Experimental Study on the Solid-Liquid Separation of Sugar Mud

Yanhui Chen, Xinjie Zhang and Linfeng Zhang

School of Mechanical Engineering, Guangxi University of Science and Technology, Liuzhou, China

gxut_jx@163.com, 930243857@qq.com, 838492376@qq.com

Keywords: The Characteristics of Sugar Mud, Dehydration Rate, Influencing Factors.

Abstract: In order to research the relevant dehydration properties of sugar mud deeply. The paper carry out the

compression dehydration experiment with sugar mud as the raw material which using the piston type

dehydration device of self-designed. The effect of the mass and the pressure on the dehydration rate of the

sugar mud was analysed according to the relationship between the time and the filtrate volume. Thus, the

type of the compression filter of the sugar mud was determined. Finally, the corresponding mathematical

formula was derived from the theory of one dimensional squeezing and dewatering.

1 INTRODUCTION

Biomass energy refers to some of the wastes

produced by agriculture, forestry and animal

husbandry. The conversion of solar energy into

internal energy and aggregated into organisms

mainly through photosynthesis in plants.

Theoretically, it belongs to renewable energy (Ma,

2012) (Chen, 2010). Sugar cane was one of the

sources of biomass energy. Sugar making plants use

sugar cane to process sugar. Most of the sugar was

used to produce white sugar. But a small portion of

the sugar was carried away by the by-products

produced in the sugar process. If the sugar sludge

was disposed of arbitrarily or discarded, it could

easily cause deterioration, decay and pollution. On

the other hand, it was also a serious waste of

resources. Comprehensive development of effective

utilization of the sugar mud, not only reduces the

waste of resources, the raw materials were provided

for the production of other products, the

corresponding environmental problems were solved,

and also brought some social and economic benefits.

However, the comprehensive utilization of sugar

mud were based on the dehydration and the drying.

Therefore, the study on the properties of sugar mud

dehydration has very important practical

significance.

2 EXPERIMENT EQUIPMENT

AND METHODS

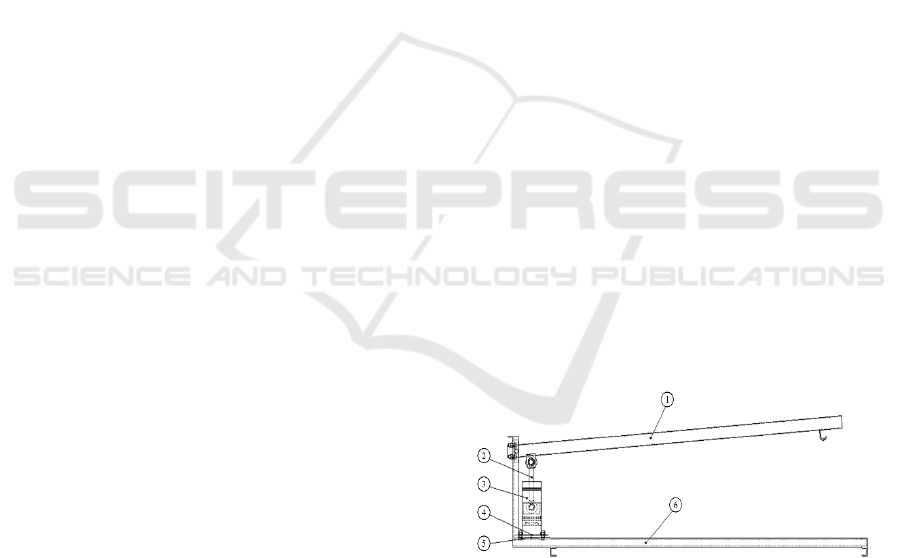

The experiment device for the compression and the

dehydration of sugar mud as shown in Figure 1. It

was mainly composed of pressure bar, piston,

cylinder, fixed plate and filter panel. The filter panel

was evenly distributed with dehydration micro-pores

about 2 mm. 300 mesh nylon filter cloth was

selected as the filter medium according to the

previous experiment.

1. Pressure bar; 2. Piston; 3. Cylinder; 4. Fixed plate;

5. Filter panel; 6. Body bracket

Figure 1: The schematic diagram of experiment device.

Experiment method: Firstly, clean and dry the

beaker with sugar mud. Then weigh it and record the

mass as

1

m

. Secondly, get the sugar mud back to

the normal temperature and pour into the beaker.

And weighed and recorded as

2

m

to ensure the

mass of the sugar mud taken as the experiment.

532

Chen, Y., Zhang, X. and Zhang, L.

Experimental Study on the Solid-Liquid Separation of Sugar Mud.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 532-535

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Finally, the 400 g, 500 g, 600g and 700g of sugar

mud gained from the weighing were poured into the

cylinder. And the dehydration experiments under the

pressure of 0.08 MPa, 0.23 MPa, 0.38 MPa, 0.53

MPa and 0.68 MPa were carried out respectively.

Meanwhile, recorded the filter time and the

corresponding amount of filtrate.

