Analytics in Supply Change Management: Is There a Dark Side?

Noushin Ashrafi and Jean-Pierre Kuilboer

University of Massachusetts Boston, 100 Morrissey blvd, Boston MA 02125, U.S.A.

Keywords: Analytics, Supply Chain Management, Global Economy.

Abstract: The growing ability to collect real-time data combined with a desire to optimize efficiency and effectiveness

have pushed the organizations to realize the value of analytics and intelligent supply chain. This study offers

an overview of supply chain management and the critical role of analytics to enhance supply chain processes

and, subsequently, performance. While efficiency and effectiveness is the ultimate measure of success for any

organization, this study recommends a look at the consequences of such success in the global economy. As

the world of commerce increasingly relies on outsourcing and the cheap labor market, the role of technology

to expedite the exploitation of that market should be scrutinized. It is time to discuss not only the contributions

of analytics to facilitate supply chain management but also its impact on exploitation through fierce

competition among suppliers operating in developing countries.

1 INTRODUCTION

Rapid strides in innovation and globalization have

resulted in tremendous opportunities and choices for

firms and customers in the marketplace. Because of

the competitive pressures, organizations are now

outsourcing and manufacturing on a global scale and

consequently facing complex circumstances where

the active management of supply chain activities is a

necessity for the sustainability of the firm. Supply

chain management revolves around two important

concepts: (1) every product that reaches the end user

represents the cumulative effort of multiple

organizations and (2) the organizations that make up

the supply chain are “linked” together through

physical flows and information flows. While physical

flow is the most visible piece of the supply chain,

Information flows allow the various supply chain

partners to coordinate and control the day-to-day flow

of goods and materials up and down the supply chain.

In such environment, companies are increasingly

recognizing the value of data and advanced analytics

tools. The ultimate goal of supply chain management

is to maximize customer satisfaction while sustaining

a competitive advantage through effective and

efficient management of the chain of activities

ranging from development, sourcing, production, and

logistics. These activities can benefit from a

conscious effort to extract value from data and

shifting from heuristics to data-driven decision

making.

As the business environment is becoming highly

dynamic, the organizations, to stay competitive, have

to deal with the intricacy of analysing a tremendous

amount of data gathered through physical flows and

information flows. A typical supply chain manages an

inflow of more than 100 gigabytes per day

(Arunachalam et al., 2017), and the volume of digital

data is expected to reach 35 Zeta bytes by 2020 (Tien,

2015). Furthermore, it is speculated that the use of

RFID tags would increase rapidly to 209 billion units

by 2021 (Marr, 2014; Tachizawa et al., 2015). This

scenario bids the firms to increasingly recognize the

value of data and advanced analytical and decision

support tools. Data Analytics can assume a pivotal

role in transforming and improving the functions of

the supply chain as it provides the required

capabilities to the various components of the supply

chain and can handle the generated big data flow. It

can easily handle historical data to provide insights as

well as control real-time data for real-time decision-

support, which can improve the agility of the

organization in a business environment that is highly

dynamic and competitive.

Therefore, the supply chain can benefit from

information technology enabled business intelligence

and analytics by providing capabilities in three

essential areas: (1) managing big data that the

businesses and supply chain generate, (2) offering

Ashrafi, N. and Kuilboer, J-P.

Analytics in Supply Change Management: Is There a Dark Side?.

DOI: 10.5220/0006946302470252

In Proceedings of the 14th International Conference on Web Information Systems and Technologies (WEBIST 2018), pages 247-252

ISBN: 978-989-758-324-7

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

247

analytical support to the supply chain processes and

(3) managing the supply chain performance. The

terms such as Supply Chain Intelligence (SCI) and

Supply Chain Analytics (SCA) have become more

common (Chae et al, 2013), and studies have shown

organizations that can respond effectively to this

information age seem to have a great deal of success

and perform better. In cases where the business

environments are uncertain, BA may have an even

more positive impact on processes such as

forecasting, designing, purchasing, production, and

marketing.

