Development of Rubber Fertilizer Machine Based on Visual

Monitorin

g

Technolo

gy

Yiguo Deng

1

, Yuan Zhang

1*

, Lijiao Wei

1

, Yeqin Wang

1

, Zhiyang Zhang

2,3

, Shengli Liu

4

, Ming Li

1

,

Xuehu Dong

1

and Jianhua Cao

2

1

Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences, Zhanjiang,

China

2

Rubber Research Institute, Chinese Academy of Tropical Agricultural Sciences, Danzhou, China

3

Agricultural Science and Technology Co., Ltd. of YIWU, Zhanjiang,China

4

The Center of CangLong Agricultural Technology Service for Zhanjiang City, Zhanjiang,China

{dyg7810}@21cn.com,zhang198414@126.com,weilijiao2008@163.com,441213852@qq.com,418727981@qq.com,105156

8484@qq.com

Keywords: Rubber, fertilization, visual monitoring, research and development.

Abstract: This article describes in detail the integration of a set of functional, agricultural machinery management

agencies, service agencies, and users composed of three linkage management technology. The technology

will be fixed-point positioning of agricultural tools, job trajectory, image acquisition, workload calculation,

index detection, agricultural management and other functions close in the management of agricultural

operations management environment, the macro-management of agricultural machinery, command and

control scheduling, operational statistics, development decisions and individual management play a positive

role in promoting. Test: Based on the visual monitoring technology, the rubber plant ditching and fertilizing

combined operation machine can finish the joint operation of ditching, fertilizing and earthing at one time to

achieve the purpose of avoiding the volatilization and loss of the limited water in the soil, thereby

improving the fertilizer utilization rate, efficiency, and lowing cost. The machine is equipped with

Dongfanghong 804 tractor, ditching depth up to 45cm, productivity 1.63hm

2

/h, fuel consumption

3.4Kg/hm

2

, fertilization uniformity 92.3%, the coverage rate is up to 96.9%.

1 INTRODUCTION

Natural rubber is an important strategic material. It

is also one of the important cash crops, unique

resources and pillar industries in the tropics in our

country. It plays an important role in promoting the

adjustment of agricultural structure in the hot zone

and increasing farmers' income. In order to

encourage the development of the natural rubber

industry, the state started the seedling subsidy

project of natural rubber seed. The Ministry of

Agriculture also formulated and promulgated the

"Regional Layout for the Advantages of Natural

Rubber", clarifying the advantages of the three

major natural rubber planting areas in Hainan,

Yunnan and Guangdong. In recent years, it is

actively rehabilitating the natural rubber plantation

area with a planting area of more than 1800 mu and

is one of the major One of the agricultural industries

(ZHANG Yuan, 2016).

In the natural rubber production cycle need to

rubber tree ditching, fertilization and other

management operations to meet the needs of the

growth of natural rubber. Fertilization is one of the

important measures of rapid growth and high yield

of rubber trees. Rubber trees that have already

started to cut rubber need to be pressed and fertilized

every year. After they stop cutting, they dig the

green ditch (about 40cm in depth), press and spread

the green, and then cover the soil. General

fertilization per acre 250 ~ 300kg, during the cut cut,

you need to top-dressing 750kg/hm

2

. At present, the

basic fertilization of rubber plantations use special

organic fertilizer, the main fertilizer to powder, but

also granular. The late 90s of last century, the

Chinese Academy of Agricultural Sciences Institute

of Agricultural Machinery and Xuwen County Qujie

friendly farm tools factory cooperation on the rubber

forest fertilizer machine, ditching and plow furrow

plow was studied, developed a plastic ditching plow,

Deng, Y., Zhang, Y., Wei, L., Wang, Y., Zhang, Z., Liu, S., Li, M., Dong, X. and Cao, J.

