Effect of Price Dynamics in the Design of Eco-Industrial Parks:

An Agent-based Modelling Approach

Ganiyu O. Ajisegiri and Frans L. Muller

School of Chemical and Process Engineering, Faculty of Engineering,

University of Leeds, Leeds, U.K.

Keywords: Industrial Ecology, Eco-Industrial Parks, Agent-based Modelling, Python.

Abstract: Even though eco-industrial parks (EIP) models have proved to transform industrial areas by strengthen the

emergence of sustainable EIP, there is a noticeable lack of research addressing the economic returns of the

participating companies in the network which fluctuates according to prices offered for the resource exchange

over time. In this paper, we develop an agent-based model sometimes refer to as bottom-up approach for the

design of EIP in which price fluctuation and demand variability are emergent properties of the interaction

among the agents. Agent-based modelling (ABM) is a computational methodology used in social science,

biology, and other fields. It represents autonomous entities, each with dynamic behaviour. The agents within

the eco-industrial park are the factories, market buyers and market sellers. The computational development

was performed in Réseau.py, which was built in Python (a programmable modelling environment) from

scratch. Based on the autonomy of each of the agents and their individual objectives, simulations were carried

out on a bio-energy based EIP (BBEIP) system in order to study the influence of price fluctuation between

the agents. The results show that variability in price is a factor for establishing symbiotic relationship among

the symbiotic agents in the EIP.

1 INTRODUCTION

Eco-industrial parks (EIP) models have proved to

transform industrial areas by strengthen the

emergence of sustainable EIP. In the last two

decades, more attention for eco-industrial park (EIP)

development projects has grown enormously among

national, regional governments and industries in

many countries (Heeres et al., 2004).

Also, industrial ecologists have suggested the

redesigning of industrial system using the natural

ecosystem. Designing or redesigning an eco-

industrial park is a complex undertaking, demanding

integration across many fields of design and decision

making. Industrial symbiosis are complex system

(Cao et al., 2009) that are viewed as self-organizing

(Chertow and Ehrenfeld, 2012, Yazan et al., 2016)

systems whose evolution is a function of complex

interactions among multiple organizations, each with

its own objectives, which may have conflicting

interests.

Since the emergence of industrial ecology in the

1950s and its take-off during the 1990s, much

progress, in theory, policy and practice has been

achieved for designing a fruitful and sustainable eco-

industrial parks. Almost all research into EIP system

involves either proposing a frame work (Martin et al.,

2009) or mathematical model (Gonela and Zhang,

2014) to design of EIP. There are few works (Cao et

al., 2009, Bichraoui et al., 2013) that focus on the

simulation of EIP to understand its complexity.

Therefore, there is still progress to be made in the area

of computational modelling of the actions and

interactions of the autonomous agents that formed the

EIP. Major problems to unravel the complexity of

EIP include but not limited to price, profit and supply-

demand fluctuations. Agent-based model (ABM) has

proved to be a promising tool to simulate (Cao et al.,

2009, Ghali et al., 2017) the evolution of eco-

industrial park.

The rest of the paper is organized as follows.

Section 2 presents the previous related research and

introduces the problem statement. In Section 3, the

description and the overview, design concepts and

details (ODD) (Grimm et al., 2006) of the model are

discussed. Section 4 give description and simulation

results of the case study used in this work while

section 5 conclude the paper.

Ajisegiri, G. and Muller, F.

Effect of Price Dynamics in the Design of Eco-Industrial Parks: An Agent-based Modelling Approach.

DOI: 10.5220/0006836300830090

In Proceedings of 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2018), pages 83-90

ISBN: 978-989-758-323-0

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

83

2 RELATED WORKS

Eco-industrial Park (EIP) is viewed by many

researchers as a self-organising complex system.