This paper primarily provides an overview of

supply chain management and the application of

business intelligence to improve its performance. We

address the notion that analytical capabilities can

guide the exclusively human decisions better and

even provide automated decisions in some SC

processes. There is no question that Companies

having better analytical capabilities with good

information system tend to have better SC

performance. However, it is essential to stir a

discussion on another aspect of global economy

triggered by the use of advanced analytics to manage

supply chain activities. Intelligent supply chain

creates insight and knowledge enabling companies,

large and small, to realize a larger profit through the

improvement of their operational efficiency and

effectiveness. However, by doing so, it also widens

the door for exploitation of the labor market in the

developing countries. Analytics facilitates competitive

pricing and optimal delivery time by its ability to drill

down and obtain information across the supply chain

including outsourcing partners in countries where labor

exploitation is a common practice.

Next section provides an overview of supply chain

management followed by an overview of business

intelligence and analytics. Section 4 looks at the role

of analytics in SCM. Section 5 provides a discussion

on the dark side of analytics and section 6 offers the

concluding remarks.

2 SUPPLY CHAIN

MANAGEMENT OVERVIEW

In the past, most organizations had focused on the

effectiveness and efficiency of business functions

such as purchasing, production, marketing, financing,

and logistics. However, they realized that lack of

connectivity among these functions could lead to a sub-

optimal organizational goal and risk the main

objectives of SC, which include creating net value

while building a competitive infrastructure and

measuring performance globally. In an organization

such as a manufacturing organization, the SC includes

all business functions involved in satisfying a customer

request such as new product development, marketing,

operations, distribution, finance, and customer service

(Chopra, 2007). Lack of integration duplicates

organizational efforts and resources and impedes

efficiency. The failure to connect demand with supply

results in poor customer service and rising costs.

SCM integrates key business processes from the end-

users through suppliers who provide products,

services, or information while adding value to all

involved. To integrate and synchronize a set of

interdependent business processes there is a need to

facilitate information exchange among these various

business entities like suppliers, manufacturers,

distributors, third-party logistics providers, and

retailers (Min, 2015).

The two main businesses processes in an SC are

inbound logistics (materials management) and

outbound logistics (physical distribution). Material

management is the process of acquiring and storing

raw materials, parts, and supplies and therefore

supports the flow of materials from purchasing,

controlling production materials, planning and

scheduling work-in-process, warehousing, shipping,

and distributing the finished products. The physical

distribution includes all logistics for providing service

to the customer, which include receiving and

processing the order, deploying the inventory, and

other related activities. While the SC is a combination

of these two business functions, it is not merely a

linear representation of one-to-one business

relationships. It is rather a network of multiple

business relationships, which brings about a

complexity requiring analytical capabilities to guide

the management and decision-making process.

3 BUSINESS INTELLIGENCE

AND ANALYTICS OVERVIEW

Business Intelligence (BI) consists of the strategies

and technologies used by the enterprise to collect,

integrate, analyze, and present business information.

The purpose of Business Intelligence is to support a

wide range of business decisions at operational and

strategic levels. Operating decisions include product

positioning or pricing while strategic decisions

involve priorities, goals, and guidelines at the

broadest level. BI technologies help identify new

opportunities and implement an effective strategy

WEBIST 2018 - 14th International Conference on Web Information Systems and Technologies

248

based on insights. The ultimate goal of BI is to

improve business decision-making and provide

actionable information in the right form for decision

makers at the right time and location (Sabherwal and

Becerra-Fernandez, 2011).

BI has a centric approach to data and therefore

relies heavily on various advanced data collection,

extraction, and analysis technologies. Experts often

consider data warehousing as the foundation of BI.

