Quality Control Monitoring by using Artificial Neural Networks for an

Iberian Ham Industry

J. A Garc

´

ıa-Esteban

1

, Bel

´

en Curto

1

, Vidal Moreno

1

and Beatriz Mart

´

ınez

2

1

Department of Computer Science and Automatics, University of Salamanca, Faculty of Science, Salamanca, Spain

2

Technology Meat Station of Castilla y Le

´

on, Guijuelo, Spain

Keywords:

Monitoring of Food Quality Control, Food Sensory Predictions, Food Machine Learning Estimation.

Abstract:

The iberian ham is a high valued product, due to this fact, it is very important to offer to the costumer a high

quality food product and to ensure its organoleptic properties. Producers have to evaluate, periodically, its

sensorial attributes by a professional tasting panel. Due to high elevated organizational and economics costs,

in addition to, the sensory fatigue and the subjectivity of the panel members, only a few product lots are sam-

pled.

In this paper is proposed a cloud manufacturing based platform to monitor the quality of Iberian ham. The

success of this solution is based on cooperation and data exchange between the main agents involved in the

process: quality manager, professional tasters, production manager, inspection authorities, etc. Intelligent al-

gorithms have been embedded into the cloud monitoring platform to predict the ham sensory properties, using

the Near InfraRed Spectroscopy data from the product samples as input.

The key feature of the solution is that the sensory analysis is performed without gathering routinely a professi-

onal tasting panel, but the solution also allows to the quality manager, with advanced visualization techniques,

to monitor what is the merit figure related with a specific type of ham or shoulder. Another important aspect

of the solution is that, due to the huge amount of data coming from the elaboration process itself are available

is possible to fine-tune continuously the machine-learning algorithms to the particular producer and use them

intelligently to increase the competitiveness.

1 INTRODUCTION

Today, in the food industry the quality control based

on sensory tasting is restricted to the availability of

expert tasters or the consumption of the product by the

clients (Siegrist and Cousin, 2009). Both the custo-

mer and the taster, value the organoleptic characteris-

tics of the product such as the odour, flavour, colour,

texture, etc (Murray et al., 2001). Until now, tasting

has been limited to a restricted set of samples to eva-

luate complete vintages and also advertising samples.

Therefore, the final consumer has not the guarantee

that the product which he has acquired has the same

sensory characteristics as the product which has been

submitted to the sensory test.

Within the Iberian pork industry, ham and shoul-

der are products with high added value (BOE, 2014)

and with well known organoleptic characteristics.

Therefore, the producers of this sector need to fully

ensure the quality of his product to the final consu-

mer. However, to accomplish sensory measures is

very labor-intensive and involves a high economic

cost and time, and in many cases the measures can

be subjective due to the tasters state (tiredness, sen-

sory fatigue, etc). Unfortunately, this means that no

all lots can be assessed with this evaluation procedure.

Therefore, ham industry needs a reliable estimation of

the all sensory parameters of a larger set of lots, that,

perfectly, could reach the totality.

In this regard, the PAT (Process Analytical

Technology) allows to analyse and control, during

the manufacturing process, the quality and safety of

industrial products in order to assure that the final

obtained product fulfills with the quality standards.

PAT allows to increase the efficiency in the on-line

quality control process and during the manufactu-

ring process. In addition, it allows continuous sy-

stem learning, which will facilitate continuous impro-

vement (Grassi and Alamprese, 2017; Rathore and

Kapoor, 2017; Sommeregger et al., 2017). Applying

PAT in food industry along with the Near InfraRed

(NIR) technology is being used recently to monitor

the critical process parameters and the quality attri-

butes (Grassi and Alamprese, 2017). In this way, the

food industry can move from a rigid quality to a flexi-

ble quality (Sommeregger et al., 2017), achieving a

628

García-Esteban J., Curto B., Moreno V. and Martínez B.

Quality Control Monitoring by using Artificial Neural Networks for an Iberian Ham Industry.

DOI: 10.5220/0006911506280635

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018), pages 628-635

ISBN: 978-989-758-321-6

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

transformation towards the fourth industrial revolu-

tion or industry 4.0 (Oio et al., 2017; Efendioglu and

Woitsch, 2017; Ruohomaa et al., 2018).

In this sense, “Cloud Manufacturing” (CM) is an

essential technology to achieve the monitoring tools

for food companies. CM supports in transforming the

industry from a traditional business model to a more

collaborative, distributed and global business model.