According to (Chertow and Ehrenfeld, 2012), EIP is

viewed as a dynamic systems comprises of companies

with participants whose aims and goals are constantly

changing with market conditions. In recent years,

many researchers have studied the dynamic of an eco-

industrial park (EIP) using different evolutionary

approaches (Kim et al., 2012, Bichraoui et al., 2013,

Ghali et al., 2017).

Agent-based modelling (ABM) is a computational

simulation methodology (Kuhn et al., 2010) used in

social science, biology, and other fields, which

involves simulating the behaviour and interaction of

many autonomous entities, or agents, over time

(Chertow and Ehrenfeld, 2012, Ghali et al., 2017).

Agent-based models, allow bottom-up (Fraccascia et

al., 2017) simulations of organisations constituted by

a large number of interacting parts. Thus, industrial

ecosystems represent a field of application. This

contribution explains what agent-based models are,

reviews applications in the field of industrial

ecosystems and focuses on a simulator of intra- and

inter-firm communications.

From a technical network perspective, ABM

seems to be useful to model complex system, by

feeding the system with rules corresponding to the

assumptions of what is most relevant regarding the

situation within the industrial eco-park and then

watch the emerging behaviour from the agents'

interactions.

(Cao et al., 2009) applied agent-based modelling

to simulate the emergence of EIP. They also

developed a new concept, the internal-flow energy, is

use to indicate the direction of an eco-industrial

system. However, their model was limited to the

simulation of profit and inventory fluctuations within

the EIP. (Kim et al., 2012) proposed an agent-based

modelling method for by-product exchange network

between by-product buyers and sellers in an industrial

park. The proposed method is limited because price

setting is not captured. (Yazan et al., 2016) adopted

an enterprise input-output approach for the design of

a perfect industrial symbiosis but the output of their

work is static.

Therefore, in this work, we focus on the

application of agent-based model to the design of EIP

in which price fluctuation is the emergent property of

the interaction among the agents. We simulate the

effect of price fluctuations to express the dynamic of

BBEIP system.

3 RÉSEAU-EIP AGENT-BASED

MODEL

In this work, a computer modelling method namely

agent-based model (ABM) is adopted and the

proposed model is named réseau-EIP. The model

name réseau-EIP is an allusion to “network of

industries”. It was developed through the Python

programming language. From literature, several

works (Zheng and Jia, 2017, Mantese and Amaral,

2018) on dynamic modelling of EIP have used many

of the known ABM toolkits; NetLogo (Wilensky and

Evanston, 1999). From our perspective, all the EIP

ABM model share a key weakness: they do not use

Python. The model description was done using ODD

(Overview, Design Concepts, and Details) protocol

by (Grimm et al., 2006). The ODD for réseau-EIP is

discussed next.

3.1 Model Description

Following the Overview, Design concepts and Details

(ODD) protocol developed by (Grimm et al., 2006)

for describing individual- based and agent-based

models, this section describes all the seven elements

of ODD as related to réseau-EIP ABM. The first

three elements provide an overview, the fourth

element explains general concepts underlying the

model’s design and the remaining three elements

provide details.

3.2 Overview

The overview of the ODD consist of three elements,

the model purpose, state variables and scales, and

process overview and scheduling. These are explain

further.

3.2.1 Model Purpose

The réseau-EIP ABM is constructed as a decision-

making tool for understanding the emergence

behaviour that favours the design of eco-industrial

parks. The model is intended to be used in assessing

the sustainability of EIP and by improving the

economic, environmental and social performance of

the industrial park. The model is used to simulate

the effect of price, demand and supply fluctuations to

express the dynamic of EIP system. In the future, the

model will be improve to estimate the impact of

energy storage system inclusion in the design of EIP

a “what-if” scenarios” incorporated, generate

hypothesis and test policy ideas related to EIP

development policy.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

84

3.2.2 Entities, State Variables and Scales

The model consists of two core entities called market

and factory agents. The factory agents represented

here as industrial plants within a network and links,

which represent the exchange of resources, while the

market agents on the other hand does not produce

anything but only buy finished goods or sell raw

materials. As indicated earlier, EIP involved

sustainable exchange of resources among partners

within the park. Therefore, a raw material to a plant

can be an output of another plant.

