Internet of Things Meets BPM: A Conceptual Integration Framework

Stefan Sch

¨

onig, Lars Ackermann and Stefan Jablonski

Department of Computer Science, University of Bayreuth, Germany

Keywords:

BPM, Internet of Things, Model Engineering.

Abstract:

Business process management (BPM) is considered as a powerful technology to design, control, and improve

processes. Recently, organizations have started contemplating the value that combining the inter-networking

of all kinds of physical devices, i.e., the Internet of Things (IoT) with BPM could bring to an organization.

BPM provides intelligent control over IoT devices by integrating and managing devices and data generated

by them in business operations. Here, data from IoT devices needs to be analyzed and actions need to be

taken based on that data. Since the real world as context of a BPM application changes drastically through

the advent of IoT, it is worthwhile to investigate how the enactment of a BPM application changes or must

be customized. In this paper, we first describe benefits and necessary adaptions w.r.t. the integration of

IoT and BPM systems. Furthermore, we tackle two concrete adaption tasks, i.e., we introduce concepts for

IoT enhanced process modeling as well as a technological integration architecture. Both approaches have

successfully been evaluated in production industry.

1 INTRODUCTION

Business process management (BPM) is considered

as powerful technology to operate, control, design,

document, and improve cooperative processes (Du-

mas et al., 2013). Processes are executed within appli-

cation systems that are part of the real world involv-

ing humans, cooperative computer systems as well as

physical objects. Internet of Things (IoT), denoting

the inter-networking of all kinds of physical devices,

has become very popular these days. IoT basically is

a cyber-physical system digitally communicating over

the internet. Devices developed nowadays, from any

industry like healthcare, manufacturing, automobile,

are equipped with a micro controller and capable of

transmitting data over a network. Businesses need

to overcome several challenges to be able to realize

cooperative orchestration and manageability of such

IoT devices (Al-Fuqaha et al., 2015). IoT has slowly

started to penetrate markets as businesses and organi-

zations have perceived the value that combining IoT

with BPM could bring to an organization. The in-

tegration of IoT and BPM impacts critical business

processes requiring integration with operational sys-

tems, from enterprise resource planning (ERP) and

customer relationship management (CRM) to special-

ist applications. BPM uses process models to manage,

update, and track large volumes of data and informa-

tion generated by these smart devices (Dumas et al.,

2013). Looking from an IoT viewpoint, BPM adds

value to IoT (and vice versa) by providing intelligent

control over IoT devices by integrating and managing

devices and data generated by them in business oper-

ations. Embedding intelligence by way of real-time

data gathering from devices and sensors and consum-

ing them through BPM helps businesses to achieve

cost savings and efficiency. Data from IoT devices

needs to be analyzed and actions need to be taken

based on that data. These actions trigger alerts or in-

voke corrective processes and activities before rou-

tine issues snowball into disasters, e.g., flight delays,

parts replacements, fire emergencies. Since the real

world as context of a BPM application changes dras-

tically through the advent of IoT, it is worthwhile to

investigate how the enactment of a BPM application

changes or must be customized through the transition

of the real world through IoT technology. This inves-

tigation leads to three fundamental research questions

that are tackled in the course of this paper: (i) What

can IoT provide in the interplay with BPM? How can

BPM concretely benefit from IoT? How must a BPM

system be adapted to the IoT world? Existing works

in this area, e.g., (Petrasch and Hentschke, 2016; Pe-

trasch and Hentschke, 2015; Graja et al., 2016; Meyer

et al., 2013; Meyer et al., 2015), exclusively focus on

extensions of standard process modelling languages

for IoT and disregard all other phases of BPM as well

as conceptual foundations. In this paper, we examine

Schönig, S., Ackermann, L. and Jablonski, S.

Internet of Things Meets BPM: A Conceptual Integration Framework.

DOI: 10.5220/0006824803070314

In Proceedings of 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2018), pages 307-314

ISBN: 978-989-758-323-0

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

307

these open research questions in a systematic way: (i)

we describe IoT characteristics and the interplay with

BPM; (ii) we outline benefits and necessary adaptions

w.r.t. the different phases of the BPM lifecycle (Du-

mas et al., 2013) which ultimately leads to a research

agenda for the integration of IoT and BPM systems;

and (iii) we introduce generic concepts and solutions

for IoT enhanced process modeling.

This paper is structured as follows: Section 2 in-

troduces characteristics of IoT applications and a clas-

sification of benefits and necessary adaptions. Sec-

tion 3 gives an overview of related work. In Section 4

we describe concepts of IoT enhanced process model

re-engineering. The introduced approaches are evalu-

ated in Section 5. The paper is concluded in Section 6.

