The Research of Electric Meter Site Ins

p

ection Data Minin

g

Haohan Zhen, Hua Shen, Feng Huang and Lei Yu

State Grid Shanghai Electric Power Research Institute, Shanghai 200051, China

zhenhaohan@126.com

Keywords: Electric meter, site inspection, data mining.

Abstract: In recent years, with the constant improvement of Power Supply Information Collection System, the data

mining of power information has been deepened. Site inspection is one of the most important way to obtain

the operating status of the meter. Data collected by Site inspection, which have wide coverage and strong

periodicity, can accurately reflect the error of electric meters, user load, operating environment etc.

Therefore, it`s necessary to include electric meters site inspection data into the source of power information

mining. In this paper, the big data mining strategy of site inspection data is discussed preliminarily, which is

helpful to analyse the running status of electric meters and user's electricity consumption more accurately ,

give full play to the role of site inspection in the operation and maintenance of the electric meter.

1 INTRODUCTION

“The Technical Administrative Code of Electric

Metering” divides electric metering devices into five

categories based on the voltage level, and sets the

site inspection cycle to 6/12/24 months for Ⅰ/Ⅱ/Ⅲ

category of electric metering devices. Detailed

operation data of the electric meter, which includes

appearance, operating errors, operating environment

and user load, can be obtained in site inspection. In

recent years, the number of Ⅰ/Ⅱ/Ⅲ category power

users increased significantly. At the same time, the

amount of data obtained by site inspection also

shows a blowout.

At present, the electric meter site inspection

focus on the operating fault and the error excess , but

lack of overall and deep mining analysis for the

mass site inspection data, which reflects the detailed

operating situation of electric metering devices. In

recent years, because of the analysis methodology

developments and the widely usage of application,

the data mining in power system has drawn more

and more attention from all parties. As the uniform

electric meter spreads across the country, and site

inspection is highly informative and digitized, site

inspection data is more truthful, reliable,

comprehensive and standardized. It lays a good

foundation for the site inspection data mining,

analysis and application.

2 ANALYSIS OF DATA TYPES IN

SITE INSPECTION OF

ELECTRIC METER

The site inspection of the electric meter is mainly

aimed at the operating error, including: general

check, wiring check, secondary side voltage drop

measurement on the related voltage transformer, the

electric meter operating error measurement, timing

error test, the combination error of meter reading,

etc. At the site of the inspection, the inspector can

obtain relative operation data of electric meter,

including timing, appearance, environment, user

load, etc. The site inspection data can be roughly

divided into numerical and non-numerical classes.

The data collected from the user site have high

reliability. Moreover, the period of site inspection

data acquisition is fixed. Therefore, the value of the

analysis on the site inspection data cannot be

ignored.

2.1 Numerical class data

The data from site inspection are mostly numerical.

In addition to the metering error (γ) of the electric

meter, the site inspection can also get the clock error

(Δt) by comparing the clock, the reading meter error

(δ) by obtaining the time-sharing electricity quantity,

92

Zhen, H., Shen, H., Huang, F. and Yu, L.

The Research of Electric Meter Site Inspection Data Mining.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 92-96

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the user’s instantaneous load (p) by calculating

voltage (U) and current (I) value, and the user’s total

electricity quantity (W) at the inspection point. The

above data can be obtained in the site inspection and

can be conveniently stored, processed and analysed.

2.2 Non-Numerical Class Data

The appearance of electric meter, operating

environments, etc. difficult to measure by value, can

be expressed in a non-numerical way. The data is

categorized in detail when obtained in order to

maintain the objectivity, as shown in Table 1

.

Table 1 Non-Numerical Data of Site Inspection

Data

Status

Corresponding Detailed Information

Appearance

Good

no dirt and oil pollution on the electric meter surface/ complete and no damage of the

shell/ LCD screen display clarity/ good button function/ complete seal

Mediocre

ash or oil on the electric meter surface/ surface lightly damaged/ key sensitivity

reduced

Alert

serious ash or oil pollution on the electric meter surface,surface damaged/ LCD

screen display blur,button insensitive

Environment

Good

appropriative power distribution room/ controllable room temperature/ dust-proof,

moisture-proof, rodent control measures/ equipped with a professional electrician

Mediocre

appropriative power distribution room/ electrician patrol/ general protective measure

in power distribution room/ ash accumulating in power distribution room

Alert

no power distribution room/ outside electric meter without protective measures/

power distribution room without electrician patrol or protective measures

By organizing data and especially combing non-

numerical data, site inspection data can be

normalized to maintain data accuracy and

objectivity, thereby preparing for data analysis and

mining.

