Improving the Joint Mobility of Acute Rotator Cuff Injury by

Portable Rehabilitation Device

Laura Jiménez Guzmán, Mariana Torrente Rocha and Hernando Leon-Rodriguez

Bio-Engineering Department, Faculty of Engineering, El Bosque University, Bogota, Colombia

Keywords: Acute Injury, Rotator Cuff Rehabilitation, External-internal Rotation, Soft-rehabilitation Robot, Portable

Robot.

Abstract: The incidence of shoulder pain in the general population is around 11.2 cases per 1,000 patients per year. It

is considered to be the most prevalent soft tissue pathology, with an estimated incidence of rotator cuff

injuries of 3.7 per 100,000 per year. The deterioration of the components of the rotator cuff is one of the

most frequent causes of musculoskeletal pain and disability in the world. The conditions of the rotator cuff

increase with the age and overuse of the joint, therefore, elderly patients are more affected. This paper

presents the development of one soft and portable rehabilitation prototype robot that aims to be evaluated

with patients in near future as a suitable device for rehabilitating acute rotator cuff injuries through clinical

examinations. The portable robot presented was design from biomechanical analysis and ranges of

kinematics and joint dynamics; aspects that determined important requirements for obtaining greater

functionality of the prototype´s portability and with the identification of pre-set tasks that executes two

types of specific movements: flexion / extension and external / internal rotation by means of a soft

rehabilitation and portable robot device.

1 INTRODUCTION

The component´s deterioration of the rotator cuff is

one of the most frequent causes of musculoskeletal

pain and disability in the world. The incidence of

shoulder pain in the general population is around

11.2 cases per 1,000 patients per year. It is

considered to be the most prevalent soft tissue

pathology, with an estimated incidence of rotator

cuff injuries of 3.7 per 100,000 per year. The rotator

cuff is composed of four muscles: supraspinatus,

infraspinatus, minor round and subscapularis, and its

functions are to offer mobility, strength and

stabilization to the glen-humeral joint, due to the

relationship between the glen-humeral ligaments and

the joint capsule. The conditions of the rotator cuff

increase with the passage of time, since they have a

direct relationship with a process of deterioration

rather than with a traumatic event, so the problem

increases with age and overuse of the joint,

therefore, elderly patients are more affected.

However, the incidence of shoulder pain in workers

reaches up to 18.3%. In order to decrease pain and

recover shoulder movement, patients are usually

treated by regular sessions with a physiotherapist.

The pathology of the rotator cuffs is associated

with the overuse of the joint, either by work, sports,

vascularity, mechanical failure located in the

supraspinatus tendon, ruptures caused by

deterioration or even by the entrapment that the

tendon suffers between the humerus and the

acromion. There are other risk factors that can lead

to a rotator cuff injury, such as obesity,

hypercholesterolemia, smoking, genetic factors,

anatomical variations, scapular dyskinesia and glen-

humeral instability. (Orth, Paré, 2017)

Rehabilitation has always been a social concern

in the fields of health study and engineering. The

effects of disability due to rotator cuff injuries

decrease a person's productivity in areas such as

population interaction, so the need for improvement

goes beyond an ideal biomechanical state.

Currently, the rehabilitation of rotator cuffs starts

from the application of conventional therapies, to the

use of robotics as alternative mechanisms, which

integrate engineering concepts such as compensation

of force, motor control at speeds calibrated

according to the motor functions of each individual

and sensory contributions that through the repetition

of exercises in intensive training programs manage

Guzmán, L., Rocha, M. and Leon-Rodriguez, H.

Improving the Joint Mobility of Acute Rotator Cuff Injury by Portable Rehabilitation Device.

DOI: 10.5220/0006913104870495

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 487-495

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

487

to recover mobility limitations. (Sicuri, 2014)

(Gonçalves, 2016) Some of the referents are Armeo

Spring who by providing support for the weight of

the arm, allows patients to use any remaining motor

function and encourages them to reach a greater

number of reach and grip movements based on

specific therapeutic objectives, from an arm grab

exoskeleton (Gijbels, 2011) (Armeo, 2018); In-

Motion Shoulder-Elbow Robot allows to quantify

the control of the motor of the upper extremities and

with the recovery of the movement, which allows

the doctors to distinguish the real recovery from the

compensation of the patient (Cannan, Hu, 2012)

(InMotion, 2018); shoulder exoskeletons; Cable-

Robots who have very good kinematic and dynamic

characteristics, and also show other properties such

as: portability and economy of costs, which also

make them suitable for medical applications and

rehabilitation even though based on the physical

nature of the cables that can only pull and not push

(Nunes, 2011); isokinetic force machines such as

Humac Norm Testing and Rehabilitation System

that allows the diagnosis and treatment of the

performance of muscles and joints of orthopaedic

patients, starting from the principle of isokinetic

force, under the correct anatomical positioning and a

positive stabilization to examine the musculature

that surrounds the shoulder. (Habets, 2018) Based on

the aforementioned developments, the new

technologies point to the use of soft materials, which

improve the ergonomics of the rehabilitation system,

within the exponents of bio-robotics is active soft

orthotic system (Kesner, 2011; Ciarán, 2017;

Galiana, 2012).