The factory agents are characterized by the state

variables: factory agent identification number (ID),

raw materials type, raw materials stock, raw materials

usage, products (finished, by-product and waste)

name, product price, price variance, output capacity

of a product type (product target), net worth and the

location (x and y co-ordinate) of the factory agent

within the EIP network. The market agent is divided

into two; the selling agent and buying agent. The

selling agent is characterized by the state variables:

selling agent ID, products (goods) name, selling

price, price variance product type (product target), net

worth balance and location. The buying agent is

characterized by the state variables: buying agent ID,

raw materials type, demand quantity, net worth and

location.

In the model, all the agents (factory, selling and

buying) interact with each other. The factory agents

at a time step fulfil its input requirement (based on

product demand) by initiating a contract with a selling

agent. After getting the input materials, the factory

agents begin to produce, determine product prices and

sell to the buying agents. Since the factory agents buy

raw material and sell its output, it can also compete

with the market agents.

A monthly time step is chosen for this work but

any time step (daily, weekly etc.) can be chosen. The

model is a grid base and there is no specific dimension

used. Each agents has its x and y axes to indicate its

location on the grid. The grid served as the réseau-

EIP boundary. No interface or visualization is built

in with the model and all output of the simulation are

exported to excel file and necessary analysis is

performed thereafter.

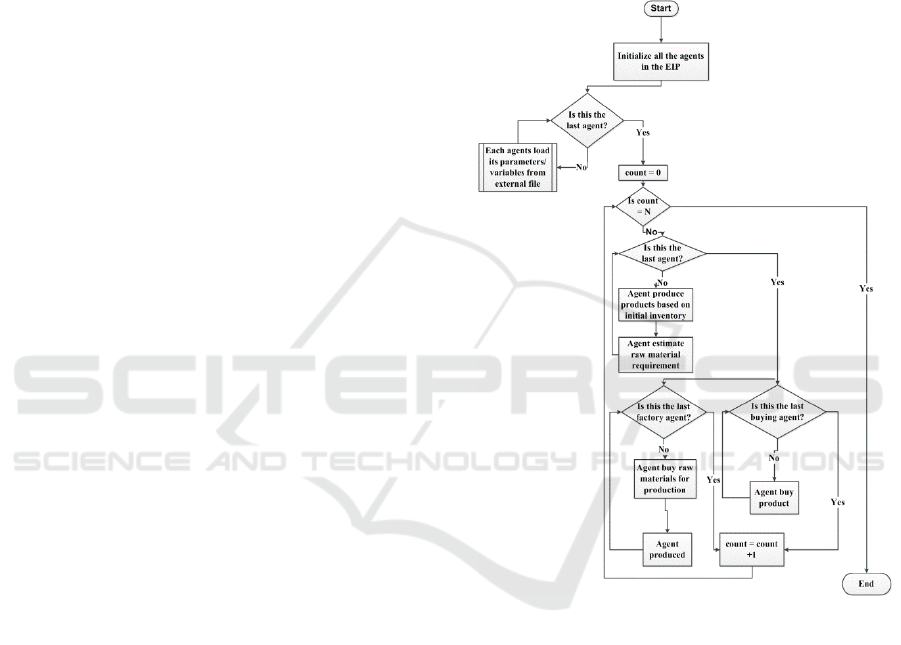

3.2.3 Process Overview and Scheduling

As shown in Figure 1, the réseau–EIP ABM runs with

a monthly time steps. Within each month or time step,

six different submodels run in succession. Each of

these submodel is discussed briefly here and a full

discussion of each submodels can be seen in the

Detail section. At the beginning of the simulation and

for each time step, the factory, buying and selling

modules load their variables and parameters from an

external file, predict production (factory agent) and

determine price. While the interaction of all the three

agents from these modules ongoing in a time step, the

transaction module begin and handles the contract

between the buyers and sellers. The history module

run next and record the history of each of the agents.

