Simplifying Data Preparation for Analysis using an Ontology for

Machine Data

Dipali Tole and Nikhil Joshi

Asia Technology Innovation Center, John Deere India Pvt. Ltd., Pune, India

Keywords: Ontology, Reasoner, Semantic Web, SQL Query, Database, Automotive Industry.

Abstract: Vehicle manufacturers gather large amounts of data through on-board sensors and other systems, for

applications, such as real-time diagnostics, prognostics, design improvements, etc. However, a lot of time is

spent in preparing the data for specific analyses. Moreover, this data preparation requires people having

expert knowledge about various data schemas and structures used, as well as the specific domain or vehicle

systems that the data pertains to. This paper proposes an approach using a formal Ontology to capture

knowledge about the domain, and a reasoner to query and prepare data. Using a demonstrative example, the

paper presents a comparison of the current approach to preparing data using experts with the proposed

approach. The preliminary findings from the study suggest that the proposed approach is promising, and

provides unique advantages specifically when faced with distributed, polymorphic data structures, that may

change over time.

1 INTRODUCTION

Nowadays, with the proliferation of sensors and

electronics in our vehicles and the advances in

communication and data storage, vehicle

manufacturers have access to large amounts of data

from various machines in operation. Analysis of this

data can provide valuable insights, such as pre-

emptive indicators of failures, load cycles, system

performance and security. Any analysis of such data

can be broadly considered to constitute three steps:

1. Data Preparation

This includes cleaning the data, removing noise and

incorrect data, filtering relevant data, combining

data from different sources, resolving conflicts and

redundancies, etc. It also involves transforming/

normalizing/ reorganizing data to a form that is

required for analysis.

2. Data analysis/modeling

This step refers to the core statistical or analytical

tasks, such as determining correlations and

dependencies, finding trends and patterns, building

mathematical models & visualisations, etc.

3. Interpretation & utilisation

This involves drawing useful insights to support

decision making and other intents of the study.

The data required for analysis is usually stored

across various databases having inconsistent naming

conventions, varying data structures and schemas,

and varying conventions for capturing data (such as

units, frequency, etc.). Moreover, the data schemas

and conventions may also change over time,

geography, or with different types of machines.

Therefore, there is need for individuals who have

intimate knowledge about the domain, implicit

assumptions pertaining to data captured, as well as

expert understanding of the schemas and database

configurations to prepare the data. Such expertise

requires years of experience, and even such

experienced experts may find it difficult to keep up

with the changing data management technologies. A

2016 survey (CrowdFlower, 2016) of data scientists

found that up to 79% of their time was spent in data

preparation. Moreover, the same survey indicated

that 78% of data scientists viewed data preparation

as the least enjoyable part of their job.

This paper explores the use of a formal ontology

to capture the semantics related to the data, and

thereby reduce the efforts and expertise required for

the data preparation step. The remainder of the paper

is organized as follows: Section 2 introduces a

demonstrative example and highlights the issues

faced in data preparation without the aid of explicit

semantics. Section 3 provides a brief background

about ontologies and their applications. It then

Tole, D. and Joshi, N.

Simplifying Data Preparation for Analysis using an Ontology for Machine Data.

DOI: 10.5220/0006892901670174

In Proceedings of the 10th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2018) - Volume 2: KEOD, pages 167-174

ISBN: 978-989-758-330-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

167

describes the creation of a formal ontology, rules,

and data instances, for the demonstrative example,

and the use of logic based reasoning for data

preparation. Section 4 further proposes core

common concepts in the form of an ontology for

machine information that can be used in the

automotive industry for various potential use cases.

Section 5 concludes the article with a discussion of

the benefits and limitations of the proposed

approach, key findings and insights from the study,

and directions for future work.

