Energy Analysis and Exergy Analysis of a New Type Solar Air

Conditioning System

Xi Bai

School of Aeronautic Science and Engineering, Beihang University, XueYuan Road, Beijing, China

Baixi_buaa@163.com

Keywords: Solar air conditioning, Heat pump, Energy Analysis, Exergy Analysis.

Abstract: This paper presents a novel type of solar air conditioning system. The steady thermodynamic analysis model

and exergy analysis model are given to analyse the performance of the novel system. The energy analysis and

exergy analysis are carried out through detailed calculation. The exergy system analysis shows that the highest

exergy destruction occurs in condensation-generation and condensation 2, which can be reduced with

parameter optimization. A range of operating conditions are selected and simulated for the novel solar air

conditioning system by changing the corresponding parameters while keeping other parameters consistent

with the design conditions. Compared with the original solar air conditioning system, the novel solar air

conditioning system possesses the advantages of low requirements for the performance of solar collectors and

smaller area of solar collectors. The novel system is also less affected by weather conditions.

1 INTRODUCTION

To reduce environment pollution and energy

conservation, solar air conditioning researches are of

great significance. Solar energy is a kind of clean and

renewable energy. Since the refrigerating demand and

the supply of solar radiation are almost in phase with

each other, the solar air conditioning system is

appealing to many researchers (Hwang, Y.,

Radermacher, R., Alili, A. and Kubo, I. 2008; Sekret,

R. and Turski, M. 2012 ). The most common kind of

solar air conditioning system, which can be seen as

the original system, is composed of solar collectors

and the single effect LiBr–H

2

O absorption chiller.

However, the original system is confronted with

many problems in practical operation, including

crucial problems like intermittency and instability. In

order to solve the existing problems, a number of

relevant studies are carried out by many researchers.

Xu presented a new solar powered absorption

refrigeration system with advanced energy storage

technology. The energy collected from the solar

radiation was transformed into the chemical potential

of the working fluid and stored in order to solve the

problem of the unconformity between solar radiation

and cooling demand (Xu, S., Huang, X. and Du, R.

2011). Lass-Seyoum tested a similar closed thermo-

chemical heat storage system. This method offers

several advantages including the possibility of long-

term storage with minimal thermal losses and a high-

energy storage density compared with sensible and

latent thermal storage principles (Lass-Seyoum, A.,

Blicker, M., Borozdenko, D., Friedrich, T. and

Langhof, T. 2012).

Ahachad combined an absorption heat pump

system and an absorption refrigeration system to form

a two-stage vapor absorption system. And the tests

conducted in Rabat (Morocco) showed that the

system can be operated at lower heat source

temperatures by using flat-plate collectors (Ahachad,

M., Charia, M. and Bernatchou, A. 1993). Jain

proposed a cascaded vapour compression–absorption

system (CVCAS) which consists of a vapour

compression refrigeration system (VCRS) coupled

with single effect vapour absorption refrigeration

system (VARS). Based on first and second laws, a

comparative performance analysis of CVCAS and an

independent VCRS has been carried out (Jain, V.,

Kachhwaha, S. and Sachdeva, G. 2013).

Prasartkaew studied the performance of a

renewable energy (solar–biomass) based on single

effect LiBr–H

2

O absorption chiller. The chiller and

overall system coefficient of performances were

found to be 0.7 and 0.55 respectively and the biomass

(charcoal) consumption for 24h operation was

24.44kg/day (Prasartkaew, B. and Kumar, S. 2010).

Y.L. Liu presented the performance prediction of a

solar/gas driving double effect LiBr-H

2

O absorption

Bai, X.