However, standard rehabilitation methods

require the attention of trained physiotherapists to

help patients through a series of movement exercises

in order to stimulate the regeneration of their muscle

control, a process that is slow, expensive, high

demand , and it requires the transfer of the patient to

a rehabilitation clinic to do a regular job with the

therapists and have a significant improvement,

therefore, the objective of this work is to design an

affordable and portable device that uses actuators

and sensors, and also , act through the movement in

the sagittal, ventral and coronal plane for the

rehabilitation of the patient from his own home

without a dedicated therapist, in order to elevate the

self-efficacy of the subject and the restoration of the

dynamics of interaction of the same with its

activities every day and with the people around him.

2 BIOMECHANICAL

EVALUATION OF PATIENT

The biomechanics establishes a specific protocol to

certain angles according to each movement as a

pattern of healthy patients presented in table 1, the

flexion from 0° to 180°, the extension from 0° to 60°

for the sagittal plane; adduction from 0° to 45°,

abduction from 0° to 180° in the frontal plane; the

flexion of 130° to 5°, extension of 40° to 50° with

respect to the horizontal plane; external rotation

from 0 ° to 40° to 60° and internal rotation from 0°

to 90°; and external and internal movements, both up

to 70°. Although the biomechanical analysis allows

limit the total movement angles of the articulation,

the functional ranges of mobility are the

representatives of movement with minimum balance

in the comfortable execution of daily activities,

angles that for this case, represent acceptable ranges

considering a process of Joint rehabilitation due to

an injury. From this, the mechanism of operation of

the prototype is designed, being specific in

movements of flexo-extension (A), and internal and

external rotation of the Shoulder (B).

Table 1: Ideal biomechanical ranges of the gleno-humeral

joint and functional ranges.

A B

Motion Flexion Extension

Internal

rotation

External

rotation

Biomechanical

range

0-180º 0-60º 0-90º 0-40º 60º

Functional

Range

0-120º 0-45º 0-70º 0-50º

Differential 60º 15º 20º 10º

In order to analyse biomechanically the Gleno-

humeral joint, two isokinetic strength tests are

performed on a patient with Shoulder injury, at

BodyTech Sport Medicine. The tests are related to

movements of flexion and extension, and external

and internal rotation. Because we want to make a

preliminary analysis of the shoulder muscle response

in terms of strength; two tests of movements were

performed to measure the concentric forces. (Tables

2 and 3)

Table 2: Isokinetic force evaluation report. Flexion and

extension shoulder (supine).