Organizations use dashboards for business performan-

ce management (BPM) making it easy to analyze and

visualize various performance metrics. The latest

phenomenon, Business Intelligence 2.0 (BI 2.0) allows

organizations to gather information from both enter-

prise databases and the Web. The querying of real-time

corporate data is in contrast to previous proprietary

querying tools that characterize previous BI software.

Web analytics tools such as Google Analytics can

analyze logs containing customer’s clickstream data,

which provide information about the trail of the user’s

online activities, thereby revealing the browsing and

purchasing patterns of the user. Organizations can use

web analytics for better website design, use heat maps

for optimizing product placement, analyze the

customer transactions better, and enable better product

recommendations. Organizations are also capable of

organizing and visualizing data by using multilingual

retrieval techniques such as knowledge mapping.

Business Analytics (BA) is the practice of

iterative, methodical exploration of an organization's

data, with an emphasis on statistical analysis.

Companies committed to data-driven decision-

making use business analytics. Data management is

the key infrastructure of BA. BA finds intelligence

within the organization's large volumes of data about

its products, services, customers, manufacturing,

sales, purchasing, and so on. Thus, the data stored in

the various corporate databases serve as inputs to BA

activities. Most of these data in the databases are

transaction oriented, which is not suitable for analysis

and report unless some processes manage the data.

Thus, the organization's data from various sources go

through integration or transformation through ETL

(extract, transform, and load) process and the

organizations often load this data into a data

warehouse, which is a centralized storage location of

data. The organization now has to use the stored data

to create business value, which requires data mining

or knowledge discovery techniques and analytical

techniques like mathematical optimization. These

techniques help the analysis of data and enable

finding useful information such as sales forecasts,

business constraints, and others. The data mining

techniques can be predictive modeling, clustering,

and association. Predictive modeling or analytics uses

statistical regression or artificial intelligence based

technologies for predicting future events upon

historical data. Prescriptive analytics, on the other

hand, involves mathematical optimization,

simulation, and so on. All these predictive and

optimization analytics are available in analytical

supply chain planning technologies such as advanced

planning scheduling (APS). Business process

management (BPM), which is similar to feedback in

open systems and a crucial component of BA, enables

monitoring, reporting, and correcting, which are the

three broad sets of business activities. Companies use

KPIs and other metrics to monitor the SC

performance. While seemingly similar, there is a

major difference between business intelligence vs.

business analytics: BI uses past and current data to

optimize the present operation while BA uses the past

and analyzes the present to prepare companies for the

future. Since both depend heavily on data analytics,

one can combine business intelligence and analytics

(BIA) as the preferred combined term.

Furthermore, SCM needs information technology

(IT) for coordination, monitoring, and optimization

of SC performance. It also needs management

processes like identifying metrics, objectives, goals,

parameters, targets, planning, defining communica-

tion methods, reporting, and feedback. These

functions are available as part of different information

system environments including SAP and Oracle.

Organizations, using IT, could institute performance

measurement processes, which could help decision-

makers to increase the effectiveness and efficiency of

their SC by focusing on the appropriate metrics (Cai

et al., 2009). In general, performance measurement is

vital in SCs. Gunasekaran and Kobu (2007) argued

that performance measurement could help the

organization identify the needs of the customer and

increase the product or service fulfillment as the

bottlenecks and opportunities are detected and

improved. The bottom line is making decisions based

on data, and enhancing process communication and

coordination is the key to success in SCM (Lim et al.,

2013). So, what is business analytics?

4 APPLICATION OF ANALYTICS

IN SCM

SCM developed quickly over time from traditional

procurement and supply management to the

integration from raw materials to end user

management. Analyzing large amounts of data and

Analytics in Supply Change Management: Is There a Dark Side?

249

information within the SC has become essential for

identifying financial conditions, information sharing,

and decision-making capabilities. The western

countries developed BI in the mid-twentieth century

to enforce this capability. BI is a decision driven

integrated technology by data analysis to help

companies improve their business processes. BI helps

in optimizing SC integration by including supply-

demand management, resource selection

management, product definition, production

management, inventory management, sales

management, relationship management, and

decision-making the analysis. BI enables real-time

information gathering and analysis using a collection

of analytical software and solutions to help users

make better business decisions. BIA includes

techniques for data extraction and transformation,

database management, data mining and recovery,

data reporting and visualization, and

multidimensional analysis.