2 DEMONSTRATIVE EXAMPLE

As a demonstrative example, let us consider that we

have sensor diagnostic data gathered through

telematics for a fleet of vehicles of an OEM. The

data would comprise of measurements or diagnostics

events from several machines identified by a unique

identifier or machine numbers, and generally

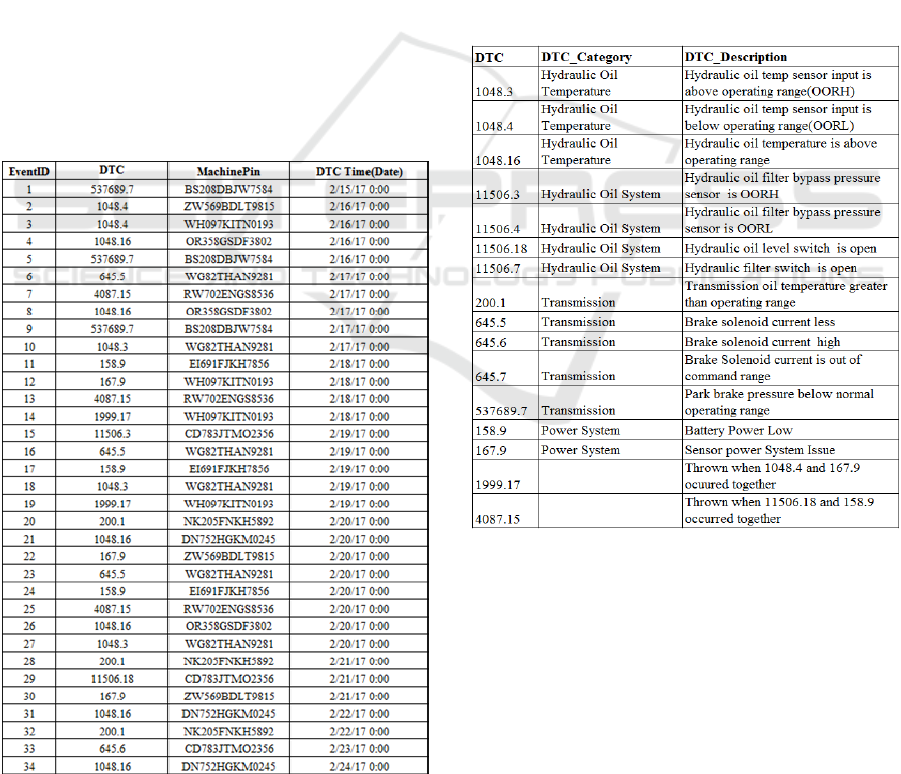

recorded chronologically. Figure 1 shows an

example of such data in the form of a database table.

This database has four fields for every entry, viz. an

Figure 1: Machine Data Table.

EventID - which provides a unique reference for

each data entry, a DTC – which provides the

diagnostic code that is reported by the machine for

the event, a MachinePin – which is the unique

identifier of the machine, and a DTCTime – which

records the date and time of occurrence.

Let us now consider that we wished to analyse

this data to find trends in a specific class of

diagnostics events, say “hydraulic oil temperature”

issues, for a particular type of machine, say

“Tractors”, over a specific period, say before “20th

Feb 2017”. In order to analyse the trends, we would

need to filter the data to remove information that is

not relevant to the study. Clearly, the information

available in Figure 1 is not sufficient to prepare the

data for this analysis. We would need the

classification of diagnostic codes to identify the

DTCs that belong to the class of “hydraulic oil

temperature” issues, and a catalogue that identifies

the type of machine given its unique identifier.

Figure 2: Classification of Diagnostic Codes.

Figure 2 shows the database table that records the

classification of diagnostic codes. It has 3 fields, viz.

the DTC, a DTC_Category – which records the class

the DTC belongs to and, a DTC_Description –

which provides a textual description of the issue the

DTC refers to. Upon close inspection of the last two

rows of the database table, it can be observed that

the DTCs 1999.17 and 4087.15 have not been

assigned a DTC_Category. This is because they are

indicative of a combination of issues as described in

the DTC_Description. Thus, an event with DTC

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

168

1999.17 is also indicative of a “hydraulic oil

temperature” issue, since it implies occurrence of

issue described by DTC 1048.4 too. However, this

information is not explicit in the data, but implicit in

the textual description.

Figure 3: Catalogue of machines in the fleet.

The type of machine can be determined using a

separate database table as shown in Figure 3. This

table has three fields, viz. MachID – which serves as

a unique identifier of a machine, a NativePin –which

is a public identifier of the machine and would also

be unique to the machine, and Category – which

records the type of machine. Note that this table uses

a different unique identifier for machines to organize

its information. Also note that the identifier stored in

the field NativePin in this table, is the same

identifier recorded in the field MachinePin in the

Machine Data table (Figure 1).

Filtering data relevant for the desired analysis,

using information in these three database tables

requires a series of operations, involving joining of

tables based on corresponding key fields, and

filtering using desired criteria. This can be achieved

using a complex query or series of queries. Figure 4

shows such a concatenated query written in SQL

(Structured Query Language), and the resulting

filtered relevant data. The query essentially follows

three steps:

i. Filter the database table for the catalogue of

machines for entries having the Category

“TRACTORS”.

ii. Join this filtered table with the Machine Data

table using correspondence of NativePin and

MachinePin fields, to filter down for events

where the correspondence is found (indicating

that the events occurred on machines that were

“TRACTORS”). Further, filter this table for

events that occurred before 20th February 2017

using the DTCTime field.

iii. Finally join this filtered table with the table

for Diagnostic codes, using correspondence of

the DTC field, and filter for entries having the

DTC_Category “Hydraulic Oil Temperature”.

