Electric Control Principle and Experimental Analysis of Rubber

Precision Fertilization

Yuan Zhang

1

, Yiguo Deng

1

, Lijiao Wei

1,2*

, Yeqin Wang

1

, Zhiyang Zhang

3

, Shengli Liu

4

, Ming Li

1

,

Xuehu Dong

1

and Jianhua Cao

3

1

Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences, Zhanjiang,

China

2

Agricultural Science and Technology Co., Ltd. of YIWU, Zhanjiang,China

3

Rubber Research Institute, Chinese Academy of Tropical Agricultural Sciences, Danzhou, China

4

The Center of CangLong Agricultural Technology Service for Zhanjiang City, Zhanjiang, China

{zhang198414}@126.com,dyg7810@21cn.com,weilijiao2008@163.com,441213852@qq.com,418727981@qq.com,105156

8484@qq.com

Keywords: Rubber, precision fertilization, electric control, experimental analysis.

Abstract: In this paper, aiming at the situation that it is difficult to control the amount of natural rubber fertilizer

mechanically, this paper introduces in detail a kind of rubber ditch electric control ditching and fertilization

combined operation machine, and its control principle, main structure and characteristics are described. The

test: the use of electric control precision fertilization control system to take the first booster and then speed

mode, the tractor carrier effectively achieve the Promise speed control knob can basically achieve the rubber

fertilization precision control, The precision index reaches 94.3%. The fertilization equipment equipped

with the control system matches the 80-horsepower tractor. The ditching depth can reach 22cm, the

productivity is 1.23hm

2

/h, the fuel consumption is 3.1kg/hm

2

, the fertilization uniformity is 90.3% and the

coverage rate is up to 98.0% , can effectively improve production efficiency and reduce production costs.

1 INTRODUCTION

Precision fertilization is one of the most important

parts of precision agriculture. It is the positioning

and quantitative fertilization. The so-called

"precision", that is, the "essence" and space in

quantity and the "quantity" in time, maximum. The

precision fertilization technology is not only

combined with the traditional fertilization

technology, but with the traditional fertilization

technology are quite different. The traditional way

of fertilization is to use the same amount of fertilizer

and fertilization within a large area or in a single

plot. In fact, there is a difference in soil nutrient

content in different parts of the same land. As a

result of the average fertilization, low fertility and

insufficient fertilization were achieved in other areas

with good fertility, while fertilization was excessive

in areas with high fertility but not in other

productive traits. As a result, fertilizer wasted, costs

were increased and environmental pollution was

inevitable (WANG Yeqin, 2016). In view of the soil

nutrients, ecological characteristics, current situation

and present production level of rubber plantations in

different rubber plantations, the timely adjustment of

the amount and mode of application of fertilizers

will further enhance the capacity and benefits of

natural rubber production. Therefore, precise

fertilization is the only way to develop fertilizer

technology.

Internationally, the research on precision

agriculture-related technologies has made relatively

rapid progress. The new technology system

developed mainly under the conditions of large-scale

operation and mechanized operation in developed

countries is applicable to large scale farms and other

areas where the technical equipment conditions And

supporting the more demanding. At present, the

overall technology and system research is still in the

theoretical exploration and testing methods and

techniques, the application is mostly for a point of

function. However, the application of precision

technology in rubber fertilization technology has yet

to be found.

In China, there are many researches on

fertilization technology. Guangxi Crane Extension

612

Zhang, Y., Deng, Y., Wei, L., Wang, Y., Zhang, Z., Liu, S., Li, M., Dong, X. and Cao, J.

Electric Control Principle and Experimental Analysis of Rubber Precision Fertilization.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 612-615

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Station Ke Fei et al reported that sugar cane

cultivating machinery can complete the processes of

soil crushing, weeding, fertilizing and earth-shaking

at the same time, which play a positive role in

improving work efficiency, saving costs and

increasing profits.3ZSP-2-type multi-functional

sugarcane fertilizer cultivator developed by Dong

Xuehu, Institute of Agricultural Machinery, Chinese

Academy of Tropical Agricultural Sciences, can be

used not only for breaking the ridge of sugarcane in

the host plant, but also for fertilizing and earth-

cultivating in accordance with the technical idea of

Combining function, structure and performance.