3 EXPERIMENT RESULTS AND

ANALYSIS

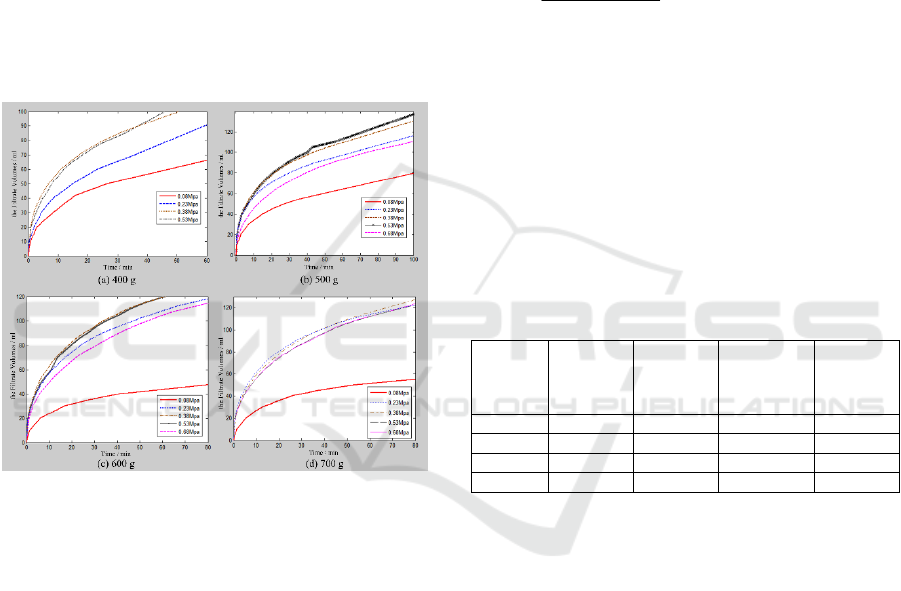

According to the above experiment method, the

sugar mud was compressed and dehydrated, and the

experiment data of time and filter were arranged as

shown in the Figure 2.

Figure 2: The relationship between time and filter of sugar

mud under different pressures

It can be seen that with the increase of pressure

on 400 g sugar mud, the filtrate volumes gradually

increased, when squeezing 500 g sugar mud, the

filtrate volumes first increased and then decreased,

mainly due to excessive pressure so that the medium

surface cake layer to accelerate the formation.

Resulting in increased filtration resistance, and the

dehydration rate decreased. When the pressure of

0.68 MPa in 600 g sugar mud, the filtrate volumes

increased more than 500 g, then the formation of

filter cake layer slowly. The mass increased to 700 g,

the four curves approximate coincidence. Increasing

the pressure has little effect, and only when the

pressure was large enough to obtain more the filtrate

volumes. However, there was a certain limit to

dewatering and dehydration.

3.1 Filtration Resistance and

Compressibility Factor

The filtration resistance shows the resistance of the

unit mass of material in unit filtration area (Wan,

2007). The data was obtained by the relationship of

vt /

and

v

in Cartesian coordinates. The constant

pressure filtration coefficient was obtained by linear

fitting, and the specific filtration resistance was

calculated by formula as shown in Table 1.

sK

msP

av

)1(2

α

(1)

In the Equation (1):

v

- the filtrate volume of

the unit filtration area;

K

- the filtration

coefficient of constant pressure; P - pressure

difference,

p

a

;

m

- wet dry ratio of filter cake;

s

- the concentration of solid mass;

- the

density of filtrate,

3

g/cm ;

- the viscosity of

filtrate,

s

p

a

;

Table 1: The filtration resistance of sugar mud under

different pressures

Filtratio

n

resistan

ce

0.23

MPa

0.38

MPa

0.53

MPa

0.68

MPa

400 g 4.20*10

15

9.99*10

15

6.48*10

15

——

500 g 4.41*10

15

6.99*10

15

8.95*10

15

2.28*10

15

600 g 4.50*10

15

5.80*10

15

8.44*10

15

1.26*10

15

700 g 2.87*10

15

4.85*10

15

1.99*10

15

8.55*10

15

The filtration ratio of the sugar mud filter cake

was in the order of about

1615

10~10

, and it was a

kind of difficult to filter materials. Besides, it was

mainly due to the existence of sugar substance,

which makes the solid particles of sugar mud exist

the larger force.

Compressibility coefficient that the material

under the action of external force volume changes

easily, according to the size of the compressibility

factor was divided into high-compression, medium-

compression, low-compression and

incompressibility of materials. According to the

relationship between the pressure and the average

filter, the logarithmic was obtained (Rushton, 2005).

Pn

av

logloglog

0

(2)

Experimental Study on the Solid-Liquid Separation of Sugar Mud

533

In the Equation (2), the relationship between

av

log and

Plog

was obtained in Cartesian

coordinates, and the compressibility coefficient was

obtained by straight line fitting as shown in Table 2.

Table 2: The compressibility coefficient of different

masses mud under different pressures

Mass/

g

400 500 600 700

Compressibility

factor

/

n

1.48 1.37 0.93 0.58

The compression coefficient of the sugar mud

was more than 0.5, which belongs to the high-

compression shrinkage material. Therefore, the

sugar mud was a kind of material which was easy to

be compressed but difficult to be filtered. So, the

pretreatment may be appropriately performed in

order to improve the dehydration rate of sugar mud.