As can be evidenced, preparing this data requires

expert knowledge of the domain to know

equivalence between fields, as well as knowledge of

the data structures to know how the information is

stored and how it can be manipulated to get the

desired information. Moreover, even with such

expert knowledge some implicit information may be

missed. For example, events with EventID 1999.17

are not captured in the prepared data although they

indicate a “hydraulic oil temperature” issue. Special

queries need to be created to look for such implicit

information.

Figure 4: Concatenated SQL query and resulting output.

Simplifying Data Preparation for Analysis using an Ontology for Machine Data

169

3 DATA PREPARATION USING

ONTOLOGIES

To overcome the issues identified in Section 2, we

propose an approach involving the creation of a

domain ontology, and performing logic based

reasoning, to assist in the data preparation.

In computer science, an Ontology is a formal,

explicit specification of the concepts, relationships,

and other distinctions that are relevant for modelling

a domain (Gruber, 2009). It provides a common

vocabulary, usually machine-interpretable, to share a

common understanding of the structure of

information among people and software agents and

helps make domain assumptions explicit (Noy &

McGuinness, n.d.). It thereby allows software

agents, often called reasoners, to identify implicit

information in the data based on first-order logic.

Such reasoners have been used to enable

interoperability between software tools, determine

inconsistencies and errors in data, automate data

classification, etc. (Ameri, et al., 2012) (Yang, et

al., 2013).

We shall explain our proposed approach using

the demonstrative example introduced in Section 2.

For this example, we use an Ontology Editor,

Protégé (Musen, 2015), provided by the Stanford

Center for Biomedical Research, Stanford

University. Protégé supports OWL-DL (Web

Ontology Language – Description Logic) as the

language for defining the Ontology. It enables

reasoning using Description Logic, which is a subset

of first-order logic (Horridge, 2011) (Wood, 2013).

We also use the Pellet reasoner (Clark, 2015) plugin

for Protégé for drawing inferences.