Energy Analysis and Exergy Analysis of a New Type Solar Air Conditioning System.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 33-40

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

33

system. Its high-pressure generator is driven by

natural gas. Simulation results illustrated that such

kind of system is feasible and economical (Liu, Y.

and Wang, R. 2004). Apart from gas boiler, there also

exist electric heaters and oil boilers used as auxiliary

equipment. For a number of absorption systems that

employed heat recovery in the industrial sector or in

large residential buildings have the auxiliary of gas or

oil, as described in the experimental studies (Pérez de

Viñaspre, M., Bourouis, M., Coronas, A., Garcı

́

a, A.,

Soto, V. and Pinazo, J. 2004; Sumathy, K., Huang, Z.

and Li, Z. 2002; Ali, A., Noeres, P. and Pollerberg, C.

2008).

In order to reduce the influences of the weather

conditions on the solar air conditioning system, a

novel solar air conditioning system with heat pump as

auxiliary equipment is proposed in this paper.

Compared with the auxiliary of gas/oil, the novel

system needs fewer additional equipment like boilers

and gas/oil tanks. The energy analysis and exergy

analysis of the novel system are carried out through

detailed calculation to get a better view of the system.

A comparison between the novel system and the

original system is also considered in this study.

2 SYSTEM DESCRIPTION

Fig. 1 illustrates the main components of the novel

solar air conditioning system. The system is mainly

composed of three subsystems: solar collecting (SC)

subsystem, heat pump (HP) subsystem and

absorption refrigeration (AR) subsystem. The SC

subsystem, using water as working medium, consists

of flat-plate solar collectors and a water pump. The

HP subsystem , using R134a as working medium,

mainly consists of evaporator 1, condensation 1,

expansion valve 1 and compressor. The AR

subsystem mainly consists of generator, absorber,

evaporator 2, condensation 2, expansion valve 2, a

heat exchanger and a solution pump,using lithium

bromide solution as working fluid pair. For reducing

the component number of the system, condensation 1

and generation can be integrated as one compact

component, condensation-generation, which can also

help the heat source keep stable.

Figure 1: The schematic diagram of a new type of solar air

conditioning system.

The working flow of the system is shown as

follows.

(1)The SC subsystem receives low-grade energy

through gathering solar radiation to warm the

working medium water. Then, the low-grade energy

was transferred to HP subsystem in evaporator 1.

(2)In the HP subsystem, the working medium

R134a is cycled among the components, transforming

the energy from evaporator 1 to condensation-

generation, which also means that the low-grade

energy is transformed to high-grade energy to ensure

the normal operation of AR subsystem.

(3)In the AR subsystem, the high-grade energy

from the HP subsystem is used to produce chilled

water in evaporation 2 for cooling application.

3 MODELS OF

THERMODYNAMIC ANALYSIS

In order to simplify the calculation of the

performance analysis, a set of assumptions are made

as follows.

(1) The analysis is made under steady conditions.

(2) The pressure losses in the pipelines and all

components are negligible.

(3) The heat transfer between all components and

surroundings is ignored.

(4) The energy consumed by the solution pump

and the water pump is negligible.

(5) The lithium bromide aqueous solution at the

outlet of absorber and generator is assumed to be in

equilibrium at their respective temperatures and

pressures.

(6) The refrigerant (water) at the outlet of

evaporator 1, condenser 1, evaporator 2 and

condenser 2 is saturated.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

34

The efficiency expression of the solar collectors is

determined as indicated in Eq. (1). The optical

efficiency is 0.67 and the linear coefficient of thermal

losses is 5.52 W/℃/m

2

0.67 5.52

SC am

SC

SC

TT

I

(1)

where I

SC

is the solar intensity. The terms T

am

and T

SC

are the environment temperature and the average

temperature of working medium in collectors

separately.

The governing equations of mass conservation

and species conservation can be expressed as

0

io

mm

(2)

- =0

io

mx mx

(3)

where m is the mass flow rate and x is mass

concentration of LiBr in the solution.

The energy balance of each component based on

the first thermodynamic for a steady state can be

expressed as

- + 0

o

i o i

mh mh Q Q W

(4)

The exergy with reference to the environment can

be expressed as

0 0 0

e h h T s s

(5)

where h

0

and s

0

are evaluated at the reference

environment.