The reporting module runs last and report all the

outputs of all the agents in external file.

Figure 1: Réseau-EIP Model Logic Flow.

3.3 Design Concepts

3.3.1 Interactions

Factory agents interact with each other and with the

market agents (buy input materials, and sell output

goods). The primary interaction between agents is the

exchange of resources. In the buying and selling

submodels, a buyer (factory or market buying agents)

establish contract with sellers (factory or market

selling agent) through transaction submodel. In the

transaction submodel, based on the quantity of goods

available and price, the buyer enter a contract with the

sellers and purchase its raw materials from the best

Effect of Price Dynamics in the Design of Eco-Industrial Parks: An Agent-based Modelling Approach

85

seller (cheapest price). The agents also interact by

also imitating each other’s attribute.

3.3.2 Sensing

All agents are assumed to know their own attributes.

It is also assumed that agents are also aware of their

environment. This information informs factory,

buying and selling agents to make decisions at any

point in time.

3.3.3 Emergence

The dynamics of the park and resources exchange

demonstrates emergence based on the lower level

interactions and decisions of factory and market

(buying and selling). Therefore, the important thing

from the model is the emergence of net worth value

of each agent based on the individual agent

interaction with other agents.

3.3.4 Adaptation

Adaptation are modelled explicitly in réseau–EIP

ABM model. Agents adapt with supply and demand

request by finding a new partner to exchange goods

with. Each factory agent always look for raw

materials to purchase either from another factory

agents or from market selling agents to produce its

output and sell to waiting buyers (factory or market

buying agents).

3.3.5 Learning

Each agent in the core entities of this model learn

from their history by using the learning procedure to

make decision at every time steps. An example is the

history of the prices of goods in the market. All

agents always check the previous price and based on

Weibull distribution function make a decision either

to change (increase or reduce) or maintain the price

for the next time step.

3.3.6 Prediction

Presently agents in the réseau–EIP ABM model do

not use any prediction models to make decisions.

3.3.7 Stochasticity

Stochasticity plays a vital role in the réseau–EIP

ABM model. At the beginning, each agents load their

parameters from an input file and based on some level

of random distributions which adds an element of

stochasticity into all subsequent runs.

3.3.8 Objectives

All agents in this model do not only seek to

collectively maximize their ”purpose”, but instead

make decision to buy, sell, produce goods and

determine price as an autonomous agents. At each

decision period, agents make decision in accordance

with the sensed data and with a set of random

techniques.

3.4 Details

3.4.1 Initialization

The réseau–EIP ABM model is initialised by using

data obtained from the literature which related to this

research area. There are three different agents

(Factory, buying and selling) as mentioned earlier.

The variables with their parameters for each agents

are organized an external excel file and the agents

pre-load their data. Based on this, users can therefore

run different scenario by varying input parameters

and observing their impact on their output.

3.4.2 Input Data

The input data are excel based and are specific for

each of the agents (factory, market buying and selling

agents). Apart from the initialization data no other

data is required to run the model. The input file is

user friendly and users can easily change the

parameter to suit the problem in question.

3.4.3 Submodels

Parameter Loading: Each agent load its parameters

from an input file. The parameters are agent specific

with a unique identifier.

Requirement Prediction: This method is used by

all the agents to predict their needed requirement at

every time step. The method is modelled based on

Gaussian distribution with mean and standard

deviation. The market agent demand is equivalent to

the requirement predicted while factory agent have

two variables to determine at the beginning of each

time step. These are the sales quantity and price.

These two variables are modelled using Gaussian

distribution also. The market selling agents only

predict the selling price of all its goods.

Production Step: Since the market buying and

selling agents do not produce anything, so nothing is

associated to this agents except for the selling agents

where the goods to be sold are readily available. In

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

86

contrary, the factory agent produce goods, therefore,

a production method is included in the factory class

as an input-output ratio formulation.