Processes such as OLAP are critical to the concept

of BI. By adopting BI techniques, organizations can

perform real-time estimations of key performance

measures such as material quantity, delivery cost, cost

of goods, inventory turnover rate. This can enable

organizations to make better decisions on business

activities. Improving customer and supplier

relationship management and increasing SC

flexibility ensure minimization of overall costs and

maximization of overall profits. BI can help

companies achieve an SC that maintains a balance

between normal production and supply, enabling

better cash flow. BI supports information sharing that

enables better SC integration so that organizations

can perform real-time data analysis for predicting

more accurate customer demands, supply chain

activities, and evaluation of the performance of

participants in the SC with a focus on suppliers. By

the high level of supply chain integration, the

organization can accrue advantages that are more

competitive and maximize the benefits for all the

stakeholders, especially in a complex and dynamic

environment. SCA is the application of BI techniques

on the SC, and it integrates the different management

processes such as planning, sourcing, making, and

delivery for analysis of SC performance. SCA aims

to extract massive real-time data collected by the SC

system for generating meaningful information for

decision-makers in the SC (Sahay and Ranjan, 2008).

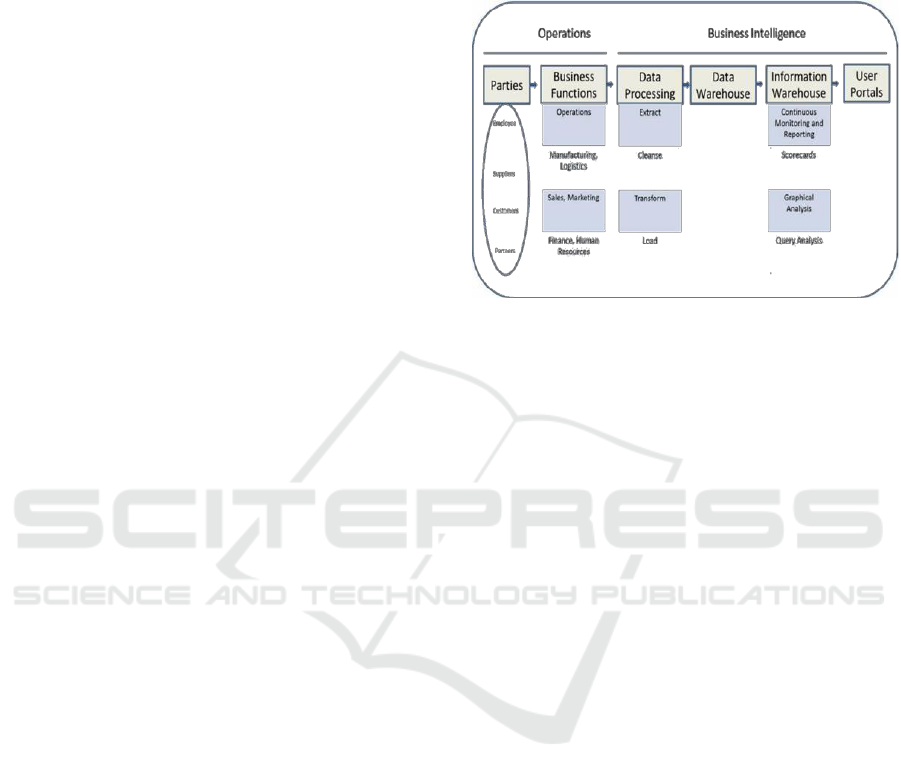

Figure 1 shows how BI supports the business

operations. The first step involves subjecting the data

from different departments such as operations,

manufacturing, distribution and logistics, sales and

marketing, finance and human resources to four main

steps of processing. They are extract, clean, transform

and load. After loading the data into a data

warehouse, BA converts the data to information for

user consumption.