Exergy destruction of a control volume based on

the second thermodynamic can be calculated as

follow,

00

- 1 1

x i o o

i

io

E m e m e W

TT

QQ

TT

(6)

The cooling COP of the novel solar air

conditioning system can be defined as follow,

12 10AR AR AR

SYS

HP

m h h

COP

W

(7)

where W

HP

is the electric energy consumption of the

HP subsystem; m

AR

is the mass flow rate of refrigerant

vapour (water) of the AR subsystem.

The exergy efficiency of the novel solar air

conditioning system can be defined as

, 2 , 1

,2 ,1

CW x CW x CW

SYS

SC x SC x SC HP

m e e

ECOP

m e e W

(8)

where m

SC

is the mass flow rate of SC subsystem; m

CW

is the mass flow rate of the chilled water in evaporator

2.

Based on the properties of the water, R134a and

lithium bromide aqueous solution, the equations

above are determined to describe the mass transfer,

heat transfer and exergy destruction in every

component.

4 RESULTS ANALYSIS UNDER

DESIGN CONDITIONS

To analyse the performance of system quantitatively,

the design operating conditions are selected as

follows.

(1) Flat-plate collectors are selected, with an area

of 100 m

2

. The inlet temperature of the collectors is

maintained at T

1SC

=70 ℃ by using variable speed

pump to regulate water mass flow rate.

(2) The condensation temperature of HP

subsystem is maintained at T

C,HP

=90 ℃, which means

the heat source temperature of AR subsystem T

HS,AR

=

T

C,HP

=90 ℃.

(3) The efficiency of the compressor is 0.63.

(4) The condensation temperature of AR

subsystem is maintained at T

C,AR

=40 ℃, the

evaporation temperature of AR subsystem is

maintained at T

E,AR

= 10 ℃.

(5) The inlet temperature of cooling water is

assumed at T

W0

=30 ℃. The outlet temperature of

cooling water to condensation 2 and absorber is

assumed at T

WC

=T

WA

=T

W0

+3 ℃.

(6) The inlet temperature and outlet temperature

of the chilled water in evaporator 2 are respectively

maintained at T

CW1

=17 ℃, T

CW2

=13 ℃.

(7) The heat exchanger effectiveness is 0.7.

Energy Analysis and Exergy Analysis of a New Type Solar Air Conditioning System

35

Table 1: Thermodynamic properties of each point in the system.

Point

temperature

pressure

concentration

specific

enthalpy

specific

entropy

mass flow rate

℃

kPa

wt%

kJ/kg

kJ/(kg·K)

kg/s

1SC

70.00

-

-

293.02

0.96

0.6

2SC

85.58

-

-

358.38

1.14

0.6

3SC

85.58

-

-

358.38

1.14

0.6

1HP

72.79

2252.2

-

428.93

1.69

0.456

2HP

95.56

3244.2

-

438.97

1.70

0.456

3HP

90.00

3244.2

-

342.93

1.44

0.456

4HP

72.79

2252.2

-

342.93

1.45

0.456

1AR

36.00

-

52.62

79.28

0.24

0.459

2AR

36.00

-

52.62

79.28

0.24

0.167

3AR

63.34

-

52.62

137.19

0.42

0.167

4AR

69.86

-

52.62

151.23

0.46

-

5AR

80.00

-

57.68

184.89

0.47

0.152

6AR

48.13

-

57.68

121.42

0.28

0.152

7AR

48.13

-

57.68

121.42

0.28

0.152

8AR

40.67

-

54.35

93.71

0.25

0.444

9AR

74.93

7.38

-

2640.13

8.46

0.015

10AR

40.00

7.38

-

167.54

0.57

0.015

11AR

10.00

1.23

-

167.54

0.59

0.015

12AR

10.00

1.23

-

2519.23

8.90

0.015

Table 2: Exergy destruction of system components.