More specifically, CM will allow cooperation and ma-

nufacturing activities at different places, departments

or organizations (Mourtzis and Vlachou, 2016). Con-

secuently, the industry will be more efficient and com-

petitive and products quality improves, which implies

an increase of the consumer satisfaction and, there-

fore, of the sales (Oio et al., 2017). By the hand of the

CM, “Big Data” (BD) appears as a technology which

allows to analyse the large amount of data that a com-

pany can have and use it intelligently to increase its

global competitiveness. Proper use of BD and mat-

hematical models can help notably to the efficiency

increment in the productivity and quality. The appli-

cation of advanced sensor systems and PAT paradigm

in combination with mathematical modelling techni-

ques of BD offer enhanced process understanding, al-

low on-line prediction of critical quality attributes and

subsequently real-time product quality control (Som-

meregger et al., 2017).

In this paper is presented ICatador, a software

platform based on Cloud Manufacturing with which is

possible to monitor the quality control process of Ibe-

rian ham and shoulders. The platform allows, on the

one hand, to keep the traditional control methods (tas-

ters panel) increasing the efficiency and allowing the

cooperation and the information exchange in a distri-

buted way. As an instrumental measurement, is used

Near InfraRed Spectroscopy (NIRS) on the samples,

which is based on the electromagnetic radiation ab-

sorption in the band from 780 to 2500 nm. NIRS is

well-known in material sensing, and its major benefit

is that it doesn’t need any sample preparation, furt-

hermore, it can yield a response on-line. Applications

of NIRS can be found in medical and biomedical stu-

dies, food science, forestry, and the pharmaceutical

and petroleum industries (Balabin and Safieva, 2011).

On the other hand, the platform incorporates Artificial

Neural Networks (ANNs), as a computational intelli-

gent technique (Big Data), to reproduce/predict the

tasters valuations about the food sensory attributes.

ANNs are computational techniques perfectly adap-

ted to discover non-linear trends between variables

(Boccorh and Paterson, 2002; Cancilla et al., 2014),

as is in our case the Near InfraRed spectrum and the

sensory attributes.

2 DEFINING THE QUALITY

CONTROL MONITORING

STRATEGY

The design goal in our strategy of the quality control

monitoring is to transfer the estimation of food or-

ganolectic properties from a tasting room to the pro-

duction chain and to tend towards at-line quality mo-

del.

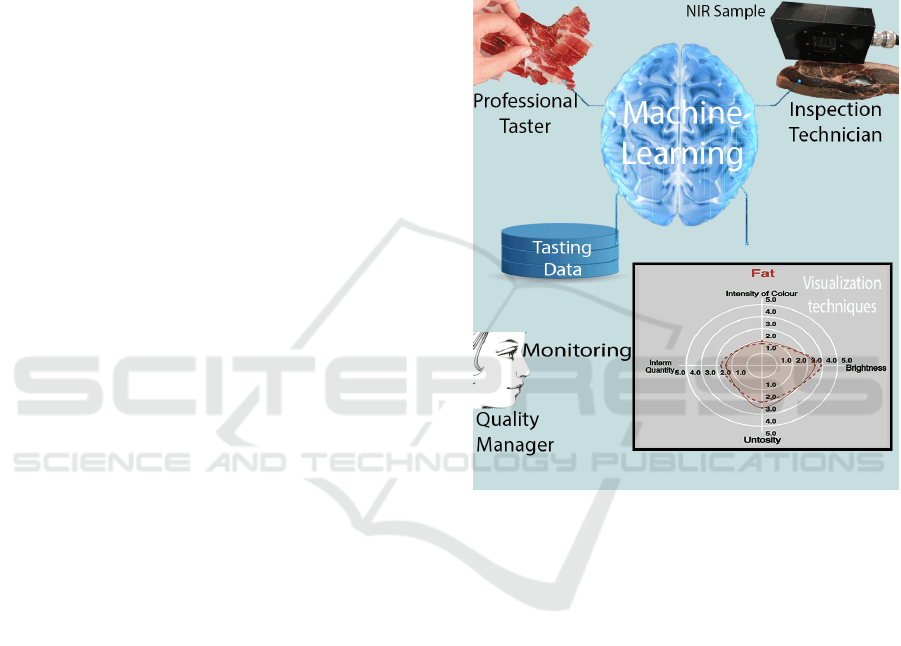

Figure 1: Conceptual scheme of the monitoring of the tas-

ting process.