Figure 1: Business Intelligence Infrastructure Source:

(Sahay and Ranjan, 2008).

BI involves customer support, market research,

distribution channels, product profitability,

inventory, and logistics analysis, statistical analysis,

and multidimensional reports. Data sources may be

enterprise resource planning (ERP), SCM and

customer relationship management (CRM) system,

customers, suppliers, manufacturing processes, new

product testing and development, market price

forecasting, customer demographical allocation, and

many others. Furthermore, after the development of

BI and IT and complex SCs, organizations have

become interested in big data real-time analytics, and

predictive analytics. In a study that surveyed

companies in the U.S., 57 percent of companies

preferred using their general company data

warehouses to support their SCA applications, while

43 percent preferred using a separate SCA-based data

warehouse. Big data predictive analytics involves

quantitative analysis, patterns and relationships

between a large amount of data, and precise analyses

based on hypothetical assumptions. In the SCA,

predictive analysis using BI has applications in

predicting timely inventory quantity, new product

failure rate, mean time to product failure, stock on the

road, monthly customer demands and orders,

relationships between different KPIs and supplier

strategies. SCM predictive analytics using big data

for both quantitative and qualitative methods can

improve SC performance by using historical data to

estimate future levels of business processes (Waller

and Fawcett, 2013).

While efficiency and effectiveness is the ultimate

measure of success for any organization, we believe

WEBIST 2018 - 14th International Conference on Web Information Systems and Technologies

250

there is a need for a forum to discuss not only the

contributions of analytics to facilitate supply chain

management but also its impact on exploitation

through fierce competition among suppliers operating

in developing countries.

5 DISCUSSION AND FUTURE

RESEARCH

In today’s global economy with the abundant volume

of available data and advancement in technology,

companies are most likely to use analytics (Trkman et

al., 2010) to improve companies’ efficiency and

effectiveness and maximizing customer satisfaction.

However, while companies and customer are the

beneficiaries of such phenomenon, the suppliers are

at a disadvantage as large companies have the

knowledge and consequently the power to pressure

them to compete and offer better deals. But, these

deals come at a cost to the unprivileged workers in the

third world. Perhaps not a new phenomenon, but the

application of analytics makes the exploitation more

common and more frequent. Increasing efficiency

sometimes goes too far such that as the saying goes

attempts ‘to cut the fat reaches the bone.’ While we

can find a great deal of literature about the benefits of

the application of analytics in supply chain

management, little has been said about its impact on

the understanding of the economic, political, and

cultural environments in the countries in which they

intend to outsource and operate.

Supply Chain managers while pursuing efficiency

and effectiveness should feel the responsibility to

improve the practice of global business and to make

a better global expansion. The role of analytics to

impend or encourage such proposition must be

explored. This study describes the extensive role of

analytics to benefit firms and their customers and then

strives to extend the conversation to include the

supplier and examine the impact of analytics on the

suppliers who are rightfully part of the global

economy and in control of the well-being of cheap

labor, specifically in developing companies. The

intention of this study is not to dampen the hype about

the analytics, rather, draw attention to another

perspective that includes the holistic role of analytics

to better our global society. The answer is not

straightforward, no research has been conducted, and

there is no evidence of any publication to draw the

attention of the developers and users of intelligent

technology.

The conversation should be around unrealistic

assumptions about a business model that uses

intelligent SC successfully and profitably but seem to

fail to account for real and salient shortcomings that

may negatively impact the global economy. To the

best of our knowledge, there is no research to

contemplate the dark side of analytics in this

perspective. Perhaps it is the time to begin such

conversation.

