A Study on the Arrangement of Outer Steam Cooler for 1000MW

Double Reheat Ultra-Supercritical Unit

Weijun Mi

1

, Haiwen Chen

2

and Wenfeng Fu

3

1

Shaanxi Xin Yuan Clean Energy Co.Ltd. ,

Yulin 719400, Shaanxi Province, China

2

School of Energy, Power and Mechanical Engineering,

North China Electric Power University,Baoding 071003, Hebei Province, China

3

North China Electric Power University, Key Laboratory of Condition Monitoring and Control for Power Plant Equipment,

Baoding 071003, Hebei Province, China

Keywords: Double reheat, fuel specific consumption, outer steam coolers.

Abstract: Taking the 1000MW double reheat ultra-supercritical unit as an example, based on analysis of the specific fuel

consumption, the effects of following arrangement modes of outer steam cooler (OSC) on the energy

consumption of unit are studied, such as the single series arrangement, double series arrangement and double

parallel arrangement, etc., and subsequently the optimum arrangement mode of OSCs is obtained, in which case

the variation law of specific fuel consumption is analyzed for each part of the thermal system and for the whole

unit. Results show that by adopting the OSCs, the feed water temperature is raised, the irreversible loss of boiler

is reduced, thus lowering the specific fuel consumption of unit. In the single arrangement mode, the specific

fuel consumption can be reduced by 0.632g/kWh at most when the OSC is arranged at No.2 high pressure (HP)

regenerative heater (RH);whereas in the double arrangement mode, the specific fuel consumption can be reduced

by 1.122g/kWh at most when the coolers are arranged in series at RH2 and RH4.

1 INTRODUCTION

Technical upgrading of coal-fired power plants to

achieve ultra-low emissions is an important measure

to make the utilization of fossil fuels clean, improve

the air quality and ease the resource constraints.

In recent years, the research on the double reheat

technology has drawn more and more attention.

Bugge et al. (

2006) pointed out that, compared with

single reheat unit, the extraction steam of the double

heat unit has a higher degree of superheat, resulting

in a high exergy loss of RH, which suppresses the unit

efficiency further improved. In an effort to undermine

the adverse effect of steam superheat at the heater

inlet on the unit, Xu et al. (2015) devised a scheme to

set up a back pressure extraction steam turbine in the

system and calculated the improved results. Kan et al.

(2014) pointed out that the use of OSC is another

simple and effective measures, while having a good

load adaptability. Niu et al. (2011) and Xia et al.

(2015), respectively, for single reheat unit and double

reheat unit, analyzed the effect of OSC on reducing

fuel consumption.

The existing research results show that the OSC

can play a significant role in reducing the superheat

of the extraction steam at the inlet of the double reheat

unit and increasing the efficiency of the unit.

However, there are few reports on the influence of

different arrangement of OSCs on the efficiency of

double reheat unit. Therefore, with a 1000 MW

double reheat ultra-supercritical unit as the research

object, we proposed a variety of schemes to deploy

OSCs. And the efficiency of the various schemes is

compared, the better arrangement is obtained.

Mi, W., Chen, H. and Fu, W.

A Study on the Arrangement of Outer Steam Cooler for 1000MW Double Reheat Ultra-Supercritical Unit.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 59-62

