Development of a Perforated Diffusive Muffler

for a Regenerative Blower

Hyun Gwon Kil

1

, Kwan Ho Jeon

1

, Bo Youn Jang

2

and Chan Lee

1

1

Department of Mechanical Engineering, University of Suwon, Hwaseongsi, Gyeonggi-do, Korea

2

R&D Center, Myunghwa Ind.Co., Ltd., Danwon-gu, Ansan-si, Gyeonggi-do, Korea

Keywords: Perforated Diffusive Muffler, Regenerative Blower, Transmission Loss.

Abstract: A perforated diffusive muffler has been developed to reduce a high noise level that is generated from a

regenerative blower. The noise consists of two components such as discrete frequency noise component at

blade passing frequency due to rotating impellers and broadband noise component due to turbulence

produced in the regenerative blower. Main contribution into the high noise level is due to the discrete

frequency noise component. In order to effectively reduce the noise level of the regenerative blower, a

perforated diffusive muffler has been designed and manufactured in this paper. Its experimental test showed

that 23 dB of noise reduction has been achieved by attaching the muffler to the regenerative blower. Noise

level of 85dBA generated by the regenerative blower was reduced to noise level of 62dBA.

1 INTRODUCTION

Regenerative blowers are widely used for

automotive, environmental and fuel cell applications

because those are usually operated with high

pressure rise at low flow capacity. However, those

generate high noise level due to their air processing

unit operating with high pressure rise at low flow

capacity (Mura and Badami, 2012). The noise

consists of two components such as discrete frequen-

cy noise component at blade passing frequency (BPF)

due to rotating impellers and broadband noise

component due to turbulence in inflow and exhaust jet

mixing. Main contribution into the high noise level is

due to the discrete frequency noise component. It is

needed to attach perforated mufflers to reduce the

discrete frequency noise component.

The perforated mufflers have been initially

analyzed by using transfer matrix method (Sullivan,

1978; Sullivan, 1979; Munjal, 1987). Numerical

simulation methods such as boundary element

method (BEM) (Wu and Wan, 1996) and finite

element method (FEM) (Saf and Erol, 2010) have

been also implemented for design of the perforated

mufflers. Most of practical applications have been

performed to reduce mainly the discrete frequency

noise component in relatively low frequency region

where the plane wave approximation can be valid

without considering higher order modes. But the

higher modes needs to be considered to design the

perforated muffler attached to the regenerative

blower. It is because the blower is operated at large

rpm with high pressure rise and the blower noise is

mainly generated at relatively high BPF. In the

authors’ previous paper at SIMULTECH 2015 (Kil

et al., 2015) a perforated muffler has been designed

in order to reduce the noise generated from a

regenerative blower with BPF 5800 Hz. Recently,

the research work has been extended to design of the

perforated diffusive muffler by adding sound

absorbing material in the perforated muffler (Jeon et

al. 2017, in Korean). In the research work, the

perforated diffusive muffler has been manufactured

and tested experimentally. The test result showed

that 23 dB of noise reduction has been achieved by

attaching the muffler to the regenerative blower.

Noise level of 85 dBA generated by the regenerative

blower was reduced to noise level of 62 dBA. The

research work is introduced in this paper in English.

2 BLOWER MODEL AND NOISE

CHARACTERISTICS

2.1 Regenerative Blower Model

A regenerative blower is composed of impellers

equipped on double sides of rotating plate and fixed

Kil, H., Jeon, K., Jang, B. and Lee, C.

Development of a Perforated Diffusive Muffler for a Regenerative Blower.

DOI: 10.5220/0006861502890296

In Proceedings of 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2018), pages 289-296