2 RESEARCH QUESTIONS

In this section, we first characterize IoT enhanced ap-

plications. Second, we describe the different anchors

where IoT can influence BPM scenarios. Based on

this, we outline further research questions in this con-

text and classify them w.r.t. the different phases of the

BPM lifecycle.

2.1 IoT Characteristics and BPM

First, we briefly highlight the most important charac-

teristics of IoT applications (Al-Fuqaha et al., 2015):

Data intensive: In IoT applications, the environment

status changes regularly. Devices, sensors and hu-

mans frequently change their status, e.g., temperature,

location or the current energy and send their status

information and data at a regular rate to a gateway

or server; Pre-processing: IoT applications depict a

tremendous amount of data, often on a very low, un-

suitable abstraction level. In many cases, data stem-

ming from sensors have to be pre-processed for fur-

ther enactment; Triggering: IoT use cases frequently

imply real time triggering of activities based on cur-

rent sensor data and defined alarm thresholds; Ubiq-

uitous: In many IoT scenarios all kinds of physical

devices as well as humans are connected through mo-

bile devices such as wearables.

These four characteristics form the basis for the

following discussion. When discussing BPM and IoT

it is worth to principally investigate the interplay be-

tween these two concepts and prepend a conceptual

discussion of this interplay before we investigate con-

crete enactment plans. We consider a BPM system

as a sphere of control. Such a system reacts to fac-

tors, events, causes etc. that are either stemming from

the system itself or stemming from the outside of this

system. In system theory, the first type of factors is

characterized as being intrinsic and the second as ex-

trinsic. An example for an intrinsic factor for BPM is

the internal state of an organizational database: there,

available agents for process executions are listed. An

extrinsic factor of a BPM application is the break-

down of power supply in a certain part of the appli-

cation. This external event causes many resources not

being available for process execution anymore.

From the viewpoint of a BPM system the IoT

world is a source for extrinsic factors. The interac-

tion between these two spheres of control can even be

specified in more detail. In principal, there are two

different communication channels between a BPM

system an IoT: a passive and an active one. We can

consider a database as implementation of a passive

communication channel. For example, IoT devices

produce data and store them into such a database (cf.

Data Provision). The BPM system can eventually ac-

cess them and incorporate them into its calculations.

In that sense, data provision from the extrinsic sys-

tem IoT extends the data reservoir of a BPM and can

thus improve and/or extend its functionality. We re-

gard things like events as a form of active communi-

cation: they are generated and sent to the communica-

tion partner to trigger some activities there (cf. Trig-

gering). For example, an IoT device sends some event

to a BPM system, which there causes the execution

of a task. According to this, an active communica-

tion channel typically triggers things in the receiving

sphere of control. By the way, these two kinds of in-

teraction - active and passive - can also occur from

a BPM system to an IoT system. For this paper the

other direction of communication is more relevant.

After having introduced the general interplay be-

tween a BPM system and an IoT environment, it is

interesting to zoom into this interplay, i.e., it is inter-

esting to see how concretely this interaction can take

place. For this reason, we introduce a general set of

modelling elements for processes. A process is char-

acterized by a couple of perspectives (Jablonski and

Bussler, 1996). The functional perspective defines

the body of a process step, in particular defines its

name, purpose, etc. The behavioral perspective de-

fines the control flow between process steps. Among

other things, incoming events trigger starting of activ-

ities, outgoing events might function as triggers for

other activities. The organizational perspective as-

signs (human) resources to process steps. The op-

erational perspective assigns services and programs

to activities. The data perspective defines input and

output data for activities and thus establishes a data

flow. The issue for characterizing the interplay be-

tween BPM and the IoT is to define how communica-

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

308

tion between these two spheres of control mutate the

functionality of the mentioned five perspectives.

Since the functional perspective is just the skele-

ton of a process step, it will not be changed notice-

ably - but more indirectly via the other perspectives

- by the IoT communication. However, all other per-

spectives will undergo positive modifications by this

interplay. The data perspective will heavily profit by

the enlarged database provided by IoT. Not just the

range of data can drastically be enlarged, but also the

accuracy and currentness of data will be improved

broadly (cf. Data intensive). This can lead to a new

quality of process execution and new ways of func-

tion provision. The latter leads to a direct improve-

ment of the operational perspective of a process step.

In addition, the organizational perspective of a pro-

cess profits from data provided by IoT. For example,

the actual geographical position of agents are reported

by wearables such that agent assignment can consider

this information and can better assign people to out-

standing tasks (cf. Ubiquitous). The behavioral per-

spective mostly benefits from the active communica-

tion between IoT and a BPM system. For example,

an IoT signal can promptly trigger starting an activ-

ity directly what can improve performance of process

execution significantly (cf. Triggering).