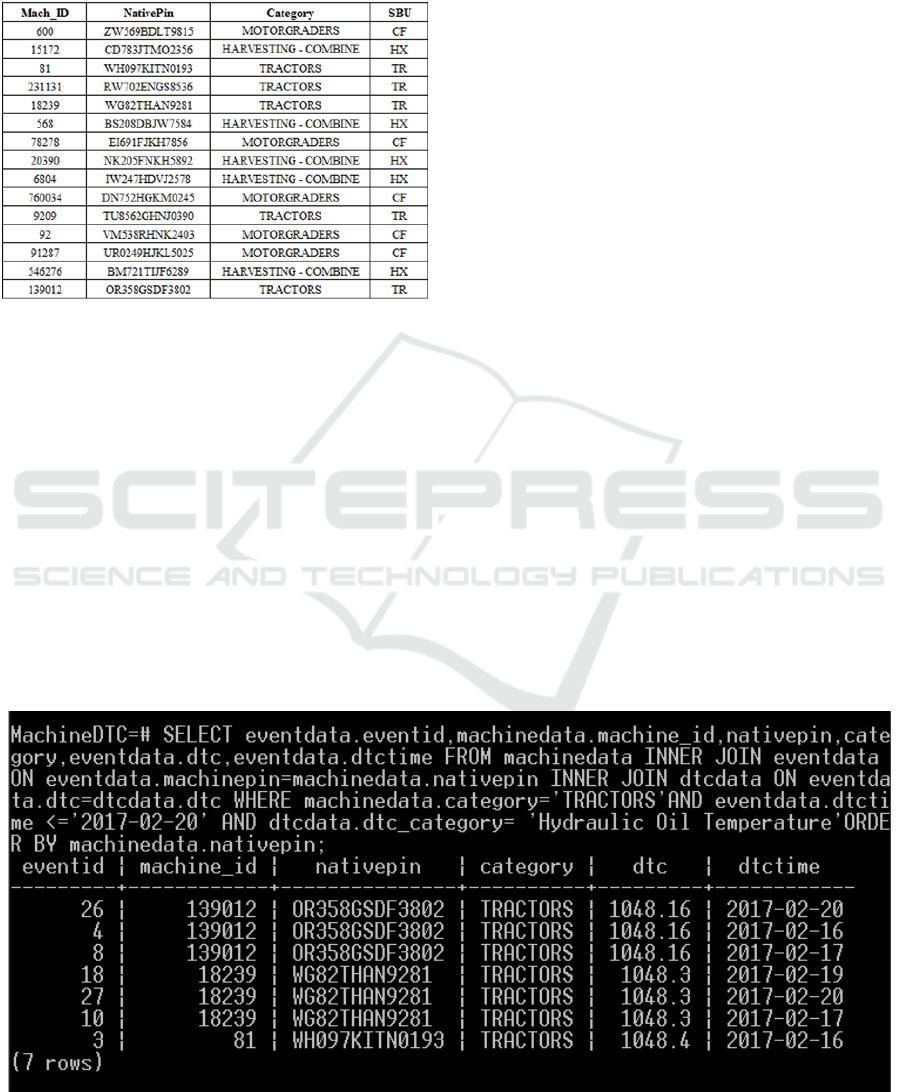

To define the Ontology, we first identify the

important concepts in the domain. In this example,

the key concepts are that of a Machine, a diagnostic

code or DTC, and a diagnostic Event, which are

defined as classes in the Ontology. Every machine

has a pin number and type or category. To capture

that, we create two new classes nativepin and

MachineCategory, and two new relationships or

object properties, namely hasNativePin, which has

Machine as the domain and nativepin as the range,

and hasCategory, which has Machine as the

domain and MachineCategory as the range.

Similarly, for a DTC we create a new class,

DTCCategory, an object property,

hasFaultCategory, and a data property

hasdescription. Finally, for the Event class we

create a class, machinepin, an object property,

hasMachinePin, an object property hasFaultCode,

and a data property, date. The domains and ranges

for these properties are shown in Table 1 below:

Table 1: Table of relationships.

Property

Domain

Range

hasCategory

Machine

MachineCategory

hasFaultCategory

DTC

DTCCategory

hasFaultCode

Event

DTC

hasMachinepin

Event

machinepin

hasNativePin

Machine

nativepin

date

Event

<dateTime>

dtcdescription

DTC

<string>

As we analyses the domain, we realise that the

classes nativepin and machinepin describe the

same concept, and hence we specify that these

classes are equivalent. Likewise, we explicitly

specify all the other classes to be disjoint from each

other. Since, we know that diagnostic events occur

on specific machines, we would like to have a

relationship that indicates the Machine that a

particular Event occurred on. Therefore, we create a

new object property, belongsTo, with Event as the

domain and Machine as the range. However, we

also realise that this information would implicitly be

present in the data through the hasMachinePin and

hasNativePin properties due to the equivalence of

machinepin and nativepin. Hence, we specify the

property belongsTo as SuperProperty Of Chain

“hasMachinePin o inverse(hasNativePin)”.

The resultant description of the domain can be

visualized as shown in Figure 5.

Figure 5: Definition of the machine data ontology.

The information specified so far is merely recording

knowledge about the domain. This information is

often referred to as the T-Box or Terminology Box.

It does not have any information about specific

instances of machines or specific diagnostic events.

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

170

That data, which is available in database tables as

shown in Figure 1, Figure 2, and Figure 3 also

needs to be specified. This information is often

referred to as the A-Box or Assertion Box. For our

example, we have prepared the database tables in

Excel, and use the Cellfie plugin (Hardi, 2016) to

create axioms specifying the A-Box in the Ontology.

It should be noted that data in any form (e.g.

SQL/JSON database) can be imported into the

ontology with the use of an appropriate mechanism.