6 CONCLUSION

The main objective of SC is to enhance the

operational efficiency, increase profitability, and

improve the competitive advantage of the

organization and its partners. This is partly achieved

by applying data analytics to supply chain

management. The utmost advantage is providing the

employees of an organization and its stakeholders

easy and timely access to the information and better

use and analysis of data. Analytics provide the critical

insights that organizations need to make informed

decisions and facilitates the scrutiny of all aspect of

business operations to make meaningful inferences or

discern unusual behaviors. Using traditional and real-

time BI, SCM can derive operational efficiency,

promote agility, and assist managers in reducing

uncertainty. All in all, analytics drives operational

efficiency and effectiveness hence enforcing an

upward jump to more profit. However, to improve the

practice of global business and to make better global

expansion decisions managers need a more

sophisticated understanding of the economic,

political, and cultural environments in the countries

in which they intend to operate. They must appreciate

how nations behave in response to the pressure of

competition and incorporate those differences in their

decision-making process.

REFERENCES

Arunachalam, D., Kumar, N. and Kawalek, J.P., 2017.

Understanding big data analytics capabilities in supply

chain management: Unravelling the issues, challenges

and implications for practice. Transportation Research

Part E: Logistics and Transportation Review (in press).

Tien, J. M. 2015. Internet of connected servgoods:

considerations, consequences and concerns. Journal of

Systems Engineering, 24 (2), pp. 130-167.

Marr, B. 2014. “Big data: 25 amazing need-to-know facts”,

available at: http://smartdatacollective.com/bernard

marr/277731/big-data-25-facts-everyone-needs-know.

Analytics in Supply Change Management: Is There a Dark Side?

251

Tachizawa, E.M., Alvarez-Gil, M.J. and Montes-Sancho,

M.J., 2015. How “smart cities” will change supply chain

management. Supply Chain Management: An

International Journal, 20(3), pp.237-248.

Chae, B. K., and Olson, D. L. 2013. Business Analytics for

supply chain: A dynamic-capabilities framework.

International Journal of Information Technology &

Decision-Making, 12(1), pp. 9-26. http://cbafiles.unl.

edu/public/cbainternal/facstaffuploads/ijitdm2013.pdf

Chopra, S., and Meindl, P. 2007. The supply chain

management: Strategy, planning, and operation. Upper

Saddle River, NJ: Pearson Education, Inc.

Min, H. 2015. The essentials of supply chain management:

New business concepts and applications. Upper Saddle

River, NJ: Pearson Education Ltd.

Cai, J., Liu, X., Xiao, Z., and Liu, J. 2009. Improving supply

chain performance management: A systematic

approach to analyzing iterative KPI accomplishment.

Journal of Decision Support Systems, 46, pp. 512-521.

Gunasekaran, A., and Kobu, B. 2007. Performance

measures and metrics in logistics and supply chain

management: A review of recent literature (1995-2004)

for research and applications. International Journal of

Production Research, 45(12), pp. 2819-2840.

Lim, P. E., Chen, H., and Chen, G. 2013. Business

intelligence and analytics: Research directions. ACM

Transactions on Management Information Systems,

3(4), pp. 1-10.

Sabherwal, R. and Becerra-Fernandez, I. 2011. Business

Intelligence: Practices, Technologies, and Management,

Wiley, 2011, ISBN: 978-0-470-46170-9.

Sahay, B. S., and Ranjan, J. 2008. Real-time business

intelligence in supply chain analytics. Journal of

Information Management & Computer Security, 16(1),

pp. 28-48.

Waller, M. A., and Fawcett, S. E. 2013. Data science,

predictive analytics, and big data: A revolution that will

transform supply chain design and management.

Journal of Business Logistics, 34(2), pp. 77-84.

Trkman, P., McCormack, K., Oliveira, M. P., and Ladeira,

M. B. 2010. The impact of business analytics on supply

chain performance. Decision Support Systems, 49, pp.

318-327. doi:10.1016/j.dss.2010.03.007

WEBIST 2018 - 14th International Conference on Web Information Systems and Technologies

252