ISBN: 978-989-758-323-0

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

289

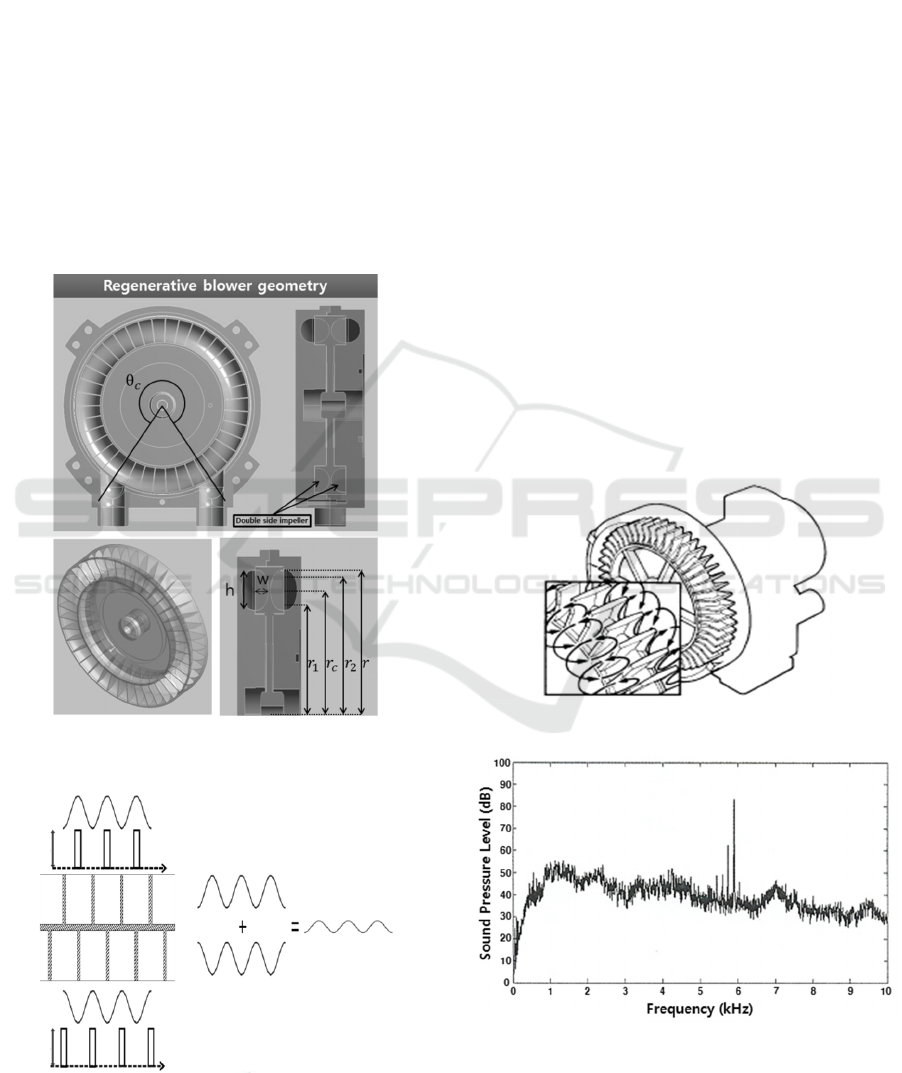

side channel covering the impellers. FANDAS-

Regen code (Lee et al., 2013) has been used to

decide the blower’s design variables and geometry

are shown in Figure 1.

In order to reduce the noise generated from

regenerative blower itself, a phase-shift cancellation

concept (Kim et al., 2014) on impeller blade

arrangement design has been implemented. Impeller

blades are equipped and arranged along angular

direction on double sides of rotating plate. Acoustic

pressure is radiating from each impeller blade in the

form of sinusoidal wave with the period of blade

pitch. If the impeller blades are arranged with

staggered type as shown in Figure 2, the acoustic

pressure radiating from impeller on one side could

be cancelled by that from impeller on another side.

Figure 1: Geometry and design variables of regenerative

blower.

Figure 2: Phase-shift cancellation concept.

2.2 Blower Noise Characteristics

The noise source considered in this research is

regenerative blower operating with high pressure

rise at low flow capacity shown in Figure 3

(Lee et

al.,

2013)

. It is widely used in various applications

including fuel cell applications. One of main

shortcomings of the regenerative blower is high

noise level. The flow inside the regenerative blower

shows typically helical-toroidal motion where fluid

rotates in and passes along the space between

rotating impeller blades and fixed side channels. It

generates two kinds of noise components such as

discrete frequency noise at BPF and the broadband

noise distributed over wide frequency range which is

produced due to inflow turbulence. Figure 4 shows

the typical pattern of noise spectrum measured from

the regenerative blower. Here BPF corresponds to

5800 Hz. The total noise level is shown as 85dB,

resulting in a 22dB reduction by applying the low

noise design concept in Figure 2. However, since the

noise level 85dB of the regenerative blower is quite

high in terms of work environment, additional noise

reduction is considered to be necessary by attaching

the perforated muffler.