Sugarcane seedlings in the new weeding, ditching,

fertilization and earth-training, quality and stability,

taking into account the fertilization of the first Order

monitoring fertilizer explored the like, but the prior

art are used in the fertilization of corn, sugarcane,

potatoes and other crops in the field has not been

published in the paper to the rubber (ZHANG Yuan,

2017; ZHANG Yuan, 2016).

At present, China's natural rubber plantation

industry is implementing its "going global"

development strategy. The high-precision and high-

precision rubber fertilization equipment developed

by the plant will have a good space for export-

oriented development. It will also be exported to

Africa, Asia and other planting countries or regions

as a foreign aid technology, It provides technical

support for the "going global" of China's natural

rubber and has a significant impact on enhancing the

international influence of the natural rubber industry.

2 FERTILIZER MACHINE

STRUCTURE AND

PRINCIPLES

2.1 Machine structure characteristics

Rubber garden electric ditching fertilizers mainly by

the rack; open plow body assembly; fertilizer device;

fertilizer assembly; limit wheel; dial grass assembly;

control system and other structural components, the

structure shown in Figure 1.

Figure 1: Rubber precision fertilizer machine structure.

The main equipment has the following structural

features:

a. Plow column, loose plow, stiffener, limit plate,

soil tooth welding in one, are free to move within the

scope of 60

。

angle to meet the needs of different

width of the ditches.

b. The pear acute angle surface is welded with an

angle adjusting mechanism, and the angle adjusting

mechanism is provided with a plurality of

positioning circular holes, which are used together

with the supporting rods welded on the pylons to

jointly adjust the width of the ditching work.

c. The cutting disc is a double-edge concave

structure, and the horizontal gap distance between

the tooth and the ground tooth can be adjusted by the

function of the positioning hole on the sleeve rod,

and the tail of the draft rod contacts with the

concave surface of the cutting disc to achieve the

function of removing weeds.

d. fertilizer device can be adjusted according to

the needs of the movable plate and the fertilizer tube

to adjust the amount of fertilizer to achieve the

purpose of fertilizer on-demand. Fertilizer hopper

specific position can be adjusted to achieve a fixed

bolt.

e. The control system can realize the constant

speed control on the fertilizing turntable in the cab,

and the quality of the scraping unit can be quantified

by controlling the turntable speed so as to achieve

the purpose of quantitative spreading.

2.2 Control method and working

principle

Tractor driving process through the rack driven

electric ditching fertilizers work, when the soil into

the tooth, cut the first contact with the ground, with

the increase of depth into the soil, cut into the tooth

with the role of the gap between the weeds, cut off

weeds, to avoid its winding pylons on the column

and increase the ditching resistance. Under the

action of the limit plate, the earthing tooth

cooperates with the tractor to sink the power, which

plays the role of limiting the plow body into the soil

without any restriction. As the tractor advances, the

earthwork and the stopper plate play the role of

loosening the soil. The principle of its own

perspective, making the soil along the two sides to

open up to the purpose of ditching. At this point in

the driver's cab connected to the toll dial control

button, the turntable began to work, with the

turntable running, the fertilizer inside the fat barrel

drops to the turntable, scraper and turntable on the

role of the relative movement of fertilizer The

Electric Control Principle and Experimental Analysis of Rubber Precision Fertilization

613

fertilizer is scraped down to the bottom of the

hopper and falls down to the back of the plow along

the drain tube. With the relative movement

occurring, the soil on both sides is automatically

backfilled after the ditching and the applied fertilizer

is covered, thereby completing the fertilization

process. In the process of fertilization according to

the demand for fertilizer by the driver to adjust the

speed governor fertilizer plate speed, so as to

achieve the purpose of quantitative fertilization.

3 ELECTRIC CONTROL

METHOD AND COMPOSITION

Electric control system mainly by the wiring device,

booster, governor, motor, fertilizer assembly, etc., a

brief structure shown in Figure 2:

Figure 2: Control system diagram.