2.2 How Can BPM Benefit from IoT?

This discussion of the interplay depicts how posi-

tively an IoT integration into a BPM system improves

and enlarges its functionality. From a BPM system,

the IoT world acts as an extrinsic factor that actively

and/or passively affects the BPM system and enables

new or enhanced functionality. In this section, we

highlight the main benefits that IoT provides for BPM

applications and classify them w.r.t. the different

phases of the BPM lifecycle (Dumas et al., 2013).

Within the modelling phase of the BPM lifecycle,

the incorporation of IoT technology can reduce the

complexity of process models, i.e., it is possible to re-

place elements and patterns due to the opportunities

of IoT. In particular, certain activities, e.g., manual

control activities, can be avoided and thus removed

from existing models. Furthermore, through the pro-

vision of a broad and highly up-to-date database, pro-

cess models can be logically extended and enriched

with new dimensions and new perspectives. For ex-

ample, pure control-flow oriented models can be ex-

tended with data dependencies stemming from IoT

devices. The location awareness of IoT devices like

wearable computers creates the opportunity to intro-

duce a locational perspective into process models and,

for instance, assign activities to the staff members

based on distance measures. These new features lead

to more fine-grained and more specific process defi-

nitions that better reflect operational reality. Also the

execution phase can benefit from the integration with

IoT. Here, real time interaction, mobile and wear-

able interfaces for process control, new signaling as

well as activity indication technology (e.g., haptic and

acustic signals of smartwatches) can lead to signif-

icant latency and activity runtime reduction that ul-

timately leads to an improved overall case perfor-

mance. Incorporating IoT technology fosters process

monitoring as well. Here, data provided and provi-

sioned by IoT sensors increases process transparency,

e.g., the remaining time until next activities as well

as certain important environmental data. Last but not

least, IoT enhances the analysis phase by increas-

ing the quality and evidence of process event logs by

recording rich process data in form of IoT sensor and

device values. This big amount of data enables and

fosters multi-perspective process mining technology

(e.g., (Sturm et al., 2017)) which automatically pro-

duces data enriched process models.

2.3 How Must BPM Be Adapted?

The discussion will show how a BPM system must be

customized to be enabled for the interplay with IoT.

We will again use the BPM lifecycle for classifying

the adjustment tasks. We distinguish between neces-

sary conceptual and technological adaptations. The

different aspects are summarized in Table 1.

First, we focus on the modelling phase of the life-

cycle where certain conceptual adaptations are neces-

sary to incorporate IoT devices and sensors into pro-

cess models. Here, it is potentially necessary to re-

engineer existing process models, i.e., activities need

to be added, removed or rearranged, data objects re-

flecting IoT values need to be added and organisa-

tional dependencies redefined. These adaptations re-

flect the inclusion of new entities stemming from IoT

technology. This re-engineering can even go to such

lengths that the used modelling language is extended

with new modelling elements to ensure understand-

ability of models. In this paper, we will tackle this is-

sue in Sec. 4. Furthermore, it is important to mention

that IoT technology introduces new dimensions into

BPM scenarios that have not been covered by existing

languages yet and thus require semantical enrichment

of languages. For instance, the assignment of activi-

ties to the closest staff member, i.e., a location depen-

dent assignment condition can easily be implemented

with IoT devices, however, is not covered in standard

languages like BPMN. The execution phase requires

several adjustments, both on a conceptual as well as

Internet of Things Meets BPM: A Conceptual Integration Framework

309

Table 1: Conceptual and technological adaptations to enable IoT/BPM integration.

Lifecycle Phase Conceptual Adaptations Technological Adaptations

Modelling

- (Re-)engineering of models

- Modelling language extension

- Semantical enrichment

Execution

- Adjustment execution engine

- Bridge abstraction gap

between low-level sensor data

and business activities

- Context variables

- Layer architecture

Monitoring

- Presentation/Visualization

of extrinsic and intrinsic data

- Layer architecture

- Big Data visualization

Analysis

- Focus on data aware mining

- Big Data methods

- Performance

on a technological level. Conceptually, it is neces-

sary to adjust the underlying BPM execution princi-

ple and engine to be able to incorporate IoT related

data into calculation of next actions. Technically, this

can be achieved by defining certain context variables

in a BPM system that hold specific values and cur-

rent status of IoT devices. Furthermore, it is necessary

to bridge the abstraction gap between low-level sen-

sor data stemming from IoT devices and high-level

business activities. While sensor data is frequently

captured with a very high frequency, i.e., many data

points are acquired, only a small number of observed

sensor values are really relevant for business activi-

ties. For instance, corrective activities are only trig-

gered if a sensor value is above a certain threshold.