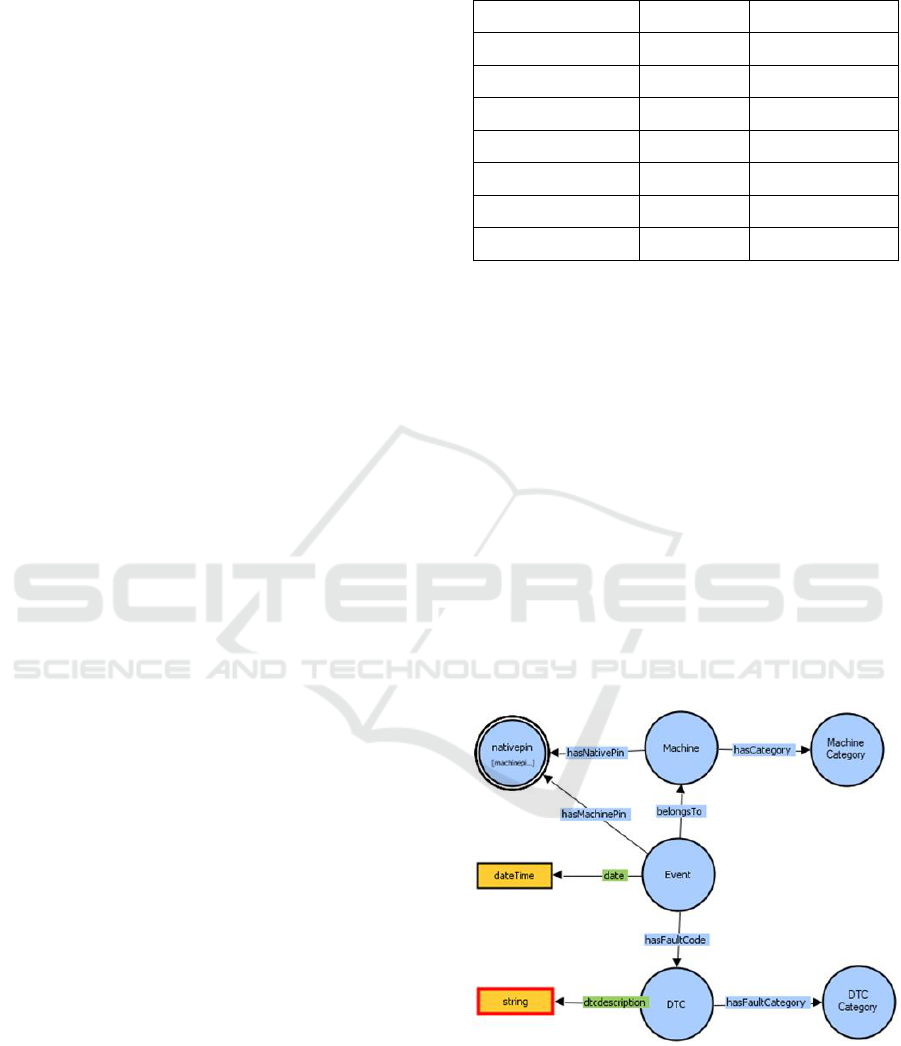

The resultant knowledge base would now have

instances for each of the concepts or classes along

with relationships that are explicitly present in the

database tables. Figure 6 is a screenshot of the

Ontology in Protégé showing an instance 14 of type

Event that hasMachinePin WH097KITN0193,

hasFaultCode 1999.17, and has date 2017-02-18.

Figure 6: Screenshot of Protégé showing an instance of

class Event.

In order to capture the implicit information about

certain diagnostic codes that indicate a combination

of issues, we can use rules that indicate the implied

axioms. For example, we can create a rule that

specifies that if there exists a relationship

hasFaultCode between an Event E and DTC

1999.17, it implies that there also exist

hasFaultCode relationships between the Event E

and DTCs 167.9 and 1048.4. Figure 7 shows the

rules captured in the Ontology.

Figure 7: Rules capturing implicit information.

Once we have the information captured in the

Ontology we can start the reasoner software to infer

implicit information in the data. For example, as

shown in Figure 8, the reasoner has inferred three

more axioms or relationships for Event 14, viz.

hasFaultCode 167.9 (DTC), hasFaultCode 1048.4

(DTC), and belongsTo 81 (Machine) as highlighted

in orange box.

Figure 8: Screenshot showing inferred information.