3 ELECTRIC METER SITE

INSPECTION DATA MINING

Electric meter site inspection data includes not only

the energy meter running information, but also

contains the relevant user information. The site

inspection data is not independently, but there is a

potential contact and influence between each other,

and this connection and influence is multi-

dimensional, non-linear。Therefore, it is necessary

to fully excavate and analyse the data from the site

inspection to explore the inherent relationship

between the meter data. The result of data mining

can be used to analyse and predict various

phenomena and situation that may occur in the

operating of electric meter.

3.1 Electric meter Operation Reliability

Prediction

Meter as a measure of electrical energy, strictly

speaking, during the operation does not allow the

process of maintenance situation. However, due to

various factors, it is difficult to avoid various faults

during the actual operation of the electric meter.

Most failures occur not by chance, but as a result of

a combination of various factors. At present, it is

difficult to conduct real-time monitoring on the

operating parameters of the electric meter in

operation. Therefore, the mastery of operating

conditions is mainly based on the site inspection

data. The operating status of the electric meter is

excavated in the site inspection data, and the

reliability of the electric meter is evaluated. Next,

the two most common failures, including the error

excess of electric meter and the voltage/current loss

are analysed.

3.1.1 Electric meter Operating Error

In the operation of the meter, the failure of operating

error excess accounts for the most. In addition to the

quality of the product and the running time, the

factors that affect the error of the electric meter

include the environmental factors such as the load,

temperature and humidity of the user. The operating

error of the electric meter can be analysed

preliminarily from the existing site inspection data.

(1) Electric meter manufacturing level

Because of the different manufacturing levels,

the operating errors of electric meters from different

manufacturers, models and batches often have great

The Research of Electric Meter Site Inspection Data Mining

93

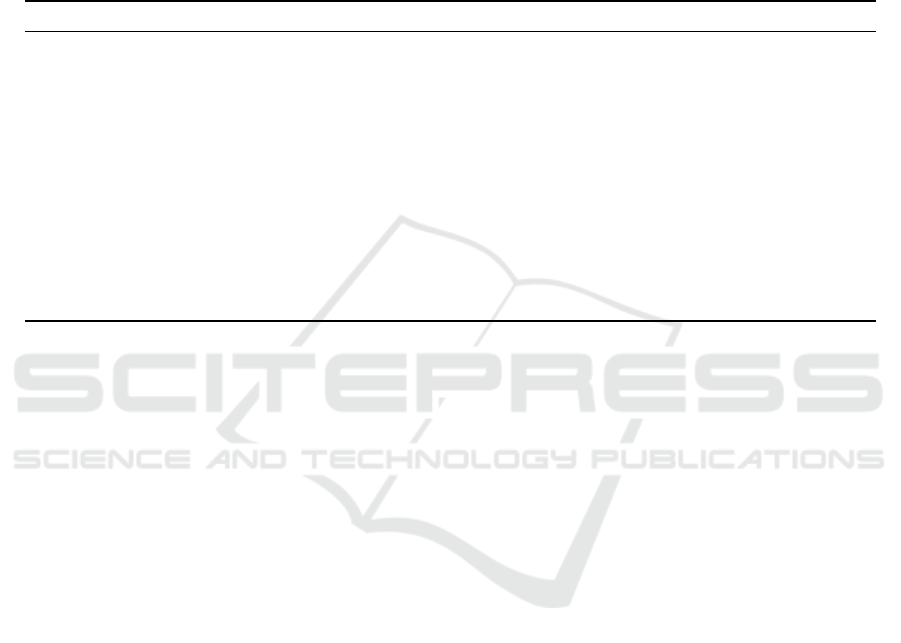

differences. Take the 2017 site inspection data as an

example: the site inspection operating error of 5

batches electric meter with similar running time is

compared, and the average absolute value and

standard deviation are analysed. As shown in Figure

1, the operating error size and dispersion of different

batches of electric meter are different. According to

the error average absolute value and standard

deviation, the different batches of electric meters can

be divided into two categories, A and B, with 0.5‰

as the dividing line, which indicates the influence of

the electric meter manufacturing level on the error.