Development of Rubber Fertilizer Machine Based on Visual Monitoring Technology.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 621-626

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

621

fertilization Machine and pressed green plow were

applied in small scale in Qujie Town, Xuwen

County, Zhanjiang City, Guangdong Province

(Figure 1), and achieved good economic and social

benefits (ZHANG Yuan, 2016). However, there

were still some problems that affected their further

promotion application. Such as fertilization machine

with two rows of operations, the rubber tree root

damage more serious, only 20 ~ 30cm depth of

ditching, reducing fertilizer efficiency, and fertilizer

is not uniform. However, ditching and pressing are

all single tasks with low efficiency and labor

intensity, and there are many problems such as

stealing, leakage and acceptance difficulties in the

management process. Abroad on the plastic garden

ditching, fertilizer and other management machinery

research is rare, rare reports.

Figure 1: Double row fertilizers for rubber.

At the same time, as the economy continues to

develop, the labor force continues to move to the

cities (WANG Yeqin, 2016; Shi Yinyan, 2017; Li

Hongjun, 2017). There are fewer and fewer workers

willing to engage in rubber plantation management

and the rubber plantation faces no one's control.

Therefore, in order to reduce the labor intensity of

rubber-field management workers, improve work

efficiency, and strengthen the long-term monitoring

and management of agricultural implements and

agricultural materials to further reduce the cost of

production management, develop a tractor

supporting plasticized ditching and fertilizing

combined operation machine , To replace the

manual fertilization operation will be the inevitable

trend of the future development of rubber plant

ditching fertilization equipment.

2 DESIGN OF WHOLE

STRUCTURE AND

MONITORING SYSTEM OF

FERTILIZER APPLICATION

2.1 Structural features

Based on the visual monitoring technology, the

rubber plant ditching and fertilization combined

operation machine is designed with the technical

ideas of combination of functions, comprehensive

performance and remote management. The standard

three-point rear suspension mainly includes the

frame, suspension system, ditching system,

Transmission system, remote monitoring system,

etc., among which the fertilizer device includes a

worm gear transmission, a main transmission shaft, a

fertilizer tank, a disc, a scraper, a fertilizer hopper, a

transmission shaft, a drainage pipe and a connecting

frame. The whole machine should be able to

complete a one-time rubber plant ditching, fertilizing,

earthwork and other joint operations and remote

office management functions. Machine structure

shown in Figure 2.

Figure 2: The main structure for rubber fertilizer machine.

Machine has the following characteristics:

First, the whole machine is designed according to

the technical ideas of function combination,

structure combination and performance

comprehensiveness, and the matching power is

moderate. Compared with the present management

status, the machine can complete the ditching,

fertilizing and earthworking together at one time to

avoid the limited Volatilization and loss of moisture,

thereby increasing fertilizer efficiency, high

efficiency and low cost (ZHANG Yuan, 2017).

Second is the use of frame-type rack structure,

open plow, soil cover and fertilization mechanism

and the use of bolting connection with the rack

bolting method, fertilizer institutions do not work,

the dynamic match only to achieve trenching

operations; such as the bolt disassembled after

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

622

matching other components , To meet the other

machine rack use, to achieve the rack of versatility.

Third, the installation of fertilizer monitoring and

alarm system, through four high-definition camera

monitoring system, the driver can observe the status

of fertilization and soil cultivation effect through the

display at any time during the work process. The use

of wireless voice alarm system real-time monitoring

of fertilizer use, the alarm host number 1.2.3.4, when

the fertilizer exhausted or can not be smooth

fertilizer, will monitor the changes in the amount of

fat will be no fat alarm number transmitted to the

bee Alarm and alarm, cab staff through the alarm to

monitor fertilizer operation or stop operations to

ensure fertilization continuity, to solve the original

drivers need to often look back and highly nervous,

prone to fatigue and other issues (Zhu Yongren,

2017; Xie Jingfen, 2017; Yang Cheng, 2017).