As can be seen, with the use of the Ontology and

reasoning, we would have rich explicit information

which can aid in data preparation for various

applications. In our example, we are looking for all

diagnostic events of a specific type, viz. “hydraulic

oil temperature” issues that have occurred on a

specific type of machine, viz. “Tractors”, over a

specific period, viz. before “20th Feb 2017”. To

prepare this data we use the Snap-SPARQL (Musen

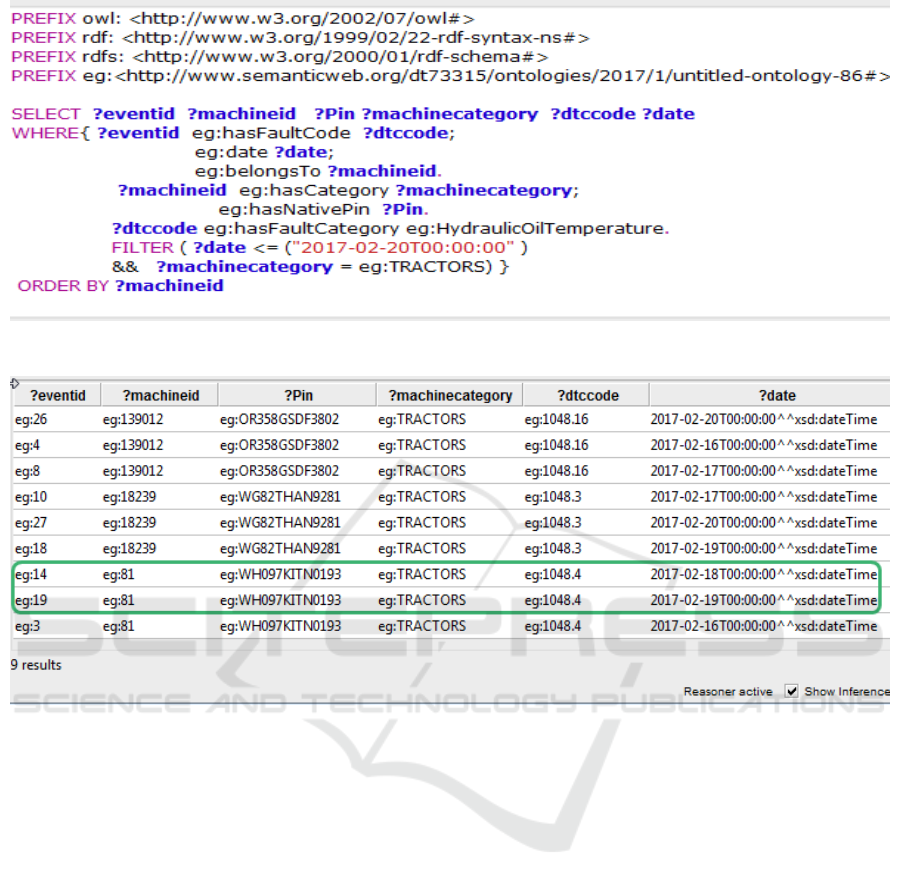

& Horridge, 2015) query language. The definition of

the query is shown in Figure 9. As can be seen from

the results of the query in Figure 10 diagnostic

events that included “hydraulic oil temperature”

issues implicitly but not explicitly in the data,

highlighted in a green box, are also identified. The

resulting data can be used for the desired analysis,

and no additional data preparation tasks are required.

As can be seen in Figure 9, the query can be

built at conceptual level, including concepts as

defined in the T-Box. Consequently, knowledge of

the domain and the needs of the application is all

that is required to carry out the data preparation task.

Knowledge of the different data structures used for

different types of information is not required.

Knowledge of database manipulation techniques,

joining, filtering and manipulating database tables is

Simplifying Data Preparation for Analysis using an Ontology for Machine Data

171

Figure 9: SnapSPARQL query to prepare data.

Figure 10: SnapSPARQL query results-prepared data.

also not required, although the user needs to be able to

interact with the knowledge base using appropriate

querying language and interface. Moreover, since

implicit information can be explicitly specified in the

knowledge base, it is not necessary to make separate

considerations during the data preparation task.

4 COMMON ONTOLOGY FOR

MACHINE INFORMATION

While the demonstrative example introduced in

Section 3 introduces the approach and the benefits of

using a domain ontology, the ontology developed for

the example is inadequate for capturing key concepts

about machine data. In this section, we identify

some core concepts and their relationships, towards

building a more complete ontology of Machine

information for the automotive industry.