The specific control process is described as

follows:

When the tractor ignition, the battery power to

the instrument line, then the electric control system

wiring device and tractor instrument wiring, the

driver opens the switch, the wiring device is

energized to the booster, the booster will tractor

battery voltage from 12V Up to 48V before

transmission to the governor, governor Promise

speed knob can be controlled at 0 ~ 360r / min motor

rotation, the motor relies on universal joints and the

transmission assembly to complete the connection to

complete the control of the fertilizer turntable ,

When the amount of fertilizer have fixed

requirements, can be installed in the tractor cab by

the governor knob speed control, so as to achieve the

purpose of fertilization control precision (Shi

Yinyan, 2017; Li Hongjun, 2017).

4 TEST

4.1 Test conditions and indicators

Electric control and machine test were carried out in

the open space and in the field respectively. The

field test was gentle slope, the slope was less than 15

degrees and the area was 1.5hm

2

. The rubber

planting distance was 6.5m.Fertilizer moisture

content of 3.7%~4.8%, soil moisture content is

12%~16%. Machine matching 80 horsepower

tractors, the main test results are as follows:

The ground test mainly tests the numerical value

of the amount of fertilizer in the unit strip when the

tractor travels at different speeds of different

fertilizers under different gear speeds.

The field test mainly tests the productivity of

pure working hours, the productivity of working

hours, the fuel consumption per unit area, the

amount of fertilizer per unit area, the depth of

ditches, the stability of ditches, the uniformity of

fertilization, the coverage of fertilizers (Zhu

Yongren, 2017; Yang Cheng, 2017).

4.2 Experimental procedure

Electric control fertilizer test process shown in

Figure 3:

Figure 3: Test process diagram.

Field test process and the effect shown in Figure

4:

Figure 4: effect picture.

4.3 Test results

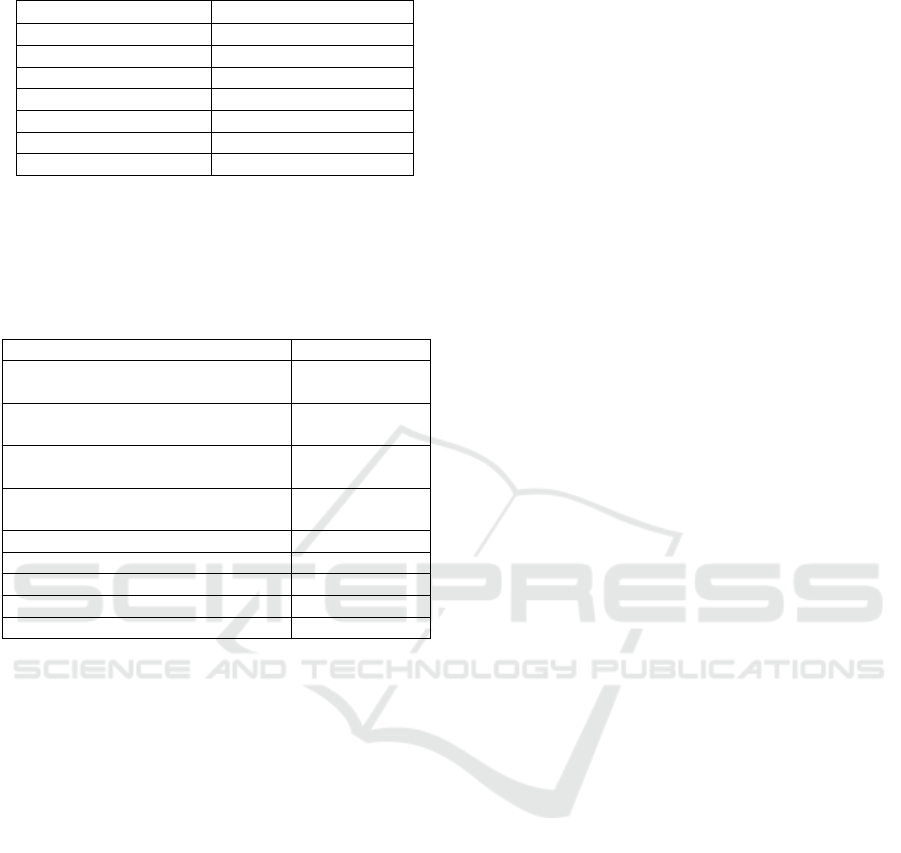

Electric control test of fertilizer test indicators in

Table 1:

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

614

Table 1: Electric fertilizer test results.

index results

D2/9S 113

D2/15S 162

D2/23S 206

D3/9S 97

D3/15S 131

D3/23S 188

S

p

eed ratio accurac

y

94.3

Note: D2 / 9S means that the tractor travels at low

speed and 2 speeds, and the amount of fertilizer applied

per meter is 113g. Speed Accuracy = (actual unit area test

value / theoretical calculation per unit area) × 100%.