Speed Force Repetitions

60/60

degrees/

seconds

Sub

Maximum

5

Maximum 5

180/180

degrees/

seconds

Sub

Maximum

4

Maximum 15

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

488

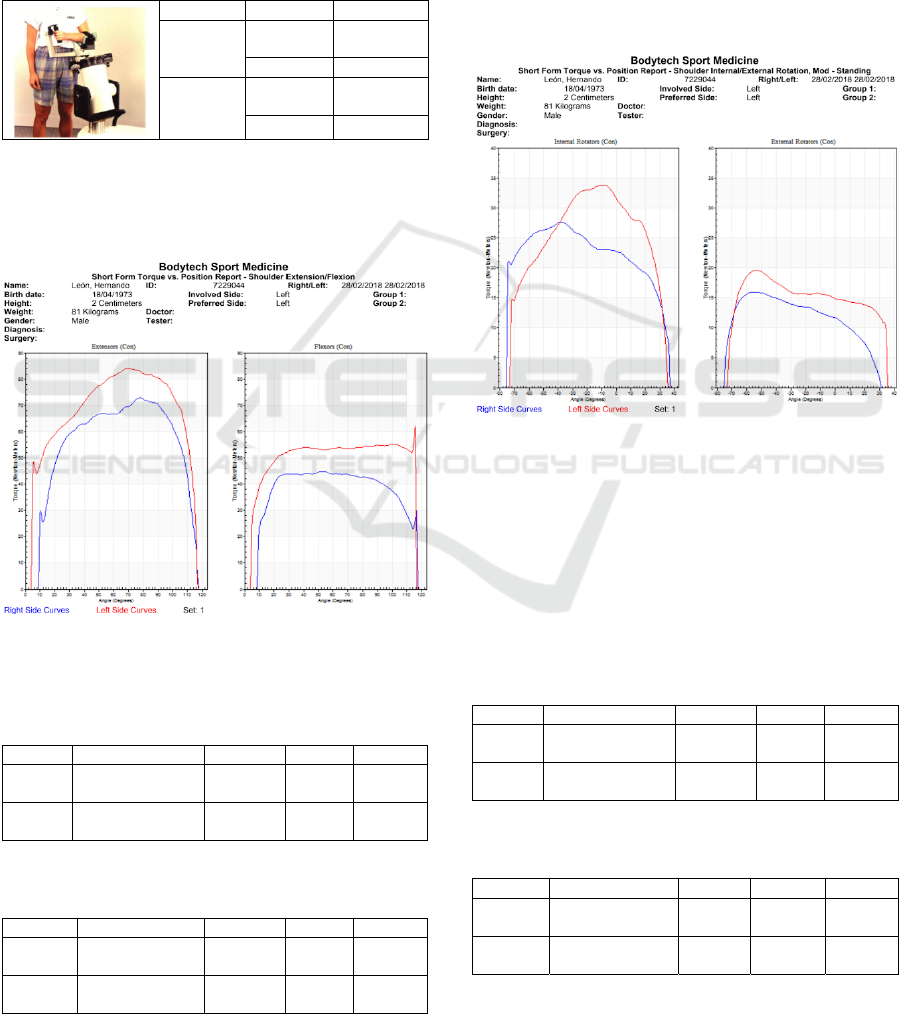

The results obtained are showing in figure 1 and

2 as follow: Curves of ratio of angles (degrees) and

torque (Newton by meters) for left and right

extremity. Tabulation of evaluation parameters for

left and right limbs in extension and flexion move-

ment, internal and external rotation: peak torque,

total work done, range of movement, deficits.

Table 3: Isokinetic stress evaluation report. Internal and

external shoulder (standing) rotation.

Speed Force Repetitions

60/60

degrees/

seconds

Sub

Maximum

5

Maximum 5

180/180

degrees/

seconds

Sub

Maximum

4

Maximum 15

Bilateral evaluation of extensors and flexors in

bilateral shoulder joints (supine) was performed on

Humac Norm Isokinetic dynamometer equipment,

complete range of motion is showing in figure 1.

Figure 1: Graphic of torque vs position shoulder

extension/flexion.

Table 4: Results evaluation of flexo test-shoulder

extension in speed of 60°/sec.

Speed Muscular Group Right Left Deficit

60°/sec

Concentric

Extenders

73 N/m 84 N/m 13%

60°/sec

Flexors

Concentric

45 N/m 65 N/m 31%

Table 5: Results flexo test-shoulder extension in speed of

180°/sec.

Speed Muscular Group Right Left Deficit

180°/sec

Concentric

Extenders

45 N/m 52 N/m 18%

180°/sec

Flexors

Concentric

35 N/m 65 N/m 50%

The results in the isokinetic evaluation,

maximum torque and total work of shoulder flexors-

extensors are identified in concentric contractions

(60, 180 degrees). Concentric isokinetic evaluation

was performed, given the following results. (Tables

4 and 5).

The second test was performing in bilateral

assessment of internal and external rotation in

bilateral shoulder joints (standing °) was performed

on Humac Norm isokinetic dynamometer

equipment, complete range of motion is showing in

figure 2.

Figure 2: Graphic or torque vs position shoulder

internal/external rotation.

In the isokinetic evaluation, maximum torque

and total work of shoulder flexors-extensors are

identified in concentric contractions (60, 180

degrees). Concentric isokinetic evaluation was

performed, given the following results. (Tables 6

and 7)

Table 6: Results of evaluation in test of internal and

external rotation of shoulder in speed of 60°/sec.

Speed Muscular Group Right Left Deficit

60°/sec

Concentric

Internal Rotation

27 N/m 34 N/m 20%

60°/sec

External rotation

Concentric

16 N/m 19 N/m 14%

Table 7: Results of evaluation in test of internal and

external rotation of shoulder in speed of 180°/sec.

Speed Muscular Group Right Left Deficit

180°/sec

Concentric

Internal Rotation

19 N/m 23 N/m 18%

180°/sec

External rotation

Concentric

8 N/m 11 N/m 25%

Improving the Joint Mobility of Acute Rotator Cuff Injury by Portable Rehabilitation Device

489

3 PROTOTYPE CONCEPTS AND

REQUIREMENTS

The design of the prototype to achieve shoulder

rehabilitation, should consider the following

requirements:

The first requirement corresponds to the way in

which the prototype adapts to the anatomical

variations of people with an age range of 49 to 60

years, starting at 95% of the percentiles, it is

possible to determine the average of the magnitudes

of each segment articulate, in order to obtain an

adjustable prototype for people who are within that

age range.