Thus, a tremendous amount of data, typically stem-

ming from various IoT devices needs to be gathered,

stored and processed. The solution to bridge this gap

is a layered architecture that manages the whole ab-

straction and aggregation process, from the acquis-

tion and processing of raw data towards the commu-

nication with a BPM system. Within the monitoring

phase it is necessary to complement process execu-

tion cockpits and dashboards with suitable data pre-

sentation and visualization concepts to represent ex-

trensic and intrinsic data of IoT devices to process

participants. From a technical point of view, the mon-

itoring of real time data of the IoT world is a se-

vere challenge since storing and in particular visual-

izing a big amount of data requires specific big data

methods. Smart data querying and visualization tech-

niques need to be deployed in BPM system interfaces

to ensure practical applicability and to prohibit perfor-

mance issues. The analysis phase depicts the applica-

tion of process mining on event logs. Traditional min-

ing techniques have a strong focus on control-flow re-

lated dependencies while especially process relevant

data is frequently neglected (van der Aalst, 2011). It

is obvious that with the integration of IoT the analysis

of process data becomes a first-class citizen in process

analysis. Through data-aware process mining the au-

tomatic analysis of event logs yields process models

with semantically enriched data dependencies. Thus,

temporal dependencies and activity runtimes can be

traced back to data values, locations and device sta-

tus stemming from IoT devices. From a technologi-

cal viewpoint, the incorporation of data into process

mining will inevitably lead to performance issues and

thus require the application of latest distributed big

data analysis techniques for process discovery (Sturm

et al., 2017). The discussion highlights that the inte-

gration of IoT and BPM requires deep conceptual and

technological adjustments in each phase of the lifecy-

cle. We claim that the content of Table 1 can be seen

as a (for sure not complete) research agenda for estab-

lishing an effective interplay between IoT and BPM.

In the next section, we show that existing work mainly

focuses on modelling language extensions.

3 RELATED WORK

Several approaches have been proposed to connect

the Internet of Things with business processes and

to make use of real world objects data when execut-

ing business processes. In (Petrasch and Hentschke,

2016; Petrasch and Hentschke, 2015) the authors

present the Internet-of-Things-Aware Process Model-

ing Method (IAPMM), a software oriented approach,

that only covers the requirements analysis so that for

design, implementation and test phases other meth-

ods have to be used. The method extends the BPMN

2.0 metamodel and consists of five steps, to detect

and model the processes, namely: Functional De-

composition, identification of IoT aspects, creation of

IoT-aware business process models, detailed specifi-

cation of processes and data elements and consistency

check of all models. The outcome is an IoT-aware

business process modeled with the IoT-aware process

model notation (IAPMN). The approach proposed in

(Graja et al., 2016) (named BPMN4CPS) also de-

scribes an extension of the BPMN 2.0 metamodel, in

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

310

which the process logic is split in three parts: the cy-

ber part, the controller and the physical part. They

are displayed as pools in the BPMN and have differ-

ent activity types, which can be executed. Further-

more the authors extended the metamodel by new task

types for Cyber-Physical Systems: the cyber task, the

manual task and the physical task. Some more no-

tation concepts in BPMN for IoT are described in

(Meyer et al., 2013; Meyer et al., 2015; Sperner et al.,

2011). The main focus is the definition and model-

ing of real world properties. In (Meyer et al., 2013;

Meyer et al., 2015) the authors present an extension of

BPMN with seven new modeling concepts (IoT Ac-

tivity, Sensing Activity, Process Resources, Physical

Entity, Real World Data Object/Store, Mobility As-

pect and IoT Process Ratios). In (Domingos et al.,

2014) an approach for implementing the problem in

the WS-Business Process Execution Language (WS-

BPEL) is introduced. It extends WS-BPEL by two

constructs: context variables, which are automati-

cally updated (synchronously or asynchronously) and

the when then construct. The authors implemented

and evaluated a prototype extension which is com-

pliant with every WS-BPEL engine. The next steps

would be to apply the concept on BPMN and evaluate

it. Other approaches implementing WS-BPEL exten-

sions with context variables are presented in (George,

2008) and (George and Ward, 2008). The variables

are updated using the publish/subscribe paradigm fol-

lowing the WS-Notification standard. The extension

was implemented by adjusting the ActiveBPEL 4.1

engine. In (Mateo et al., 2012) the authors integrate

distributed resources into WS-BPEL by formalizing

a fragment of WS-BPEL together with the WSRF

(Web Services Resource Framework). In (Schmidt

and Schief, 2010) the authors propose an approach

for enabling IoT-based agile business processes. They

implemented it by extending business process models

by information on variance and triggers for variance.