Fig 1 Comparison of Mean Absolute Value and Standard

Deviation of Electric meter Error

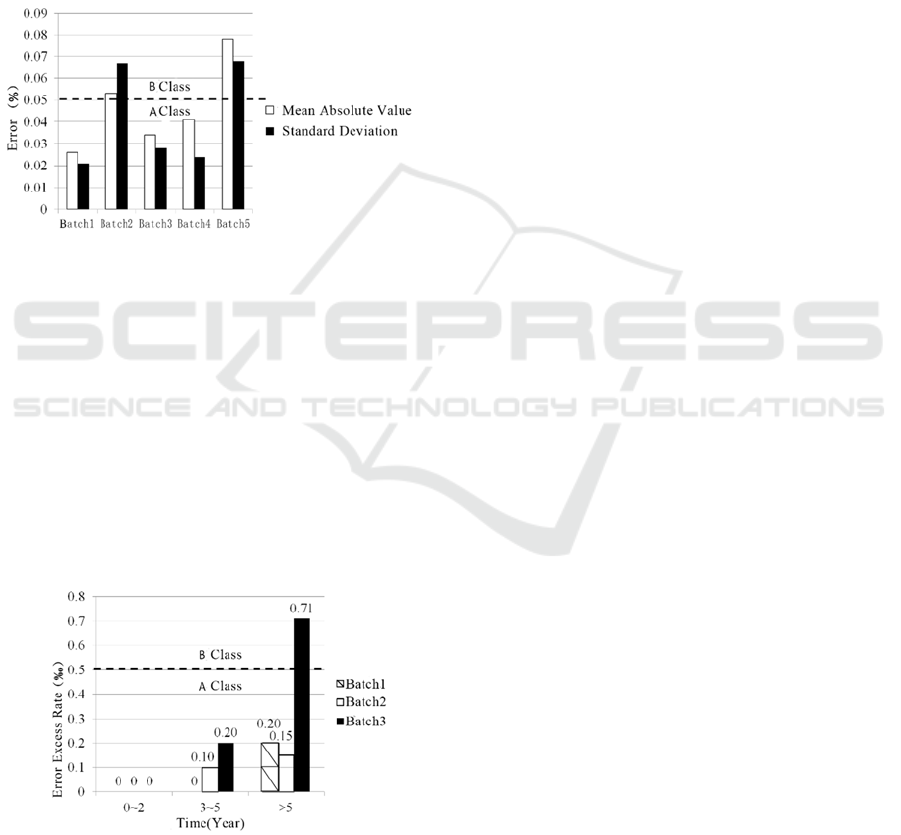

(2) Electric meter running time

With the increase of running time, the error

excess rate of the electric meter increased obviously.

The error excess rate of the different running time of

3 batches of the electric meter is shown in Figure 2.

The batch 3 whose operation period expires and fails

to be changed in time reaches 0.71‰, far more than

the other batches. The batch 3, which runs more than

5 years, is divided into B class, with 0.5‰ as the

dividing line, according to the operating error

excess.

Fig 2 Comparison of Error Excess Rate of Different

Electric meter Running Time

(3) User Maintenance

The error of 10 electric meter operating errors

found in the first quarter of 2017 is analysed. The 10

users cover industrial, commercial and

administrative institutions, and the user's power

distribution facilities are properly maintained.

Therefore, from the existing site inspection data

analysis, the operation error of the electric meter is

less related to the external environmental factors,

such as the maintenance of the user.

Based on the existing site inspection data, the

operating error of the electric meter is mainly related

to the product batch (difference in manufacturing

level) and running time. The results of the analysis

can be used to predict the performance of the electric

meter. According to the division of the above A and

B class, the operation error of the Double-B class

electric meter should be paid attention to in the site

inspection. If the corresponding batch has expired

the operation period, it is necessary to speed up

changing the meter to reduce the operation error

excess of the electric meter.

3.1.2 Voltage/Current Loss

The loss of voltage and current caused by fuse burn-

out in voltage and current transformer is one of the

most frequent faults that affect the accuracy of

measurement. There are many factors that lead to

fuse burn-out. It is not only related to the quality of

fuse, but also related to the external factors such as

the operating environment. It is generally believed

that lightning is one of the important reasons for fuse

burn-out or damage. After fuse burn-out, the electric

meter can record the time of failure. Taking the fuse

burn-out fault data found in site inspection in 2016

and 2017 in a certain area as an example, August~

November is a high failure period, which is about 2

times of that in other months, as shown in Figure 3.

July ~September is the high incidence of lightning in

the region. A part of the fuse has not been fused

directly after a lightning strike, but it can continue to

run for a period of time in the case of damage.

Therefore, November ~ November is still a period of

high incidence of voltage and current loss caused by

fuse burn-out.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

94

Fig 3 Time Distribution of Voltage/Current Loss

In view of the seasonal characteristics of voltage and

current loss caused by fuse burn-out, effective

preventive measures and investigation methods

should be taken, such as checking fuse before

thunderstorm season. In addition, with the

continuous improvement of the Power Supply

Information Collection System, online trouble-

shooting and timely repair can be made to reduce the

metering errors caused by the failure.

In summary, the analysis of field test data can

extract the characteristics of all kinds of electric

meter on-site fault, and it is of great significance to

predict the running stability of the electric meter. At

the same time, with the continuous application of

new devices, all kinds of operating status are

changing. Based on real-time updating of site

inspection data, it can better track all kinds of state

variables and develop more perfect inspection

strategies.

3.2 Analysis of User's Electricity

Consumption Behaviour

With the establishment of Power Supply Information

Collection System, the collection of user power data

is more comprehensive and perfect, which is the

important data source of current power big data

analysis. However, besides voltage, current and

power, the site inspection data contains many

peculiar non-electrical data, which can provide a

more comprehensive description of user electricity

consumption behaviour.