The second requirement is based on the fact that

the design must be ergonomic in order to allow its

portability and comfort at the moment of the

execution of the therapies.

The third requirement refers to the affordability

of the prototype since its low robustness decreases

the acquisition value, as well as decreases in costs,

which leads to the displacement of people to

healthcare entities by a therapy, since the proposal

goes focused on a type of independent therapy

developed in the home.

The fourth requirement is based on the

appropriate selection of actuators, whose function is

to mobilize the arm and forearm in 4 different types

of movements: flexion, extension, internal and

external rotation according to the degrees of

functionality of the patient. The movement is

continuously passive, since the high torque is

inversely proportional to the speed of the actuator.

The fifth requirement relates the benefits

provided by the prototype in terms of the execution

of therapies to improve the joint mobility of rotator

cuff injury and the investment that is made.

4 PROTOTYPE DESIGN

The methodology developed for the prototype

design starts from the population delimitation to

which it is addressed. This is how the dimensions of

this, are based on the average of Latin American

percentiles of men and women from 49 to 59 years,

based on the prevalence of injury in women for their

fourth decade of life and in men from the fifth.

Based in the biomechanical evaluation and the

mentioned requirements a concept prototype

showing in figure 3 is designed under the operation

of a portable system driven by two gear-motors. The

kinematic and dynamic analyses are based on two of

the movements adapted by the articulation: flexion /

extension, external / internal rotation which activate

two degrees of freedom respective to the movements

of flexion and extension, and internal and external

rotation. The prototype consists of two supports for

the arm and the forearm, which will maintain the

extremity in the ranges of joint movements, required

performing the different rehabilitation exercises.

(Nef, 2011; Kim, 2017; Hunt, 2013).

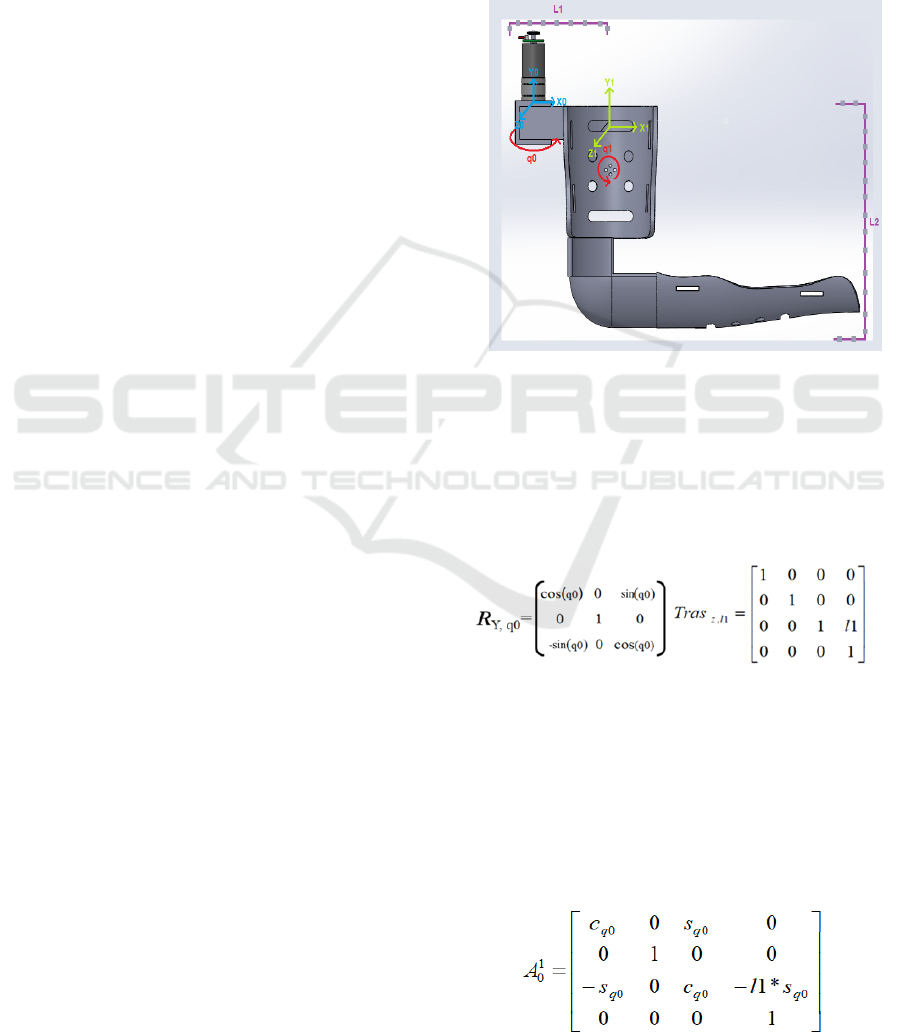

Figure 3: Design of shoulder rehabilitation robot first

joint.