Input exergy

kJ

Output exergy

kJ

Exergy destruction

kJ

Exergy destruction ratio

%

Evaporator 1

-33.39

-34.02

0.63

7.17

Compressor

-36.68

-38.20

1.52

17.21

Expansion valve 1

-48.26

-49.06

0.80

9.12

Condensation-generation

-34.30

-36.35

2.05

23.28

Absorber

10.69

9.57

1.12

12.76

Condensation 2

2.58

1.29

1.28

14.59

Evaporator 2

0.84

0.04

0.80

9.09

Expansion valve 2

0.03

-0.10

0.12

1.39

Heat exchanger

12.55

12.07

0.48

5.40

total

-

-

8.80

-

By using the aforementioned equations, the

thermodynamic parameters of the system under the

design operating conditions can be calculated.

The effect of the chemical exergy of solution is

neglected in most relevant studies, which is also

neglected in this paper. Reference temperature and

pressure here is set to be T

0

= 25 ℃ and p

0

=101.325

kPa for the exergy analysis. The calculation results of

the exergy analysis of various components are

presented in Table 2. As can be deduced from Table

2, among all the components, condensation-

generation has the highest exergy destruction,which

accounts for 23.28 % of the total amount of exergy

destruction. The condensation-generation requires a

great amount of heat to produce refrigerant vapour

(water) from lithium bromide aqueous solution. In

addition, the refrigerant vapour (water) leaves the

condensation-generation for condensation 2

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

36

overheated, which constitutes a thermodynamic loss

in the condensation-generation and leads to extra

cooling requirement in condensation 2. Therefore, the

condensation 2 has the second highest exergy

destruction. The exergy efficiency can be improved

with parameter optimization.

5 PERFORMANCE ANALYSIS

5.1 The influence of SC subsystem on

system

The function of SC subsystem is to provide energy to

drive the solar air conditioning system. In this section,

the changes in the energy and exergy provided by SC

subsystem are investigated with increasing the water

mass flow rate of the solar collectors (m

SC

) from with

0.2 kg/s to 1.0 kg/s at different inlet temperatures

(T

1SC

).

Figure 2: The curves between energy provided by SC

subsystem and its mass flow mate.

Figure 3: The curves between exergy provided by SC

subsystem and its mass flow mate.

Fig. 2 shows the combined effect of m

SC

and T

1SC

on the energy output of the SC subsystem. The energy

provided by the SC subsystem increases with the

increasing of water mass flow rate, and then

converges to a constant value. In order to get more

energy from the solar intensity, it is better to select a

lager mass flow rate. Considering that the water pump

will consume more power with the mass flow rate

increasing in practical work, an overall consideration

should be given to select a medium value of m

SC

. It is

also can be seen that the SC subsystem provide less

energy with the increase of T

1SC

, which means the

efficiency of solar collectors decreases with the

increase of T

1SC

.

It is observed in Fig. 3,the effect of m

SC

on the

exergy output of SC subsystem does not produce the

same behaviour as it does on the energy output of the

SC subsystem. And there exists a value of m

SC

which

makes the exergy provided by the SC subsystem

maximum. It also differs from the trends in Fig. 2 that

the maximum exergy provided by the SC subsystem

under different values of T

1SC

differs slightly.

