Stud

y

on A

pp

lication of Thermoelectric Generation Technolo

gy

Qin Wang, Fenglin Wang and Yuxin Yang

1

City College, Wuhan University of Science and Technology, Wuhan 430083, China

E-mail

:

279365291@qq.com

Keywords: Thermoelectric generation, Seebeck effect, performance test.

Abstract: Thermoelectric generation, which can covert thermal energy to electrical directly, is a green, energy saving

and environmentally friendly technology. Based on Seebeck effect, a simple thermoelectric generator was

designed in this paper by using Bi

2

Te

2

thermoelectric material. In order to study the performance of

thermoelectric generator, experiments were done in the case of cold end temperature was independent

controlled and was not independent controlled in the paper. When the cold end temperature was controlled,

the generation efficiency was improved. The test conclusion has important significance in improvement and

industry application of the thermoelectric generator.

1 INTRODUCTION

Thermoelectric generation technology is a green,

energy conservation and environment protection

technology. Thermoelectric generation can convert

thermal energy to electric energy directly without

consumption and emission (ZHAO Jian-yun, ZHU

Dong-sheng, ZHOU Ze-guang et al, 2010). The

working principle of this technology is Seebeck effect

of thermoelectric materials. When the temperature of

two kinds of semiconductors is different, the two

semiconductors can produce direct current after being

interconnected. Then the thermal energy is converted

to electricity without additional electricity energy

(CHEN Wei-wei, ZHANG Rui, WANG Jian-zhong,

2013).

As present the green power generation means are

mainly solar photovoltaic power generation,

hydropower, wind power and so on. But these power

generation methods are heavily reliant on

environment, and there will be great energy loss

during the power generation. Thermoelectric

generation technology is not restricted by

environment and doesn’t need energy conversion

process. So, this technology is of much greater value

on research and application (WEI Jie-ting etc, 2010)

(CHEN Lin-gen, MENG Fan-kai, SUN Feng et al,

2013).

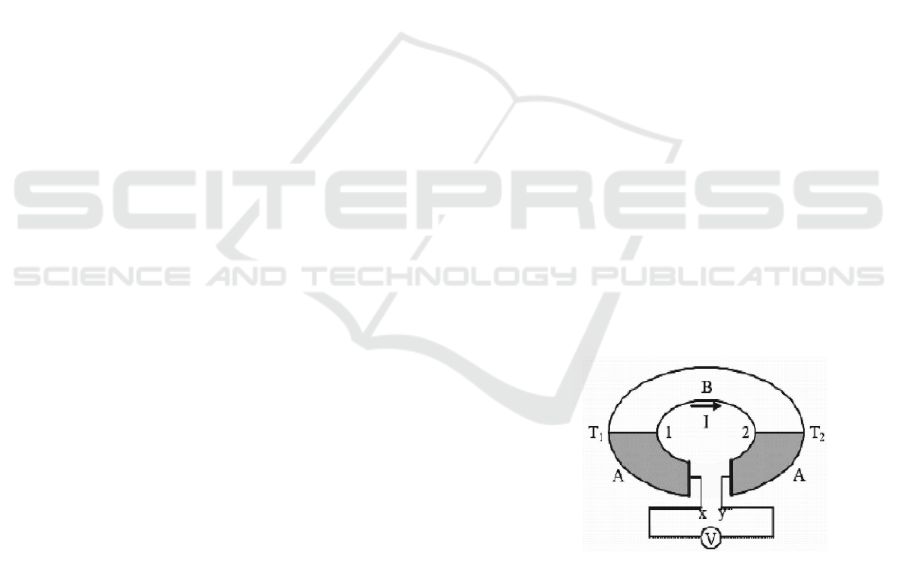

2 THE SEEBECK EFFECT

German scientist Seebeck discovered the Seebeck

effect in 1821. Two different metals are joined

together at first. When one of the metal is in high

temperature

1

T (hot end) and the other is in low

temperature

2

T (cold end), there is an open circuit

voltage at the cold end. This phenomenon is known

as the Seebeck effect (figure 1).