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

59

2 METHODOLOGY

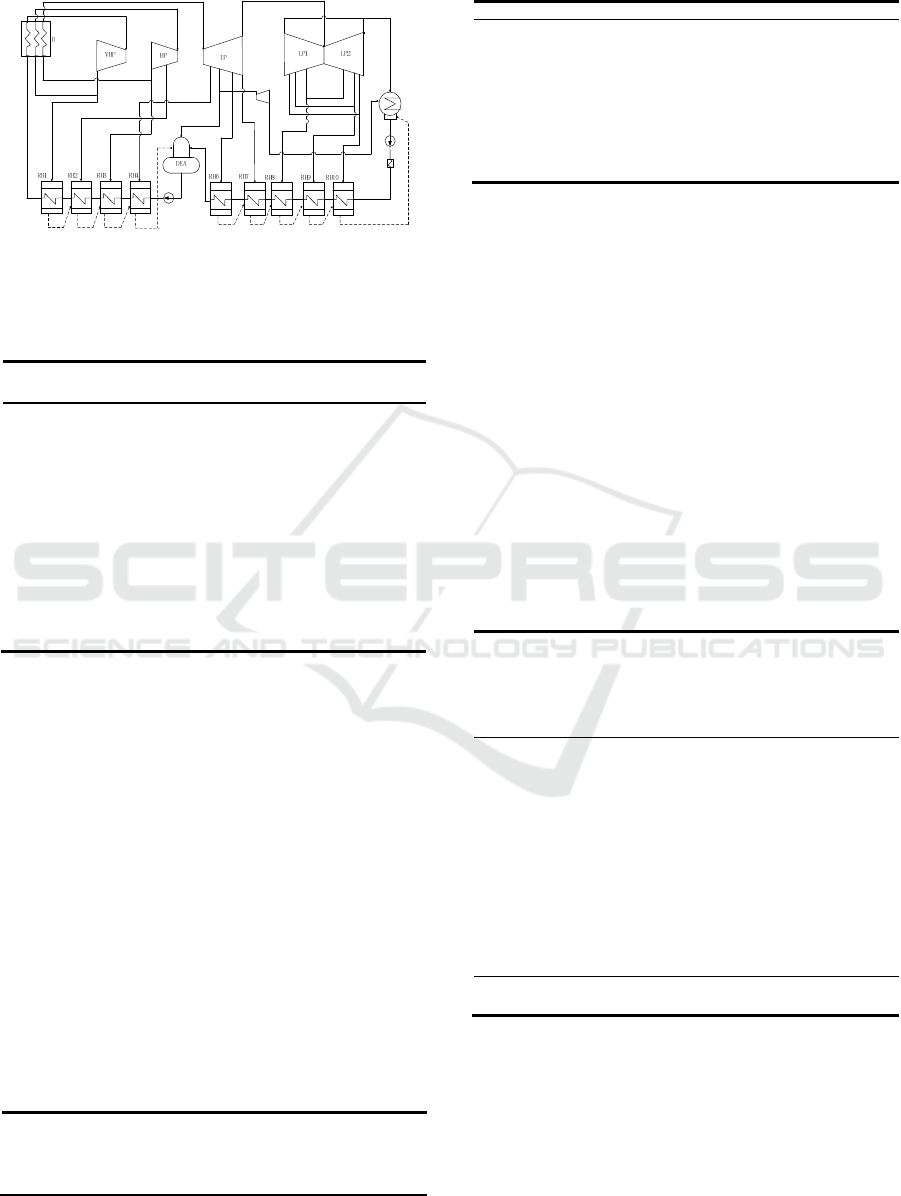

Figure 1: Thermodynamic system of the reference double

reheat power plant.

Table 1: Extraction steam parameters at various stages of

the system.

Extraction Pressure

(MPa)

Temperature

(℃)

Superheat

(℃)

1 8.932 415.624 112.824

2 6.009 525.462 249.778

3 3.334 433.645 193.865

4 1.855 529.304 320.691

5 1.038 442.431 260.921

6 0.718 389.589 123.609

7 0.392 309.989 167.109

8 0.127 189.002 82.572

9 0.059 118.761 33.391

10 0.022 61.984 0

Taking a 1000MW double reheat ultra-

supercritical unit as the Base Case, its thermal system

is shown in Fig.1. The initial parameters of the unit

are 31MPa / 600 ℃ / 610 ℃ / 610 ℃, the second

and fourth extraction steam are the first extraction

after the first reheat and the second reheat,

respectively. The regenerative system has four HP

RHs, five low pressure (LP) RHs and a deaerator.