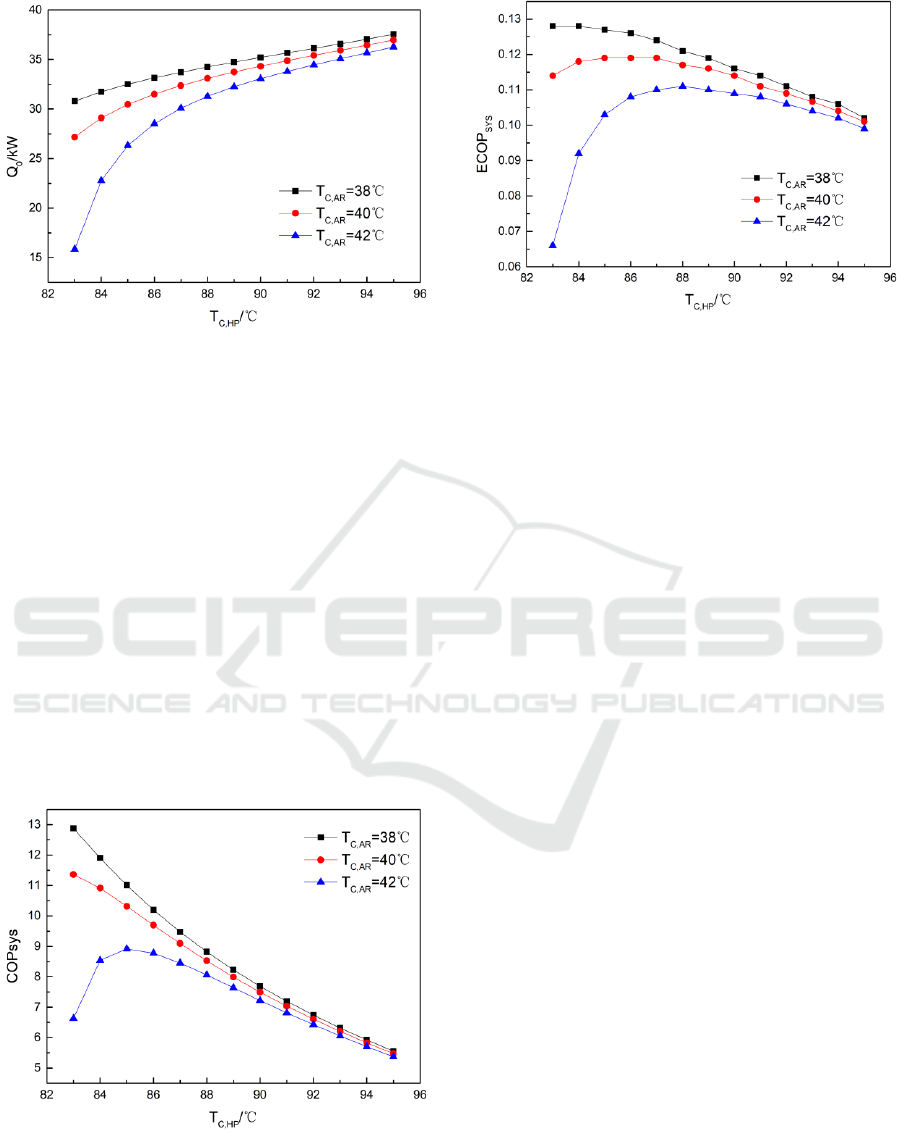

5.2 The influence of HP subsystem on

system

Working as auxiliary heating equipment, the function

of the HP subsystem is to guarantee the temperature

of the heat source of the AR subsystem. In this

section, the influence of the condensation temperature

of HP subsystem (T

C,HP

) on the system performance

is investigated, at different condensation

temperatures of AR subsystem (T

C,AR

). T

C,HP

is

considered to vary from 83 ℃ to 95 ℃, while T

C,AR

is

set as 38 ℃, 40 ℃ and 42 ℃ respectively.

Fig. 4 shows the variation of the refrigerating

capacity of the novel solar conditioning system with

the condensation temperature of SC subsystem

(T

C,HP

). As can be seen from Fig. 4, the refrigerating

capacity of the novel solar conditioning system

increases when the condensation temperature of the

HP subsystem (T

C,HP

) increases. This is mainly

caused by the reasons below. (1) The condensation

temperature of the HP subsystem (T

C,HP

) affects the

AR subsystem as the temperature of heat source. As

we know the refrigerating capacity of the absorption

refrigeration system increases with the increase of its

heat source temperature. (2) The amount of energy

from the SC subsystem is also amplified by the HP

subsystem.

Energy Analysis and Exergy Analysis of a New Type Solar Air Conditioning System

37

Figure 4: The curves between refrigerating capacity and

T

C,HP

.