4 THE MATHEMATICAL

RELATION BETWEEN THE

DEHYDRATION RATE OF

SUGAR MUD WITH THE MASS

AND THE PRESSURE

The Equation of Kozeny-Carman (Zhao, 2006)

based on the Porseuille theory not only describes the

microstructure of the filter cake, but also reveals the

inherent relationships among many factors in the

filtration process . The mathematical equation as

k

L

P

SK

u

2

0

2

1

3

)1(

(3)

In the Equation (3):

- porosity;

- average

linear velocity of liquid filtration,

sm/

;

1

K - the

constant of Kozeny, generally taken as 5;

0

S -

particle specific surface area,

32

/ mm

;

k

L - the

thickness of the cake layer,

m

;

In a simplified model of dehydration rate, Zhang,

J. Z.

(Zhang, 2015) assumed that the sugar mud was

saturated material and that the solid particles were

evenly distributed. The liquid phase was forced

during the compression, ignoring the solid phase and

the sugar mud was incompressible cake under high

temperature. According to the experiment done in

this paper showed that sugar mud was a highly

compressible filter cake at room temperature.

Let the filter area of

A

, the volume of sugar mud

dehydration

V

, the dehydration time t, the filtration

rate could be expressed as

A

dt

dV

u

(4)

According to the solid phase in the filtration

process remains the same principle, it was known

that

)1()1(

00

VV

(5)

In the Equation (5):

0

- the initial porosity;

0

V -

the initial volume of sugar mud,

3

m

;

A differential equation with above three

simultaneous equations to obtain porosity with the

variation of time.

k

L

VSK

PA

dt

d

3

00

2

01

)1(

(6)

The porosity of the constant pressure filtration

stage could be expressed as (Chen, 1993)

kS

AL

M

1

(7)

The relationship between the mass and the

volume of sugar mud in the dry state as

)1(

00

AL

M

V

s

d

d

(8)

The Equation (7) and Equation (8) were

substituted the Equation (6), and got

3

2

01

22

)1(

MmSK

AP

dt

d

d

s

(9)

In the Equation (9):

M

- the mass of sugar mud,

kg

;

d

m - the mass of dry sugar mud,

kg

;

d

V - the

volume of dry sugar mud,

3

m

;

s

- the density of

the dry sugar mud,

3

/ cmkg ;

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

534

The variables were solved separately.

t

MmSK

AP

d

s

2

01

22

2

2

0

2

2

0

0

0

0

0

2

1

1

ln

(10)

Saturated sugar mud porosity ratio was equal to

the ratio of water content, the rate of dehydration

Mm

出

, then the moisture content was

1

1

1

1

1

0

0

(11)

In the Equation (11):

- the moisture content;

0

- the initial moisture content;

出

m - the

dehydration mass of sugar mud;

After the simplification, the relationship between

the dehydration rate of sugar mud and time under

different mass and pressure was obtained

t

MmSK

AP

d

s

2

01

22

2

0

2

2

00

)1()(2

(12)

5 CONCLUSIONS

(1) In the pressure range of this experiment, the

average filtration ratio of sugar mud filter cake was

in the order of

1615

10~10

. It was difficult to filter

materials. And it was mainly due to the existence of

sugar substance, which makes the solid particles of

sugar mud exist the larger force.

(2)The coefficient of the compressibility of the

sugar mud was more than 0.5, which belongs to the

high-pressure shrinkage material.

(3) On the basis of reasonable assumptions, the

sugar mud was determined as a high compression

material. And the relationship between the

dehydration rate of the sugar mud and the change of

time under different mass and pressure was deduced.

ACKNOWLEDGEMENTS

This work is supported by Guangxi Science and

Technology Development Program Funded Projects:

The construction of the comprehensive experiment

platform about earthmoving machinery operation

process (No. GuiKe 1598021-2).

REFERENCES

Ma, J., Ma, X. Y., Li, Q., 2012. Utilization and Research

Progress of Biomass Energy. Journal of Anhui

Agricultural Sciences.

Chen, Y. L., Gao, J. X., Li, Y. H, 2010. Potential of bio-

energy substitute fossil energy and environmental

effects. China Environmental Science.

Wan, Y. Q., 2007. Study on Sludge Filter Dewatering

Property in Municipal Swage Treatment Plant.

Zhengzhou University.

Rushton, A., Ward, A. S., Holdich, R. G., 2005. Solid-

liquid two-phase filtration and separation technology.

Chemical Industry Press.

Zhao, Y., 2006. Study on the Microstructure of the Filter

cake and the Expression Filtration Theory. Zhejiang

University.

Zhang, J. Z., Tang, X., Zhou S. J., 2015. Simplified

dehydration rate model for hot press dehydration of

filter mud in sugar factory. Light Industry Science and

Technology.

Chen, S. Z., 1993. Separation of heterogeneous phase

system. Chemical Industry Press.

Experimental Study on the Solid-Liquid Separation of Sugar Mud

535