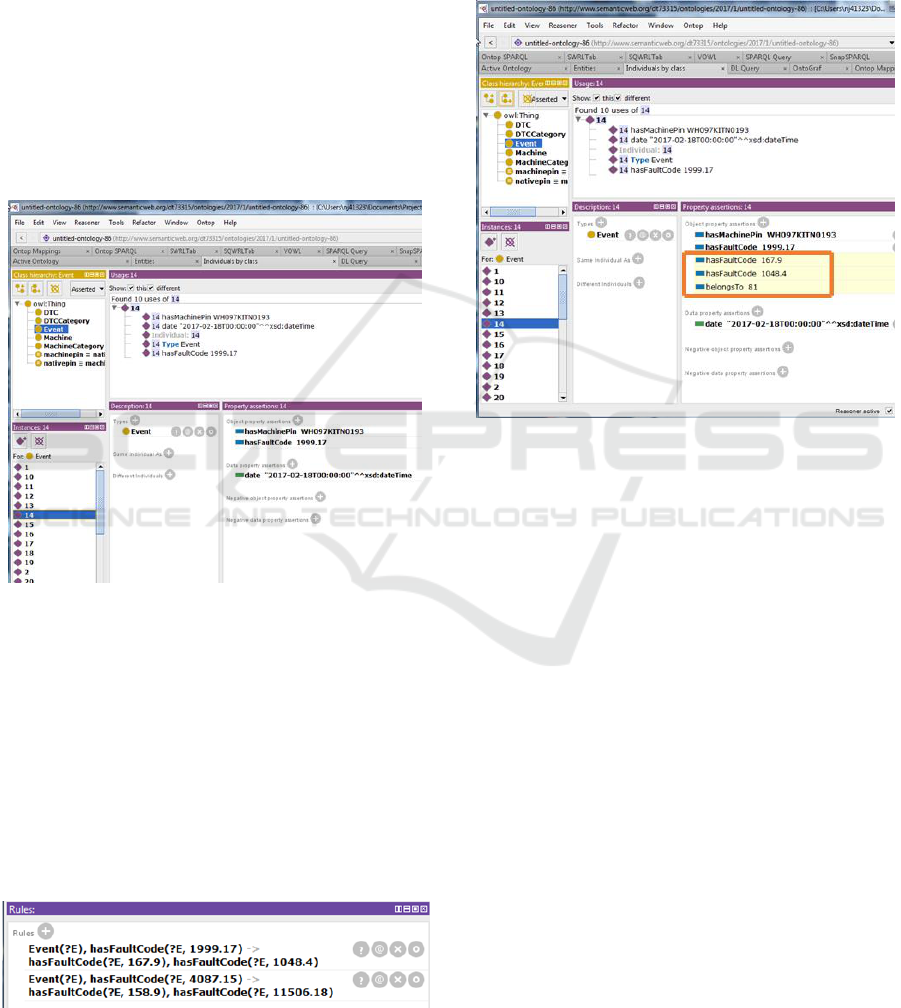

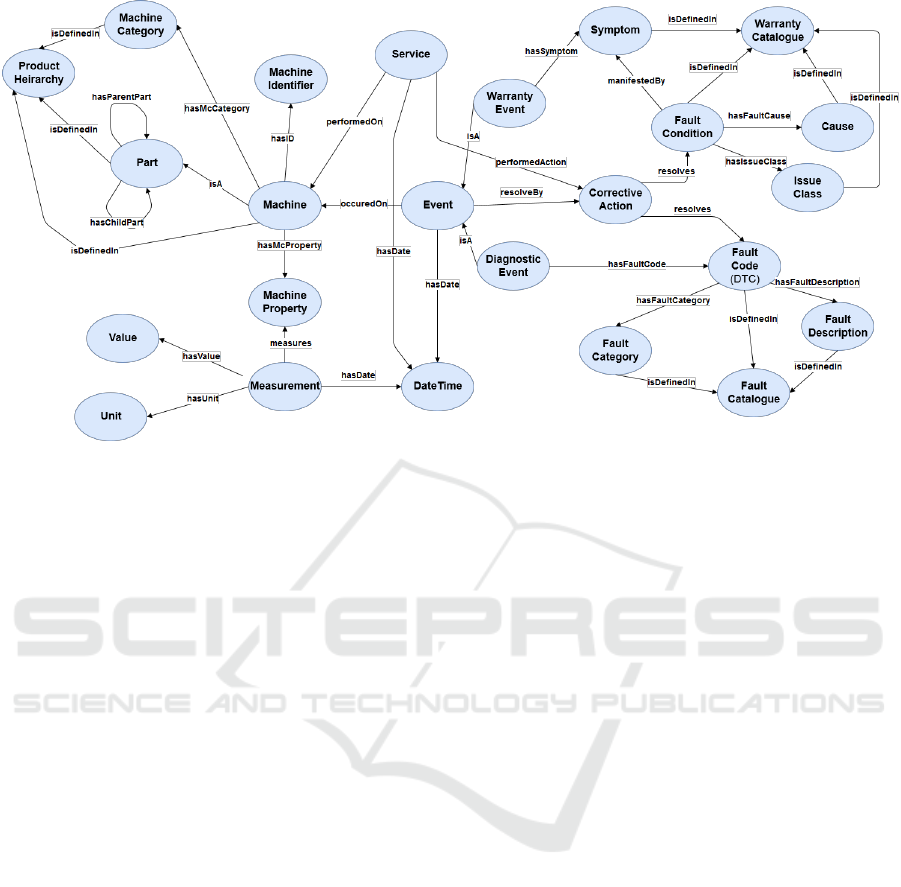

The developed ontology is shown in Figure 11.