Purchasing Method: Only the buying agents

(Factory and Market agent) buy goods/raw material.

Therefore, this method is only associated to these two

agents. For each time step, each buyer check all the

prospective sellers and make contract with all the

sellers that have the quantity of goods to purchase.

The sellers are appended in a list and the buyers buys

from the cheapest seller until its requirements are

fulfilled.

3.5 Decision Making

The price of product that agent buys is based on the

best price in the EIP at any time. The price is

randomly generated using Gaussian distribution

(normally distributed). In the future work, we intend

to extend the decision making of the agent via some

rule e.g. price setting, price versus quality and quality

alone.

4 CASE STUDY

A case study is conducted for only one input-output

factory type in order to demonstrate the effectiveness

of the proposed methodology and gain some

managerial insight in the emergence of EIP. It is

believe that if the model works for a single input-

output system, it will definitely works for multiple

input-out EIP system. To build our simulation we

used data referring to real case study concerning two-

stage bioenergy based eco-industrial park (BBEIP)

discussed in (Gonela and Zhang, 2014). Figure 2

shows the potential structure of the proposed EIP

system. The system include six factories with their

possible connection. Each of the factories can also

make possible connection between the different

external markets if the price of the external markets

agent over shadow the factory agents. Three of the

factories are combined heat and power plant (CHP)

differentiated by their unique identifier, CHP1,

CHP2, CHP3. The CHP’s use biogas as main input

raw material apart from other input which are not

included in this simulation to fulfil the single input-

output scenario to produce electricity.

The other three factories are, anaerobic digestion

(AD), represented as AD1, AD2 and AD3. The AD

plants use electricity as one of its input to generate

biogas. The main input material for the AD system is

the waste from cattle and food and bio-solid wastes

but is not being consider in this work. Apart from the

factories, the EIP also contains three infinite sink

agents (market buyers B1, B2 and B3) that willing to

buy from the source agents at a considerable price and

also infinite source agents (market sellers, S1, S2 and

S3). The infinite market agent either buys or sells

directly from/to the factory agents.

Figure 2: Bio-energy based Eco-industrial Park (BBEIP)

System.

The initial data for the anaerobic digestion and

combined heat and power plants were obtained from

(Gonela and Zhang, 2014). The three CHP plants

separately have demand capacity for biogas

(methane) ranging from 80,000 – 500,000 cubic

meter per month while the AD plants utilizes food and

bio-solid wastes in the range of 0.3 million tons and

required energy within 30 – 65 megawatt.