The core of quality control monitoring is a set

of algorithms based on machine learning techniques

using a supervised learning set of functions that will

allow to predict the valuations of a professional taster,

having as input data a measurement provided by an

instrument, such as can be a NIR spectrometer (Fig.

1). The ultimate aim is not to replace the tasters pa-

nel, but to accelerate the tasting process by means of

alternative and objective valuation sources.

In our monitoring strategy, materialized in a cloud

platform, different actors have been defined, each

with a different role. All of them collaborate in the

quality control process of the food product, from dif-

ferent places of the company or the other companies.

The monitoring strategy is supported in a cloud plat-

form, which has been called ICatador, whereby the

collaborative process is established.

One of the main actors is the professional taster

(Fig. 1). The tasters will value the product following

a traditional methodology. They will introduce their

Quality Control Monitoring by using Artificial Neural Networks for an Iberian Ham Industry

629

scores directly through mobile devices, laptop or de-

sktop computers. Initially, this information provided

to the system will be used to train the prediction algo-

rithm (Fig. 1). In successive phases this information

will be used to optimize the algorithms of supervised

learning.

The organizer of taste panel will define the sen-

sory profile according to the product type. The sen-

sory profile contains the organoleptic attributes to

be evaluated by professional tasters, such as flavour,

odour, texture, etc. Different profiles can be defined

for each product type and, even, several profiles for

the same product type, if the quality standards are

modified. Automatically, tasters will have, through

the platform, the sensory attributes to be scored. The

procedure, the related legislation, the description of

the attributes, and in general any documentation can

be included by the organizer, and used as help by the

tasters

The quality inspection technician (Fig. 1) will be

the responsible of making the instrumental measures

of each ham sample. This task can be carried out

manually in the laboratory or at the line production

through a portable instrument and, in the best case,

automatically at line. Configuring the particular type

of product, the instrumental measures will be regis-

tered in the platform. Automatically, the sensory at-

tributes of this product will be predicted through the

obtained functions via supervised learning. These

functions, one for each attribute, are embedded in the

cloud platform.

Another actor involved in the monitoring strategy

is the responsible of supervising the products quality

from the tasting data (Fig. 1). The cloud platform ma-

kes easier the work of this user, because it allows him

to add, delete or modify products, and it is possible

to update the complete information concerning them,

such as the feeding of the animal of provenance, the

quality and the origin of this animals, date of ripening

start, ... The most remarkable feature of plataform is

that quality manager can check and visualize imme-

diately (Fig. 1), the values predicted by the machine

learning algorithm (artificial tasting) and the valuati-

ons that tasters make over the time. He can compare

the human scores with predictions, so that it can feed-

back the ratings and tune prediction functions to cor-

rect deviations.

3 SENSORY AND

INSTRUMENTAL

MEASUREMENTS

To perform a predictive evaluation of the Iberian ham

and shoulder organoleptic characteristics, such as vi-

sual appearance of lean, fat streaks, rancidity of fat,

characteristic odour, texture and flavour, is needed

sensory and instrumental measures of food samples.

The Iberian ham and shoulders with known racial

percentages and different feeding varying from acorn,

meadow feed and normal feed, were elaborated by the

partners of Guijuelo Protected Designation of Origin

(Spain). The sensory and instrumental tests have been

performed on 62 ham and shoulder samples, elabora-

ted by different partners. At the end of the ripening

process, tests were made for both products in labora-

tory (NIR spectroscopy) and sensory room.

In our work, the sensory evaluations were perfor-

med by a panel of 4 members trained in the use of

the QDA (Quantitative Descriptive Analysis) metho-

dology. The tasting panel was trained at the ITACYL

Meat Technology Station. As instrumental measu-

res have been used the data of NIR spectroscopy of

the ham and shoulder samples, which is based on the

electromagnetic radiation absorption in the band from

780 to 2500 nm. The NIRS measurements were obtai-

ned in the Analytical Chemistry laboratory of the Uni-

versity of Salamanca.

3.1 Sensory Measures

The sensory profile of the ham and shoulder were

carried out by a panel formed by 4 members trained

in the use of the QDA methodology (Murray et al.,

2001), which provides an objective description of the

products in terms of perceived sensory attributes.