Figure 3: Regenerative blower.

Figure 4: Noise spectrum of a regenerative blower.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

290

3 THEORY

3.1 Sound Transmission Loss and

Insertion Loss

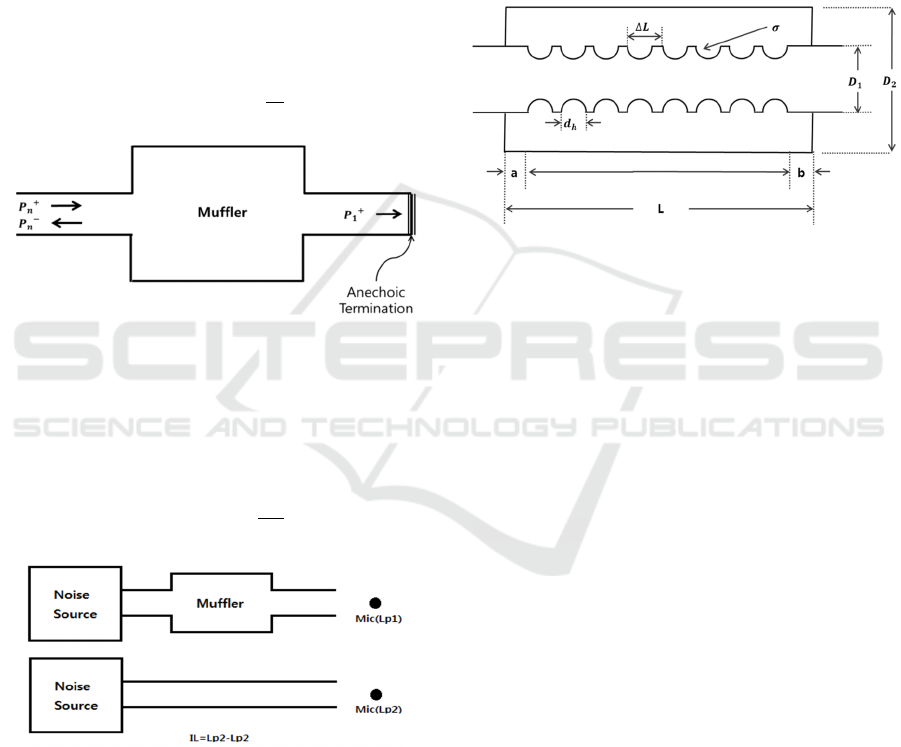

In order to reduce the noise generated from the

blower, a perforated muffler is attached to the

blower. The noise attenuation performance of the

muffler is evaluated in terms of transmission loss

(TL) and insertion loss (IL).

TL is defined as the logarithmic ratio between

the incident sound power

at the inlet of the

muffler and the transmitted sound power

at the

outlet of the muffler as

TL = 10

(1)

Figure 5: Layout for transmission loss.

If the area of the inlet is same as the area of the

outlet, TL can be experessed with complex

amplitude of the incident pressure

and complex

amplitude of transmitted pressuer

as

TL = 10

(2)

Figure 6: Layout for insertion loss.

IL is defined as the difference between sound

power level Lp

2

at the termination without the

muffler and sound power level Lp

1

at the

termination with the muffler installed as shown in

Figure 6. In the case of IL, it is not necessary to

install an anti-reflection terminal as shown in Figure

5. Thus it is closer to an actual value of sound loss

because all actually installed connectors related to

the blower and the muffler are considered. If the

cross sectional area of the inlet is equal to the cross

sectional area of the outlet and the outlet is anti-

reflected, TL and IL become equal. Assuming this

condition, TL has been considered to design the

muffler in this paper.

3.2 Methods to Evaluate TL

3.2.1 Transfer Matrix Method

Figure 7: Perforated muffler.