According to the definition of in Eq. (7), COP

YSY

can intuitively reflect the electric power consumption

of the novel solar air conditioning system, instead of

reflecting the solar energy consumption. Fig. 5 shows

the variation of COP

SYS

with the condensation

temperature of SC subsystem (T

C,HP

). As can be seen

from Fig. 4, with T

C,HP

increasing, the electric power

consumption of the system also increases to transform

the low-level energy to a higher level, which leads to

a decline in COP

SYS

. Although high COP

SYS

provides

a better operating condition for the AR subsystem, the

electric power consumption caused by the HP

subsystem increases in a faster speed, which

ultimately leads to the decline of COP

SYS

. When T

C,HP

is set as 90 ℃, COP

SYS

is more than 7.5, which is

much higher than the normal vapour compression

refrigeration systems.

Figure 5: The curves between COP

SYS

and T

C,HP

.

Figure 6: The curves between ECOP

SYS

and T

C,HP

.

The novel solar air conditioning system adds the

heat pump as auxiliary equipment, which consumes a

certain amount of electric energy to ensure the normal

operation of the AR subsystem. Since the solar energy

and electric energy differ in quality, for the purpose

of getting a better view of the energy consumption of

the system, exergy analysis is carried out, which takes

the quality of energy into consideration. The exergy

efficiency of the novel system is defined as Eq. (8).

According to Eq. (8), ECOP

SYS

can indicate the

exergy consumption of the novel system. As can be

seen from Fig. 6, with T

C,HP

increasing, the exergy

efficiency of the novel system increases at first and

then decreases slightly. In a certain range of T

C,HP

, the

consumption of electric power brings a better use of

the exergy. When T

C,HP

is higher than a certain value,

more input exergy is supplied to the system and more

exergy losses occur.

Figs. 4-6 can be used to select design parameters

when the systematic design is carried out. To prevent

the risk of crystallization and to get a medium

COP

SYS

, T

C,HP

should not be too high. However, T

C,HP

should be as high as possible in order to get a larger

refrigerating capacity of the novel system. The

selection of parameter needs overall considerations.

5.3 The comparison of novel and

original system

In this section, the performance of the novel system

is compared with the original system through

quantitative calculation. The original system here is

composed of solar collectors and a single-effect LiBr

absorption refrigeration system, with no auxiliary

heating equipment. The calculation conditions

include two solar radiation intensities, the low solar

radiation I

L,SC

=0.4 kW/m

2

and the high solar radiation

I

H,SC

=0.8 kW/m

2

.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

38

The refrigerating capacity (Q

0

) and the area of

solar collectors corresponding to unit refrigerating

capacity (A

s

) are selected as standards of the

comparison between the novel system and the

original system. The value of A

s

can reflect the initial

investment of the system to a certain extent.

The results of comparison between the novel

system and the original system under different

operating conditions are shown in Table 3. As seen in

Table 3, when the solar collectors work at a lower

temperature (T

1SC

=70 ℃) the novel system produces

34.32 kW and 9.00 kW refrigerating capacity

respectively in high solar radiation and low solar

radiation, while the original system fails to give

normal operation. When the solar collectors work at

a higher temperature (T

1SC

=80 ℃), the refrigerating

capacity of the new system is larger than the original

system. Through the comparison between two

systems, there is a conclusion that the novel system

are less affected by the weather condition. The novel

system has lower requirements for the performance of

solar collectors than the original system, which makes

the use of flat-plate collectors reasonable.

It also can be concluded from Table 3 that the

novel system needs much smaller area of solar

collectors to produce the same refrigerating capacity.

With the advantages of low requirements for the

performance of solar collectors and smaller area of

solar collectors, the initial investment of the novel

system is positive compared with the original system.

Table 3: Performance comparison of new solar air conditioning system and original solar air conditioning system.