4.1 Kinematic Design

The kinematic system was obtained from a reference

axis of the shoulder, which was proposed for the

design of the system in the arm. (figure 3)

(1)

The rotation matrix RY, q0 gives the projection

of the coordinates in two coordinate systems. The

equation 1 is the first rotation matrix it is evident

that the system rotates on the Y axis and the

articulation that rotates on this axis is the one called

q0. In the translation matrix Tras z, l1 we can see

which link is transferred for the first system and on

which axis the movement is observed. In this case,

link 1 moves on the z axis.

(2)

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

490

The equation 2 is the homogenous

transformation matrix A01, we can see the

projection of system 0 in system 1 and we can see

the sum or product point between the matrices of

rotation and translation. The breasts and cosines that

are evident in the rotation matrix, are the projections

of the vectors in both x and y.

(3)

The rotation matrix RZ, q1 gives the projection

of the coordinates in two coordinate systems. In the

first rotation matrix it is evident that the system

rotates on the Z axis and the articulation that rotates

on this axis is the one called q1. In the translation

matrix Tras

x,l2

you can see which link is transferred

to the second system and on which axis the

movement is observed. In this case, link 2 moves on

the x-axis.

(4)

In the homogeneous transformation matrix A12,

we can see the projection of system 1 in system 2

and we can see the sum or product point between the

matrices of rotation and translation.

(5)

After obtaining the homogeneous transformation

matrix of the system q1 and q0, multiplication or

cross product of both homogeneous matrices is

performed to find the position of the end terminal,

with respect to the whole system.

(6)

The Jacobian matrix is used to determine the

speed of movement in each of the axes, which is

solved by the partial derivative of the last column of

the total homogeneous transformation matrix, which

represent each of the axes in descending order.

The dynamic system develops from the

description of the movement together with the forces

involved in the system. To determine the kinetic

energy, it was necessary to calculate the velocity

vector, which is composed of the sum between the

vector derivative of r

CM

centre of translational mass

plus the angle of rotation, by the cross product of the

vector r

CM

of centre of mass.

Once the velocity vector is found, the kinetic

energy and the potential energy are found.

(7)

(8)

(9)

The vector r

1

is composed of a medium of link 1

in the direction i0, while the vector w1 is given by

the rotation q0 in the opposite direction to the

movement -j

0

, the vector v

1

is given by a means of

link1 by the rotation q0 in the address k.

(10)

After determining each of the variables (

1 y

), we find the velocity, which gives us as a result,

since the derivative of R1 with respect to q0 is 0.

(11)

Once the velocity is found, the value is replaced

in the kinetic energy equation, where WT is the

transpose of the vector

and I is a matrix of

inertia.

(12)

In addition to this, the potential energy is found

where m1 corresponds to the mass of the first link

Improving the Joint Mobility of Acute Rotator Cuff Injury by Portable Rehabilitation Device

491

and g to the value of gravity.

(13)

For the second joint articulation of the system

showing in figure 3, the same methodology was

carried out, with which the energies were obtained in

the first articulation. With the difference that for the

second system the articulation had to be taken into

account to find the value of the variable

.