The perforated muffler is consists of parallel coupled

coaxial duct as shown in Figure 7. The two ducts are

joined together by a perforated section. The coaxial

duct has constituent sub-components with straight

parts and parts with holes, respectively. The acoustic

pressure (

,

,

,

) and volume velocity

(

,

,

,

) at the left inlet end of the coaxial duct

can be related with the acoustic pressure(

,

,

,

)

and volume velocity (

,

,

,

) at the right outlet

ends of the coaxial duct in the matrix form (Sullivan,

1978; Sullivan, 1979; Bang, 2001) as

,

,

,

,

=

[

]∏

,

,

,

,

(3)

Here

and

correspond to transfer matrices of

sub-components with straight parts and parts with

holes, respectively. means the number of the

sub-components. Considering the impedance

regarding to the relation of the pressure difference

and volume velocity through each hole, the pressure

and volume velocity at the inlet of the muffler can

be related to the pressure and volume velocity at the

outlet as

,

,

=

[

]

,

,

(4)

Development of a Perforated Diffusive Muffler for a Regenerative Blower

291

where

[

]

is the overall transmission matrix. Here

the impedance at each hole can be determined using

the empirical formula in the reference (Sullivan,

1978)

=

[6×10

+×

(

+0.75

)

] (5)

where ρ,c,

and are density of air, speed of

sound, hole diameter and acoustic wavenumber at a

given frequency, respectively. The detailed

description in the formulation of the transfer matrix

can be referred in the reference (Sullivan, 1979:

Bang 2001). From the relation in Equation (4), TL

can be evaluated as

TL = 20log

|

+

+

+

|

(6)

where

(, = 1,2) is the corresponding element

of the transfer matrix.

(= /

) and

(= /

)

mean the characteristic impedance of two duct with

section area

and

, respectively. The transfer

matrix method is generally used with the assumption

of linear sound propagation of a plane wave in the

muffler. The plane wave limit of a circular duct

corresponds to the case below the cut-off frequency

(Eriksson, 1980) with the first asymmetric mode

that is

(,)

= 0.586/

(7)

On the other hand, the first circularly symmetric or

radial mode generated at cut-off frequency is

expressed as

(,)

= 1.22/

(8)

3.2.2 Finite Element Method

Numerical simulation methods play an increasingly

important role in the design of mufflers as well as

other NVH applications. FEM offers an

advantageous combination of modelling flexibility,

computational efficiency and result accuracy.

Comparing to the boundary element method (BEM),

FEM allows modelling more complex physics of

acoustics considering multiple fluid domains, sound

propagation in a mean flow and effects of

temperature gradients in a fluid medium. FEM can

be especially used to design of mufflers to reduce

relatively high frequency noise considering the

higher modes above the cut-off frequency as well as

to design the mufflers with relatively complex

shapes.

Figure 8: Structural shape and finite element model of a

muffler.

The linear wave equation for perfect gas with no

damping is expressed in terms of pressure and

speed of sound as

∇

=

(9)

At each frequency in the interested frequency range

that Equation (9) becomes Helmholz’s equation as

∇

=−

(10)

where P, mean complex pressure amplitude and

the acoustic wavenumber at the given frequency,

respectively. The three dimensional acoustic domain

of the muffler is divided into elements in Figure 8.

The variational formulation of the muffler problem

allows to formulate the discretized equation of linear

systems of algebraic equations as

[

A

]{

}

=

{

}

(11)

where

[

A

]

,

{

}

and {f} are the coefficient matrix,

sound pressure amplitude vector of nodal values and

forcing function vector of nodal values, respectively.

In the present muffler problem, {f} is only a non-

zero value at the inlet pipe according to Dirichlet

boundary condition with unit pressure.

In this study, the finite element method approach

is done by a commercial FEM program ACTRAN of

MSC software company. For more efficient way to

model perforation of the muffler, meshes on the

perforated tube are replaced by the two inner and

outer concentric surfaces with acoustic transfer

admittance. For the acoustic transfer admittance, the

transfer admittance of the perforated plate (Mechel,

2008) with the same perforation pattern of the

perforation tube is used.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

292

4 DESIGN

4.1 Design Concepts

TL of the perforated muffler is dependent on design

variables such as inner diameter

and outer

diameter

, porosity σ, total length in Figure 7.

The inner diameter

is determined to be fitted to

the outer diameter of the blower. The outer diameter

is determined considering the cut-off frequencies

in Equations (7) and (8) although TL performance is

increased by increasing the cross-sectional area ratio

between the inlet and outlet ducts at frequencies

below the corresponding cut-off frequency. The

initial design length of the muffler can be

determined considering the axial modal frequencies

of the cavity itself as =

(

/2

)

( = 1,2,⋯). It

leads to decision of the initial data as

= 0.019,

= 0.06 and = 0.083.The corresponding

cut-off frequencies are

(,)

= 3320 and

(,)

= 6913.