Panel members were trained (ISO, 1994; ISO,

2003) on the sensory profile of ham during 18 ses-

sions. During the training was encouraged that the

group developed a common vocabulary for the evalu-

ation of the sensory characteristics, which contained

simple and specific terms that made easier the des-

cription of products. In the QDA methodology, re-

ference scales are used to evaluate the texture inten-

sity (Piggot and Mowat, 1991), olfactory-taste para-

meters, and also some foods are proposed as standards

to stablish the scale (B

´

arcenas et al., 2003). Specifi-

cally, the organiser had set the sensory profile with

23 sensory attributes, framed within of: visual ap-

pearance of lean (intensity, homogeneity and bright-

ness), fat (intensity of colour, brightness, untosity, in-

termuscular quantity), fat streaks (quantity, homoge-

neity, thickness and uniformity), characteristic odour,

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

630

texture (stickiness, hardness, crumbling, fibrousness,

pastiness and juiciness), flavour (intensity of sweet-

ness and saltiness), characteristic flavour (intensity

and persistence) and, finally, rancidity of fat. Du-

ring the panel training, the evaluators along with the

organizer agreed the established reference standards,

the terminology definitions and the evaluation techni-

ques. For quantification the intensity of each attribute,

6 point scales are used, where “0” is the lack of para-

meter, “1” is the minimal intensity and “5” is the max-

imum intensity for each of the parameters (B

´

arcenas

et al., 2003).

In the product evaluation phase, the hams and

shoulders were scored by panelists according to the

description list defined during the training. The sen-

sory measures on which our work is based correspond

to different tasting sessions of the ham and shoulders.

This sensory information constitutes the training

data and the neural networks validation.

3.2 Instrumental Measures

Spectroscopic sensors are optimal instruments for real

time analysis during manufacturing, being rapid, non-

invasive, very flexible, and rugged. NIRS, in particu-

lar, with its ability to fingerprint food materials and to

simultaneously analyze different phenomena, is one

of the predominant e-sensing technologies used in

PAT (Grassi and Alamprese, 2017). The NIR techno-

logy is based on the electromagnetic radiation absorp-

tion in the band from 780 to 2500 nm and provides a

spectrum represented as values of log

1

R

where R

is the reflectance against the wavelength. The NIR

spectra were obtained with an analyser Foss NIR 5000

in the band of 1100-2000 nm with a spectral reso-

lution of 2 nm. The recording of NIR spectra (Fig.

2) was performed applying the carbon fiber probe di-

rectly on the ham or shoulder sample, at room tem-

perature (20-23

o

C). Previously to each record, the

probe window was cleaned to minimize the cross-

contamination.

The recorded information constitutes the instru-

mental measures which are used for neural network

Figure 2: NIR spectra corresponding to a ham sample.

off-line training and validation. When working on-

line, the NIR records of each ham or shoulder sample

constitute the instrumental measures for the sensory

attributes prediction through ANN. The quality ma-

nager can observe the NIR spectra of each sample to

detect possible errors.

4 PREDICTION MODEL BASED

ON ARTIFICIAL NEURAL

NETWORKS

The mathematical model used to estimate the sensory

characteristics of the ham and shoulder samples is

based on ANNs, which are framed within no-lineal

(Della-Lucia and Minim, 2010) statistical data mo-

deling tools. Specifically, a Multi-Layer Perceptron

(MLP) ANN was used, where the processing ele-

ments (PE) are structured in three layers: an input

layer where the instrumental measures will be ente-

red, an intermediate or hidden and an output layer

where the sensory attribute to be evaluated is obtai-

ned.

The software application JavaNNS (Java Neural

Network Simulator) has been used as design, trai-

ning and validation tool of the ANN. The ANN mo-

del used is implemented within the application as a

“multi layer perceptron network”. After several tri-

als, the network model is constituted as follows:

• An input layer with three processing elements

(PE), whose inputs are the principal components

(PCA) of the NIR spectra. The NIR spectra that

has been recorded ranges from 1100 to 2000 nm

with a spectral resolution of 2 nm. With 3 values

of Principal Components from NIR spectrum, the

99.98% of the spectral variability is expressed. In

this way the spectral information is compressed

and the number of input values is reduced from

451 to 3.