4.2 Design and Operation

Characteristics

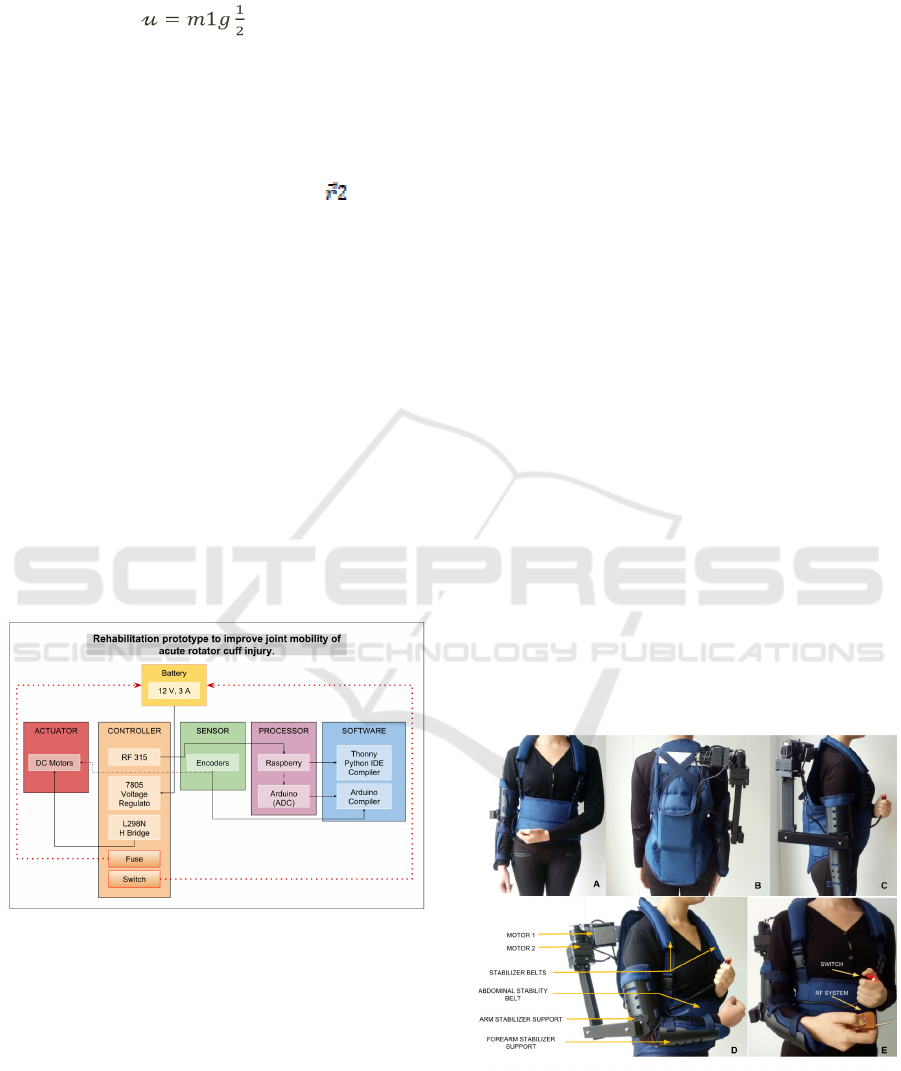

As shown in Figure 4, the operation of this prototype

starts from a 12V power supply that ensures its

portability, which supplies the L298N (Bridge H)

that gives the control of rotation of two motors,

which act as actuators of the system. Because it is

necessary to determine the ranges of extension /

flexion movement, external / internal rotation, the

angles are sensed by using two encoders, one for

each motor. The control of the motors, is given by

means of a processor Raspberry PI 3B, controlled by

the software compiler Thonny Python IDE. A 7805

voltage regulator is implemented because the

software voltage should not exceed 5V.

Figure 4: Schematic diagram of control architecture.

The prototype involves direct contact with

patients to be scaled at an industrial level, therefore,

and thinking about the safety of the patient, requires

a fuse that has the function of dampening the high

currents that the circuit can reach; Added to this, it

has an emergency button (Switch), which will be

activated by the patient in case of alarm, causing the

entire system to shut down completely and stop its

operation. The movements will be controlled and

executed by an emitter-receiver radio frequency

system, which will carry with it the pre-established

therapy routines.

4.3 System Prototype

Once the requirements are known, this prototype is

designed to perform specific therapies by means of

an emitter receiver control system, which the patient

will have to resort to perform a specific task that

starts from the movement of flexion, extension,

internal and external rotation within the angles of

functionality of the joint. The prototype consists of

two stabilizing components showing in figure 5.

The first component consists of a piece that

supports the forearm and the arm, and has an

elongation fabric that allows the user to have

mobility in the elbow (A). The second component is

an abdominal stabilizer, which brings stability to the

back, and so that the therapy is exercised upright,

without complications to the spine, in addition, the

trellis has two shoulder straps or stabilizers that they

allow the weight of the actuators to dissipate through

them, in addition, the trellis has a pocket that groups

the electronic components, in order to make it easy

to access adjustments or even remove the battery to

charge it (B). The figure 6 is showing the actuator

that exerts the movement of flexion - extension, has

a support that is connected directly to the trellis and

a connector that intertwines the other actuator,

which performs the external and internal rotation

movement and is connected to the forearm support

by a piece which lengthens as the flexion movement

(C) is performed.

Figure 5: Prototype of shoulder rehabilitation robot

system. (A) front and (B)posterior sagittal axis of the

device placed on patient. (C) Right view. (D) Stabilizing

components. (E) Control accessories.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

492

Figure 6: Prototype of shoulder rehabilitation robot

system. Side view of the device in movement of extension

to 45 ° (A), position of anatomical zero (B) and movement

of flexion to 120 ° (C) of Shoulder. Front view of the

device in movement of external rotation at 50 ° (A),

anatomical zero position in 90 ° elbow flexion (B) and

internal rotation movement at 70 ° (C) of Shoulder.