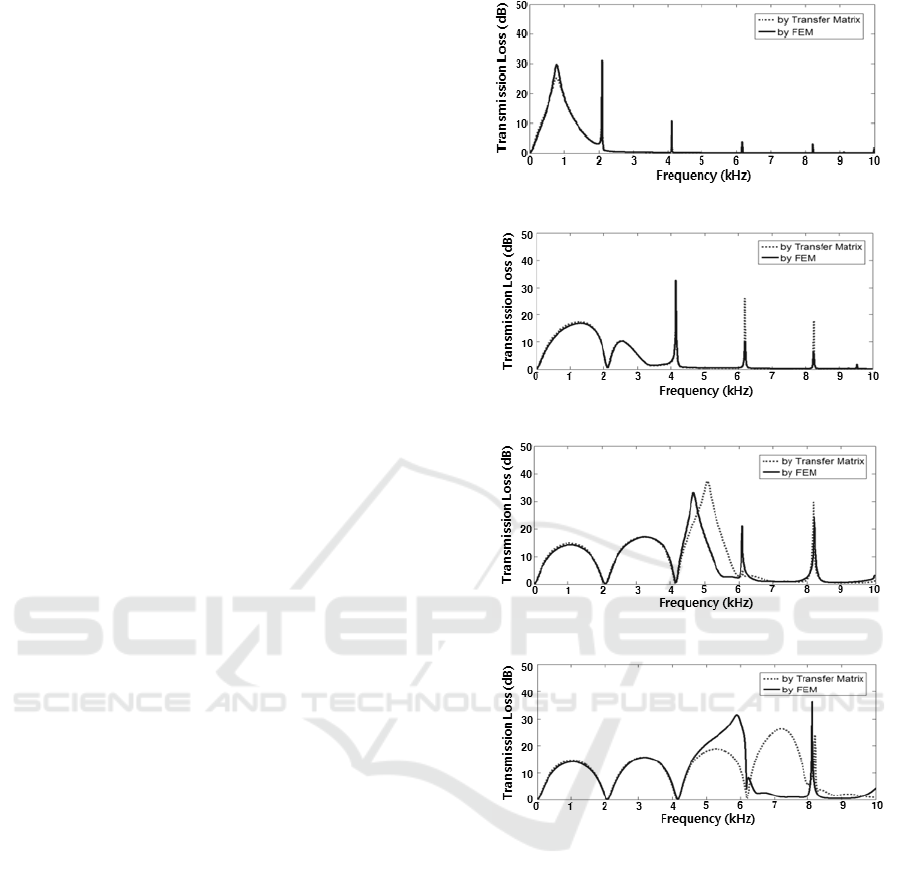

Figure 9 shows the dependence of TL on the

porosity of the muffler and also comparison of TL

result obtained by FEM with TL result obtained by

the transfer matrix method with the dependence of

the porosity. The comparison shows some

differences between two results especially above the

cut-off frequency

(,)

= 3320 as shown in

Figure 9(c) and (d). This phenomenon is shown

more clearly as the porosity is increased. It is

because TL results obtained by FEM includes the

contribution of all higher modes while the only

plane wave is considered in the transfer matrix

method.

Characteristics of the perforated muffler are

represented by the combination of the acoustic mode

of the outer tube and the effect of the resonance due

to porosity of holes in the inner perforated tube.

Those phenomena can be considered in designing

the perforated muffler. Figure 9(a) shows that at low

porosity a peak at an annular cavity resonator

resonance related to the porosity is clearly separated

from peaks of cavity axial modal frequencies in

higher frequency region. As the porosity is increased

in Figures 9(b)-(d), two peaks related the annular

cavity resonance related to the porosity and the

cavity modal frequency tend to merge and to be

strongly coupled. One can find an optimum porosity

at which two peaks merge into a single peak having

relatively broad transmission loss at a particular

frequency band that includes BPF in the nose

spectrum generated by the blower.