• A hidden layer with 5 PE

• A output layer with 1 PE which corresponds to the

modelled sensory characteristic.

For each sensory characteristic, a network, with

the previously topology commented, is built. These

ANNs were trained using the 80% of the dataset,

randomly selected for each ANN. Once each ANN

was trained, its accuracy were evaluated on the test

dataset formed by the remaining 20%. These data

were not shown during the training and were selected

randomly for each ANN.

Quality Control Monitoring by using Artificial Neural Networks for an Iberian Ham Industry

631

5 CLOUD PLATFORM

IMPLEMENTATION

ICatador system is developed to be used in cloud from

any computing device (PCs, tablets, smartphones...)

so that it can be accessible from any place and any

moment.

ICatador has a MVC (Model-View-Controller) ar-

chitecture. Views are developed in HTML, the con-

trollers in Javascript using the open source frame-

work AngularJS. Finally, data model is developed in

a MySQL database. Model has functionalities which

allow selecting automatically the sensory profile to

which a product belongs, making that this fact fully

transparent to users who only have to introduce or

consult data. For the communication between the da-

tabase and the controllers is used a DAO (Data Access

Object) pattern, which is developed in PHP, making

easier maintenance works.

To make easier the ICatador adaptation to new

sensory profiles or to changes in existing ones, a tem-

plate system has been implemented which will allow

to add, modify or delete sensory profiles according to

the needs of the users. All of it is transparent for them

with a dynamic adaptation.

Graphics and visual representations have been de-

veloped using the D3.js library which allows the

graphic representation from the data. Therefore,

thanks to this library, the system can create different

graphical visualizations (histograms, parallel coordi-

nates, radars) to represent the sensory attributes infor-

mation, either from human or artificial scores.

6 RESULTS: SENSORY

ATTRIBUTES PREDICTION IN

ICatador

As main result, ICatador is the cloud platform that

can be used by ham producers and quality regulatory

agencies for on-line quality control of their products,

following the PAT guidelines to monitoring the pro-

duct sensory parameters. The quality manager, tas-

ters, tasting panel organizer and the production line

inspection technician collaborate (Fig. 1), from dif-

ferent places, on the quality control tasks. The con-

tributions of each agent are combined to increase the

efficiency and to fulfil demands of the food industry.