Table 1 shows the steam parameters of the

regenerative system. The OSCs are respectively

arranged in single series mode on the extraction pipes

of four HP RHs of the unit, all the feed water passes

through the steam cooler and then enters the boiler.

3 RESULTS AND DISCUSSION

Table 2: Comparison of thermal efficiency among

different arrangements of single OSC.

Position of

OSC

Feed water

temperature

(℃)

Superheat

reduction (℃ )

Thermal

efficiency

of the unit

(%)

Specific

fuel

consumpti-

on of the

unit

(g

/kWh

)

Base

Case

- 304.503 - 50.979 266.826

Schem

e1

RH1 307.992 81.486 51.014 266.659

Schem

e2

RH2 312.452 208.126 51.099 266.207

Schem

e3

RH3 307.783 127.157 51.036 266.592

Schem

e4

RH4 308.562 227.481 51.085 266.361

Based on Ebsilon platform, the thermal system

with integrated OSC is simulated and the system node

parameters are obtained. The thermal efficiency

parameters of the four schemes and the Base Case are

calculated as shown in Table 2 by using the analysis

of specific fuel consumption. When taking scheme 2,

the OSC is arranged in front of the RH2, the best

energy-saving effect can be obtained. Compared with

the Base Case, the scheme can reduce the specific

fuel consumption of the unit by 0.619 g/kWh and the

thermal efficiency of the unit by 0.12%. The

distribution of additional specific fuel consumption is

shown in Table 3. Compared with the Base Case, the

additional specific fuel consumption of each

equipment in scheme 2 is reduced, except for the feed

pump system.

Table 3: Distribution of specific fuel consumption in

reference system and scheme 2.

Specific fuel consumption

Base

Case

Scheme 2

Reduction

of Specific

fuel

consumpti-

on

Additional specific

fuel consumption

(g/kWh)

Boiler 119.473 118.632 0.841

Turbine 6.738 6.733 0.005

Condenser 11.860 11.815 0.045

RHs 2.901 2.887 0.014

Pump 1.058 1.069 -0.011

Specific fuel consumption of the

uni

t

(g/kWh)

266.826 266.216 0.610

Utilization of the steam superheat at the inlet of

the heater reduces the heat exchange temperature

difference of RH2 by 208.126K, reducing the

additional specific fuel consumption of the RH by

0.014 g/kWh. At the same time, the temperature of

feed water is increased by 7.949K, which reduces the

additional specific fuel consumption of the boiler by

0.841g/kWh. Due to the increase of feed water mass

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

60

flow and flow resistance, the additional specific fuel

consumption of pump is increased by 0.011g/KWh,

but the value is far less than the overall reduction of

additional specific fuel consumption of other

equipment. In conclusion, the contribution of the

OSC to the thermal efficiency of the unit is mainly

reflected in reducing the additional specific fuel

consumption of the boiler and less affecting the

reduction of the irreversible loss of the RH itself. The

reason is that the utilization of the superheat of the

steam at the heater inlet greatly increases the

temperature of feed water to bring it closer to the

optimal value of the system.

It can be seen from Table 1 that the superheat of

the second extraction and the fourth extraction has the

most potential for utilization. Therefore, when using

double steam coolers, it should be arranged at RH2

and RH4, respectively, with series and parallel

arrangement,

recorded as scheme 5 and scheme 6.

Table 4: Thermal efficiency comparison of installing

double OSCs.

Temperature

(℃)

Thermal

efficiency of

the unit

(%)

Specific fuel

consumption

of the unit

(g/kWh)

Base Case

304.503 50.979 266.826

Scheme 5 317.124 51.192 265.513

Scheme 6 312.857 51.158 265.742

In scheme 5, the main feed water passes through

RH1 and then enters into the double OSCs

respectively and then enters the boiler. In order to

reduce the thermal deviation at the outlet flow mixing

of double OSCs, the feed water mass flow into the

RH2 steam cooler is set to be 70% of the total flow.