Field test of the whole index value in Table 2:

Table 2: Machine test index results.

index results

Pure working hour productivity

( h

m

2

/h)

1.23

Operating hours productivity

( h

m

2

/h)

0.8

Fuel consumption per unit area

(

k

g

/h

m

2

)

3.1

The amount of fertilizer per unit area

(

k

g

/h

m

2

)

1220

Ditch de

p

th

(

c

m

)

22

Ditch de

p

th stabilit

y

(

%

)

88.9

Fertilizer uniformity(,%) 90.3

Fertilizer coverage(% ) 98.0

Fertilizer breaking rate(%) 0.1

5 CONCLUSIONS

a.The electric control precision fertilization control

system, take the first booster and then speed mode,

the effective implementation of the tractor carrier

promise speed control knob can basically achieve

the precision of rubber fertilization control, accuracy

Indicators of 94.3%, while speed accuracy, control

reliability and other indicators have yet to be long-

term optimization and research.

b.Rubber Park electric trenching fertilizer

machine according to the basic realization of the

rubber plantation ditch management, fertilizer

agronomy simultaneously. Machine matching 80

horsepower tractors, ditching up to 22cm depth, the

productivity of 1.23hm

2

/h, fuel consumption

3.1Kg/hm

2

, fertilization uniformity 90.3%, coverage

up to 98.0%, which can effectively improve

production efficiency and reduce production costs.

ACKNOWLEDGEMENTS

This work was financially supported by the Central

Public-interest Scientific Institution Basal Research

Fund for Chinese Academy of Tropical Agricultural

Sciences(1630022015018&1630132017003);Public

Welfare Research and Capacity Building of

Guangdong Province (2017A02028012);2017

provincial agricultural development and rural work

special "natural rubber processing of key

technologies in Thailand application"(Yue Nongji

[2017] No.39);Natural Science Foundation of

Hainan Provincial(20155204); Chinese Academy of

Tropical Agricultural

Sciences(1630132016015);Science and Technology

Program special of Zhanjiang City(2015A03023)and

Collaborative innovation and platform environment

construction special of Guangdong Province

(2017A040406003).

I would like to thank the members of the

research group for their selfless help, especially the

communication author Wei Lijiao,and the guangba

farms in Hainan Province for the project test of

strong support.

REFERENCES

WANG Yeqin,DENG Yiguo,ZHANG Yuan,etc.Design of

natural rubber precision ditch fertilization

machine[J].Advances in Intelligent Systems

Research,2016.vol.154:719-724.

ZHANG Yuan,WEI Lijiao,DENG Yiguo,etc.Test and

Effect Evaluation of 3XSP-1 Rubber

Fertilizer[J].Modern Agricultural Equipment,2017.226

(1):37-41.

ZHANG Yuan,DENG Yiguo,WEI Lijiao,etc.Development

and Experimental Analysis of Ditching Fertilizer

Application in Rubber[J].Modern Agricultural

Equipment,2016.224(5):50-54.

Shi Yinyan,Chen Man,Wang Xiaoyue,etc.Analysis and

Experiment of Fertilizing Performance for Precision

Fertilizer Applicator in Rice and Wheat

Fields[J].Transactions of the Chinese Society for

Agricultural Machinery,2017,(8): 97-103.

Li Hongjun,Jia Rongcong.Intelligent fertilization machine

design[J].Electronics World,2017,(17): 187.

Zhu Yongren.Design of Orchard's Machine Structure with

Ditching and Deep Fertilizing[J].Journal of

Agricultural Mechanization Research,2017,(12): 102-

106.

Yang Cheng,Cang Ying,Zhou Zhiyan,etc.Design and Test

of Pneumatic Fertilizer Applicator Variable Ratio

Fertilization Control System Based on PID

Algorithm[J].Journal of Shenyang Agricultural

University,2017,(3): 320-327.

Electric Control Principle and Experimental Analysis of Rubber Precision Fertilization

615