As shown in the figure, the ontology captures five

aspects of machine information, viz. the structural

and product hierarchy as envisaged by the enterprise

for their family of products, sensor and measurement

data for a machine, service and maintenance records,

diagnostic event data, and warranty event data.

Such an ontology would enable users to capture

key concepts of machine information. Depending

upon the information captured and configured in

various databases, it may be necessary to include

additional concepts and relationships. In some cases,

the concepts and relations mentioned in the ontology

may not be explicit in the data and would need to be

inferred using reasoners. It is typical for the enterprise

to manage these five aspects of machine information

in separate databases. Use of such a complete

ontology, with appropriate mappings for the

databases, will enable complex analysis of machine

data. For example, one could study trends in sensor

measurements or occurrence of diagnostic trouble

codes in a period immediately preceding specific class

of warranty event, or identify correlation between

diagnostic events and sensor measurements.

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

172

Figure 11: Preliminary core ontology of Machine Information for Automotive industry.

5 CONCLUSION

In this paper, we have used a demonstrative a

domain ontology for machine information, along

with mapped data and reasoning to simplify

knowledge tasks. We have also presented a set of

core concepts that would be useful for developing a

more detailed ontology of machine information

across the automotive industry.

The proposed approach is expected to be

advantageous when performing analysis across

multiple and polymorphic data sources that capture

information of sensors, or reporting different types

of diagnostic events, etc. The proposed approach

separates the activities of maintaining the

equivalence between concepts, mapping of data

fields to concepts, and preparing data for specific

analytics activities. Thus, expert knowledge about

the evolution of the data structures, may not be

needed on the part of the individual performing data

preparation tasks.

The proposed method, therefore, shows benefits

in terms of reduction in the effort and expertise

required to perform the data preparation tasks.

However, the approach is computationally more

expensive, due to the additional logic based

computation needed from the reasoner. Also, the

domain information and the mapping between the

database tables and the concepts defined in the

Ontology, needs to be maintained, while the domain

as well as the databases evolve over time.

Finally, the proposed approach also has the

potential to enable merging concepts from multiple

domains, e.g. diagnostic data and warranty data,

identifying overlapping concepts and relationships,

and reasoning over combined datasets to draw

insights on the complex dependencies and

behaviours that are implicit in the data. Present day

vehicles are complex assemblies involving sub-

systems developed by different vendors. Therefore,

the authors argue for development of standard

ontologies for machine information. This would be

highly advantageous in drawing useful knowledge

and insights from the machine information being

collected.

REFERENCES

Ameri, F., McArthur, C. & Urbanovsky, C., 2012. A

Systematic Approach to Developing Ontologies for

Manufacturing Service Modeling. Graz, Austria, s.n.

Clark, K., 2015. Pellet Reasoner. [Online] Available at:

https://github.com/stardog-union/pellet [Accessed

March 2018].

CrowdFlower, 2016. 2016 Data Science Report, s.l.:

CrowdFlower.

Gruber, T., 2009. Ontology. In: L. Liu & M. T. Özsu, eds.

Encyclopedia of Database Systems. US: Springer US,

pp. 1960-1976.

Hardi, J., 2016. Cellfie plugin. [Online] Available at:

https://github.com/protegeproject/cellfie-plugin/wiki

[Accessed 6 Mar 2018].

Horridge, M., 2011. A Practical Guide to Building OWL

Ontologies Using Protégé 4 and CO-ODE Tools

Edition 1.3.

Simplifying Data Preparation for Analysis using an Ontology for Machine Data

173

Musen, M. A., 2015. The Protégé project: A look back and

a look forward. AI Matters, June, 1(4), pp. 4-12.

Musen, M. & Horridge, M., 2015. Snap-SPARQL: A Java

Framework for working with SPARQL and OWL.

Bethlehem, PA, USA, s.n.

Noy, N. F. & McGuinness, D. L., n.d. Ontology

Development 101: A Guide to Creating Your First

Ontology, s.l.: Stanford University.

Wood, M., 2013. Semantic Web, OWL & Protégé.

[Online] Available at: https://docslide.us/documents/

semantic-web-owl-protege.html [Accessed 3 March

2018].

Yang, K., Kim, W., Yang, J. D. & Kim, Y. K., 2013.

Ontology Matching for Recommendation of HS Code.

Hong Kong, s.n.

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

174