3.2.1 Maintenance of user equipment

According to the site inspection data, the equipment

maintenance of different properties power user is

quite different. Table 2 shows the maintenance of

different properties power user measurement devices

in a certain area. The maintenance evaluation

criterion is based on table 1.

Table 2 Operation and Maintenance of Different Properties Power Users Facilities

Users Properties

Appearance Environment

Good Mediocre Alert Good Mediocre Alert

Large industry 93.1% 6.9% 0.0% 89.7% 10.3% 0.0%

Government agency 98.0% 2.0% 0.0% 98.0% 2.0% 0.0%

School & Hospital 95.7% 4.3% 0.0% 93.5% 6.5% 0.0%

Small industry 76.0% 14.8% 9.2% 67.3% 12.8% 19.9%

Commercial

property

73.2% 17.1% 9.3% 67.9% 22.7% 9.4%

According to the appearance of the user's power

equipment and the operating environment, the

maintenance of the power equipment can be judged.

Large industrial, government agencies, schools,

banks, hospitals have strict electric equipment

management system. The power distribution

environment of those users is better, and the

distribution personnel are more fixed and

professional. Therefore, equipment failure can be

detected in time. And overall, the small industry,

commercial property and other power users are

equipped with low professional technicians, and the

maintenance of power equipment is not enough.

In view of the differences in the maintenance of

the user equipment, the power supply enterprise

should formulate the differential measures to guide

users to maintain the electrical equipment and

reduce the failure of the equipment.

The Research of Electric Meter Site Inspection Data Mining

95

3.2.2 Peripheral Data Acquisition in Big

Data Analysis

With the establishment and application of the Power

Supply Information Collection System, the analysis

of the user's electrical behaviour can be extended to

the big data analysis of the full sample. The Power

Supply Information Collection System is able to

collect real-time information, includes user’s

voltage, current, power, electricity amount and so

on, as well as the inherent user electrical properties,

address and so on. Through the full sample data

mining, the user behaviour can be analysed and

predicted.

The information contained in the site inspection

data is irreplaceable, such as user geographic

environment information, user nature of centralized

area, etc., and it is a supplement data of the Power

Supply Information Collection System. The user

address information in the Power Supply

Information Collection System is only a single

address, and lacks relevant geographical

environment information. For example, the user

address is on the sea or near the river. When the

address information is wrong, it can be corrected by

site inspection data immediately. The Power Supply

Information Collection System treat each power user

as a separate data, lack of integrity. However, site

inspection can classify power user according to the

same properties, and treat the users as a whole, such

as large industrial area, commercial street users, high

tech park etc. Through the combination of the Power

Supply Information Collection System and the site

inspection, the user's electrical data will be more

perfect and comprehensive, and the data mining will

be more detailed and deeper.

4 CONCLUSIONS

The electric meter site inspection can get the

electrical and non-electrical data of user metering

equipment, and has the advantage of data channel`s

uniqueness. The data has the characteristic of full

coverage, and has a certain real-time performance.

The operating statues of the electric meter can be

predicted preliminarily, and the user's electricity

behaviour can be excavated, with the help of the

mining in site inspection data. Combined with the

Power Supply Information Collection System, site

inspection data will play its unique advantages and

provide effective information in big data analysis to

making data mining more in-depth.

REFERENCES

DL/T448-2000 Technical Administrative Code of Electric

metering

Cheng Yingyin, Yang Huaxiao. Study on Operation Error

Analysis and State Evaluation Method of Electric

metering Device [J]. Advanced Technology of

Electrical Engineering and Energy, 2014,33(5):76-79.

Wang Wenjing. Stduy on the Site Operation Management

Strategy of the Electricity Meter. [J]. Electricity

Measurement & Instrumentation, 2014,11: 23-27.

Yue Mei. Analysis on the Operation Failure of the Electric

meter and the Effective Operation Management

Mechanism [J]. Technology Innovation and

Application, 2015,11: 162-163.

Zeng Peiliang. Overview of on-line monitoring technology

of electric metering device [J]. Electronic Test,

2012,12: 7-9.

Cheng Yingying, Hou Xingzhe, Xiao Ji. Design and

Realization of Condition Management System of

Gateway Electrical Energy Metering Device [J].

Electrical Measurement & Instrumentation, 2013,

50(572): 87-92,120.

Xiang Bin. The Running State of the Electric metering

Device Management System Design and

Implementation [D]. Chengdu: University of

Electronic Science and Technology of China, 2013.

Xie Lubin, Luo Xiuhong, Hu Xinmei. Discussion on

Electric metering Mechanism Field Check Period for

Special Transformer User [J]. Electric Switchgear,

2013,1:16-17.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

96