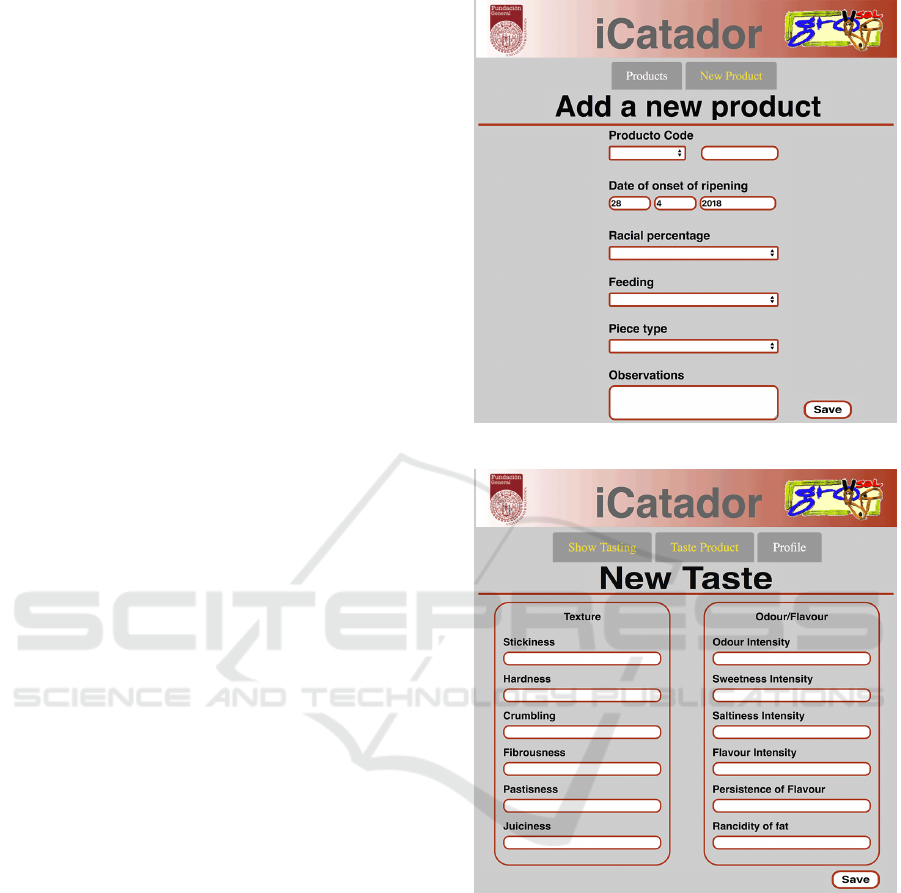

In ICatador, the quality manager introduces the

products (Fig. 3) which will be evaluated, with all

the data concerning them (racial percentages, animal

feeding, elaboration date, ...).

The organizer of the panel draws up the sensory

Figure 3: New product entry in ICatador.

Figure 4: “Odour/Flavour” and “Texture” of sensory profile

used by the tasters.

profile (Fig. 4) with the attributes (fully configura-

ble), identifies the products to be tasted, selects the

tasters according to their characteristics stored in the

Database, chooses the help regulation and documen-

tation and, once the tasting is done, scores the tas-

ters. Through forms (Fig. 4), the tasting panel mem-

bers will enter their evaluations directly into the plat-

form, once they are identified, using mobile devices

such as tablets or smartphones. By the product iden-

tifier, ICatador recovers the sensory profile which the

product belongs. Automatically, the sensory attribu-

tes, that tasters have to enter, will be showed together

with the working procedure and the help descriptions.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