2.2 working principle

As the tractor moves forward, the ditching plow

begins to dig in and ditches. At the same time, the

tractor power is transmitted to the power

transmission shaft through the power output shaft,

the universal transmission assembly is transmitted to

the gearbox of the implement, the speed is reduced

by a pair of bevel gears and the direction is changed,

Until the worm gear decelerates and changes the

direction of transmission to drive the disk in the

fertilizer application device to rotate (Liu Jinbao,

2017; Wu Yujuan, 2017). As the mixed fertilizer

passes through the conical hopper and falls onto the

disk, the rotating disk moves the mixed fertilizer

along the scraper and in the lateral direction Offset

and along the edge of the disk down to the next

fertilizer funnel, and then by the next fertilizer, so as

to directly and quantitatively directly drop the ditch

to open a good furrow ditch, at the same time, ditch

plow side of the soil and continuous friction soil

self-coverage Fertilizers to complete the ditching,

fertilization and earthwork and other operations.

2.3 Monitoring system components and

installation location

Remote monitoring system's core components

include: mainframe, camera, digital display, GPS

antenna, sensor groups and ancillary components.

Which sensors are:

a.Power Sensor: measure real-time power of

agricultural machinery

b.Speed sensor: measure the real-time speed of

agricultural machinery

c.Acceleration sensor: obtain real-time

acceleration of agricultural machinery, when the

agricultural machinery complex operating conditions,

the "turbulent forward" acceleration inevitably

changes rapidly, the statistical variance is much

larger than other operations

d.Image Sensor: Obtain agricultural work images,

using image processing algorithms to extract

relevant information.

e.plow body identification sensor: to obtain the

type of agricultural machinery.

The specific core components of the installation

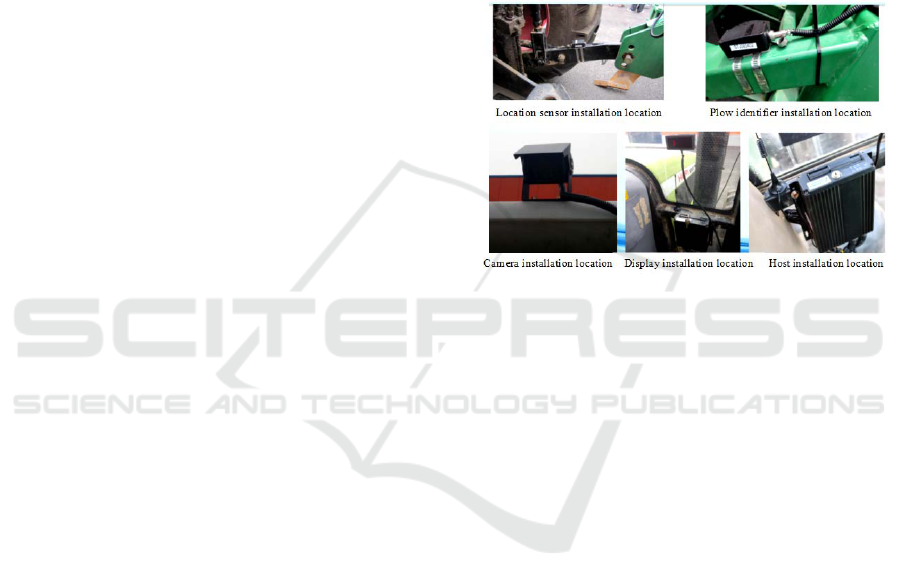

location shown in Figure 3.

Figure 3: Remote monitoring system installation of the

main parts.

3 FUNCTIONAL DESCRIPTION

Based on the visual monitoring technology, the

rubber plant ditching and fertilization combined

operation machine was tested in the field of rubber

mechanization demonstration base of Guangdong

Friendly Farm in Xuwen County, Zhanjiang,

Guangdong Province. The field test was flat with an

area of 0.67hm2 and rubber planting distance of 4.8-

5.8m. Rubber density of 25 to 33 plants / mu.