To integrate these extensions, two blind-spots had to

be brightened, the environment and the actual process

activities. The authors describe concepts, how to do

those challenges in a system. A system to realize and

evaluate the ideas is the ADiWa project.

4 PROCESS (RE-)ENGINEERING

The adaptation of BPM approaches already has to

start in the modelling phase. In order to reflect the

consequences of IoT involvement in BPM, existing

process modeling languages and process models can

and need to be remastered.

4.1 Language (Re-)Engineering

Recent research (Petrasch and Hentschke, 2016; Pe-

trasch and Hentschke, 2015; Graja et al., 2016) sug-

gests extensions regarding modelling notations as

well as process execution languages. Since these ex-

tensions have already been presented in Sec. 3, we

focus on a systematization of extension types. Exist-

ing conceptual process modeling languages have to

be extended to cope with the requirements and the

potential emerging due to the involvement of the IoT

world. This comprises further discriminations regard-

ing the different activity types to be able to represent

IoT-supported activities. It is necessary to reconsider

the capabilities for representing the operational as-

pect of processes. Yet, modelling elements related to

this perspective are limited to semantics like ”what

tool can be used”. With the involvement of IoT con-

cepts it is additionally possible to shift the responsi-

bility for the whole activity execution to the IoT. This

cannot be represented with existing process model-

ing languages (Graja et al., 2016). In order to make

IoT-enhanced models executable again, it is necessary

to extend existing transformations from conceptual to

executable models (Domingos et al., 2014).

4.2 Process Model (Re-)Engineering

We distinguish between model changes through par-

tial replacement or substantial enrichment of model

contents. In this section, we describe some exemplary

manifestations for each type.

The examples for potential model changes are

represented using an abstract process modeling lan-

guage. We forgo using an existing graphical language

because non of them is able to fully cope with all con-

cepts we discuss later. However, the abstract language

reuses well-known modelling elements from existing

languages. Rectangles and circles represent an activ-

ity or an event from the BPMN 2.0 language, respec-

tively. The activity Act in Fig. 1 (b) is IoT enabled,

i.e., involves communication with IoT devices. All

edges are defined in the graphical declarative nota-

tion ConDec (Pesic et al., 2007). This means, for in-

stance, that Manually observe is the first activity in all

process instances, it can be repeated and it has to be

eventually followed by an event Condition fulfilled.

We additionally use a diamond-shaped symbol to in-

dicate data-based conditions that further restrict the

execution of those activities it is connected with. We

use circles with user symbols to denote roles and as-

sociated resources. Since we explicitly do not suggest

a new process modeling language we omit a more de-

tailed discussion of the modeling elements.

Internet of Things Meets BPM: A Conceptual Integration Framework

311

WITHOUT IoT

WITH IoT

Act

Manually

Observe

Init

Condition

fulfilled

Act

Notice need

for action

Prepare

action

Notice need

for action

Act

(a)

IoT

→ BPM

Act

(b)

BPM

→

IoT

Figure 1: Example applications for the IoC principle.

Inversion of Control (IoT to BPM). One major

difference that follows from the involvement of IoT

in BPM systems is the opportunity to implement the

Inversion of Control (IoC) principle. Coming from

the software design discipline this principle describes

guidelines for improving software modularity. In its

core it states that the flow of interactions in a com-

puter program is determined at runtime based on data

objects and their interactions. Transfered to the topic

of IoT-BPM integration this means the replacement

of dedicated pull requests for information with push

operations from the information provider. Due to the

rich communication abilities of IoT devices they can

act as such an provider. An abstract example for re-

flecting this change in a process model is visualized

in Fig. 1 (a). Without involving the IoT these infor-

mation can only be accessed actively. Following the

IoC principle one can remove the representation of

this manual access from the model and insert an in-

coming signal event element. This can be used to lay

the focus on the information usage instead on its ac-

quisition and busy-waiting activity can be eliminated.

