optics

Express, 18, 24516-24521 (2011).

Yao, Y., Dong, N., Chen, Vanga, S. K.

and Bettiol, A. A.,

“Proton beam writing of Nd: GGG crystals as new

waveguide laser sources”, Optics Letters, 36 4173-4175

(2011).

Wooten, E. L.

et al., “A Review of Lithium Niobate

Modulators for Fiber-Optic Communications

Systems”, IEEE Journal of Selected Topics in Quantum

Electronics, 6, 69-82 (2000).

Zhao, Jin-Hua, Liu, Xiu-Hong, Huang, Qing, Liu, Peng,

Wang Lei and Wang, Xue-Lin, Nuclear Instruments

and Methods in Physics Research Section B: Beam

Interactions with Materials and Atoms, 268, 2923–

2925 (2010)

Ziegler, J.F., “SRIM-2003”, Nucl. Instr. and Meth.B, 219–

220, 1027 (2004), and http://www.srim.org

Zou, J., Zhao, F. and Chen, R. T., “Two-step K

+

-Na

+

and

Ag

+

-Na

+

ion-exchanged glass waveguides for C-band

applications”, Applied Optics, 41, 7620-7626 (2002).

Design, Ion Beam Fabrication and Test of Integrated Optical Elements

285