Dongfanghong 804 tractor matching machine, the

main test results in Table 1:

Development of Rubber Fertilizer Machine Based on Visual Monitoring Technology

623

Table 1: This caption has one line so it is centered.

index result

Pure working hours productivity

(h

m

2

/h)

1.63

Operating hours productivity

(

h

m

2

/ h

)

1.21

Fuel consumption per unit area

(

k

g

/ h

m

2

)

3.4

The amount of fertilizer per unit

area(kg

/

h

m

2

)

1206

Ditch depth( c

m

)45

Ditch de

p

th stabilit

y

(

%

)

88.7

Fertilizer uniformit

y

(

%

)

92.3

Fertilizer coverag(%) 96.9

Fertilizer breaking rate(%) 0

The whole machine is working properly, remote

monitoring system better play a monitoring role, the

operator of agricultural machinery with the

corresponding guidance. Specific functions are as

follows:

A.Automatic positioning of agricultural

machinery

Description: Machine through the remote

monitoring of agricultural machinery installed on the

terminal equipment, the agricultural machinery of

the geographical location, driving status, speed,

direction and other data transmitted to the server,

and then through the background data calibration

system check, put these data to the platform and in

The map depicts the real-time location of the farm

machinery.

Application examples shown in Figure 4:

Figure 4: Agricultural machinery positioning map

B.Agricultural track query function

Description: The system will be agricultural

positioning data to describe the formation of

trajectory. The trajectory can be depicted at once so

as to show the overall driving situation. The

trajectory can also be simulated point-by-point and

point-by-point.

Application examples shown in Figure 5:

Figure 5: Agricultural machine trajectory query map

C.Image information collection function

Description: When the farm machinery is

activated, the platform operator can take pictures in

real time through the camera module of the remote

monitoring equipment terminal. The image is

transmitted to the image server by using the network

of the device. If the signal is unstable, the image

fails to be transmitted, and the device automatically

stores the image, and sends the image to the image

server when the signal is in a pause. The image

server will store every image uploaded by each

agricultural machine for customers to invoke

viewing and other functions (job statistics, etc.) of

the call.

Application examples shown in Figure 6:

Figure 6: Agricultural machinery image acquisition map

D.Agricultural machinery area calculation

function

Description: The system analyzes the agricultural

locomotive locating data, farm machinery image

information and time-series statistical data, and

calculates the farmwork area using the unit

integration approximation algorithm. Its working

principle is similar to measuring acres instrument,

taking into account the disturbing factors of

agricultural non-farming tracks (Song Xuefeng,

2017).

Application examples shown in Figure 7:

Figure 7: Agricultural machinery summary map

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

624

E.Agricultural operation indicators detection

Description: According to the multi-sensor on

the remote monitoring equipment of agricultural

machinery, the relevant data of agricultural

machinery torque are uploaded to the server, and the

system judges whether the agricultural machinery is

in working status according to the above data and

the occurrence time of the operation. Such as

agricultural machinery ongoing operation will

automatically open the image acquisition function,

the system based on intelligent image recognition

system, combined with soil conditions set by the

calculation of indicators.

Application examples shown in Figure 8:

Figure 8: Agricultural machinery data analysis

4 CONCLUSIONS

a.The basic successful application of a set of

functions set of agricultural machinery management

agencies, service agencies, users composed of three

linkage management technology, the positioning of

the farm tools, job trajectory, image acquisition,

workload calculation, index detection, agricultural

management and other functions close Combining

and serving the management environment of

agricultural machinery, it plays a positive role in

promoting the macro management, command and

dispatch, operation statistics, development decision-

making and individual management of agricultural

machinery.

b.The rubber plantation ditching and fertilization

combined operation machine based on visual

monitoring technology basically fulfilled the

requirement of synchronous dredging and fertilizing

agronomy in rubber plantation field, in line with the

development direction of modern agricultural

machinery. Equipped with Dongfanghong 804

tractor, the machine can reach a depth of 45cm, a

production rate of 1.63hm2 / h, an oil consumption

of 3.4kg / hm2, a uniform fertilizer rate of 92.3%

and a coverage rate of 96.9%, which can effectively

increase production efficiency and reduce

production costs.