Inversion of Control (BPM to IoT). Triggering

IoT activities from BPM activities is relevant, too. In

many cases, e.g. in the manufacturing industry, it is

necessary to prepare certain activities. This can be,

for instance, the physical movement to a machine that

requires an user intervention. Due to the connectiv-

ity improvement provided by IoT it is often possible

to eliminate this preparation step. The prepared activ-

ity element can then be replaced by the representation

of an IoT-enabled activity. An example is shown in

Fig. 1 (b). The example shows the elimination of a

step Prepare action by enabling the interaction with

IoT for the step Act. Hence, IoC in this context means

that the execution of an activity is separated from its

concrete implementation. However, this requires that

process modeling languages are able to represent this

kind of activities what is discussed later. A second

aspect is related to the ability of IoT devices to com-

municate directly. Without IoT involvement there are

activities that contain a manual retrieval of data from

one device, their interpretation by a human process

participants and a subsequent action based on the re-

sulting information basis. If the interpretation part of

this activity can be automated, the whole activity can

be automated, too. The reason is that the communica-

tion between IoT devices can be standardized through

protocols like MQTT.

Plain Control Flow vs. Data-driven Flow. Beside

automation and control shifts, IoT provides the oppor-

tunity to enrich existing models with additional infor-

mation that could not be obtained and, hence, could

not be modelled with offline environments. Thus, so

far control-flow dependencies between activities can

now be justified by enriching them with data con-

ditions stemming from IoT. We distinguish between

three different types of data enriched conditions that

have been defined in the context of multi-perspective

declarative process modelling (Burattin et al., 2015):

The activation condition is a statement that must be

valid when a certain triggering activity happens. For

example, whenever Retrieve information is executed

and a certain sensor value v

1

is smaller than a certain

threshold x, then eventually Act has to follow. The

correlation condition is a statement that must be valid

when the triggered activity happens and relates cer-

tain values of the triggering as well as the triggered

activity. For instance, whenever Retrieve informa-

tion is executed, then eventually Act must follow and

the value for v

1

associated with Retrieve information

must be the same as for Act. Target conditions exert

limitations on values that are associated to the trig-

gered activity. As an example, when activity Retrieve

information is performed, then eventually Act must

be executed and the value for a certain variable v

1

as-

sociated with Act must be x. Though the three con-

dition types are well established, their applicability

spectrum can be extended due to the availability of

more sensor data and real-time data provisioning pro-

vided by IoT devices.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

312

Arbitrary vs. Efficient Resource Allocation. The

enrichment of existing process models with additional

information is not limited to data conditions. Due to

the possibility of, for instance, location tracking of

organizational resources it is possible to improve the

overall process performance by a more efficient re-

source allocation. For example an activity that can

be assigned to an arbitrary resource as long as this

resource fills the compulsory role. IoT devices like

GPS trackers are able to locate resources. Hence, it

is possible to additionally define constraints on their

distances to the location where the activity should be

formed. The distance can potentially be replaced by

any other property of human process participants that

is tracked by IoT devices. The current section is in-

tended to be a proof that process modeling can ben-

efit from information and infrastructure provided by

IoT. However, the examples are rather a baseline for

further research and a first attempt for a classification

of IoT influences on process modeling tasks. Hence,

both the different influences and their classification

should be investigated further in future research.