4.1 Simulation Results and Discussion

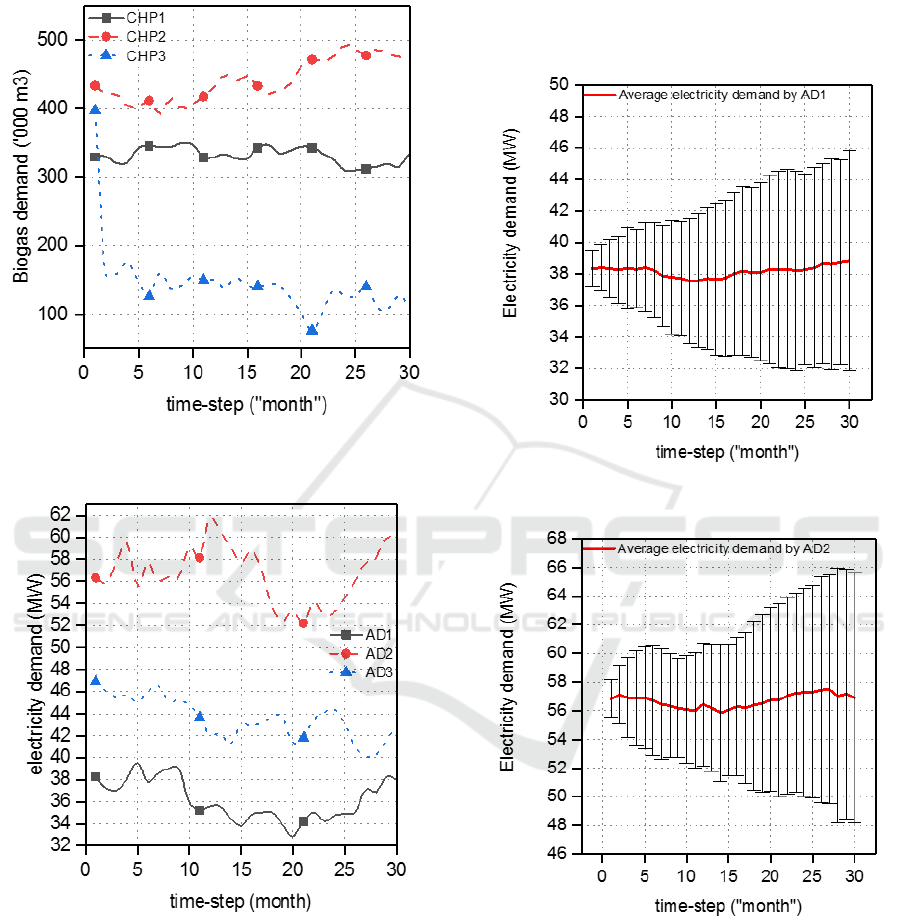

The results of a single simulation run are shown in

figures 4 – 5. Figure 3 show the demand evolution of

the three combined heat and power plant (CHP) while

figure 5 shows the demand evolution of the three

anaerobic digestion plants AD1, AD2 and AD3 in the

EIP. Note that one simulation cycle stands for a time

period of one month. This was found to be enough to

give a stable final configuration. It can be seen that

CHP2 has a higher demand evolution with average

value around 480,000 cubic meter per month. CHP3

demand for biogas is the lowest while CHP1 has a

demand in between the value of CHP2 and CHP3.

This is understandable based on the demand capacity

of each of the three combined heat and power plant.

However, Figure 4 shows the electricity demand on

monthly basis by the AD plants. AD2 has the highest

demand per month while AD1 has the lowest. The

demand by each plants is basically based on their

Effect of Price Dynamics in the Design of Eco-Industrial Parks: An Agent-based Modelling Approach

87

demand capacity. Variation in the demand for

electricity or biogas by each of the respective process

plant is based on the price variation in the market.

Figure 3: Biogas demand per month by combined heat and

power (CHP) plants.

Figure 4: Electricity demand per month by CHP plants.

It is generally accepted that single realization of a

stochastic process usually generates illustrative

information that is not representative of the general

system behaviour. So the simulation was run fifty

times to generate average demand and the error over

30 step. Some statistical characteristics, such as

average, standard deviation and correlation

coefficient, can be obtained from these random

variables. The result of the average demand and the

error margin for each agents in the EIP per period is

shown in Figure 6 – 9. 50 simulation runs were

carried out to assess the effect of the initial conditions

for all the agent. Figure 5 and 7 show the average

demand of electricity by AD And AD2.

Figure 5: Average electricity demand by AD1.

Figure 6: Average electricity demand by AD2.