4.4 Control System

The coupling that has the encoders in the motors

allows us to know the position angle in which the

stabilizing support is, this is a main part in the

control system of the prototype, however, the

therapy protocol is organized by time and execution

angles, which is programmed through the raspberry

microcontroller Pi 3B that has as operator the remote

control, which executes the specific tasks according

to the therapy that the user wishes to perform.

The kinematic and dynamic conceptual system

developed are based on two of the movements

adapted by the articulation: flexion / extension,

external / internal rotation, which represent a need

for assistance with the aim of achieving efficient

rehabilitation, following patterns of movements that

although they start of international therapy process,

allows the proper monitoring of them. From the

kinematics, the velocities and total accelerations of

the system are obtained from the position of the

terminal end of the forearm.

5 DISCUSSION RESULT AND

CONCLUSIONS

The rupture of the components of the rotator cuff is

one of the main causes of musculoskeletal pain as

well as disability. Rehabilitation is understood as the

set of methods that aims to recover a function or

activity that has been diminished or lost due to

illness or trauma; When talking about robotic

rehabilitation, various approaches are found such as

robotics for mobility, for personal rehabilitation,

developments of prostheses and orthoses, of social

assistance and as observed in the present

development, for upper and lower extremities. It

should be noted that all these approaches are based

on the use of conventional therapies at the

beginning, that over time and the influence of

alternative mechanisms, engineering concepts are

integrated for medical purposes. The new

technologies point to the use of soft materials, which

improve the ergonomics of the rehabilitation system,

within the exponents of bio-robotics is Active Soft

Orthotic System, the main reference for the

execution of this device.

The difficulty in the application of technologies

for the rehabilitation and joint mobility of the rotator

cuff was born in two main causes, technological and

medical. The technological causes, because the

current robotic advances are complex and based on

kinematic chains of rigid links that lead to little

ergonomics, hand in hand with the implements used

in the maintenance of the same that represent high

costs, increasing prices for institutions providers and

providers of related services. The medical causes, in

addition to being a degenerative process that triggers

abrupt tensions on the supraspinatus tendon or

dislocations, which lead to the increase of

musculoskeletal diseases, are also related to the

stress generated by repetitive work, reflected in

direct pathologies to the shoulder and pain joint,

increasing injuries in upper limbs.

The analysis of the kinematic system of the

shoulder allowed differentiating the movements

produced by the five joints (the acromioclavicular

joint, the sternoclavicular joint, the scapula-thoracic

joint and the gleno-humeral joint) that make up the

shoulder, the passive limitations that offer stability

to the joint complex, Static stabilizing elements such

as anatomical differences in joint surfaces and

ligaments. On the other hand, dynamic analysis

states that the main stabilizers of the shoulder are the

muscles that belong to the gleno-humeral joint.

Likewise, we identified the two types of forces

exerted by the shoulder (compression and shearing),

and the anatomical rotations exerted by the gleno-

humeral joint such as: adduction / abduction,

internal / external rotation, flexion / extension by

Euler angles.

The tests performed on the isokinetic

dynamometer Humac Norm allowed to analyse the

complete biomechanical ranges of movement by

Improving the Joint Mobility of Acute Rotator Cuff Injury by Portable Rehabilitation Device

493

means of the bilateral evaluation of flexors and

extensors of the shoulder, as well as internal and

external rotators of the joint. Isokinetic contractions

refer to maximum contractions of the muscle groups

involved with constant velocities along the radius of

joint movement, which allowed during the design of

operation of the device, to establish optimal ranges

of speed according to pre-established requirements,

together with the design of sets in terms of

repetitions and angular variation, discriminating

each type of movement. The complete protocol was

followed for the tests mentioned above in the

Humac, accompanied by medical personnel trained

in facilities of the BodyTech Sport Medicine Center.

The patient chosen for the execution of the test is

within the age range related to the prevalence of the

appearance of the pathology associated with rotator

cuffs, that is, between 40 and 50 years of age.

The isokinetic strength assessment reports,

provide relationship curves between the right and

left sides of the shoulder for each movement, and

quantification of evaluation parameters such as:

peak torque or maximum force moment, which

indicates the maximum capacity of the muscle to

generate strength and comparison of agonist and

antagonist muscles determined in the five initial

repetitions for each movement; Total work done,

defined as the torque product per distance traveled,

that is, the areas under the presented curves that

indicate the capacity of the subject to produce torque

and the estimation of muscle resistance indexes; and

the Power that determines the torque produced

depending on an angular distance traveled in a time

of execution of movement, which expresses the

relationship between the value of work produced in

the time required to complete the exercise.

Based on the quantitative study of the

anthropometry of the working population in

Colombia, with an age range of 20-59 years and a

percentile of 95% which determines that below that

measurement value the population is found, the

measures were determined necessary to build the

device, however, because the anthropometric tables

are separated by sex, an average of each

measurement was made between man and woman to

have a value per measurement, so that the device

was not exclusive regardless of the gender.