In scheme 6, the inlet water supply of the double

OSCs comes from the outlet of their corresponding

RHs, respectively. According to the method of Ref.

(

XU Chuanpu, 1990), the feed water splitting

coefficient is chosen. It is calculated that when the

mass flow of RH2 steam cooler and RH4 cooler is

respectively 5.5% and 3% of the feed water mass

flow before shunting, the thermal efficiency of the

unit is the best. The comparison of thermal efficiency

between the two schemes and the Base Case is shown

in Table 4.Compared with the Base Case, the

temperature of feed water is increased by 12.621K,

the specific fuel consumption of the unit is reduced

by 1.313g/kWh, and the thermal efficiency of the unit

is improved by 0.213%. Because of the smaller mass

flow in the steam coolers in scheme 6, the

temperature of the feed water is less increased and the

reduction effect is lower than that of scheme 5.

Table 5 shows comparison of specific fuel

consumption of between the best single OSC

arrangement (scheme 2), the best double arrangement

(scheme 5) and the Base Case. Compared with the

single arrangement, when the double arrangement is

adopted, the superheat of the steam at the inlet of the

heater can be utilized to a greater extent. The

additional specific fuel consumption of the boiler,

turbine, condenser and RHs in the system is reduced.

And there is not much difference between the

additional specific fuel consumption of the pump

system. Therefore, the use of double series

arrangement is significantly better than single

arrangement.

Table 5: Distribution of fuel specific consumption in

different systems.

Specific fuel consumption

Base

Case

Scheme

2

Scheme

5

Additional specific

fuel

consumption(g/kWh)

Boiler 119.473 118.632 117.934

Turbine 6.738 6.733 6.861

Condenser 11.860 11.815 11.768

RHs 2.901 2.887 2.647

Pum

p

1.058 1.069 1.081

Specific fuel consumption of

the unit (g/kWh)

266.826 266.216 265.483

4 CONCLUSION

When using a single steam cooler, the best effect can

be obtained by arranging it at the RH2, which can

reduce specific fuel consumption by 0.619g/kWh.

When using double OSCs arrangement, arranged in

the RH2 and RH4 in series of the best way, can reduce

specific fuel consumption 1.313g/kWh.

The OSC enhances the thermal efficiency of the

unit mainly by reducing the additional specific fuel

consumption of the boiler, while contributing little to

reduce the additional specific fuel consumption of the

RH itself.

ACKNOWLEDGMENTS

This research is supported by the Special Funds of

the National Natural Science Foundation of China

(No. 51606066).

A Study on the Arrangement of Outer Steam Cooler for 1000MW Double Reheat Ultra-Supercritical Unit

61

REFERENCES

Bugge J, Kjær S, Blum R. High-efficiency coal-fired power

plants development and perspectives[J]. Energy, 2006,

31(10–11):1437-1445.

Xu G, Zhou L, Zhao S, et al. Optimum superheat utilization

of extraction steam in double reheat ultra-supercritical

power plants[J]. Applied Energy, 2015, 160:863-872.

KAN Weimin, SONG Jinghui, ZHOU Luyao, et al.

Analysis of variable working condition of installing

external steam cooler for ultra-supercritical unit[J].

Turbine Technology, 2014, 01:63-65.

NIU Zhongmin, DING Yiyu. Analysis of thermal economy

of installing external steam cooler of ultra-supercritical

1000 MW unit[J]. Thermal Power Generation, 2011,

12:67-69.

XIA Xiaohua, YANG Yu, FAN Shiwang, et al. Heat

consumption analysis for the 1000 MW double-reheat

steam turbine with external steam coolers[J]. Power

Equipment,2015, 29,(3):160-163.

XU Chuanpu. Study on optimal feedwater splitting

coefficient of external parallel type steam cooling

system[J]. Power Station Auxiliary Equipment, 1990,

3:65-68.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

62