632

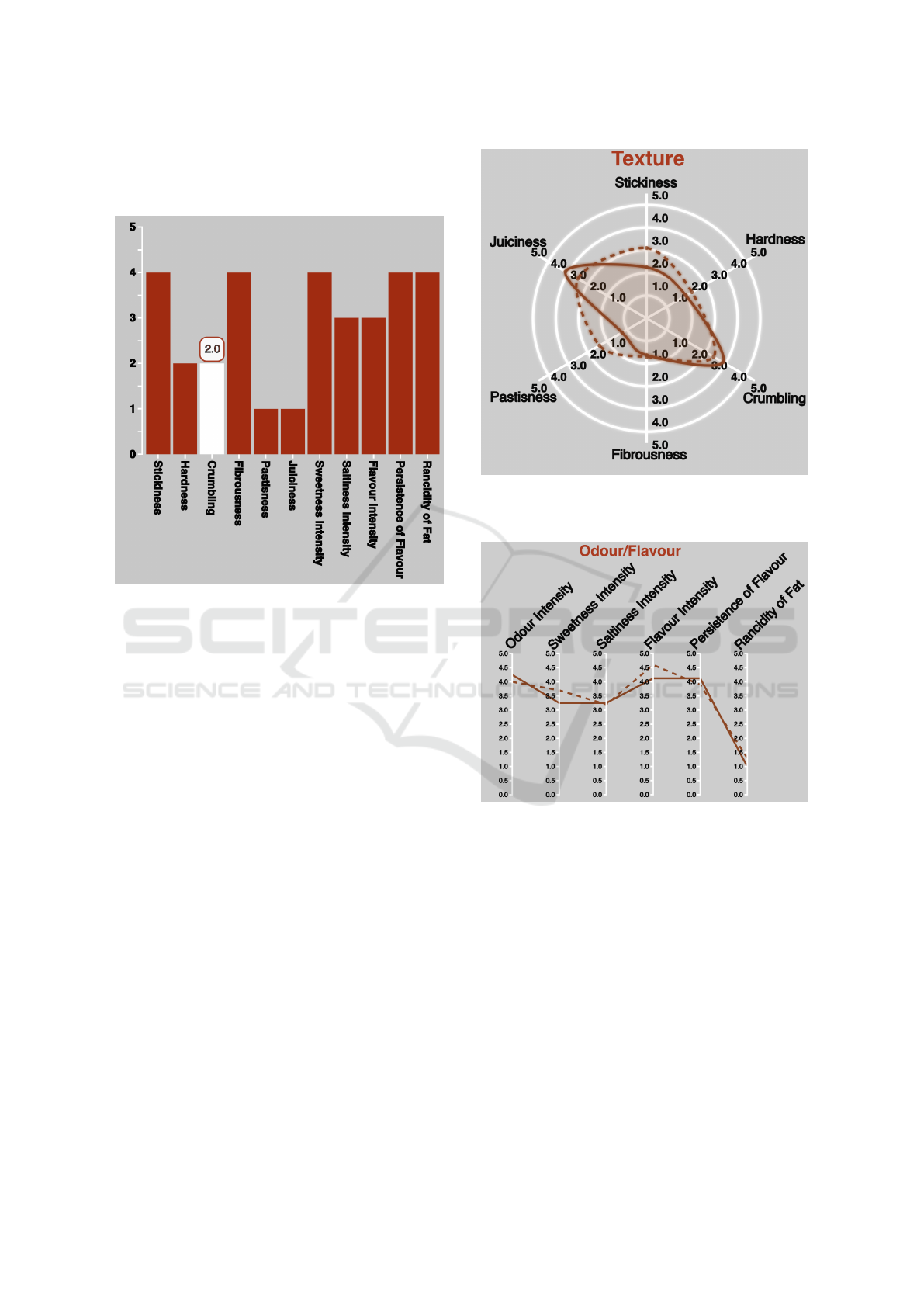

The quality manager can visualize the attribute sco-

res completed by tasters, individually or on average,

through graphs as a histogram (Fig. 5).

Figure 5: Histogram of the panel scores of a determinate

sample.

The spectral analyser generates a file with the

data of the NIR spectroscopy of the sample. The in-

spection technician, in production, incorporates the

file in the ICatador Database, selecting the date and

the product identification. Actually, in our monito-

ring platform this task is performed manually from

the laboratory, or from any place of the manufacturing

plant, but, thanks to actual technological innovation,

this information can be incorporated automatically.

The quality manager can observe the NIR spectra of

each sample (Fig. 2) to detect possible errors.

After the training and validation of each neural

network (which is performed off-line) with Deep-

Learning techniques, the quality manager, in his daily

work, can use ICatador to predict the sensory attribu-

tes of a product. An artificial tasting (tasting based

on ANN) is extraordinarily simple and it can be per-

formed anywhere in which a NIR analyser is availa-

ble. The starting point is the NIR record that is per-

formed of a product sample and, then it is enter to

ICatador through a file. After its loading, when the

option “Artificial tasting” is clicked, the platform ICa-

tador calculates the organoleptic attribute predictions

which have been configured for this product by the

quality manager.

Using advanced visualization techniques, the re-

sults, grouped by categories, are displayed through

Figure 6: Artificial tasting (discontinuous line) of the attri-

butes of “texture” against the average of professional tasters

(continuous line).

Figure 7: Artificial tasting (discontinuous line) of the attri-

butes of “Odour/Flavour” against the average of professio-

nal tasters (continuous line).

graphs of parallel coordinates (Fig. 7) or radars. The

quality manager, at a glance, can have the “merit fi-

gure” of the considered sample (Fig. 6) to detect the

deviations from the expected quality. The merit figu-

res are grouped according to the attribute typologies.

The result will be stored in the Database for subse-

quent analysis for the system participants (quality ma-

nagers, production managers, etc.).

7 CONCLUSIONS

In food industry, the quality control operations based

on the sensory analysis are restricted to the availabi-

Quality Control Monitoring by using Artificial Neural Networks for an Iberian Ham Industry

633

lity of the experts, which implies relatively high eco-

nomic costs, a certain degree of subjectivity associa-

ted with the sensory fatigue, and, in addition of the

arduous organisational task. This restrictions impose

that the quality control are reduced to certain lots.

As an alternative approach, the machine learning

techniques along with instrumental measures appear

as an intelligent solution to obtain a reliable estimate

of the sensory parameters of the food products.

In this work, a monitoring tool supported on a

cloud platform, has been presented. The core of

the ICatador tool is a suite of intelligent algorithms

(ANNs) which calculate organoleptic attributes esti-

mates using NIR spectrometry data from samples as

input.

To make possible that the ICatador monitoring

tool had all the ham and shoulders quality data avai-

lable, the main agents (quality manager, tasters, tas-

ting organizer, quality inspector) collaborate and ex-

change information from different points and, in ad-

dition, instrumental data are systematically incorpora-

ted. This collaborative model based on the data, will

allow to have a wide range of data coming from the

production process itself. In this way, the intelligent

algorithm suite can be tuned and adapted to the pro-

cess itself to avoid deviations.