Once the prototype was built according to the

anthropometric measurements, it was possible to

demonstrate that it is an ergonomic prototype, since

the actuators adapt to the anatomical characteristics

of the Glenohumeral joint, because the insertions of

the actuators are similar to the anatomical insert that

exists between the humerus and the omoplate.

However, the joint module constructed generates an

additional weight because the plate that holds it has

a smaller size compared to the size of the module,

which indicates that an additional piece must be

created that keeps the module rigid on the trellis, this

to reduce the additional weight generated by the lack

of support.

ACKNOWLEDGEMENTS

The authors wish to thank César Rocha Libreros,

orthopaedic surgeon and reconstructive and knee

arthroscopy surgeon of Fundación Cardio Infantil,

for the clinical vision he gave us on the subject of

rehabilitation.

REFERENCES

Armeo® Spring-Hocoma, [Online accessed: 18/3/2018];

https://www.hocoma.com/solutions/armeo-spring

Ciarán T. O’Neill, Nathan S. Phipps, Leonardo Cappello,

Sabrina Paganoni and Conor J. Walsh; 2017, A Soft

Wearable Robot for the Shoulder: Design,

Characterization, and Preliminary Testing; IEEE Int

Conf Rehabil Robot.

Domien Gijbels, Ilse Lamers, Lore Kerkhofs, Geert

Alders, Els Knippenberg, Peter Feys; The Armeo

Spring as training tool to improve upper limb

functionality in multiple sclerosis: a pilot study;

Journal of Neuro Engineering and Rehabilitation

2011, 8:5.

Galiana Ignacio, Hammond Frank L., Howe Robert D. and

Popovic Marko B. 2012; Wearable Soft Robotic

Device for Post-Stroke Shoulder Rehabilitation:

Identifying Misalignments; IEEE/RSJ International

Conference on Intelligent Robots and Systems October

7-12, 2012. Vilamoura, Algarve, Portugal.

Gonçalves Rodrigo, Antunes Cerejo; 2016, A Robotic

System for Musculoskeletal Rehabilitation of the

Shoulder; Biomedical Engineering - Universidade de

Lisboa.

InMotion ARM™ Interactive Therapy System - Bionik

Labs; http://bionikusa.com/healthcarereform/upper-

extremity-rehabilitiation/inmotion2-arm/. [Online

accessed: 18/03/2018].

Habets Bas, Staal J. Bart, Tijssen Marsha and Cingel

Robert van; 2018, Intrarater reliability of the Humac

NORM isokinetic dynamometer for strength

measurements of the knee and shoulder muscles;

Res Notes (2018) 11:15.

Hunt Justin, Lee Hyunglae, Artemiadis Panagiotis; A

Novel Shoulder Exoskeleton Robot Using Parallel

Actuation and a Passive Slip Interface; Journal of

Mechanisms and Robotics; 2017.

James Cannan and Huosheng Hu, 2012. Upper Body

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

494

Rehabilitation A Survey; University of Essex,

Colchester CO4 3SQ, U.K; ISSN 1744-8050.

Kesner, S., Jentof, L., Hammond III, F., Howe, R., &

Popovic, M.; 2011, Design Considerations for an

Active Soft Orthotic System for Shoulder

Rehabilitation; 33rd Annual International Conference

of the IEEE Engineering in Medicine and Biology

Society (EMBC).

Kim Bongsu and Deshpande Ashish D; 2017, An upper-

body rehabilitation exoskeleton Harmony with an

anatomical shoulder mechanism: Design, modeling,

control, and performance evaluation; The International

Journal of Robotics Research; 1–22.

Nunes W., Rodriguez L. and Oliveira L.; 2011, Cable

based parallel manipulator for rehabilitation of

shoulder and elbow movements; IEEE Int Conf

Rehabil Robot.

Nef Tobias, Guidali Marco and Riener Robert; 2009,

ARMin III – arm therapy exoskeleton with an

ergonomic shoulder actuation; Applied Bionics and

Biomechanics Vol. 6, No. 2, June, 127–142.

Orth T., Paré J., Froehlich J. E.; 2017, Current concepts on

the genetic factors in rotator cuff pathology and future

implications for sports physical therapists.

International Journal of Sports Physical Therapy.

2017;12 (2):273-285.

Sicuri Chiara, Porcellini Giuseppe, Merolla Giovanni;

2014, Robotics in shoulder rehabilitation; Muscles,

Ligaments and Tendons Journal 2014; 4 (2): 207-213.

Improving the Joint Mobility of Acute Rotator Cuff Injury by Portable Rehabilitation Device

495