Figure 1: Illustrative diagram of the Seebeck effect.

If the temperature of hot end and cold end is

maintained at

1

T and

2

T (

12

TT> )respectively,

there is a potential difference in the open position of

the conductor, and the value is:

()

12AB AB

UTT

α

Δ= −

(1)

Wang, Q., Wang, F. and Yang, Y.

Study on Application of Thermoelectric Generation Technology.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 63-66

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

63

In the type (1),

AB

α

is the relative Seebeck

coefficient of two conductors of A and B.

A

BAB

ααα

=−

. The unit of

AB

α

is

VK

μ

.

3 DESIGN OF

THERMOELECTRIC

GENERATOR

Two different types of P and N semiconductor

thermoelectric materials are in series by deflector

with high electrical conductivity at first. The

semiconductor thermoelectric generator can be got

after the deflector is fixed on the ceramic plate. When

the temperature of thermoelectric generator both ends

is different, and the high temperature and low

temperature is kept at

1

T and

2

T separately, there

will be a voltage. If there is load resistance in the

circuit, there will be electric current.

3.1 Design of thermoelectric generator

cold end

As shown in Fig. 2, 1 is the aluminium alloy shell.

The thermal conductivity of shell is good. Then heat

can be transmitted to the hot end much faster, and the

cooling of cold end will be accelerated. 2 is storage

battery, which can store electricity up for flexible use.

3 is voltage stabilizing module, which can ensure the

stability of output voltage. 4 is thermoelectric

generator module. Many of the semiconductor

thermoelectric generators are joined together by

series-parallel connection. Then the thermoelectric

generator module is got. The number and the series-

parallel connection can be adjusted according to the

demand of output current voltage and the shape of

thermoelectric generator. 5 is heat-transfer silicone

grease, which makes the connection between the

semiconductor thermoelectric generator both ends

and the shell much better. And the heat conduction

efficiency will be high. 6 is the output interface. The

standardized output interface is conducive to flexible

use of the energy storage (YANG Su-wen, XIAO

Heng, OU Qiang, et al, 2012).

Figure 2: The structure of cold end.

3.2 Design of thermoelectric generator

hot end

As shown in Fig. 3, which is structure of the

thermoelectric generator hot end. The structure of

thermoelectric generator hot end is similar to the

structure of thermoelectric generator cold end. The

only difference of hot end and cold end structure is 7,

which is a layer of insulating material. This material

can ensure the normal work of the battery, voltage

stability and output module when the heat comes

from hot end.

Figure 3: The structure of hot end.

3.3 The simple thermoelectric

generator

The Seebeck coefficient of various materials are

measured through tests, as shown in table 1:

Table 1: The Seebeck coefficient of common

thermoelectric materials

Material

Seebeck coefficient

(μV/K)

Impurity

type

Bi

2

Te

2

260 P

-270 N

Sb

2

Te

3

133 P

Bi

2

Se

3

-77 N

PbTe 380 P

1

2

3

4

5

6

7

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

64

-320 N

Si

0.8

Ge

0.2

540 P

B

4

C 250 P

The high cost performance Bi

2

Te

2

is chosen as

thermoelectric materials of the thermoelectric

generator through experiments. The simple

thermoelectric generator is got by making series

between two semiconductor thermoelectric generator

pills. The output voltage is 3.01 V and the current is

0.07 A of the semiconductor thermoelectric generator

when the hot end temperature is 115℃ and the cold

end temperature is 51.9℃。

4 PERFORMANCE TESTS

There are two tests to study the performance of

semiconductor thermoelectric generator (LI Ying-lin,

HUANG Hu, 2011). The two tests are the cold end

temperature be not independent controlled test and

the cold end temperature be independent controlled

test (XIAO Zhe-peng, WU Wen-ge, FENG Xia,

2014) (WANG Chang-hong, LI Na, LIN Tao, et al,

2016) (WANG Chang-hong, LIN Tao, ZENG Zhi-

huan, 2014).