(a)

(b)

(c)

(d)

Figure 9: Transmission loss obtained by FEM (−) and

transfer matrix method ( ⋯) with dependence on the

porosity (σ) ∶(a) 1%, (b) 3%, (c) 11.5%, (d) 22%.

4.2 Design and Evaluation of Noise

Reduction Performance

The design concept described at section 4.1 has been

implemented to design of a perforated muffler. The

inner diameter of the muffler has been determined to

be fitted to the outer diameter of the blower as

=

0.019. The outer diameter has been determined to

be

= 0.052to increase the cut-off frequency as

(,)

= 8000 comparing with the initial cut-off

frequency

(,)

= 6913. The length of the

muffler has been determined as L=59mm to expand

Development of a Perforated Diffusive Muffler for a Regenerative Blower

293

frequency bandwidth for noise reduction comparing

with the initial length = 0.083. The porosity of

the holes has been determined to be σ = 36% to

reduce discrete frequency noise at BPF. The noise

reduction characteristics of the muffler with those

specifications are shown in Figure 10 is analyzed as

follows.

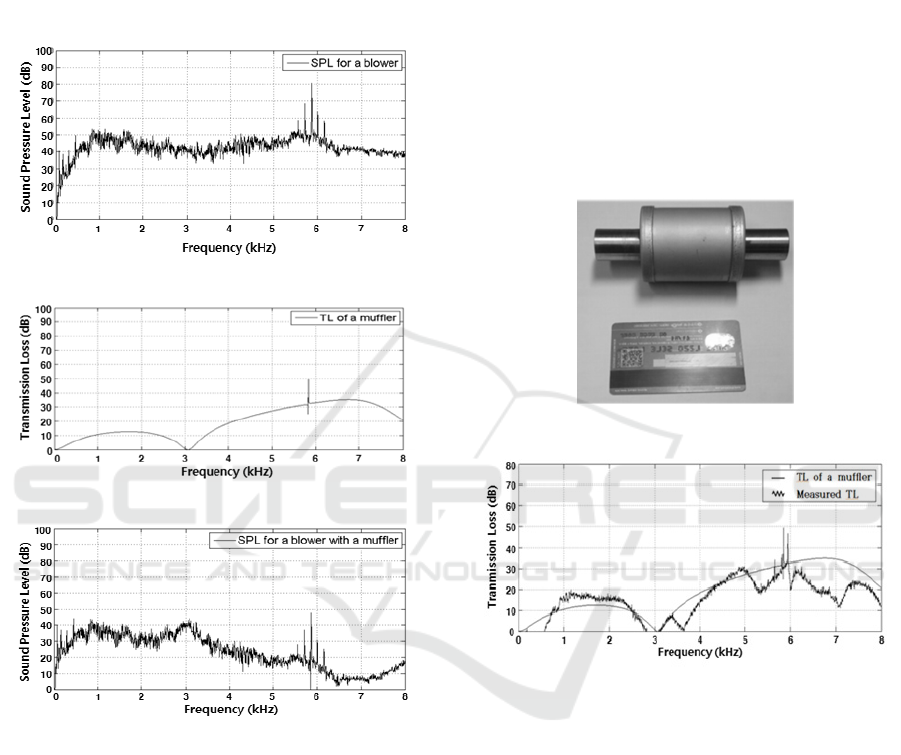

(a)

(b)

(c)

Figure 10: (a) blower noise spectrum, (b) TL of the

designed perforated muffler and (c) reduced noise

spectrum.

The regenerative blower generates the noise of

overall sound pressure level (SPL) 84 dB(A) with

the frequency spectrum shown in Figure 10(a), that

has two kinds of noise components such as discrete

frequency noise at BPF 5,800Hz and the broadband

noise distributed over wide frequency range. By

attaching the perforated muffler with TL in Figure

10(b), the overall SPL of 84 dB(A) is expected to be

reduced to 66 dB(A) in Figure 10(c) that represents

the reduced noise spectrum by attaching the

perforated muffler to the regenerative blower.

5 EXPERIMENT AND RESULTS

5.1 Performance of the Perforated

Muffler

The perforated muffler has been manufactured. It

has a relatively small size with length less than the

length of a credit card as shown in Figure 11. TL of

the manufactured perforated muffler has been

measured by comparing noise levels with and

without the muffler with the layout of the IL as

shown in Figure 6. It matches relatively well the

estimated value of TL as shown in Figure 12.