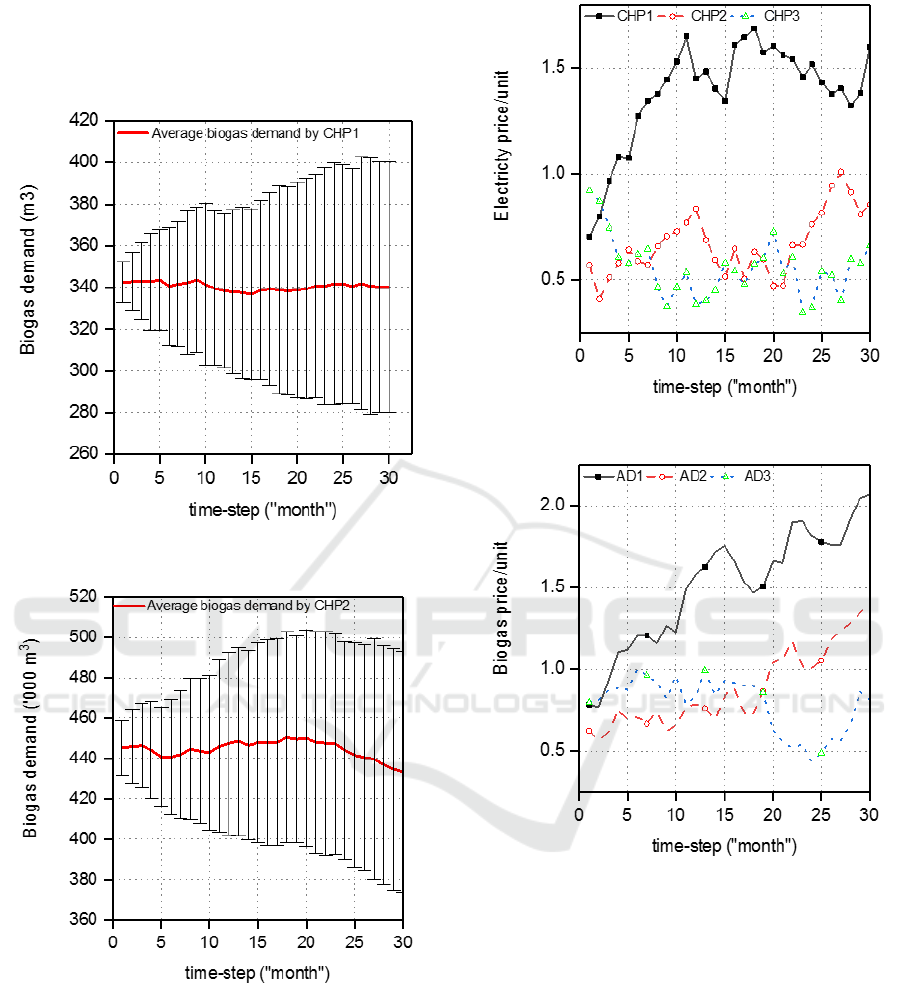

Figure 7 and 9 show the average biogas demand.

It can be seen that the demand for biogas by CHP1

with a mean of 340,000 cubic meter and standard

deviation (SD) of 40 while CHP2 has an average

demand of 440,000 cubic meter and SD of 50.

The result of a single run for the price evolution

are shown in Figure 9– 11. Figure 10 show the sales

price of electricity per month for each of the

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

88

combined heat and power plant. In the figure, it can

be seen that CHP2 has the lowest average price per

step and has overshadow effect on the remaining two

CHP’s.

Figure 7: Average biogas demand by CHP1.

Figure 8: Average biogas demand by CHP2.

Figure 10 show the sales price of biogas per

month for each of anaerobic digestion plant. In the

same vein, AD2 has the best price and that dictates

why it dominates the transaction in the EIP. It can be

concluded that price variation is a factor that needs to

be consider in the dynamic simulation of eco-

industrial Park.

Figure 9: Electricity price/unit.

Figure 10: Biogas price/unit.

5 CONCLUSION

In this paper, agent-based modelling has been used to

simulate eco-industrial parks in order gain insight on

their behaviour to internal and external decision

criteria. An EIP system consisting of six different

process plants and infinite source and sinks (market

buyers and sellers) were developed. The sink agents

buy from the source agents based on the lowest price

at any period. In conclusion, this study shows that the

ABM is a useful tool that can be used in simulating

periodic demand and supply. The study also show

price variation is a factor to be consider in the model

Effect of Price Dynamics in the Design of Eco-Industrial Parks: An Agent-based Modelling Approach

89

of eco-industrial Park. As future work, we will

investigate how price setting by each of the agent will

have effect over the configuration of the EIP. We

intend to investigate the effect energy storage system

will have in the supply/demand mismatch that can

occur in the EIP system.