Through the proposed approach, iberian ham ma-

nufacturing companies can carry out an intelligent

production based on the data, they can get that final

product gathers the same sensory characteristics fixed

in the production goals.

The Icatador platform that has been presented in

this paper combines the use of Information and Com-

munication Technologies with Artificial Intelligence

techniques such as ANNS. Therefore, it can be in-

cluded within the concept of Industry 4.0, and contri-

butes to the digitization of the industry. Its goals are

to improve efficiency, quality control times, flexibility

and enables a distributed responsibilities within of the

industrial sector.

ACKNOWLEDGEMENTS

This work has been supported by the General Founda-

tion of the University of Salamanca through the Plan

TCUE 2015-2017, co-financed by European Regional

Development Fund (ERDF) and the Castilla - Le

´

on

Council.

REFERENCES

(1994). ISO 11035: 1994:sensory analysis – identification

and selection of descriptors for establishing a sensory

profile by a multidimensional approach.

(2003). ISO 4121: 2003: Sensory analysis – guidelines for

the use of quantitative response scales.

(2014). Real decreto 4/2014, de 10 de enero, por el que se

aprueba la norma de calidad para la carne, el jam

´

on,

la paleta y la ca

˜

na de lomo ib

´

erico.

Balabin, R. M. and Safieva, R. Z. (2011). Biodiesel classi-

fication by base stock type (vegetable oil) using near

infrared spectroscopy data. Analytica Chimica Acta,

689(2):190–197.

Boccorh, R. K. and Paterson, A. (2002). An artificial neu-

ral network model for predicting flavour intensity in

blackcurrant concentrates. Food Quality and Prefe-

rence.

B

´

arcenas, P., Elortondo, F. P., and Albisu, M. (2003).

Sensory changes during ripening of raw ewes’ milk

cheese manufactured with and without the addition of

a starter culture. Food Science.

Cancilla, J. C., Wang, S. C., D

´

ıaz-Rodr

´

ıguez, P., Matute, G.,

Cancilla, J. D., Flynn, D., and Torrecilla, J. S. (2014).

Linking chemical parameters to sensory panel results

through neural networks to distinguish olive oil qua-

lity. Journal of Agricultural and Food Chemistry.

Della-Lucia, S. M. and Minim, L. A. (2010). Redes neurais

artificiais: fundamentos e aplicac¸

˜

oes. In UFV, V. E.,

editor, An

´

alise sensorial: estudos com consumidores,

chapter 9, pages 258–279. Springer-Verlag New York,

Inc.

Efendioglu, N. and Woitsch, R. (2017). A modelling met-

hod for digital service design and intellectual property

management towards Industry 4.0 caxman case. Inter-

national Conference on Serviceology.

Grassi, S. and Alamprese, C. (2017). Advances in NIR

spectroscopy applied to process analytical technology

in food industries. Current Opinion in Food Science.

Mourtzis, D. and Vlachou, E. (2016). Cloud-based cyber-

physical systems and quality of services. The TQM

Journal.

Murray, J. M., Delahunty, C., and Baxter, I. A. (2001).

Descriptive sensory analysis: past, present and future.

Food Research International.

Oio, K.-B., Lee, V.-H., Tan, G. W.-H., Hew, T.-S., and Hew,

J.-J. (2017). Cloud computing in manufacturing: The

next industrial revolution in malaysia? Expert Systems

with Applications.

Piggot, J. R. and Mowat, R. G. (1991). Sensory aspects of

maturation of cheddar cheese by descriptive analysis.

Journal of Sensory Studies.

Rathore, A. S. and Kapoor, G. (2017). Implementation of

quality by design towards processing of food products.

Preparative Biochemistry and Biotechnology.

Ruohomaa, H., Kantola, J., and Salminen, V. (2018). Va-

lue network development in Industry 4.0 environment.

Advances in Intelligent Systems and Computing.

Siegrist, M. and Cousin, M.-E. (2009). Expectations influ-

ence sensory experience in a wine tasting. Appetite.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

634

Sommeregger, W., Sissolak, B., Kandra, K., von Stosch,

M., Mayer, M., and Striedner, G. (2017). Quality by

control: Towards model predictive control of mamma-

lian cell culture bioprocesses. Biotechnology Journal.

Quality Control Monitoring by using Artificial Neural Networks for an Iberian Ham Industry

635