Figure 11: Perforated muffler.

Figure 12: TL of a perforated muffler.

5.2 Effects of Sound Absorbing

Material

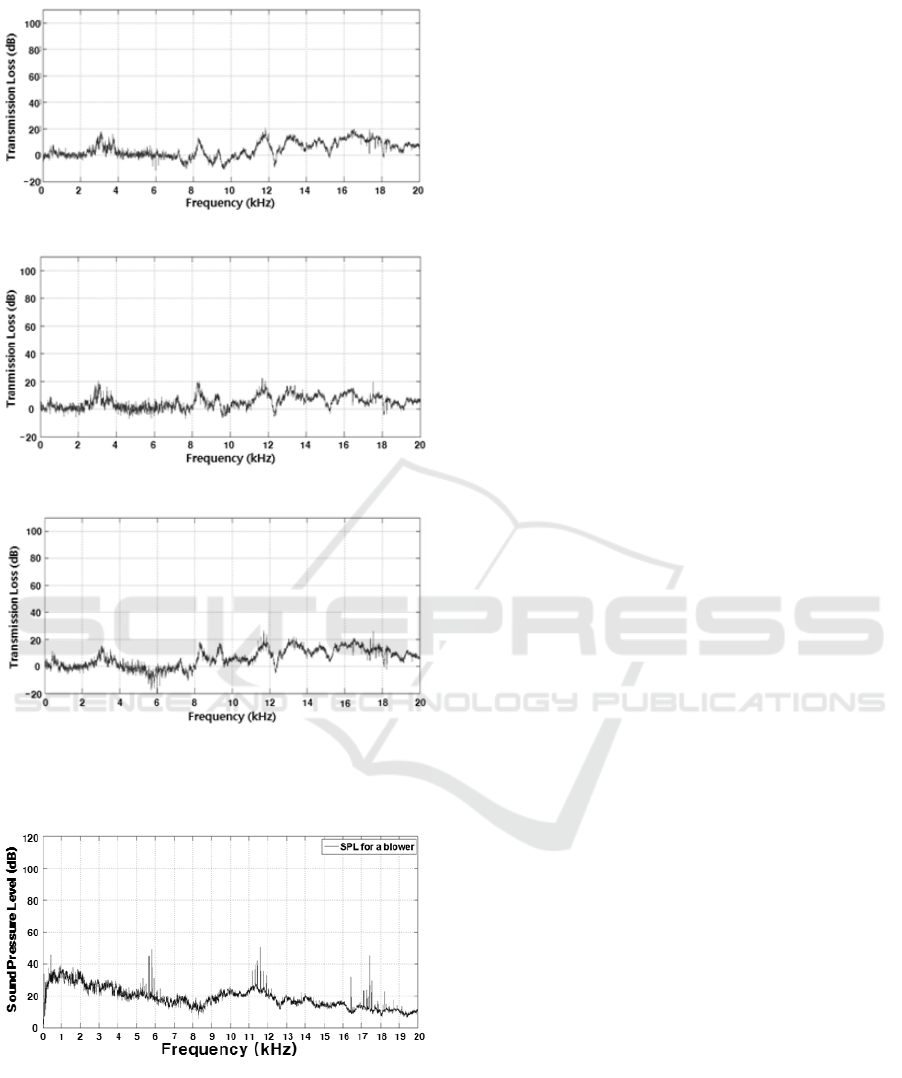

Fig. 12 shows low value of TL at 3 kHz. In order to

increase the noise absorption performance around 3

kHz, three sound absorbing materials such as PU

foam 32k, Melamine foam G, and Websuler 300G

(NYCO, 2010) are selected to insert each of those

between the coaxial ducts of the muffler. Three

perforated diffusive mufflers with those sound

absorbing materials, respectively, were manufactur-

ed. TL of each perforated diffusive muffler has been

measured and noise absorbing performance of each

material itself was separated as shown in Figure 13.

It shows that those materials have all noise

absorption effects at 3kHz and frequencies above 8

kHz.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

294

(a)

(b)

(c)

Figure 13. Noise absorbing performance (a) PU foam 32k,

(b) Melamine foam G and (c) Websuler 300G.