4.1 Voltage admeasurement test of the

cold end temperature be not

independent controlled

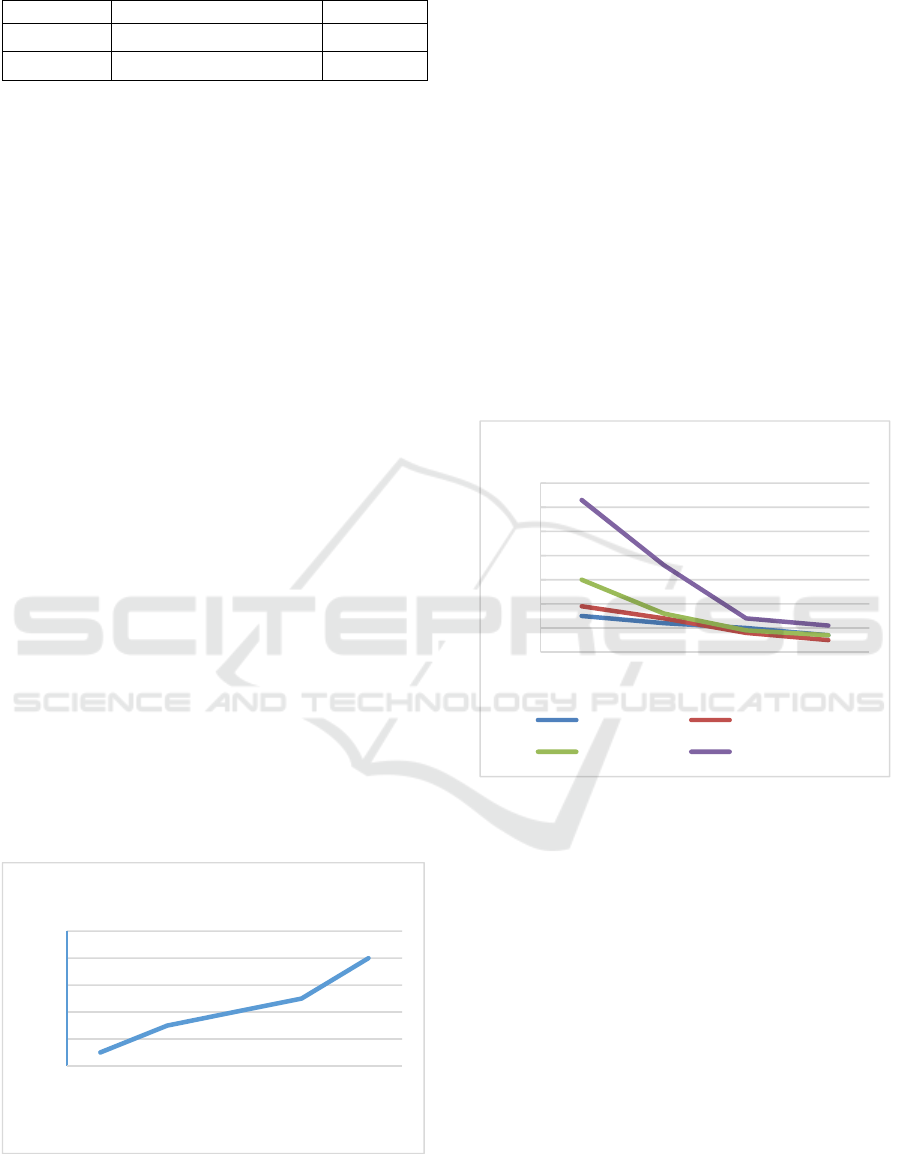

The output voltage of different temperature

difference is showed in Fig. 4, which is obtained by

heating the hot end directly while the cold end

temperature is not fixed. The temperature difference

between cold end and hot end is measured by

electronic thermoscope.

Figure 4: The output voltage with different temperature

differences

From Fig. 4, the output voltage increases as the

temperature difference increases. When the

temperature difference reaches the maximum, the

output voltage will reach the maximum value. The

larger the temperature difference is, the more

obviously the voltage will increase with the

increasing of temperature difference.