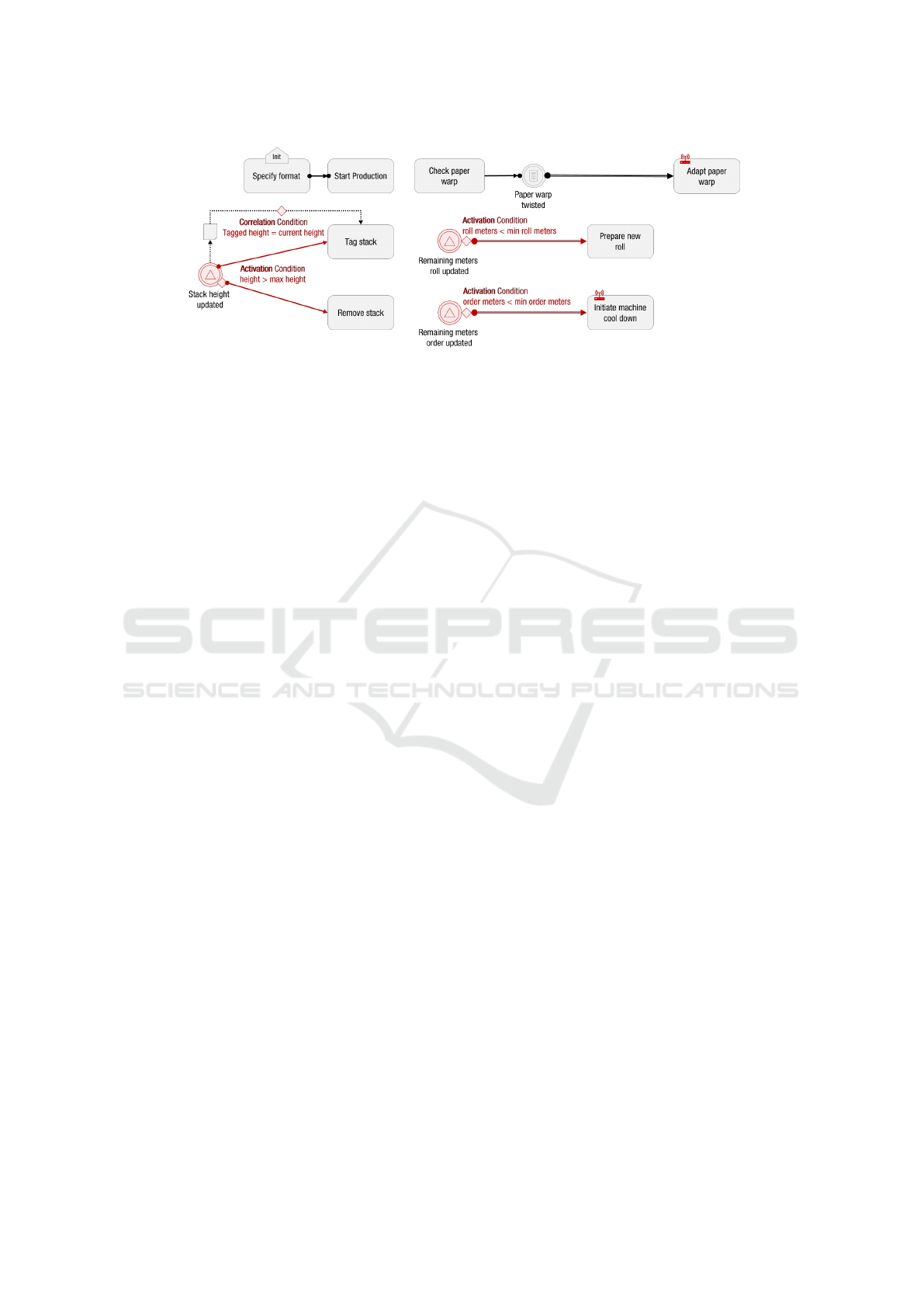

5 EVALUATION IN INDUSTRY

We describe the evaluation of the proposed concepts

by means of an application in industry. The tech-

niques have been implemented in a corrugation plant.

The application of IoT devices and integration with

the existing BPM system lead to several process im-

provements. IoT provides the opportunity for re-

engineering existing process models. This is evalu-

ated using the example of a real-life process for cor-

rugated paper production. Among other aspects this

process contains many observation tasks like, for in-

stance, Check stack height or Check remaining meters

roll followed by one or more compensation steps like

Tag stack or Prepare new roll. Each compensation

step is a successor of one observation activity. The

latter gives humans insights about the state of the ma-

chines. Some states, for instance, Max. stack height

reached and Min. meters reached, require human in-

tervention and hence trigger a compensation step.

Before the emergence of IoT the observation tasks

were performed as repetitions of manual information

pull requests. It was up to the human process par-

ticipants to gather and interpret these information pe-

riodically. Because of these repetitions the observa-

tion tasks have been intuitively foregrounded. Hence,

the process model also focuses on these observation

tasks rather than the impact of the information that

are retrieved. The model shows a view of the tasks

and their relationships that is limited to the functional

and behavioral perspectives. Since the process mainly

consists of activity pairs that are rather unordered

and highly repetitive a declarative modeling style was

used. With the emergence of IoT information can be

provisioned without manual pull requests. Hence, the

repetitive observation steps could be eliminated com-

pletely as it is shown in Fig. 2. This reduces the num-

ber of activities in the model and changes the empha-

sis to the actions that have to be taken to keep the

process working. The model was enriched with infor-

mation that are related to the data-oriented perspec-

tive. Without IoT these information were hidden in

the knowledge of the human process participants.

Some tasks in the production process required the

physical movement of human performers to a partic-

ular location. With IoT it is possible to perform inter-

actions between these performers and the production

machines ad hoc, i.e. without any physical movement.

In the process model shown in Fig. 2 the steps Adapt

paper warp and Initiate machine cool down are IoT-

enabled activities. This means that the model now

shows interactions between human participants and

production machines explicitly and that latter are re-

sponsible for the performance of certain actions. IoT

provided opportunities to rework a process model in

terms of reducing the number of activities and chang-

ing types. Additionally the model could be enriched

with information that are provided by IoT devices.