ACKNOWLEDGEMENTS

This work was financially supported by the Central

Public-interest Scientific Institution Basal Research

Fund for Chinese Academy of Tropical Agricultural

Sciences(1630132016015&1630022015018);2017

provincial agricultural development and rural work

special "natural rubber processing of key

technologies in Thailand application"(Yue Nongji

[2017] No.39);Public Welfare Research and

Capacity Building of Guangdong Province

(2017A02028012);Collaborative innovation and

platform environment construction special of

Guangdong Province (2017A040406003);Natural

Science Foundation of Hainan Provincial(20155204);

Chinese Academy of Tropical Agricultural

Sciences(1630132017003)and Science and

Technology Program special of Zhanjiang

City(2015A03023) .

I would like to thank the members of the

research group for their selfless help, especially the

communication author Zhang Yuan,and the friendly

farms in Guangdong Province for the project test of

strong support.

REFERENCES

ZHANG Yuan,DENG Yiguo,WEI Lijiao,etc.Development

and Experimental Analysis of Ditching Fertilizer

Application in Rubber[J].Modern Agricultural

Equipment,2016.224(5):50-54.

ZHANG Yuan,DENG Yiguo,WEI Lijiao,etc.Development

and Experimental Analysis of Ditching Fertilizer

Application in Rubber[J].Modern Agricultural

Equipment,2016.224(5):50-54.

WANG Yeqin,DENG Yiguo,ZHANG Yuan,etc.Design of

natural rubber precision ditch fertilization

machine[J].Advances in Intelligent Systems

Research,2016.vol.154:719-724.

Shi Yinyan,Chen Man,Wang Xiaoyue,etc.Analysis and

Experiment of Fertilizing Performance for Precision

Fertilizer Applicator in Rice and Wheat

Fields[J].Transactions of the Chinese Society for

Agricultural Machinery,2017,(8): 97-103.

Li Hongjun,Jia Rongcong.Intelligent fertilization machine

design[J].Electronics World,2017,(17): 187.

ZHANG Yuan,WEI Lijiao,DENG Yiguo,etc.Test and

Effect Evaluation of 3XSP-1 Rubber

Fertilizer[J].Modern Agricultural Equipment,2017.226

(1):37-41.

Zhu Yongren.Design of Orchard's Machine Structure with

Ditching and Deep Fertilizing[J].Journal of

Agricultural Mechanization Research,2017,(12): 102-

106.

Development of Rubber Fertilizer Machine Based on Visual Monitoring Technology

625

Xie Jingfen,Liu Bin.Development and Application of

Intelligent Precision Fertilizer Machine[J].Agricultural

Development and Equipments,2017(11):32.

Yang Cheng,Cang Ying,Zhou Zhiyan,etc.Design and Test

of Pneumatic Fertilizer Applicator Variable Ratio

Fertilization Control System Based on PID

Algorithm[J].Journal of Shenyang Agricultural

University,2017,(3): 320-327.

Liu Jinbao,Zhao Yan,Zheng Xuan,etc.Agricultural

Development and Equipments[J].Journal of Gansu

Agricultural University,2017(3):140-147.

Wu Yujuan,Song Changcai.Design and Realization of

Automatic Fertilization System for Orchard Micro

Fertilizer Applicator[J].Agricultural Equipment &

Technology,2017(1):8-9.

Song Xuefeng,Zhang Fengwei,Dai Fei,etc.Parameter

optimization for fertilizer block crushing device of

fertilizer machine based on discrete element

method[J].Journal of Hunan Agricultural

University(Natural Sciences,2017,(2): 206-211.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

626