ACKNOWLEDGEMENTS

This research is supported by Tertiary Education

Trust Fund (TETFUND, Nigeria) and the European

Union’s Horizon 2020 research and innovation

programmed under SPIRE-06-2015 Energy and

resource management systems for improved

efficiency in the process industries Grant Agreement

no. 680843.

REFERENCES

Bichraoui, N., Guillaume, B. & Halog, A. 2013. Agent-

based Modelling Simulation for the Development of an

Industrial Symbiosis - Preliminary Results. Procedia

Environmental Sciences, 17, 195-204.

Cao, K., Feng, X. & Wan, H. 2009. Applying agent-based

modeling to the evolution of eco-industrial systems.

Ecological Economics, 68, 2868-2876.

Chertow, M. & Ehrenfeld, J. 2012. Organizing Self‐

Organizing Systems. Journal of Industrial Ecology, 16,

13-27.

Fraccascia, L., Albino, V. & Garavelli, C. A. 2017.

Technical efficiency measures of industrial symbiosis

networks using enterprise input-output analysis.

International Journal of Production Economics, 183,

273-286.

Ghali, M. R., Frayret, J.-M. & Ahabchane, C. 2017. Agent-

Based Model of Self-Organized Industrial Symbiosis.

Gonela, V. & Zhang, J. 2014. Design of the optimal

industrial symbiosis system to improve bioethanol

production. Journal of Cleaner Production, 64, 513-

534.

Grimm, V., Berger, U., Bastiansen, F., Eliassen, S., Ginot,

V., Giske, J., Goss-Custard, J., Grand, T., Heinz, S. K.,

Huse, G., Huth, A., Jepsen, J. U., Jørgensen, C., Mooij,

W. M., Müller, B., Pe’er, G., Piou, C., Railsback, S. F.,

Robbins, A. M., Robbins, M. M., Rossmanith, E.,

Rüger, N., Strand, E., Souissi, S., Stillman, R. A., Vabø,

R., Visser, U. & Deangelis, D. L. 2006. A standard

protocol for describing individual-based and agent-

based models. Ecological Modelling, 198, 115-126.

Heeres, R. R., Vermeulen, W. J. V. & De Walle, F. B. 2004.

Eco-industrial park initiatives in the USA and the

Netherlands: first lessons. Journal of Cleaner

Production, 12, 985-995.

Kim, H., Ryu, J.-H. & Lee, I.-B. 2012. Development of an

agent-based modeling methodology for an industrial

byproduct exchange network design. Industrial &

Engineering Chemistry Research, 51, 10860-10868.

Kuhn, J. R., Courtney, J. F., Morris, B. & Tatara, E. R.

2010. Agent-based analysis and simulation of the

consumer airline market share for Frontier Airlines.

Knowledge-Based Systems, 23, 875-882.

Mantese, G. C. & Amaral, D. C. 2018. Agent-based

simulation to evaluate and categorize industrial

symbiosis indicators. Journal of Cleaner Production,

186, 450-464.

Martin, M., Ivner, J., Svensson, N. & Eklund, M.

Classification of Industrial Symbiosis Synergies::

Application in the Biofuels Industry. Industrial

Symbiosis and Eco-Industrial Parks, 2009. GIN 2009,

2394.

Wilensky, U. & Evanston, I. 1999. NetLogo: Center for

connected learning and computer-based modeling.

Northwestern University, Evanston, IL, 4952.

Yazan, D. M., Romano, V. A. & Albino, V. 2016. The

design of industrial symbiosis: an input–output

approach. Journal of Cleaner Production, 129, 537-

547.

Zheng, K. & Jia, S. 2017. Promoting the Opportunity

Identification of Industrial Symbiosis: Agent-Based

Modeling Inspired by Innovation Diffusion Theory.

Sustainability, 9, 765.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

90