Figure 14: Noise spectrum of regenerative blower with

attached perforated diffusive muffler.

5.3 Performance of the Perforated

Diffusive Muffler

Each muffler was attached to the regenerative

blower and noise was measured. The overall noise

levels were 65dB, 62dB and 70dB, respectively.

Figure 14 shows the noise (62 dB) characteristics of

a blower that is attached to the perforated diffusive

muffler with noise absorbing material as Melamine

form G.

6 CONCLUSIONS

A perforated diffusive muffler has been designed

and manufactured to reduce a high noise level that is

generated from a regenerative blower. The noise

consists of two components such as discrete

frequency noise component at blade passing

frequency due to rotating impellers and broadband

noise component due to turbulence produced in

blower. Main contribution into the high noise level

is due to the discrete frequency noise component. In

order to effectively reduce the noise level of

regenerative blowers, a perforated muffler has been

modelled in this paper. In order to identify important

design factors, the design parametric study has been

performed using transfer matrix method and finite

element method (FEM). It has been implemented to

design the perforated muffler that effectively

reduces the high noise level of the regenerative

blower. Effects of noise absorbing materials have

been investigated experimentally. By combining

effects of a perforated muffler and noise absorbing

material, a perforated diffusive muffler has been

designed and manufactured. Its experimental test

showed that 23 dB of noise reduction has been

achieved by attaching the muffler to the regenerative

blower. Noise level of 85dBA generated by the

regenerative blower was reduced to noise level of

62dBA.

ACKNOWLEDGEMENTS

This work was supported by the Energy Technology

Development Program of the Korea Institute of

Energy Technology Evaluation and Planning

(KETEP) granted financial resource from the

Ministry of Trade, Industry and Energy, Republic of

Korea (20172010106010).

REFERENCES

Mura, M. and Badami, M. 2012. Leakage effects on the

performance characteristics of a regenerative blower

for the hydrogen recirculation of PEM fuel cell,

Development of a Perforated Diffusive Muffler for a Regenerative Blower

295

Energy Conversion and management, 55.

Sullivan, 1979. A method for modelling perforated

muffler components. I. Theory, Journal of Acoustical

Society of America, 66(3).

Sullivan, 1979. A method for modelling perforated

muffler components. II. Applications, Journal of

Acoustical Society of America, 66(3).

Munjal, M. L., 1987. Acoustics of ducts and mufflers with

application to exhaust and ventilation system design,

John Wiley & Sons.

Wu, T. W., Wan. G. C., 1996. Muffler performance

studies using a direct mixed-body boundary element

method and a three-point method for evaluating

transmission loss. ASME Transaction, Journal of

Vibration and Acoustics, 118.

Saf., O., Erol, H., 2010. On acoustics and flow behavior of

the perforated mufflers, 17

th

International Congress on

Sound & Vibration.

Kil, H. G., Kim, K. Y. and Lee, C., 2015. Design of a

perforated muffler for a regenerative blower used in

fuel cell application, Proceedings of the 5

th

International Conference on Simulation and

Modelling Methodologies, Technologies and

Application. SCITEPRESS.

Jeon, K. H, Jang, B. Y., Lee, C. and Kil, H. G., 2017.

Development of a muffler attached to a regenerative

blower, Journal of Fluid Machinery (in Korean), 20(4).

Lee, C., Kil, H. G., Kim G.C., Kim, J. G., Ma, J.H., Chung

K.H., 2013. Aero-acoustic Performance Analysis

Method of Regenerative Blower, Journal of Fluid

Machinery, 16(2) (in Korean).

Kim, J. K, Lee, K. Y., Lee, C., Kil, H. G., 2014.

Development of a low-noise regenerative blower for

fuel cell application, Journal of Fluid Machinery, 17(2)

(in Korean).

Bang, K. H, 2001. An experiment study on the

transmission loss of perforated tube mufflers, Ph.D

Thesis (in Korean) Kookmin University.

Eriksson, L. J., 1980. Higher order mode effects in circular

ducts and expansion chambers, Journal of Acoustical

Society of America, 66(3).

ACTRAN user manual, version 13.0, MSC software

company

Mechel, F. P., 2008. Formulas of Acoustics, Springer, 2

nd

edition.

NYCO, 2010. Nam Yang Novitech CO., LTD. Catalog.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

296