Therefore, the power generation efficiency can be

improved by increasing the temperature difference

between the hot end and the cold end.

4.2 Voltage admeasurement test of the

cold end temperature be

independent controlled

The output voltage is showed in Fig.5, which is

obtained by changing the cold end temperature while

the hot end temperature is fixed.

Figure 5: the voltage output with different temperature of

the cold end

As shown in Fig.5, with the same temperature of

hot end, the voltage reduces when the temperature of

cold end rises. In the case of the same temperature

difference, the higher voltage can be obtained when

the temperature of cold end is lower. The reason for

the phenomenon is that the resistance of the

semiconductor thermoelectric generator film

increases when the temperature of cold end rises.

So, the higher temperature difference power

generation efficiency can be obtained by reducing the

temperature of cold end during the application.

5 CONCLUSIONS

In this paper, a simple and easy thermoelectric

generator device is made by using the high cost

2,98

3,00

3,02

3,04

3,06

3,08

20,1 25,7 57,8 67,8 70,0

Temperature difference(℃)

Output voltage(V)

2,90

3,00

3,10

3,20

3,30

3,40

3,50

3,60

10 30 50 70

Temperature of cold end(℃)

Output voltage(V)

Hot end 80℃ Hot end 90℃

Hot end 100℃ Hot end 110℃

Study on Application of Thermoelectric Generation Technology

65

performance Bi

2

Te

2

as thermoelectric materials.

When the temperature of cold end is independent

controlled, the efficiency of power generation will be

improved. There is great research value for the

improvement and industrial low-grade waste heat

utilization of the power generation device.

ACKNOWLEDGEMENTS

Thanks the sponsors of this international conference

to provide us a precious academic platform.

REFERENCES

ZHAO Jian-yun, ZHU Dong-sheng, ZHOU Ze-guang et al,

2010. Research progress of thermoelectric power

generation. Electricity technology, Vol. 134, No. 3, pp.

310-313.

CHEN Wei-wei, ZHANG Rui, WANG Jian-zhong, 2013.

Design and implementation of lithium-ion battery

charged device based on semiconductor thermoelectric

generator. Journal of Hangzhou Dianzi University, Vol.

33, No. 5, pp. 175-178.

WEI Jie-ting etc, 2010. The study on easte heat recover of

electric gorge coal stove based on semiconductor

thermoelectric power generation. J. Changchun Inst.

Tech. (Nat. Sci. Edi.), Vol. 11, No. 2, pp. 86-89.

CHEN Lin-gen, MENG Fan-kai, SUN Feng et al, 2013.

Analysis on energy-saving potential of recycle waste

hest of iron and steel industry based on thermoelectric

power generation technology. Research on Iron &

Steel, Vol. 41, No. 6, pp. 41-43.

YANG Su-wen, XIAO Heng, OU Qiang, et al, 2012.

Simulation on performance of thermoelectric

generator applied in waste heat recovery. Computer

Simulation, Vol. 29, No. 11, pp. 341-344.

LI Ying-lin, HUANG Hu, 2011. Thermal power generation

technology and its application. Journal of Nanjing

Normal University (Engineering and Technology

Edition), Vol. 11, No. 3, pp. 23-29.

XIAO Zhe-peng, WU Wen-ge, FENG Xia, 2014. Design

and fabrication thermoelectric power generator for

waste heat recovery. Machinery Design &

Manufacture, No. 10, pp. 259-261.

WANG Chang-hong, LI Na, LIN Tao, et al, 2016. Research

on thermoelectric properties of semiconductor P-N

type thermoelectric power generation device. Function

Material, Vol. 47, No. 12, pp. 12147-12151.

WANG Chang-hong, LIN Tao, ZENG Zhi-huan, 2014.

Analysis and simulation of semiconductor

thermoelectric power generation process. Acta Phys.

Sin., Vol. 63, No. 19, pp. 1972011-1972015

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

66