T

1SC

=70 ℃

T

1SC

=80 ℃

I

H,SC

=0.8 kW/m

2

I

L,SC

=0.4 kW/m

2

I

H,SC

=0.8 kW/m

2

I

L,SC

=0.4 kW/m

2

Novel system Q

0

(kW)

34.32

9.00

28.31

4.28

Original system Q

0

(kW)

-

-

22.13

3.22

Novel system A

s

(m

2

/kW)

2.91

11.11

3.53

23.36

Original system A

s

(m

2

/kW)

-

-

4.52

31.06

It should be mentioned that the numerical

calculating results could be different if the operating

conditions change. However, the conclusion of the

advantages of the novel system will not be

overthrown.

6 CONCLUSIONS

In this study, for the analysis of a novel solar air

conditioning system with a heat pump as auxiliary

equipment, first law of thermodynamics and second

law of thermodynamics are applied in every

component. The main results obtained are concluded

below:

(1) The exergy analysis of the system shows that

the highest exergy destruction occurs in

condensation-generation and condensation 2. The

exergy destruction can be reduced with parameter

optimization.

(2) With the increase of T

C,HP

, the refrigerating

capacity of the novel system decreases, while the

COP

SYS

increases roughly. There is a value of T

C,HP

making the ECOP

SYS

maximum. When T

C,HP

=90 ℃,

COP

SYS

is more than 7.5.

(3) Compared with the original solar air

conditioning system, the novel solar air conditioning

system enjoys advantages of low requirements for the

performance of solar collectors and smaller area of

solar collectors.

Additionally, the results of the exergy analysis

presented in this paper can also be used in

thermoeconomic optimization of the novel solar air

conditioning system in future researches.

REFERENCES

Hwang, Y., Radermacher, R., Alili, A. and Kubo, I. (2008).

Review of Solar Cooling Technologies. HVAC&R

Research, 14(3), pp.507-528.

Sekret, R. and Turski, M. (2012). Research on an adsorption

cooling system supplied by solar energy. Energy and

Buildings, 51, pp.15-20.

Xu, S., Huang, X. and Du, R. (2011). An investigation of

the solar powered absorption refrigeration system with

advanced energy storage technology. Solar Energy,

85(9), pp.1794-1804.

Lass-Seyoum, A., Blicker, M., Borozdenko, D., Friedrich,

T. and Langhof, T. (2012). Transfer of laboratory

results on closed sorption thermo- chemical energy

storage to a large-scale technical system. Energy

Procedia, 30, pp.310-320.

Ahachad, M., Charia, M. and Bernatchou, A. (1993). Solar

absorption heat transformer applications to absorption

Energy Analysis and Exergy Analysis of a New Type Solar Air Conditioning System

39

refrigerating machines. International Journal of

Energy Research, 17(8), pp.719-726.

Jain, V., Kachhwaha, S. and Sachdeva, G. (2013).

Thermodynamic performance analysis of a vapor

compression–absorption cascaded refrigeration

system. Energy Conversion and Management, 75,

pp.685-700.

Prasartkaew, B. and Kumar, S. (2010). A low carbon

cooling system using renewable energy resources and

technologies. Energy and Buildings, 42(9), pp.1453-

1462.

Liu, Y. and Wang, R. (2004). Performance prediction of a

solar/gas driving double effect LiBr–H2O absorption

system. Renewable Energy, 29(10), pp.1677-1695.

Pérez de Viñaspre, M., Bourouis, M., Coronas, A., Garcı

́

a,

A., Soto, V. and Pinazo, J. (2004). Monitoring and

analysis of an absorption air-conditioning

system. Energy and Buildings, 36(9), pp.933-943.

Sumathy, K., Huang, Z. and Li, Z. (2002). Solar absorption

cooling with low grade heat source — a strategy of

development in South China. Solar Energy, 72(2),

pp.155-165.

Ali, A., Noeres, P. and Pollerberg, C. (2008). Performance

assessment of an integrated free cooling and solar

powered single-effect lithium bromide-water

absorption chiller. Solar Energy, 82(11), pp.1021-10

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

40