Though these information can also be retrieved with-

out involving IoT they have not been represented in

the corrugated paper production process model. Since

IoT makes these information explicit they became at-

tractive for improving this process model.

6 CONCLUSION

We investigated how the enactment of a BPM appli-

cation changes or must be customized through the

transition of the real world through IoT technology.

We described IoT characteristics and the interplay

with BPM and outlined benefits and necessary adap-

tions w.r.t. the BPM lifecycle. Our discussion high-

lighted that the integration of IoT and BPM requires

deep conceptual and technological adjustments in

each phase of the BPM lifecycle. We tackled two con-

crete adaption tasks, i.e., we introduced generic con-

cepts and solutions for IoT enhanced process model-

ing and a technological integration architecture. Fi-

nally, we implemented and evaluated our solutions in

a corrugated paper production industry use case. For

future work, we will focus on the different tasks that

were skeched in the research agenda. We will adjust

and apply a distributed declarative process mining ap-

Internet of Things Meets BPM: A Conceptual Integration Framework

313

Figure 2: IoT enhanced process model.

proach (Sturm et al., 2017) to event logs in the de-

scribed production industry scenario.

REFERENCES

Al-Fuqaha, A., Guizani, M., Mohammadi, M., Aledhari,

M., and Ayyash, M. (2015). Internet of things: A

survey on enabling technologies, protocols, and appli-

cations. IEEE Communications Surveys & Tutorials,

17(4):2347–2376.

Burattin, A., Maggi, F. M., and Sperduti, A. (2015). Con-

formance checking based on multi-perspective declar-

ative process models. CoRR, abs/1503.04957.

Domingos, D., Martins, F., C

ˆ

andido, C., and Martinho, R.

(2014). Internet of Things Aware WS-BPEL Busi-

ness Processes Context Variables and Expected Ex-

ceptions. Journal on Universal Computer Science,

20(8):1109–1129.

Dumas, M., La Rosa, M., Mendling, J., Reijers, H. A., et al.

(2013). Fundamentals of business process manage-

ment, volume 1. Springer.

George, A. A. (2008). Providing context in ws-bpel pro-

cesses. Master’s thesis, University of Waterloo.

George, A. A. and Ward, P. A. (2008). An architecture for

providing context in ws-bpel processes. In Conference

of the center for advanced studies on collaborative re-

search: meeting of minds, page 22. ACM.

Graja, I., Kallel, S., Guermouche, N., and Kacem, A. H.

(2016). BPMN4CPS: A BPMN extension for mod-

eling Cyber-Physical Systems. In Enabling Tech-

nologies: Infrastructure for Collaborative Enterprises

(WETICE), pages 152–157. IEEE.

Jablonski, S. and Bussler, C. (1996). Workflow manage-

ment: modeling concepts, architecture and implemen-

tation.

Mateo, J. A., Valero, V., and Dıaz, G. (2012). Bpel-rf: A

formal framework for bpel orchestrations integrating

distributed resources. preprint arXiv:1203.1760.

Meyer, S., Ruppen, A., and Hilty, L. (2015). The things

of the internet of things in bpmn. In CAISE, pages

285–297. Springer.

Meyer, S., Ruppen, A., and Magerkurth, C. (2013). Internet

of things-aware process modeling: integrating iot de-

vices as business process resources. In International

Conference on Advanced Information Systems Engi-

neering, pages 84–98. Springer.

Pesic, M., Schonenberg, H., and Van der Aalst, W. M.

(2007). Declare: Full support for loosely-structured

processes. In EDOC, pages 287–287.

Petrasch, R. and Hentschke, R. (2015). Towards an Internet-

of-Things-aware Process Modeling Method - An Ex-

ample for a House Suveillance System. In Manage-

ment and Innovation Technology International Con-

ference.

Petrasch, R. and Hentschke, R. (2016). Process Modeling

for Industry 4.0 Applications - Towards an Industry

4.0 Process Modeling Language and Method. In Inter-

national Joint Conference on Computer Science and

Software Engineering.

Schmidt, B. and Schief, M. (2010). Towards agile business

processes based on the Internet of Things. Advanced

Manufacturing and Sustainable Logistics, pages 257–

262.

Sperner, K., Meyer, S., and Magerkurth, C. (2011). In-

troducing entity-based concepts to business process

modeling. In International Workshop on Business

Process Modeling Notation, pages 166–171. Springer.

Sturm, C., Sch

¨

onig, S., and Di Ciccio, C. (2017). Dis-

tributed Multi-Perspective Declare Discovery. In BPM

Demos.

van der Aalst, W. (2011). Process mining: discovery, con-

formance and enhancement of business processes.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

314